Preparation method of fine-grain biological magnesium-zinc alloy plate

An alloy plate, magnesium-zinc technology, applied in the field of preparation of fine-grained bio-magnesium-zinc alloy plate, can solve the problems of difficult grain size sub-micron level, unfavorable large-scale production, material size limitation, etc., to achieve excellent biophase Capacitance and safety, good prospects for biomedical and industrial applications, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of fine-grained bio-magnesium-zinc alloy plate, with reference to figure 1 shown, including the following steps:

[0028] A magnesium-zinc alloy cast slab containing 2% by weight of Zn, the balance of Mg and less than 0.01% of impurities is prepared; the size of the cast slab is 50mm (length) × 50mm (width) × 22mm (thickness).

[0029] The magnesium-zinc alloy cast slab is heated to a set temperature of 295°C, and rolled in a single pass at a temperature of 295°C, with a rolling reduction of 80%; as a preferred method, the rolling speed is 14m / min; Fine-grained magnesium-zinc alloy sheet.

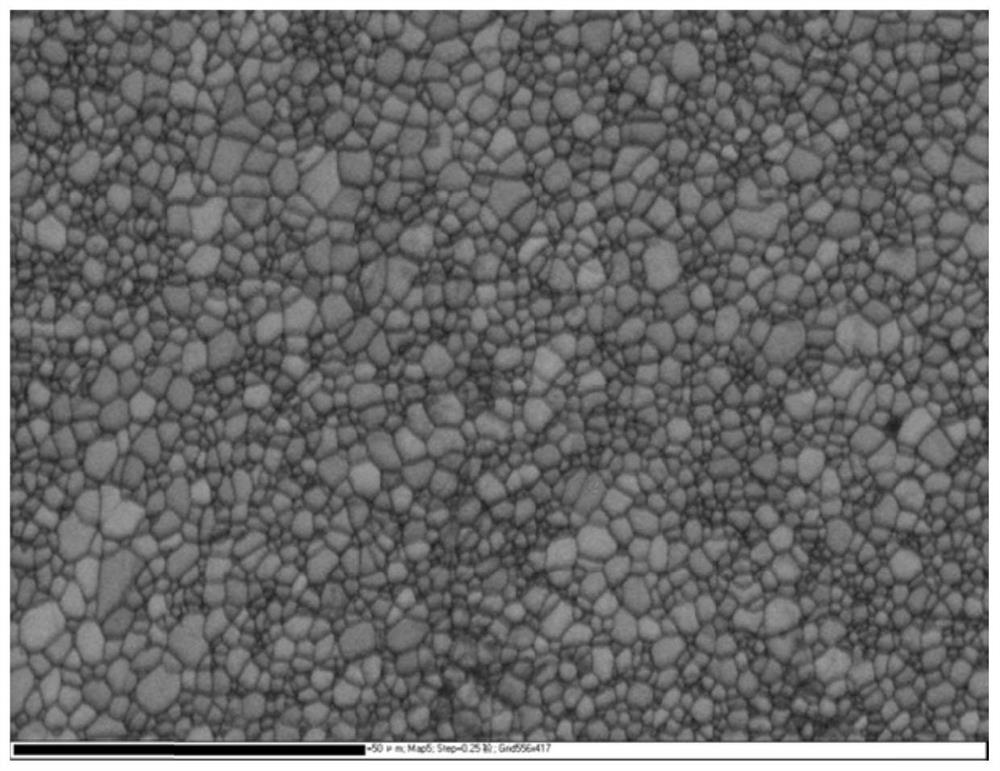

[0030] refer to figure 2 As shown, it can be seen from the figure that a fine-grained magnesium-zinc alloy plate with a fine grain size of about 1 μm-2 μm can be obtained through the above-mentioned preparation method. The yield strength of the fine-grained magnesium-zinc alloy sheet at room temperature is 185MPa, and t...

Embodiment 2

[0032] This embodiment provides a method for preparing a fine-grained bio-magnesium-zinc alloy plate, comprising the following steps:

[0033] Prepare a magnesium-zinc alloy cast slab containing 2.1% by weight of Zn and the balance of Mg; the size of the cast slab is 60mm (length)×50mm (width)×25mm (thickness).

[0034] The magnesium-zinc alloy billet is heated to a set temperature of 290°C, and rolled in a single pass at a temperature of 290°C, the rolling reduction is 75%; the rolling speed is 12m / min; Magnesium zinc alloy sheet.

