Patents

Literature

531results about How to "Play a role in heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Universal health-care board and preparation method thereof

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

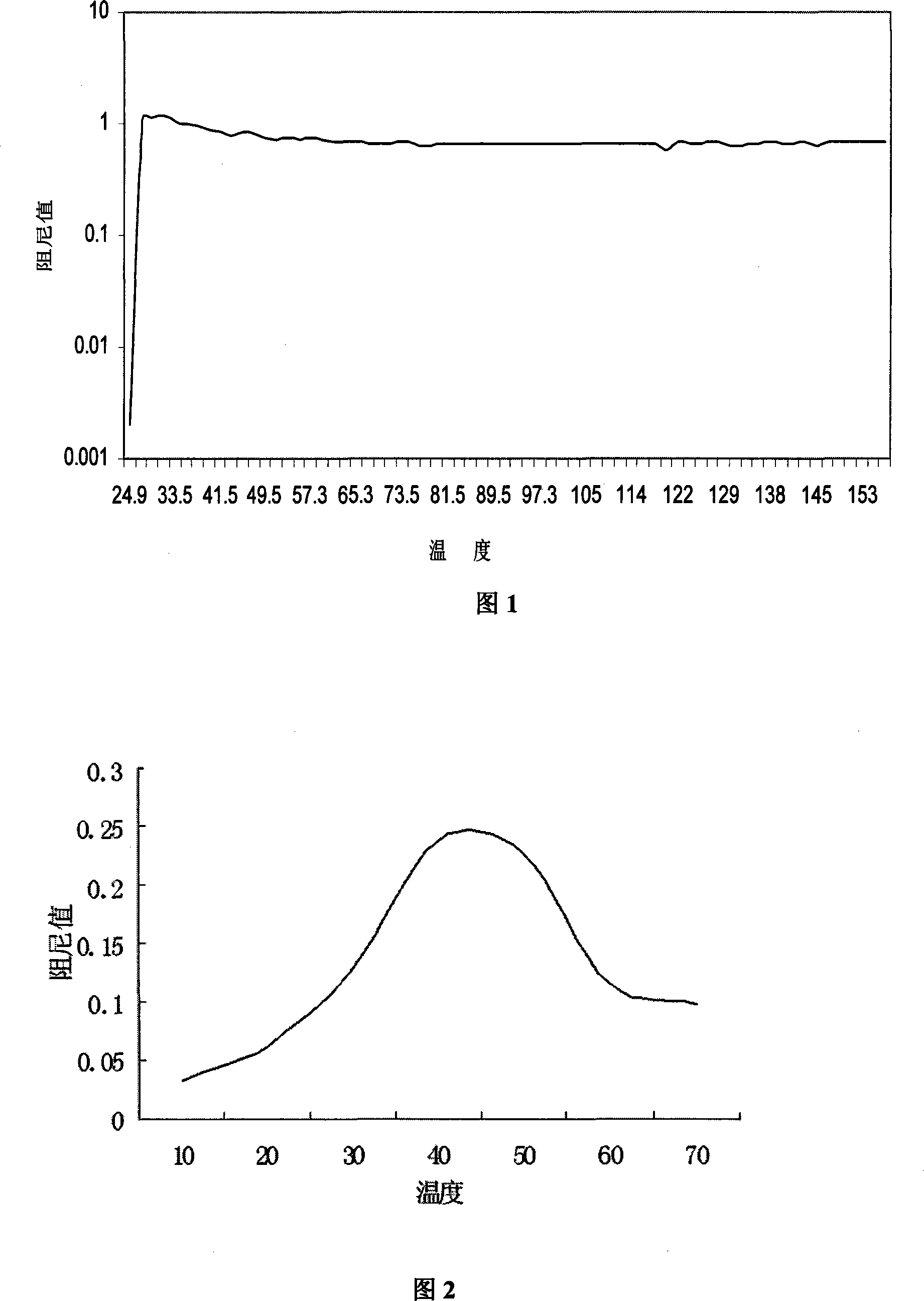

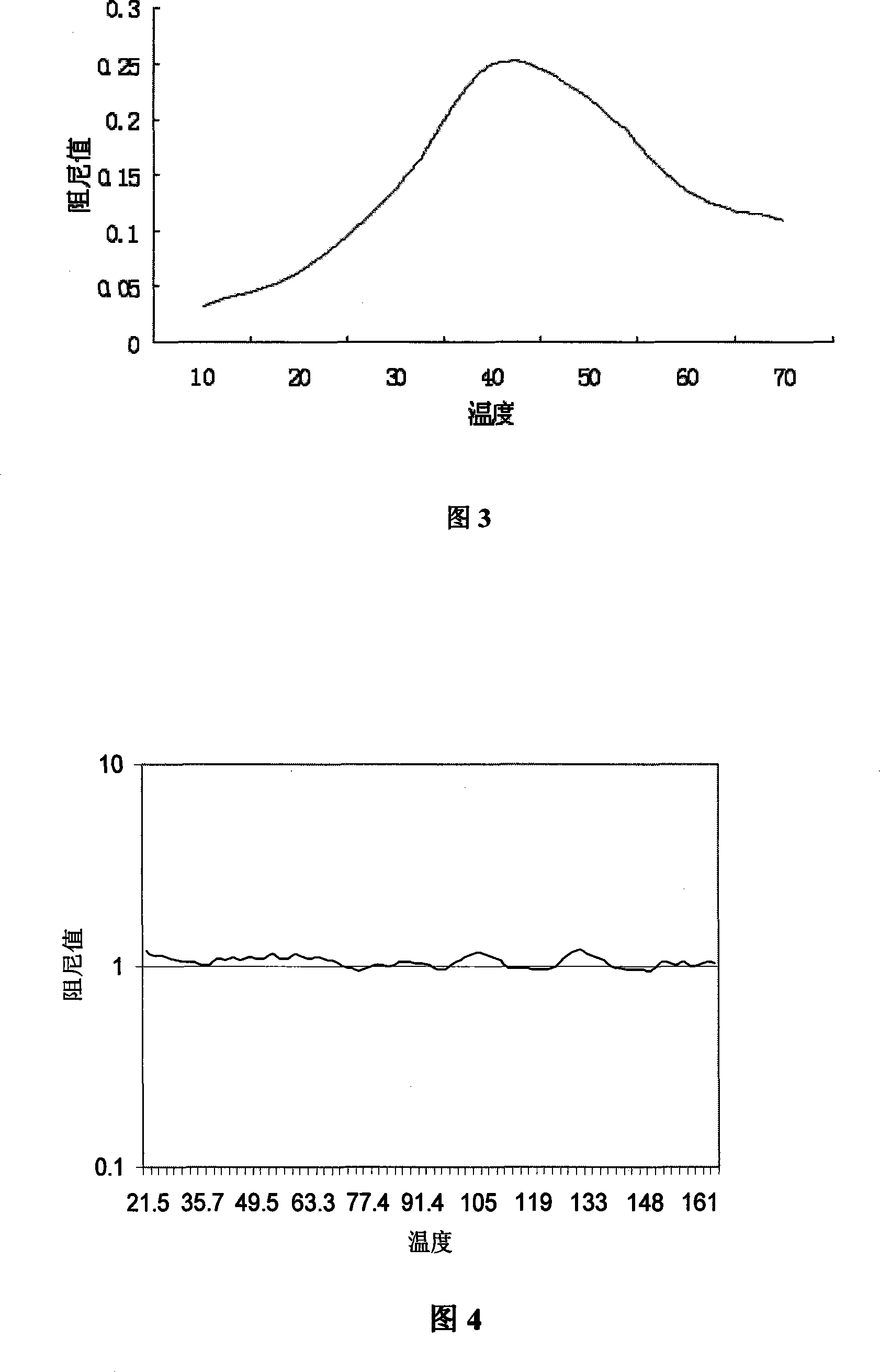

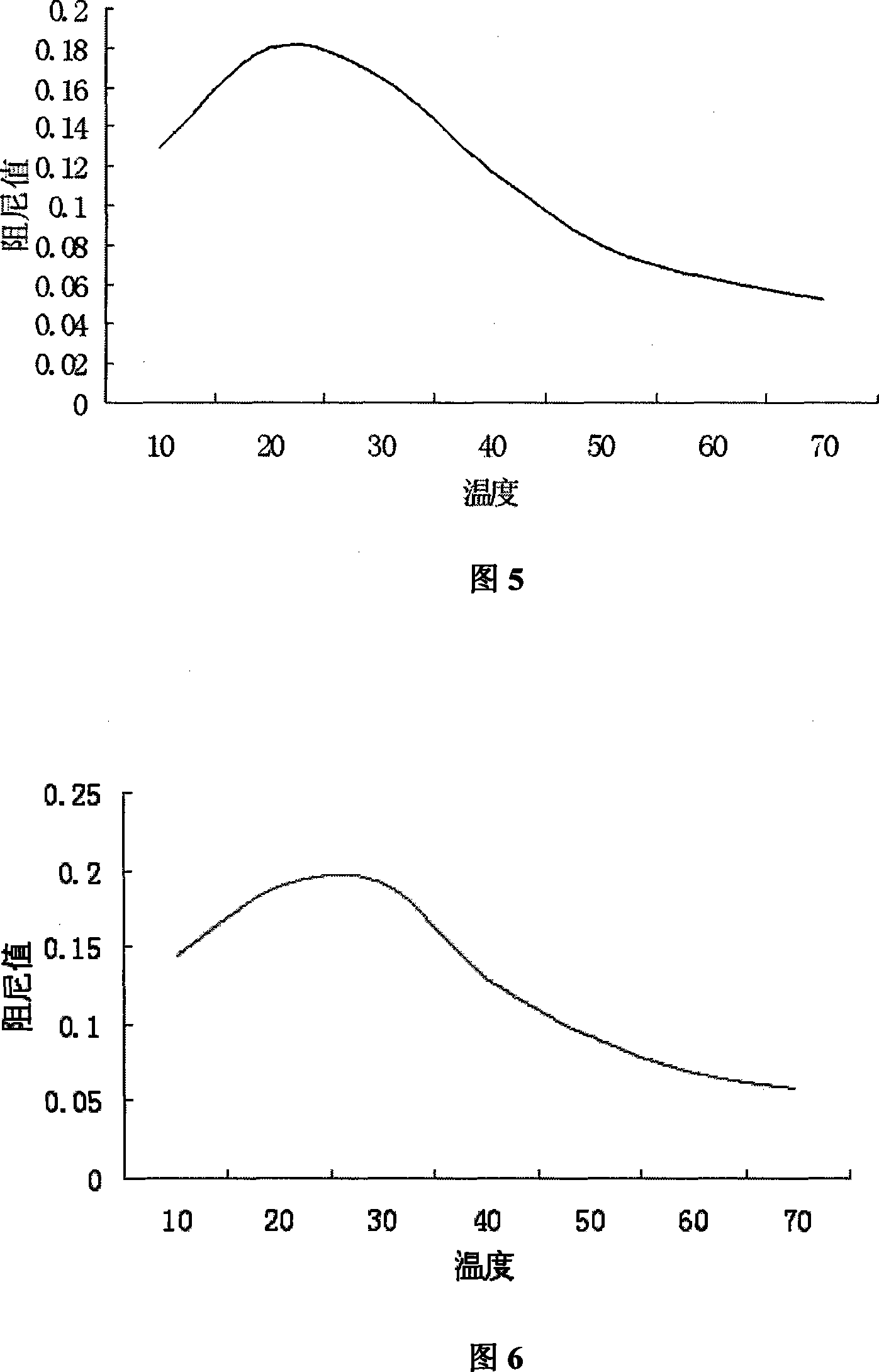

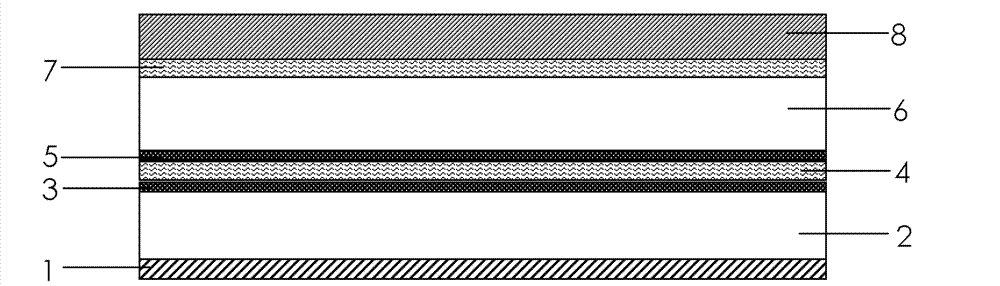

Polyacrylates interpenetrating network polymer emulsion and high damping material thereof

The invention provides polyacrylic ester interpenetrating network polymer emulsion and highly damped materials, pertaining to the high molecular polymer technological field. The polymer emulsion group consists of protecting adhesive, emulsifier, activator, buffering agent, cross-linking agent, water and monomers, wherein, the monomers comprises butyl acrylate, methacrylic acid, acrylic acid epoxy propyl ester, cinnamene, etc., and polymerize in an interpenetrating network shape. The highly damped materials used for decreasing vibration of vehicles are prepared by the emulsion after addition agent, filing materials and water are added. Since the emulsion of the invention, hollow glass microbeads and talc are used as the important components of the filling materials, the high molecular adhesive and elastic material of the invention has better damped performance, the tenacity and elasticity of the material are enhanced, the intensity of tension, and flexural rigidity resistance and wearing resistance of the material are improved, therefore, the effects of vibration decreasing, noise decreasing, sound and heat insulation can be achieved under various complicated conditions.

