Ultra-thin ammonia corrosion resisting moving pressure container steel plate and production method thereof

A technology of mobile pressure and production method, which is applied in the field of steel materials, can solve the problems of poor ammonia corrosion resistance, achieve low cost, good weldability, and purify steel inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples. The following examples are only illustrative technical solutions of the present invention, and do not limit the present invention in any form .

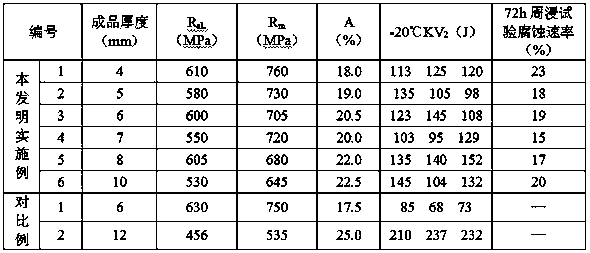

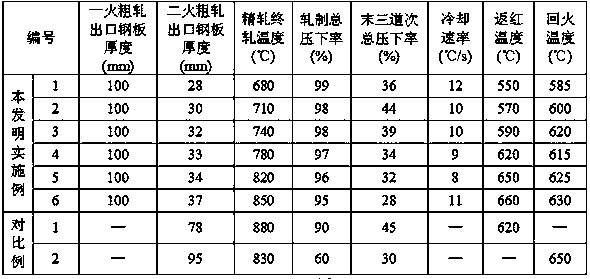

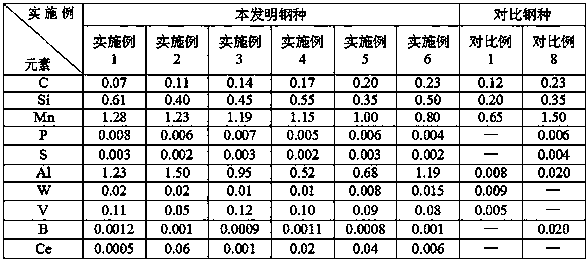

[0044] The following table 1 is a list of mass percentages of chemical components contained in the steel plates of various embodiments of the present invention and comparative examples;

[0045] The following table 2 is the value list of each process parameter in the main process steps of the steel plate of each embodiment of the present invention;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com