Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

A technology with needle-like structure and low yield-to-strength ratio, applied in the field of low-alloy steel and its production, can solve the problems of only 60mm maximum thickness, insufficient component safety and high yield-to-strength ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

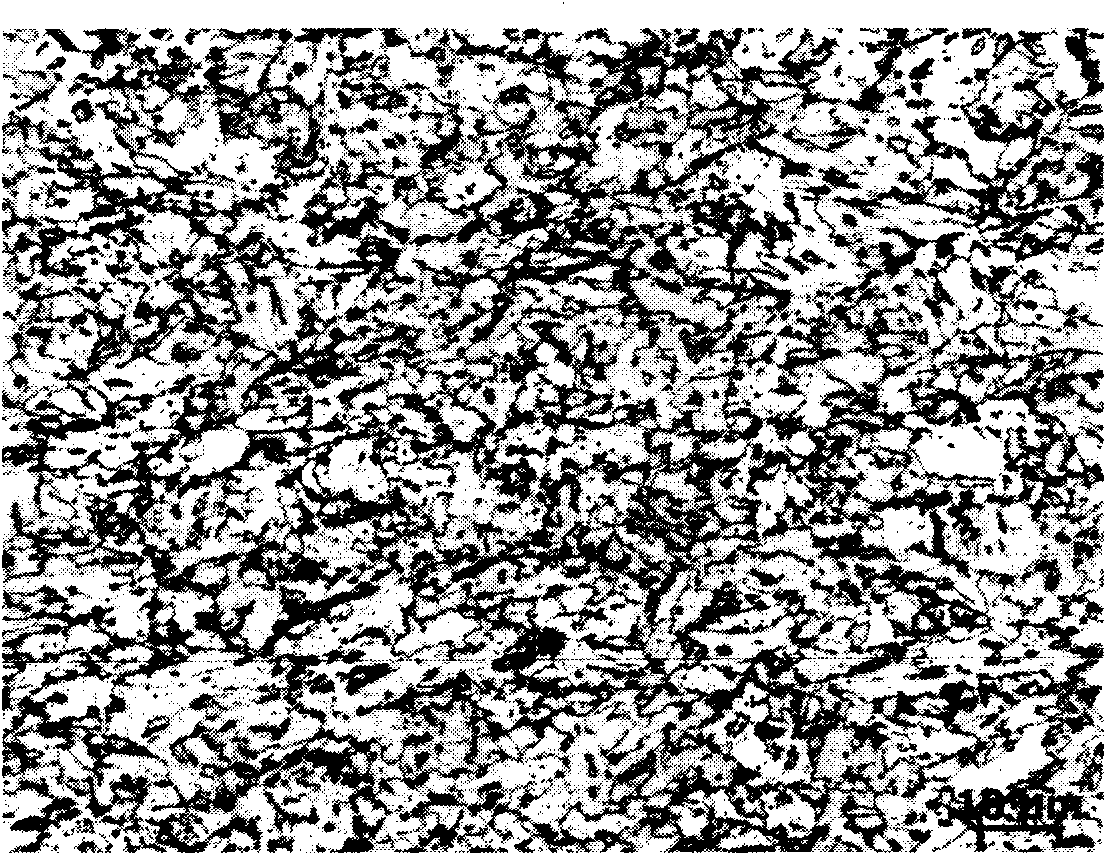

[0050] Such as figure 1 As shown, the components and weight percentages of the non-quenched and tempered acicular high-strength low-yield ratio weathering steel are:

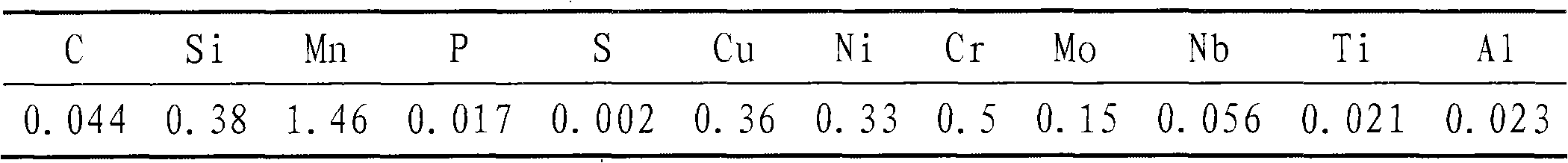

[0051] Basic composition: C 0.03~0.08%, Si 0.30~0.60%, Mn 1.30~1.80%, P≤0.015%, S≤0.010%, Cu 0.30~0.60%, Ni 0.20~0.50%, Cr 0.40~0.80%, Mo0 .10~0.40%, Nb 0.030~0.080% and Ti≤0.04%;

[0052] Optional ingredients: two or more of AlS≤0.04% and RE≤0.40kg / t steel or Ca≤0.005%;

[0053] And the balance of Fe and impurities.

