Environment-friendly composite stone plate and preparation method thereof

A production method and technology of composite panels, applied in the field of decorative materials, can solve problems such as moisture resistance, corrosion resistance, and waterproofing, and achieve the effects of reducing specific gravity, saving raw materials, and increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

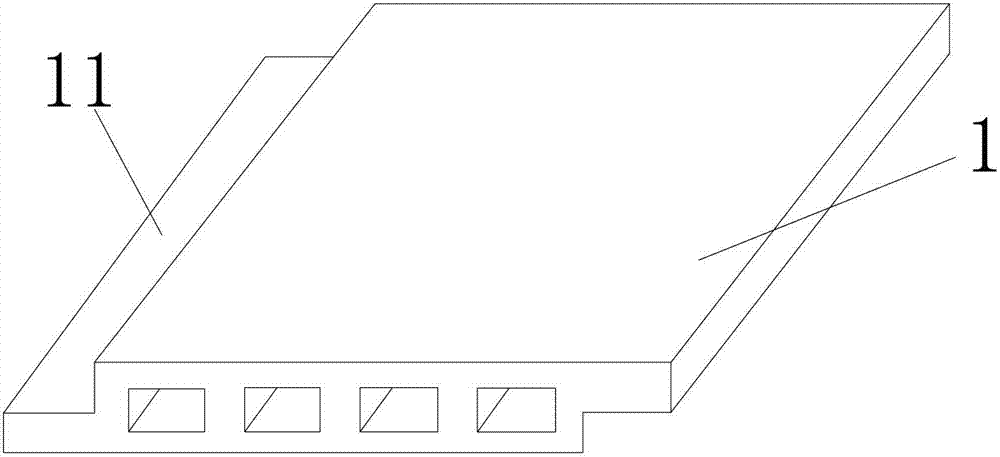

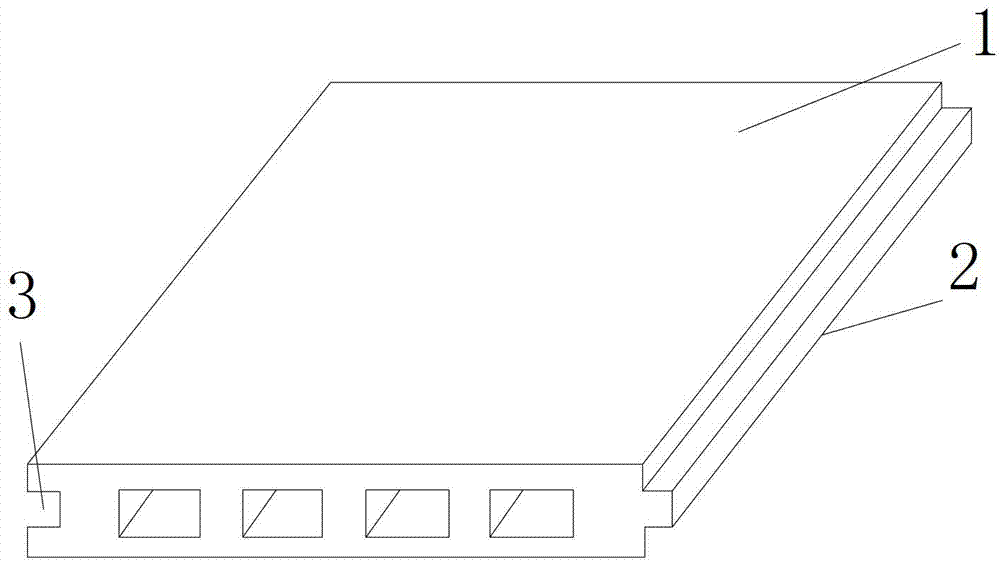

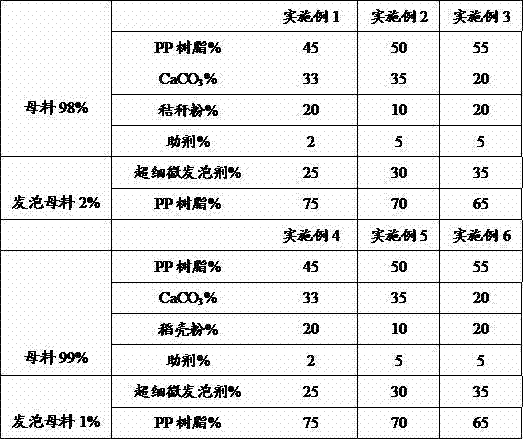

[0041] The environment-friendly stone composite board of the present invention includes a composite substrate, the surface of the composite substrate is provided with a printing layer, and the composite substrate is formed by processing the following raw materials in mass percentage:

[0042] a) Masterbatch 98-99%, said masterbatch is composed of the following components in terms of mass percentage:

[0043] PP resin 45-55%

[0044] CaCO 3 20-35%

[0045] Filler 10-20%

[0046] Auxiliary 2-5%;

[0047] b) 1-2% foaming masterbatch, said foaming masterbatch is composed of the following components in terms of mass percentage:

[0048] Super fine blowing agent 25-35%

[0049] PP resin 67-75%;

[0050] The sum of the mass percentages of the components in the above raw material a) is 100%, the filler is a mixture of one or more of 600-1000 mesh straw powder, sawdust powder, and rice husk powder, and the CaCO 3 The fineness is 1000-1500 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com