Owner:JILIN UNIV

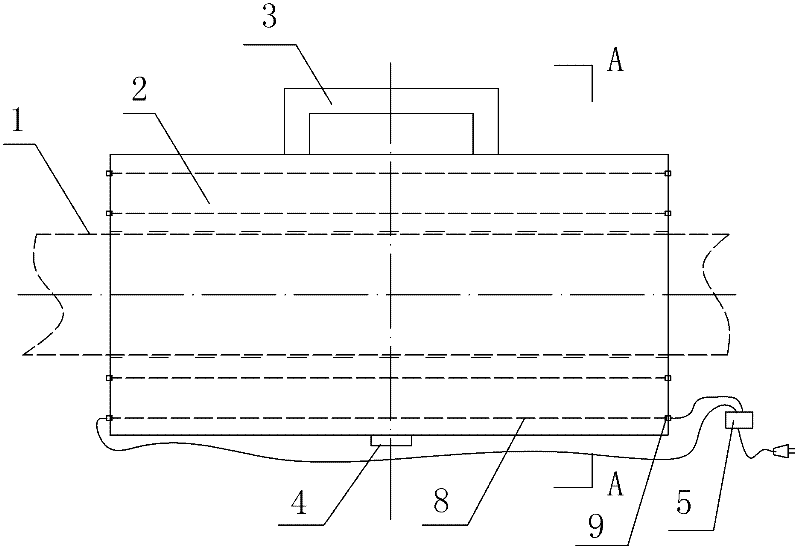

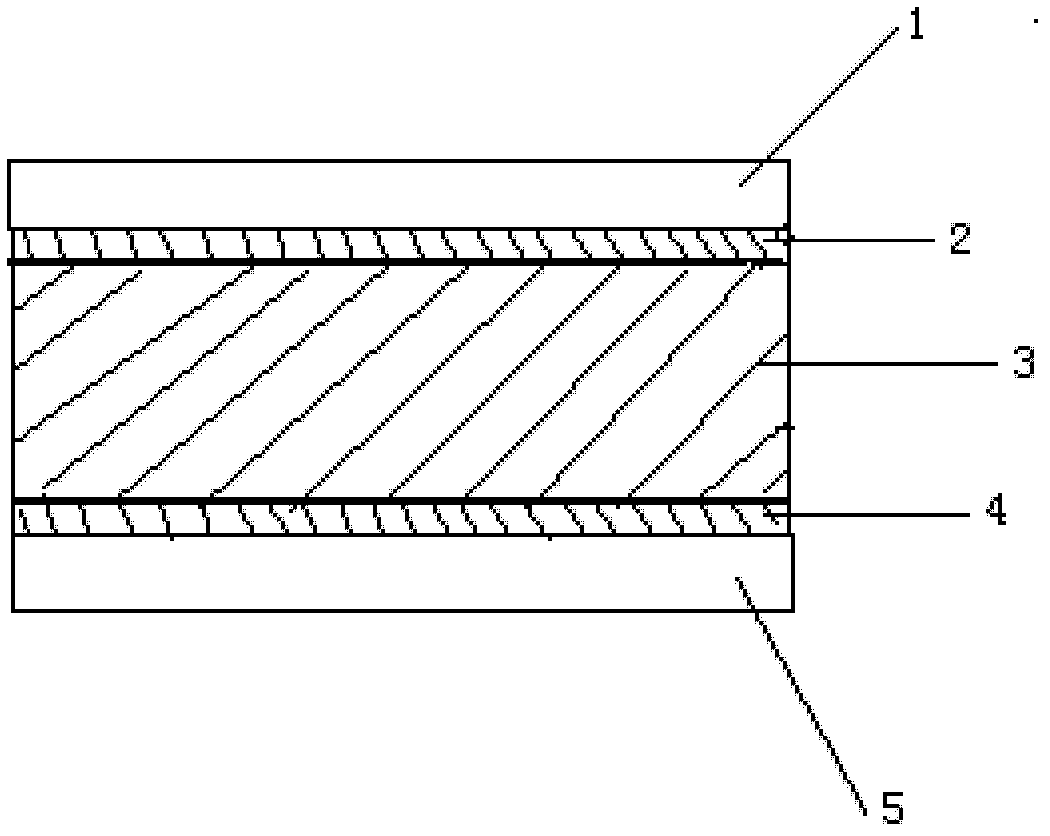

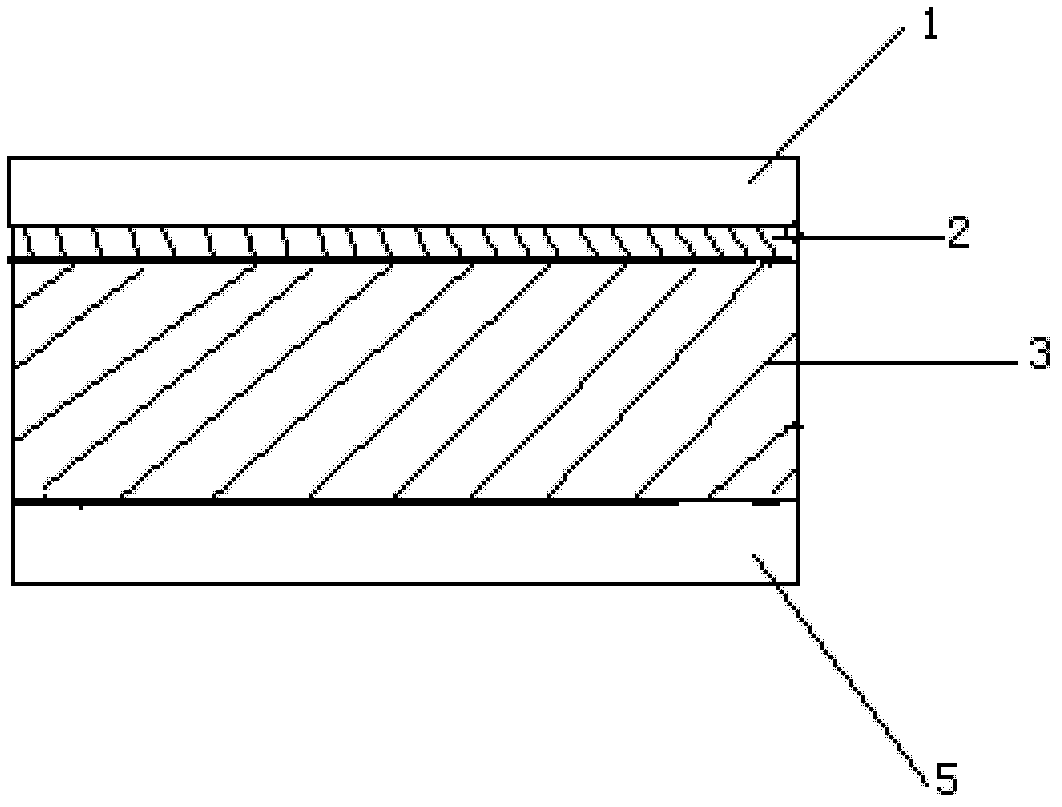

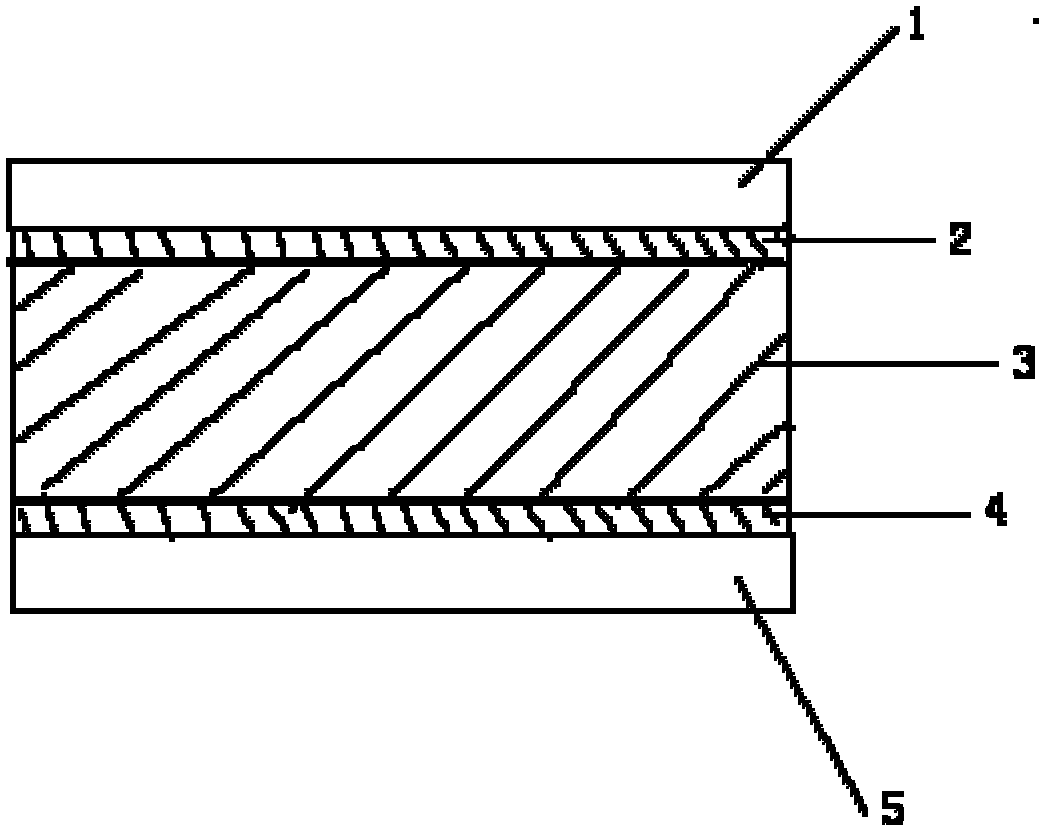

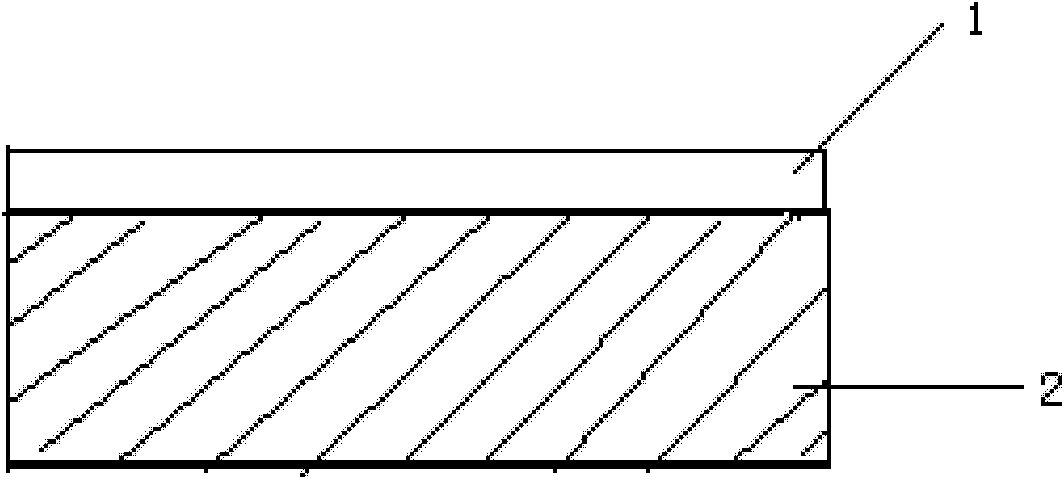

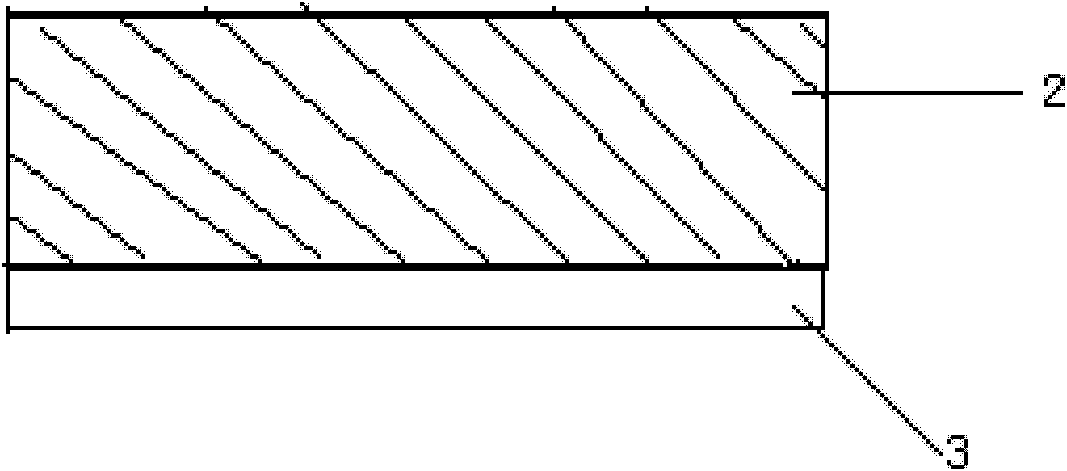

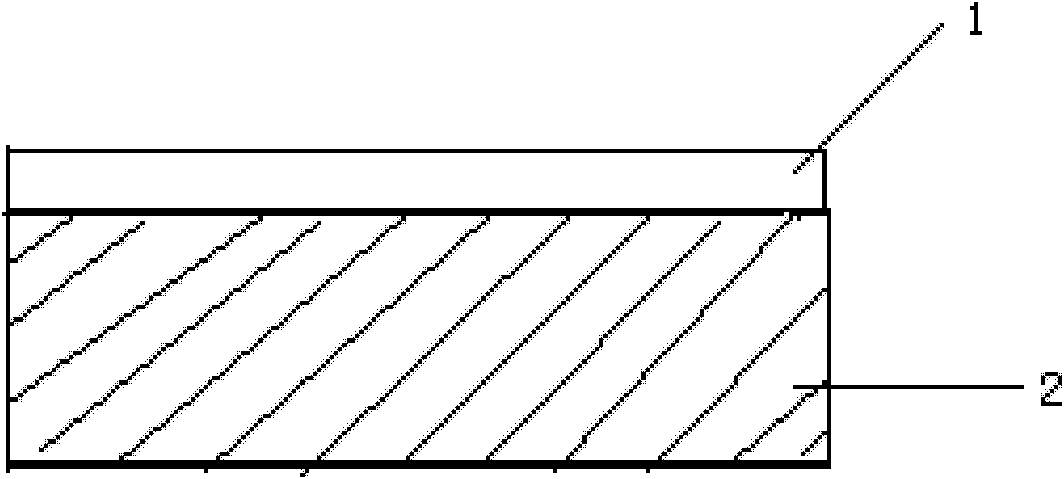

Double layer PET structural heat-insulation film

InactiveCN102774111AReduce visible light reflectanceGood heat insulationSynthetic resin layered productsMetal layered productsColoring agentsMonolayer

The invention relates to the technical field of heat-insulation films, and particularly relates to a double layer PET structural heat-insulation film. The heat-insulation film has a layered composite structure, and comprises, from upper to down successively, a hardening coating having a protective effect, a colorless and transparent first PET layer, a coating layer A which is disposed on the first PET layer and has a heat-insulation effect, a first adhesive layer, a transparent second PET layer, a second pressure-sensitive adhesive layer and an anti-sticking layer, wherein the second PET layer is colored or colorless transparent PET; a coating layer B is disposed between the second PET layer and the first adhesive layer; or the coating layer B can be replaced by adding a coloring agent in the first adhesive layer when the second PET layer is the colorless transparent PET. Compared with a single layer heat-insulation film, the double layer PET structural heat-insulation film has lower visible light reflectivity and better heat-insulation performance.

Owner:SOUTHWESTERN INST OF PHYSICS

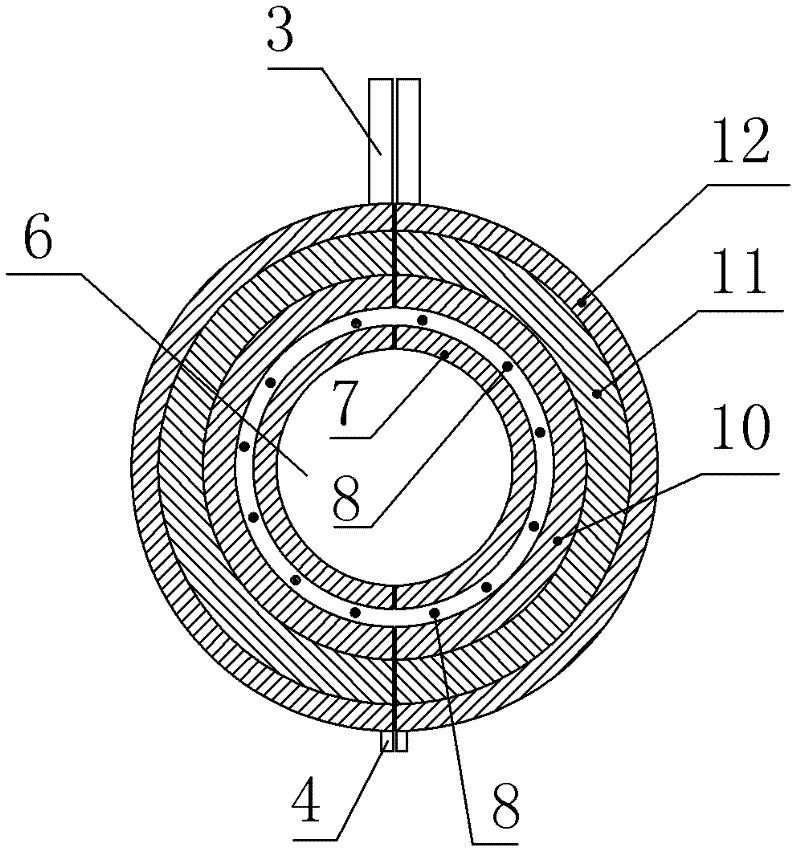

Distributed stress/temperature sensing optical fiber coordinate locating device

InactiveCN102519623AHigh precisionEasy to handleForce measurement by measuring optical property variationThermometers using physical/chemical changesElectricitySEMI-CIRCLE

The invention relates to a locating device capable of measuring corresponding coordinate position of a distributed sensing optical fiber in a measured structure. A distributed stress / temperature sensing optical fiber coordinate locating device is characterized in that the locating device comprises two semi-circle annular members, wherein the bottom ends of two semi-circle annular members are connected in a buckling manner; the upper ends of two semi-circle annular members are connected in a buckling manner; two semi-circle annular members form an annular structure with an optical fiber through hole inside; two semi-circle annular members comprise outer surface layers and inner surface layers; the inner surface layers are arranged in the outer surface layers; an electric heating wire is arranged between each outer surface layer and each inner surface layer; a lead wire connected with a wire connection head of each electric heating wire is respectively connected with a corresponding output end point in a power supply control box; each outer surface layer is composed of an iron layer, an asbestos layer and a ceramic layer, which are arranged from inside to outside; and each inner surface layer is a glass layer. According to the method, a measurement circuit composed of the distributed sensing optical fiber can be subjected to accurate coordinate location.

