High-strength welding electrode

A high-strength, welding rod technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of low yield strength of deposited metal and cannot match the high-strength properties of the base metal, so as to improve the yield strength , good comprehensive mechanical properties, and simple composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

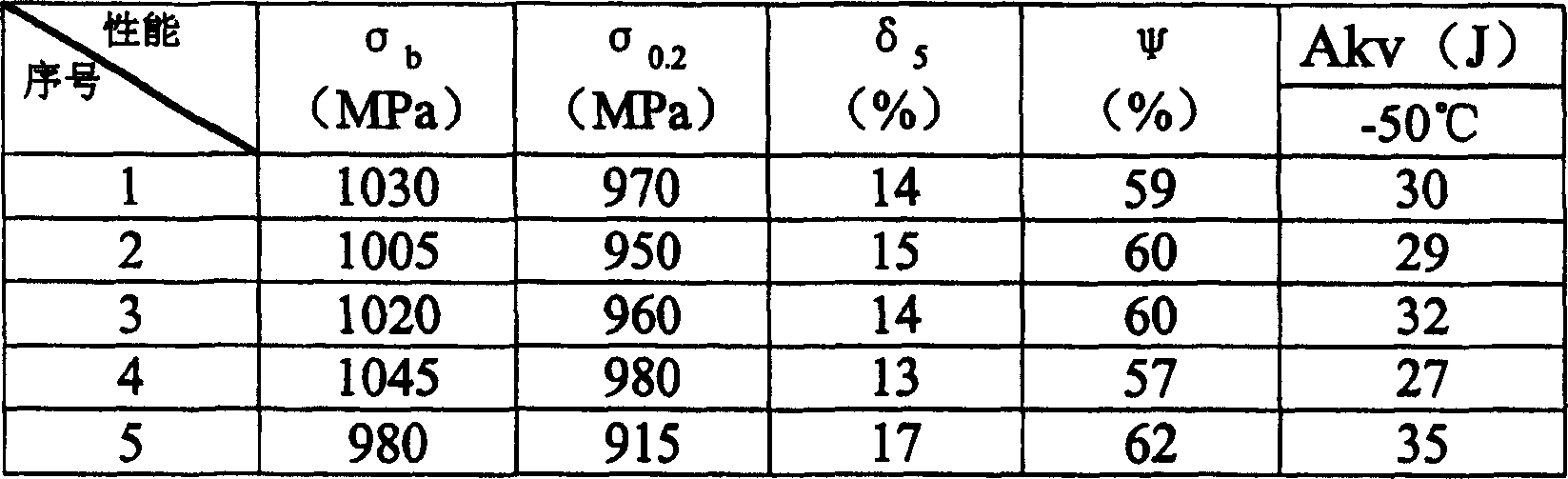

[0007] The electrode of the embodiment of the present invention obtains a deposited metal with good comprehensive mechanical properties after alloying the welding core or partially alloying the welding core and coating. According to the set composition requirements, a total of 2 heats of steel were smelted. The steel ingot was first forged into a 110mm billet, then rolled into a φ8mm wire rod, and finally drawn into an alloy welding core with a diameter of φ4mm. The forging temperature is 1180°C, and the final forging temperature is 850°C; the drawing passes are 5 passes. In order to achieve coating alloying, we selected high-quality H08E wire rod and drew it into a welding core with a diameter of φ4mm. The specific chemical composition of the welding core is listed in Table 1. The coating composition ratio of the welding rod of the embodiment is shown in Table 2; the preparation of the welding rod is to press it into a welding rod on a common oil pressure welding rod coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com