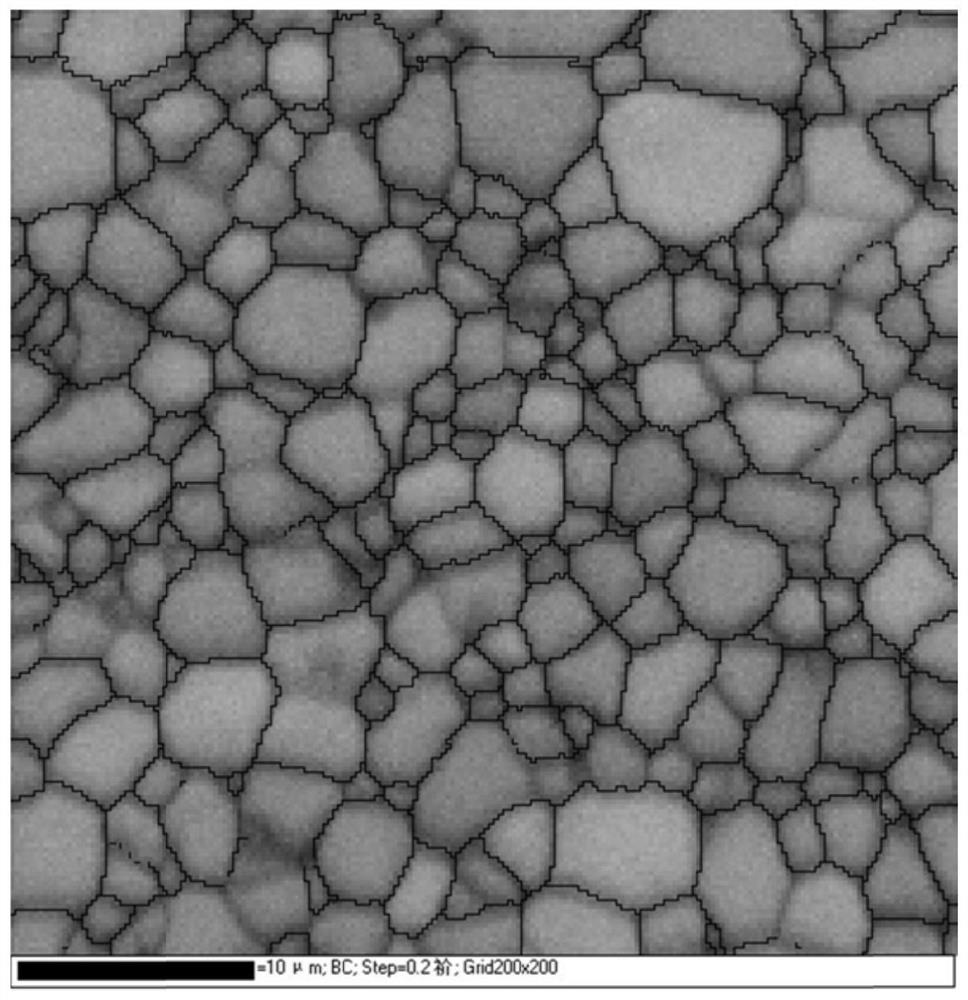

[0035] refer to image 3 As shown, it can be seen from the figure that a fine-grained magnesium-zinc alloy plate with a fine-grain size of about 3 μm-6 μm can be obtained through the above-mentioned preparation method. The room temperature yield strength of the fine-grained magnesium-zinc alloy sheet is 175MPa, and the tensile strength is 238MPa; the average corrosion rate of the fine-grained magnesium-zinc alloy sheet immersed in simulated body...

Embodiment 3

[0037] The present embodiment provides a kind of preparation method of fine-grained bio-magnesium-zinc alloy plate, with reference to figure 1 shown, including the following steps:

[0038] Prepare a magnesium-zinc alloy cast slab containing 1.9% by weight of Zn and the balance of Mg; the size of the cast slab is 60mm (length)×50mm (width)×20mm (thickness).

[0039] The magnesium-zinc alloy billet is heated to a set temperature of 295°C, and rolled in a single pass at a temperature of 295°C, with a rolling reduction of 85%; a rolling speed of 12m / min; Magnesium zinc alloy sheet.

[0040] refer to Figure 4 As shown, it can be seen from the figure that a fine-grained magnesium-zinc alloy plate with a fine grain size of about 1 μm-3 μm can be obtained through the above-mentioned preparation method. The yield strength of the fine-grained magnesium-zinc alloy sheet at room temperature is 175MPa, and the tensile strength is 245MPa; the average corrosion rate of the fine-grained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com