[0054] At the same time, the welding cold crack sensitivity coefficient Pcm of this steel type is ≤ 0.20, and the ASTM G101-01 corrosion resistance index is > 6.0.

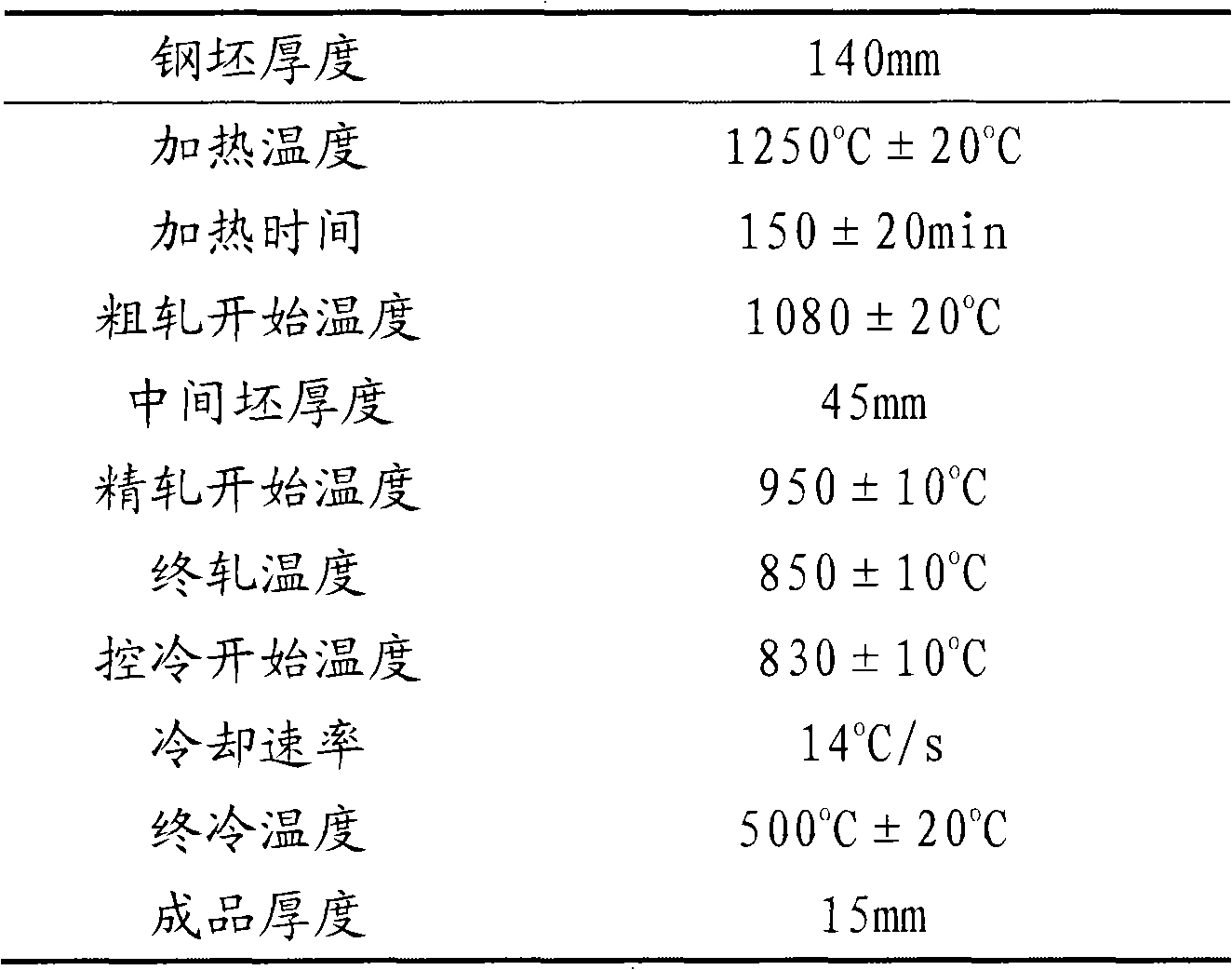

[0055] The preparation process of the above-mentioned steel grades is described below:

[0056] Firstly, the molten iron is smelted in a 150kg laboratory vacuum inductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com