Compressing double deoxidizer for steelmaking and preparation method thereof

A composite deoxidizer, pressed-type technology, applied in the field of pressed-type composite deoxidizer for steelmaking and its preparation, can solve the problems such as difficult removal of deoxidized products, increased steelmaking cost, unstable quality, etc., to reduce nozzle knots The effect of no tumor problem, less alloy burning loss, and improved spheroidization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

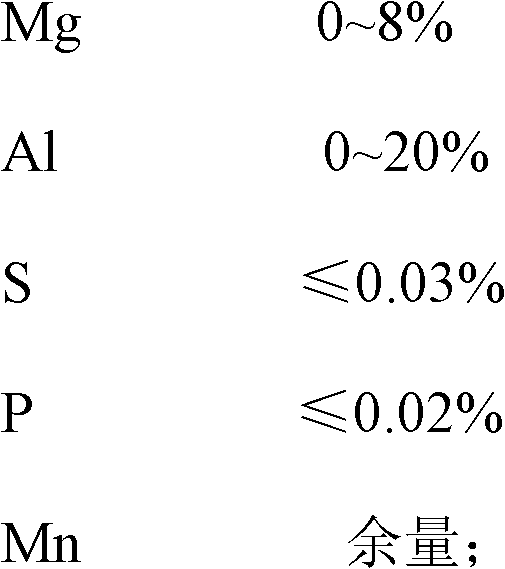

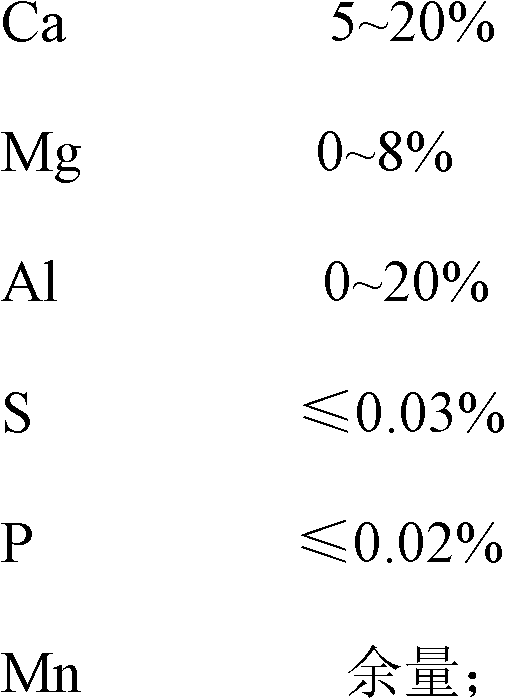

[0027] Use 15Kg of aluminum powder + 110Kg of electrolytic manganese + 15Kg of passivated calcium powder + 7.5Kg of passivated magnesium powder + 3Kg of alkaline sodium silicate aqueous solution and put them into the mixer for 20 minutes. 20T high-pressure briquetting machine, after pre-pressing, the pressed pellets are screened through the screen, and the pellets that meet the requirements are transported into the mesh belt oven through the belt conveyor, and the underscreen material is re-entered into the briquetting machine through the belt and elevator for pressing; Dry 20min at 120°C in a mesh belt oven to obtain residual moisture at 0.5%, and the pellets whose strength reaches the requirements (strength reaches 120 times / m), are packaged and stored after cooling; obtain 150Kg of the product, and the assay components are as follows:

[0028] Ca 9.95%; Mg 4.98%; Al 9.9%; Mn; 73.1%: S: 0.02%; P: 0.02%, Si: 0.25%;

Embodiment 2

[0030] 15Kg of aluminum powder + 110Kg of electrolytic manganese + 15Kg of passivated calcium powder + 7.5Kg of passivated magnesium powder + 2Kg of alkaline sodium silicate aqueous solution + 1kg of silica sol are put into the mixer and stirred for 20 minutes. Add a high-pressure briquette machine with a pressure of 20T. After pre-pressing, the pressed pellets are screened through a screen, and the pellets that meet the requirements are transported into the mesh belt oven through a belt conveyor. machine pressing; dry 50min at 105°C in a mesh belt oven to obtain pellets with a residual moisture of 0.8% and a strength that meets the requirements (strength reaches 86 times / m), and pack and store after passing the cooling; obtain 150Kg of the product, and test the ingredients as follows:

[0031] Ca 9.5%; Mg 4.5%; Al 9.6%; Mn: 72%: S: 0.02%; P: 0.02%, Si: 0.27%;

Embodiment 3

[0033] Aluminum powder 15Kg + electrolytic manganese 110Kg + passivated calcium powder 15Kg + passivated magnesium powder 7.5Kg + alkaline sodium silicate aqueous solution 1Kg + 1kg aluminum hydroxide gel + polyvinyl alcohol 1kg put into the mixer and stir for 20 minutes. After the conveyor reaches the hoist, evenly add a high-pressure briquetting machine with a pressure of 20T. After pre-pressing, the pressed pellets are screened through a screen, and the pellets that meet the requirements are transported into a mesh belt oven through a belt conveyor. The belt and elevator re-enter the briquetting machine for pressing; the drying temperature is 100°C, and the pellets are taken out after 60 minutes. The measured residual moisture is 0.8%, and the pellets whose strength meets the requirements (strength reaches 82 times / m), after passing the cooling Packing storage; obtain product 150Kg, assay composition is as follows:

[0034] Ca 9.6%; Mg 4.7%; Al 9.68%; Mn: 72.6%: S: 0.02%; P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com