Owner:CHINA FIRST METALLURGICAL GROUP +1

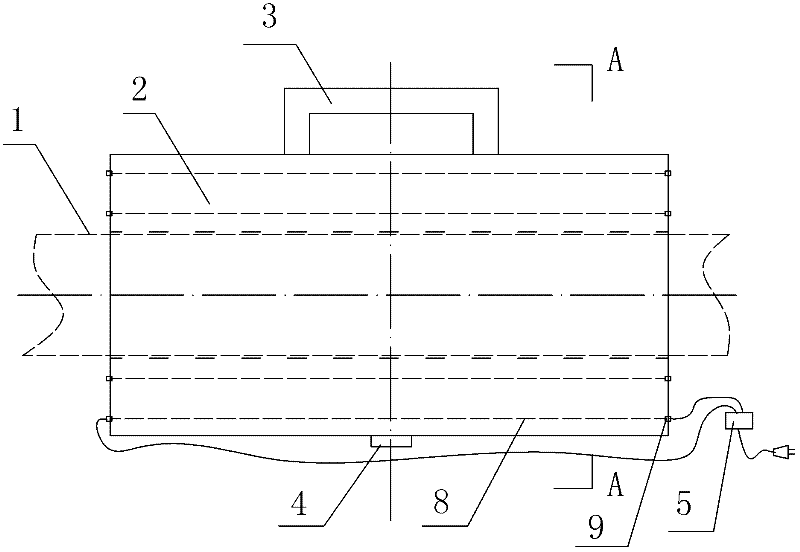

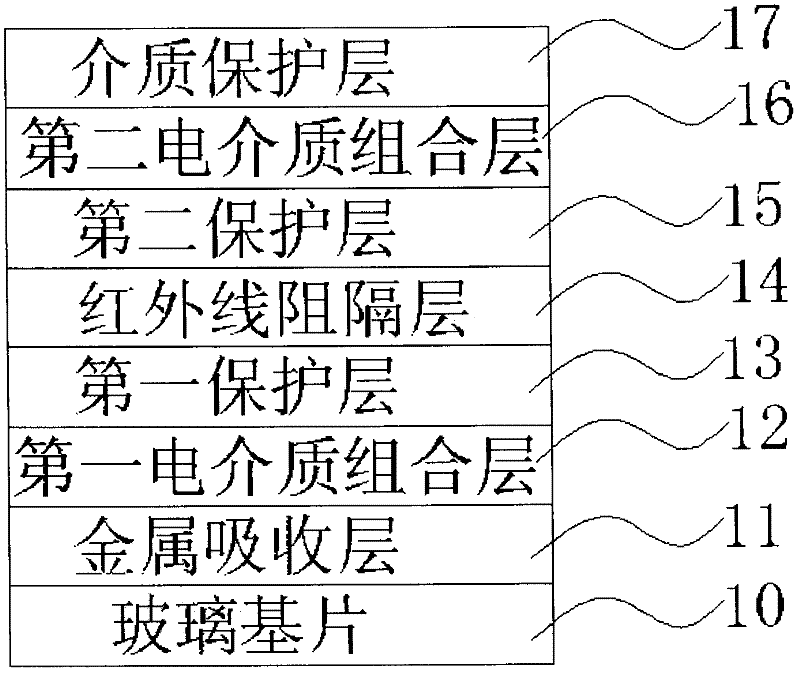

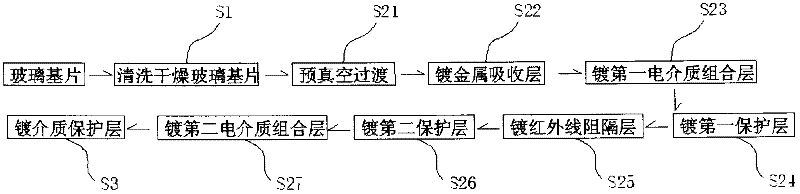

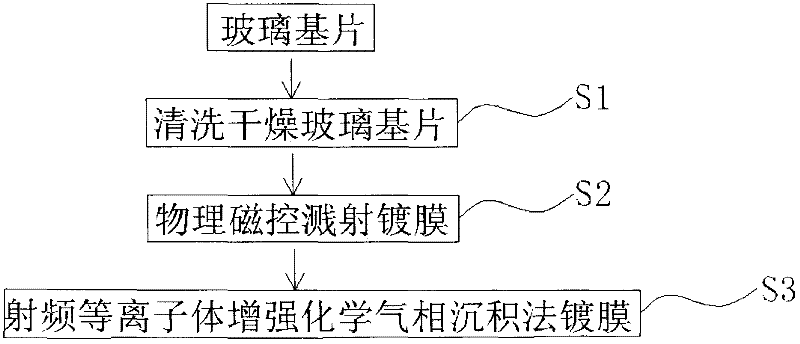

Enhanced protection type toughened low-radiation coated glass and manufacturing process thereof

InactiveCN102529209APromote absorptionReduce reflectionVacuum evaporation coatingSputtering coatingLight pollutionOptical transmittance

A medium protecting layer is added to the outermost layer of ordinary low-radiation coated glass to serve as an enhanced protecting layer so that the ordinary low-radiation coated glass has high chemical stability, abrasion resistance and oxidation resistance and low friction coefficient and particularly improves scratch resistance, toughened low-radiation coated glass is convenient and simple to transport and process, and the finished product rate of production is greatly improved. In particular, the lowered processing requirements enable more small glass deep-processing enterprises to produce the low-radiation coated glass, and a foundation is established for popularization of environment-friendly energy-saving products. In addition, a metal absorbing layer is first coated on the glass, reflectivity of coated products can be greatly reduced, the problem of light pollution of the toughened low-radiation coated glass with low light transmittance is solved, and the toughened low-radiation coated glass products can meet the requirements of the market at present.

