Ammonia corrosion resistant solvent-free insulated impregnating resin as well as preparation method and application thereof

An insulating impregnating, solvent-free technology, applied in the field of insulating impregnating resin, can solve the problems of workshop operators' health damage, insufficient ammonia corrosion resistance, waste of resources and environment, etc., and achieve excellent ammonia corrosion resistance, good electrical performance, and VOC emissions. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

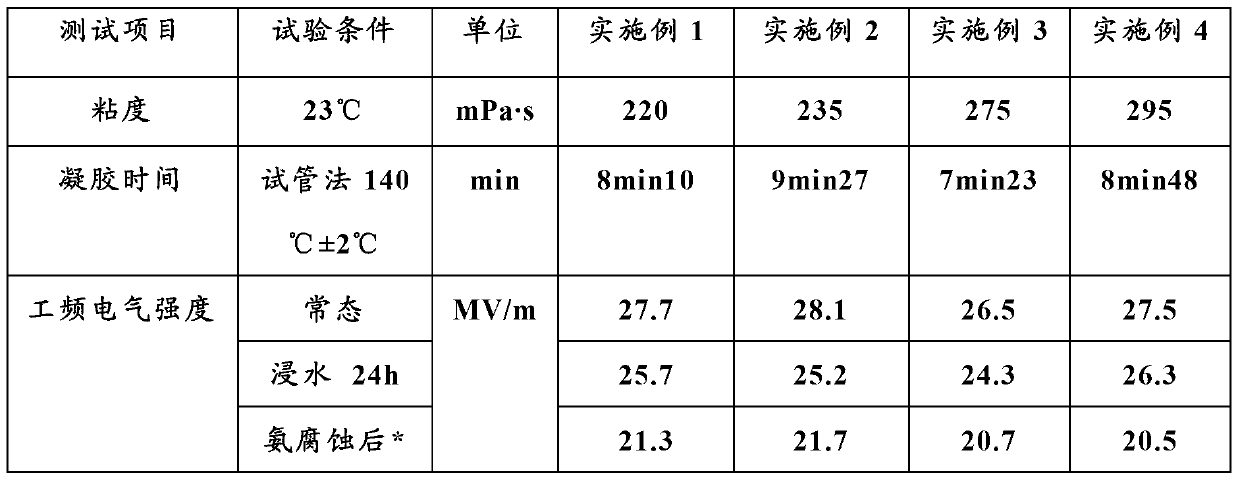

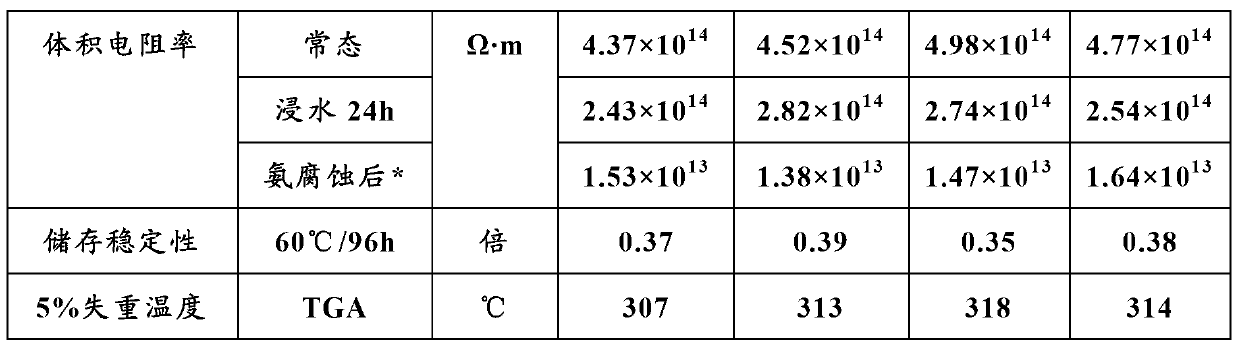

[0030] Weigh 100g epoxidized polybutadiene resin (weight average molecular weight 2000, the molar ratio of epoxy group to double bond is about 1:1, purchased from Tianjin Institute of Synthetic Materials Industry), 100g bisphenol F epoxy resin , heated to 80°C, stirred and added 12g curing agent 594, stirred and reacted for 40min, added 60g vinyl cyclohexene dioxide, 40g vinyl toluene, then added 1.0g tert-butyl peroxybenzoate, 0.01g p-hydroxyanisole , fully stirred evenly to obtain ammonia corrosion-resistant solvent-free impregnating resin. The prepared impregnation resin was cured by baking at 150°C for 5 hours, and the performance was tested. See Table 1 for the results.

Embodiment 2

[0032] Weigh 100g of epoxidized polybutadiene resin (weight average molecular weight 1500, the molar ratio of epoxy group to double bond is about 1.5:1), 80g of bisphenol F epoxy resin, heat to 60°C, stir and add 8g to solidify Agent bc120 stirred and reacted for 50min, added 45g dimethyl-substituted vinyl dioxide cyclohexene, 35g vinyltoluene, then added 1.2g tert-butyl peroxybenzoate, 0.006g p-hydroxyanisole, fully stirred evenly, and obtained Ammonia resistant solvent-free impregnation resin. The prepared impregnation resin was cured by baking at 130°C for 8 hours, and its performance was tested. See Table 1 for the results.

Embodiment 3

[0034] Weigh 150g of epoxidized polybutadiene resin (weight average molecular weight 800, the molar ratio of epoxy group to double bond is about 0.5:1), 135g of novolac epoxy resin, heat to 100°C, stir and add 16g of curing agent 594 Stir the reaction for 30 minutes, add 55g of dimethyl-substituted vinyl dioxide cyclohexene, 50g of vinyltoluene, then add 1.35g of tert-butyl peroxybenzoate, 0.27g of p-hydroxyanisole, and stir well to obtain ammonia-resistant Corrosive solvent-free impregnation resin. The prepared impregnation resin was cured by baking at 160°C for 2 hours, and the performance was tested. See Table 1 for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com