Owner:林嘉宏

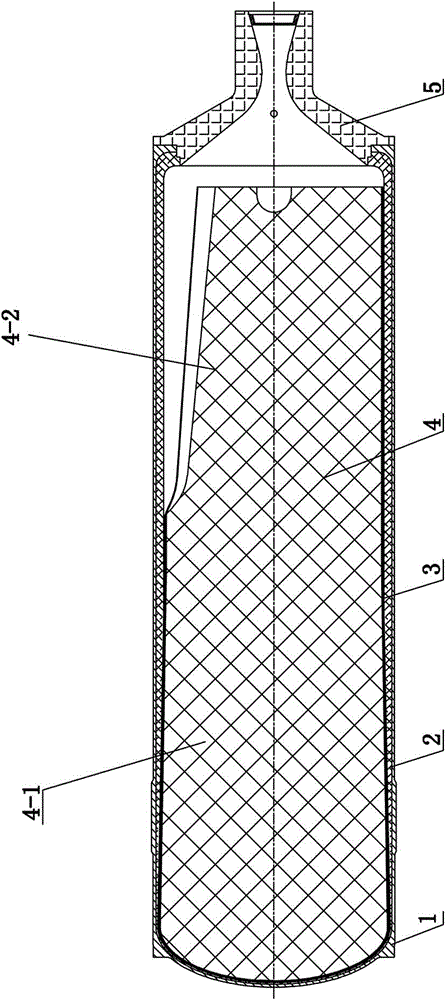

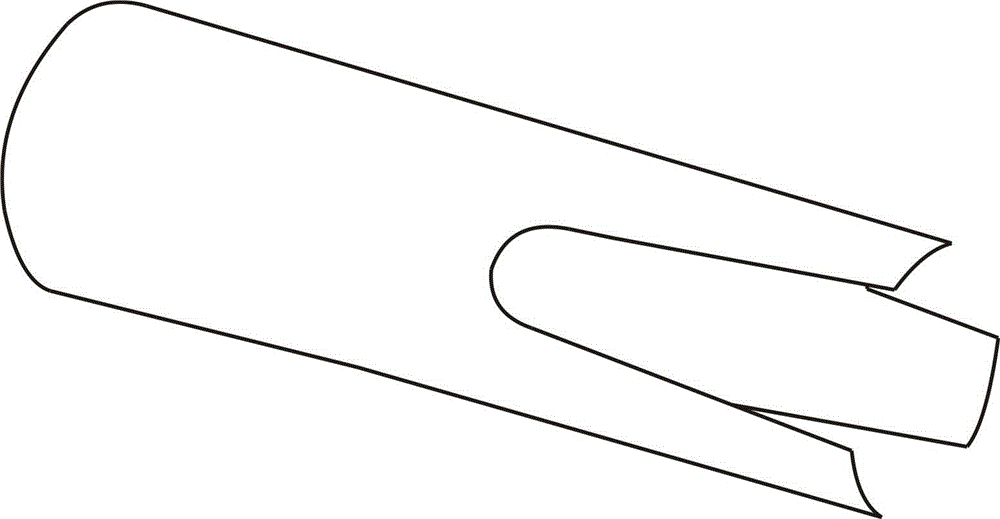

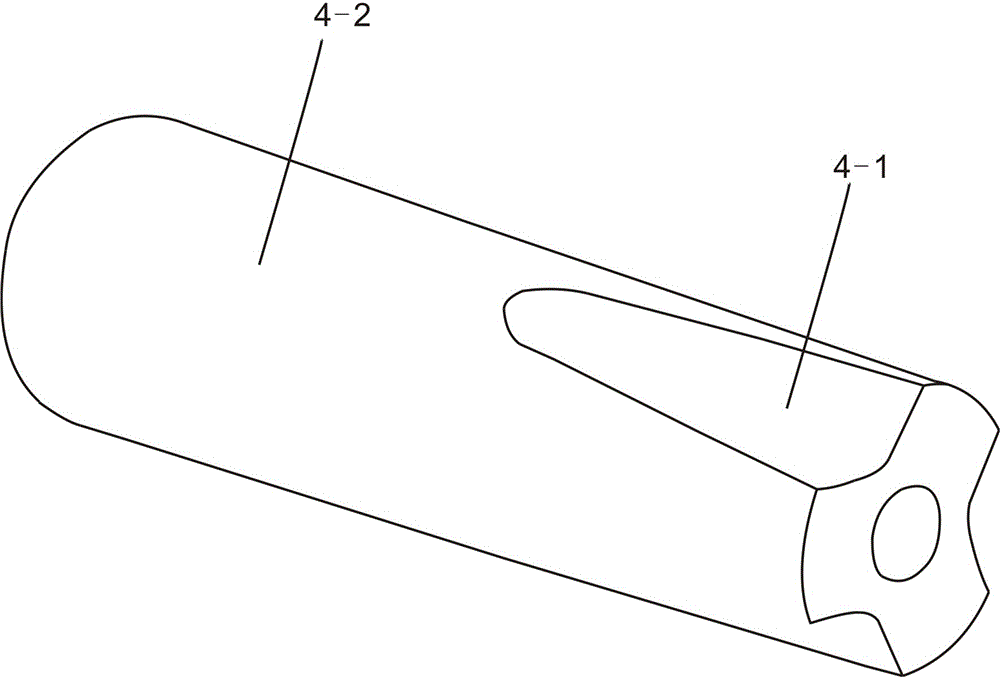

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

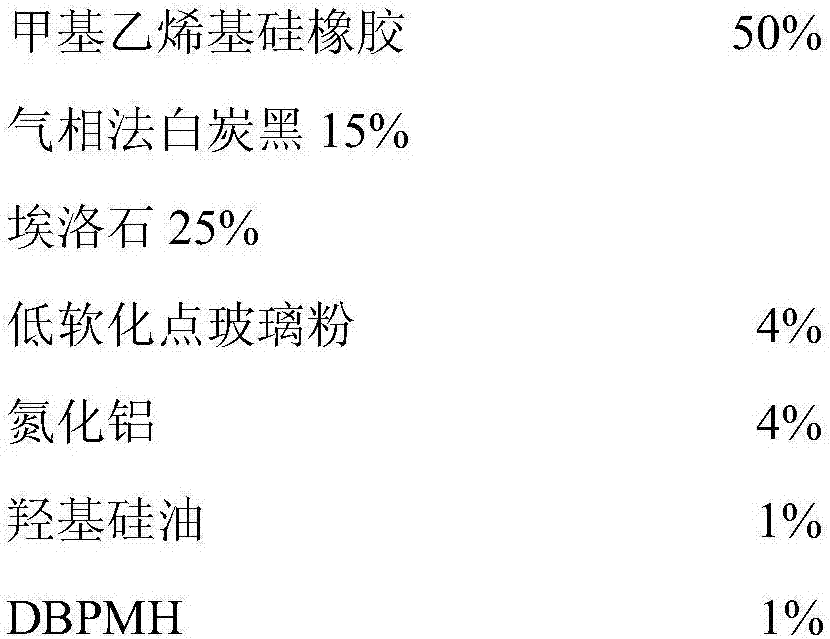

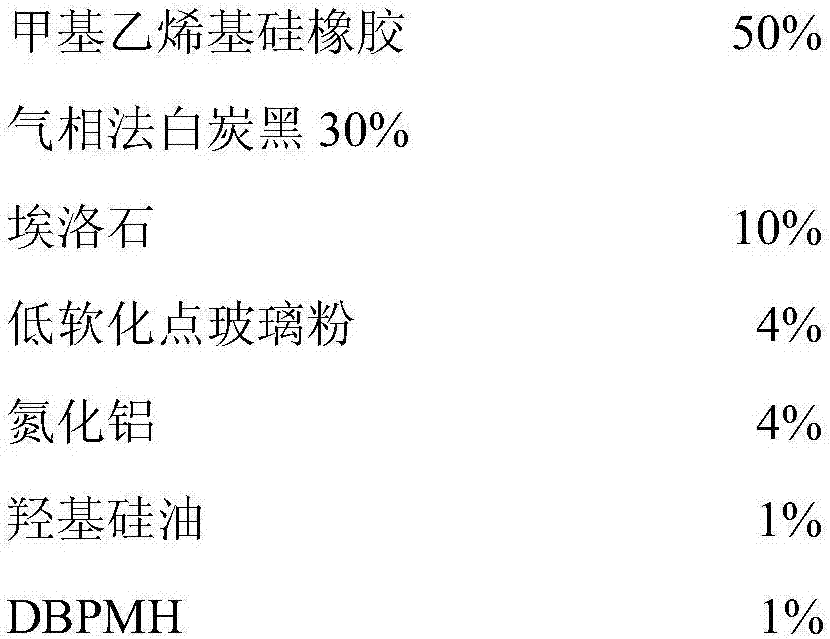

Low-temperature ceramic silicone rubber and preparation method thereof

ActiveCN107163585ASmall mechanical propertiesPlay a role in heat insulationHalloysitePolymer science

The invention discloses low-temperature ceramic silicone rubber and a preparation method thereof. The low-temperature ceramic silicone rubber comprises the following raw materials by mass percent: 40-80% of silicone rubber, 10-30% of fumed silica, 15-30% of halloysite, 3-8% of a heat conducting filler, 3-10% of a flux, 1-5% of hydroxyl silicone oil and 1-3% of a vulcanizing agent. During preparation, raw materials are uniformly mixed in a rubber internal mixer or a rubber open mixer to obtain a rubber compound, the rubber compound is vulcanized at the temperature of 150-180 DEG C to obtain ceramic silicone rubber vulcanized rubber, the first-stage vulcanization time is 5-15 min and the second-stage vulcanization time is 2-4 h. The technical method is simple, the prepared ceramic silicone rubber vulcanized rubber has favorable mechanical performance and can be converted into a hard ceramic body at a low ceramization temperature, the ceramic body has the three-point bending strength exceeding 3 MPa and is quick in forming, and wires and cables have more remarkable flame-retardant and fire-retardant effects.

Owner:SOUTH CHINA UNIV OF TECH

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

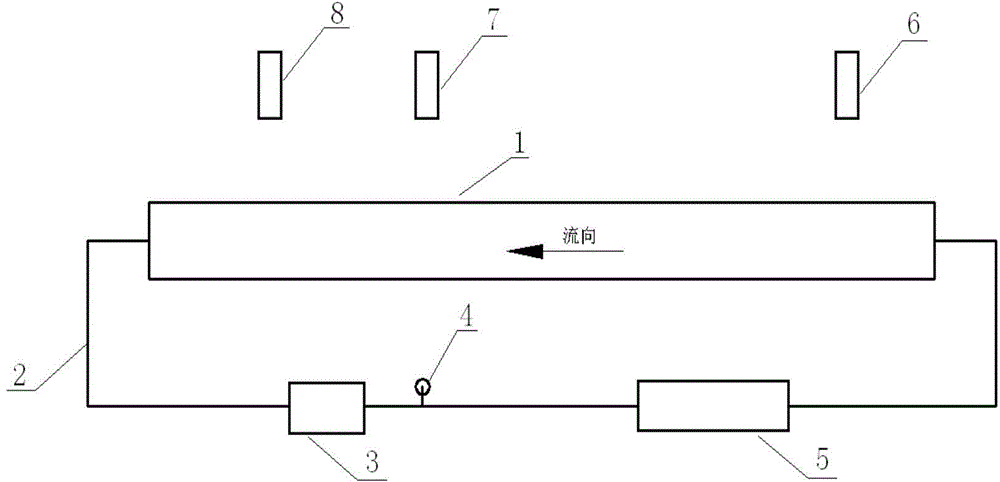

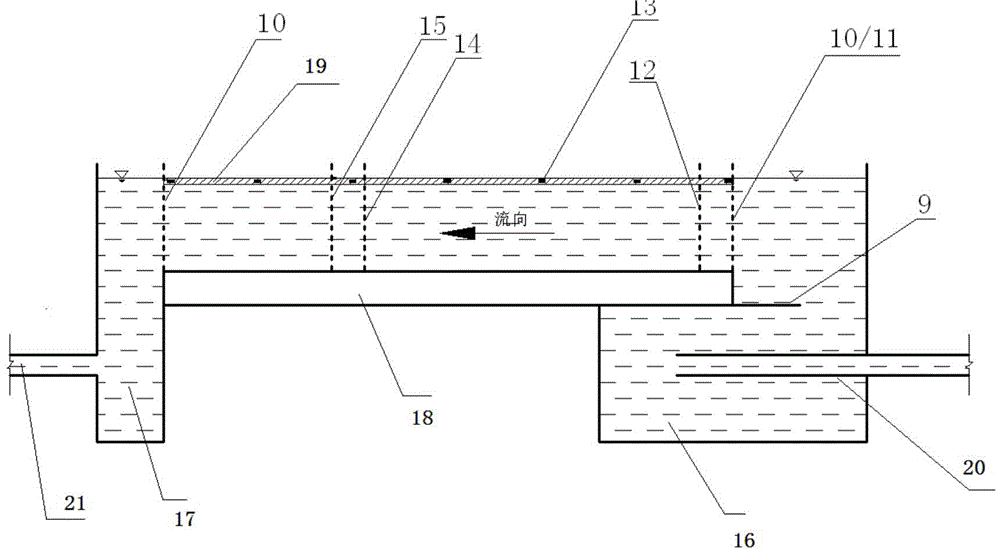

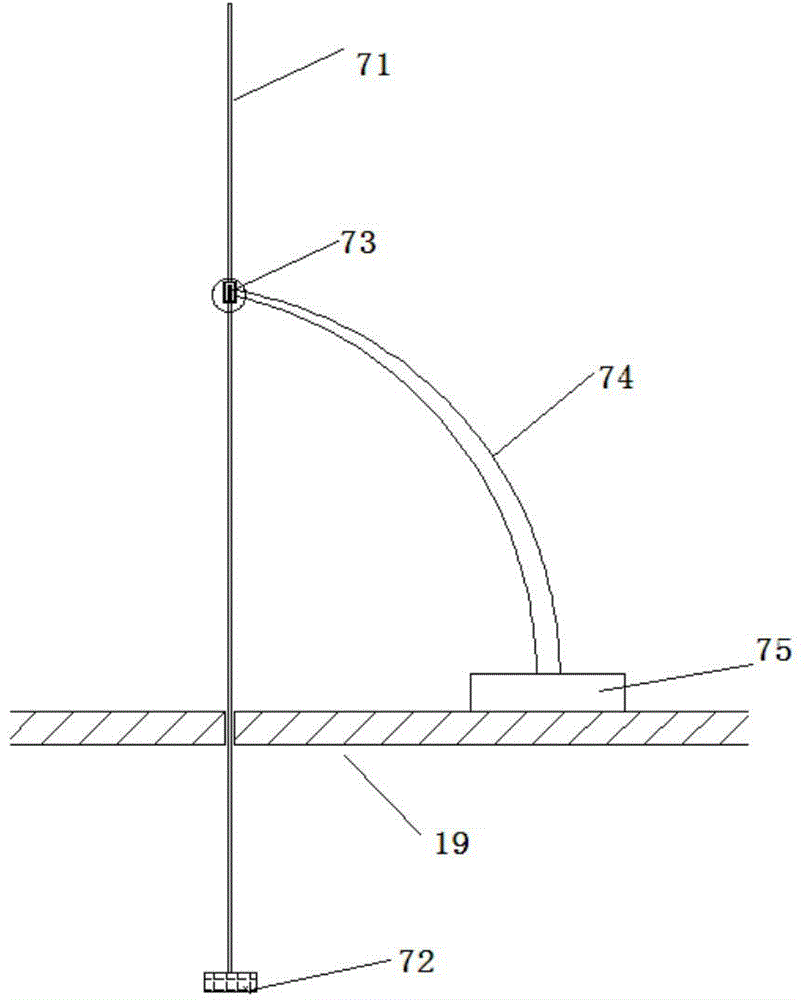

Ice water heat exchange coefficient experimental apparatus and measurement method

The invention provides an ice water heat exchange coefficient experimental apparatus which comprises a water tank 1, a water pump 3, a gate valve 4, a thermoregulator 5, a current meter 6, an ice thickness change measuring instrument 7 and a temperature recorder 8, wherein the water pump 3, the gate valve 4 and the thermoregulator 5 are sequentially connected through a pipeline 2 and form a loop; measurement probes of the current meter 6 and the temperature recorder 8 are positioned in the water tank 1; a measurement probe of the ice thickness change measuring instrument 7 is positioned in an ice layer 19 and water in the water tank. The invention also provides a method for measuring an ice water heat exchange coefficient by utilizing the device. The device well simulates reservoir icing and low-flow speed water flow conditions, acquires an ice water heat exchange coefficient of a corresponding reservoir and provides a design basis for water conservancy projects, also avoids the difficulty of developing reservoir ice water heat exchange coefficient prototype measurement in a rushing frigid zone reservoir area and provides great convenience and implementation possibility for research.

Owner:SICHUAN UNIV

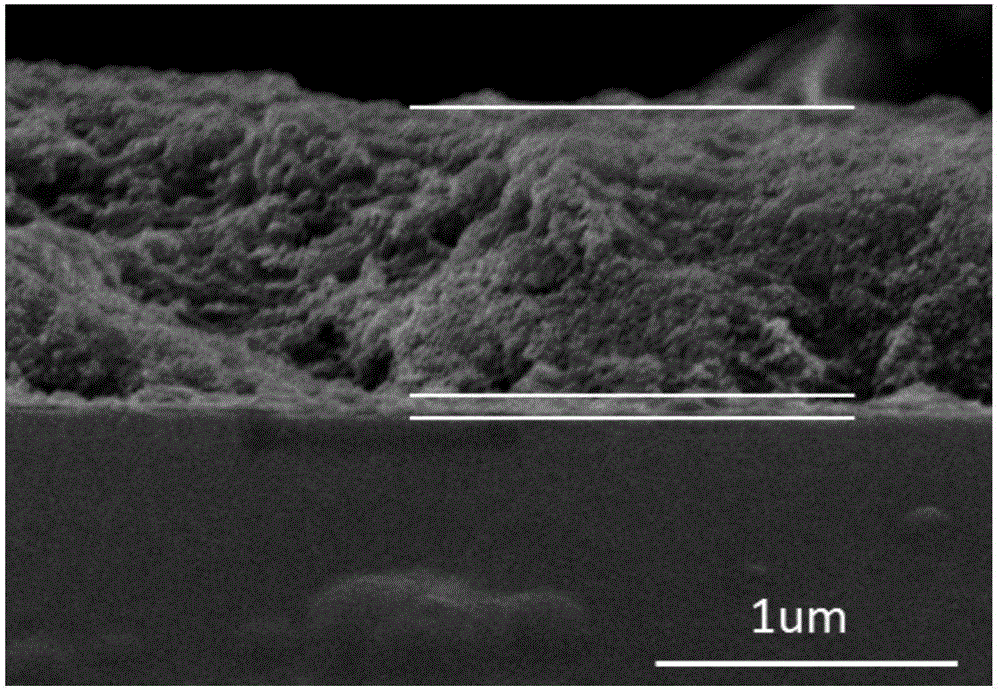

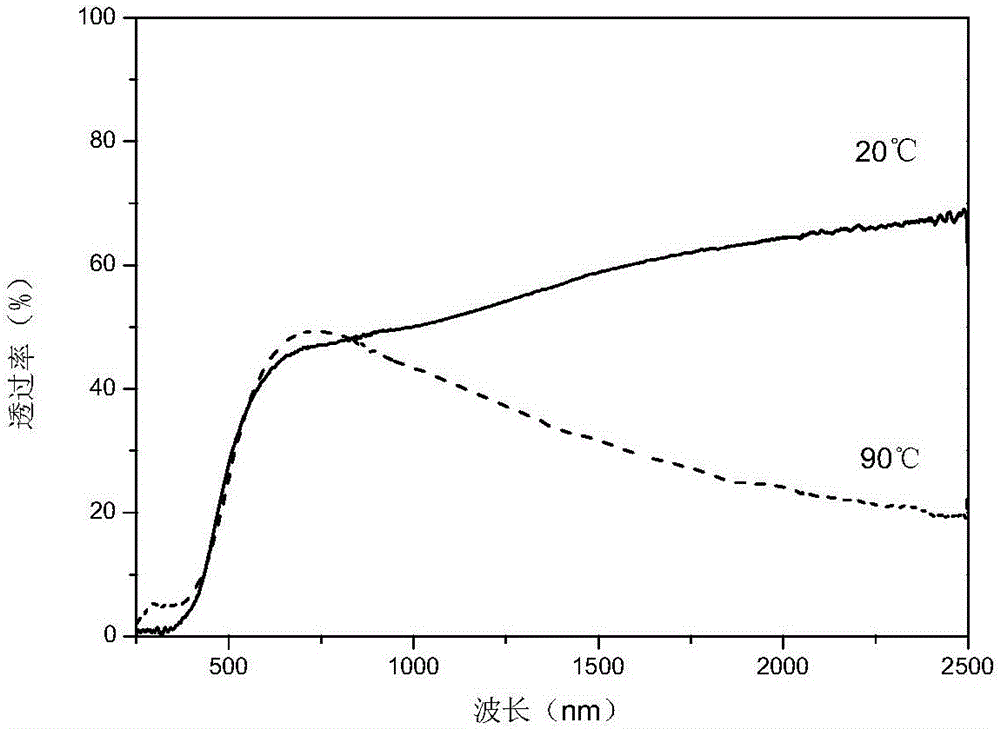

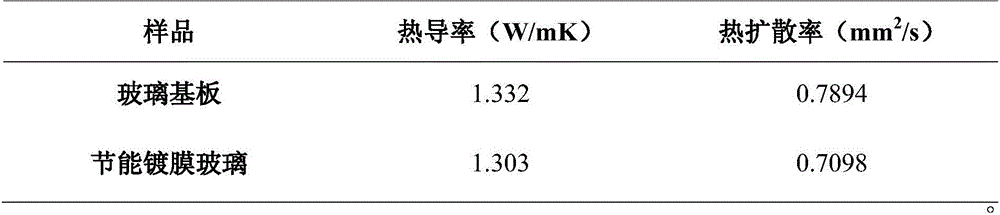

Energy-saving coated glass and preparation method thereof

The invention discloses energy-saving coated glass. Glass is used as a base plate, a vanadium dioxide thermochromic layer and a silicon dioxide aerogel layer sequentially deposit on the glass. Different heat propagation modes of heat conduction and radiant heat blocking are integrated, and the energy-saving coated glass has heat -insulating and thermochromic functions. Oxidization of the vanadium dioxide layer is retarded by introducing the silicon dioxide aerogel layer, and meanwhile a permeability improvement effect can be played. The invention further discloses a preparation method of the energy-saving coated glass. Firstly, the glass base plate is subjected to hydrophilic treatment; the surface of the glass base plate subjected to hydrophilic treatment is coated with a vanadium dioxide precursor layer by adopting a sol-gel method; the surface of the vanadium dioxide precursor layer is coated with a silicon dioxide aerogel precursor layer by adopting a sol-gel method; finally, the energy-saving coated glass is obtained through heat treatment, the heat treatment temperature is 550-580 DEG C, and the time is 1-10 hours.

Owner:ZHEJIANG UNIV

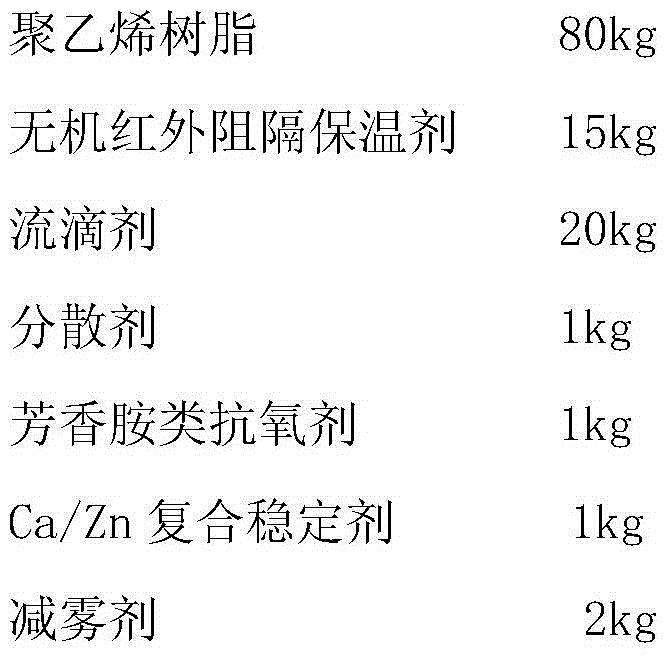

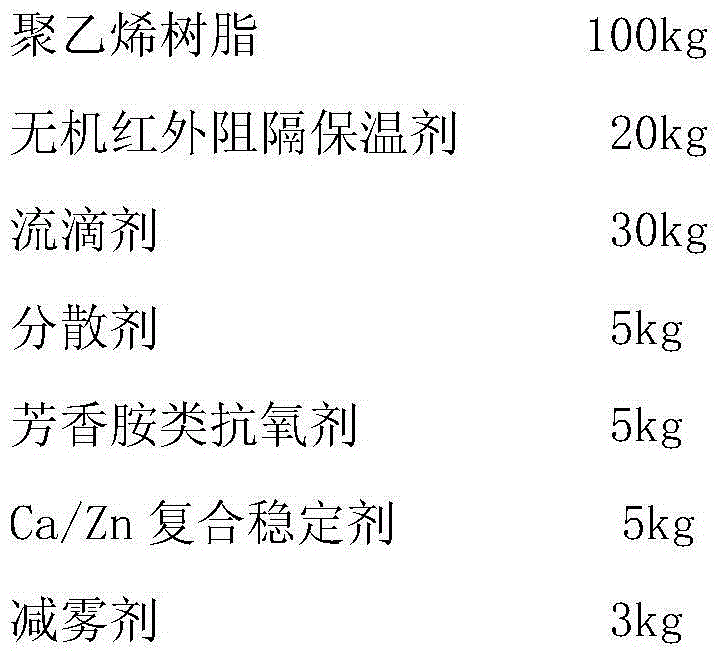

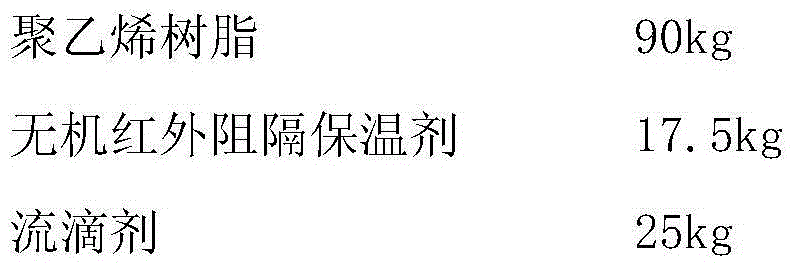

Heat insulation and preservation plastic film

The invention relates to a heat insulation and preservation plastic film. The heat insulation and preservation plastic film is prepared from the following raw materials in parts by weight: 80-100 parts of polyethylene resin, 15-20 parts of an inorganic infrared heat insulation and preservation agent, 20-30 parts of a dripping agent, 1-5 parts of a dispersant, 1-5 parts of an aromatic amine antioxidant, 1-5 parts of a Ca / Zn composite stabilizer and 2-3 parts of a fog reducing agent. The heat insulation and preservation plastic film provided by the invention has high strength and good performance, can prevent a large amount of infrared rays from entering a greenhouse in the daytime and play a role in insulating heat and can prevent energy from dissipating in the nighttime and play a role in preserving heat.

Owner:TIANJIN KAIXUAN PLASTIC PROD

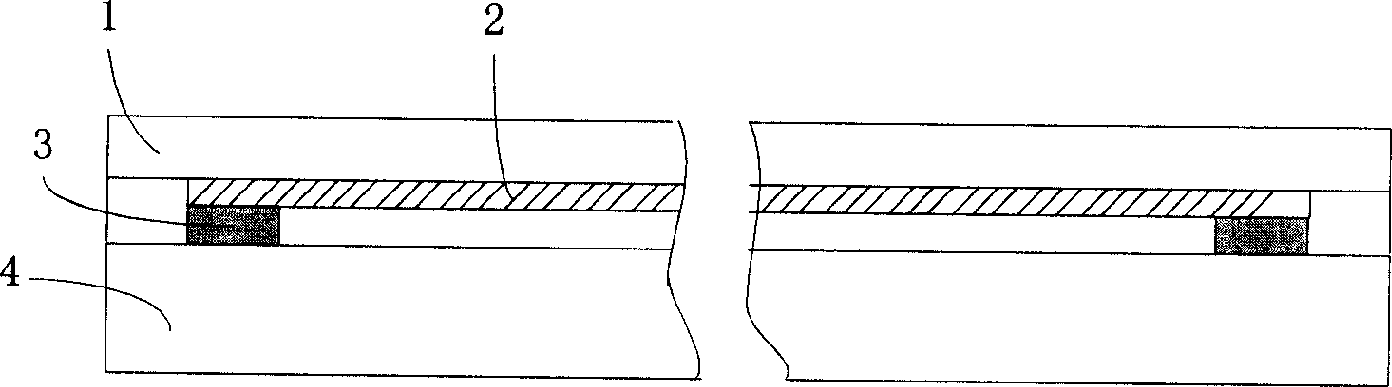

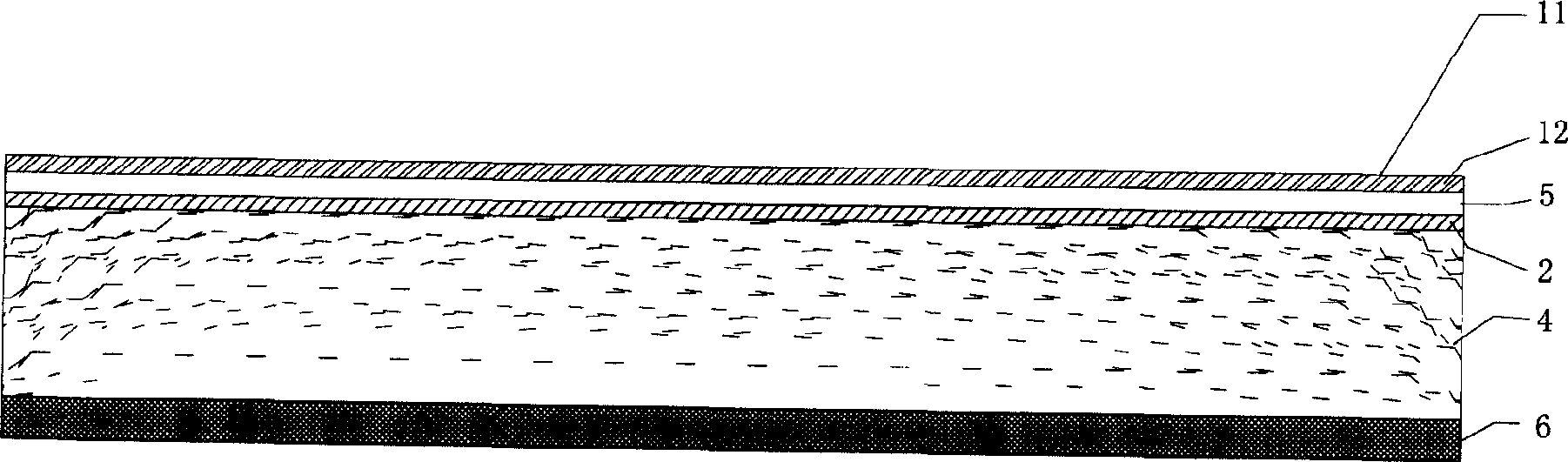

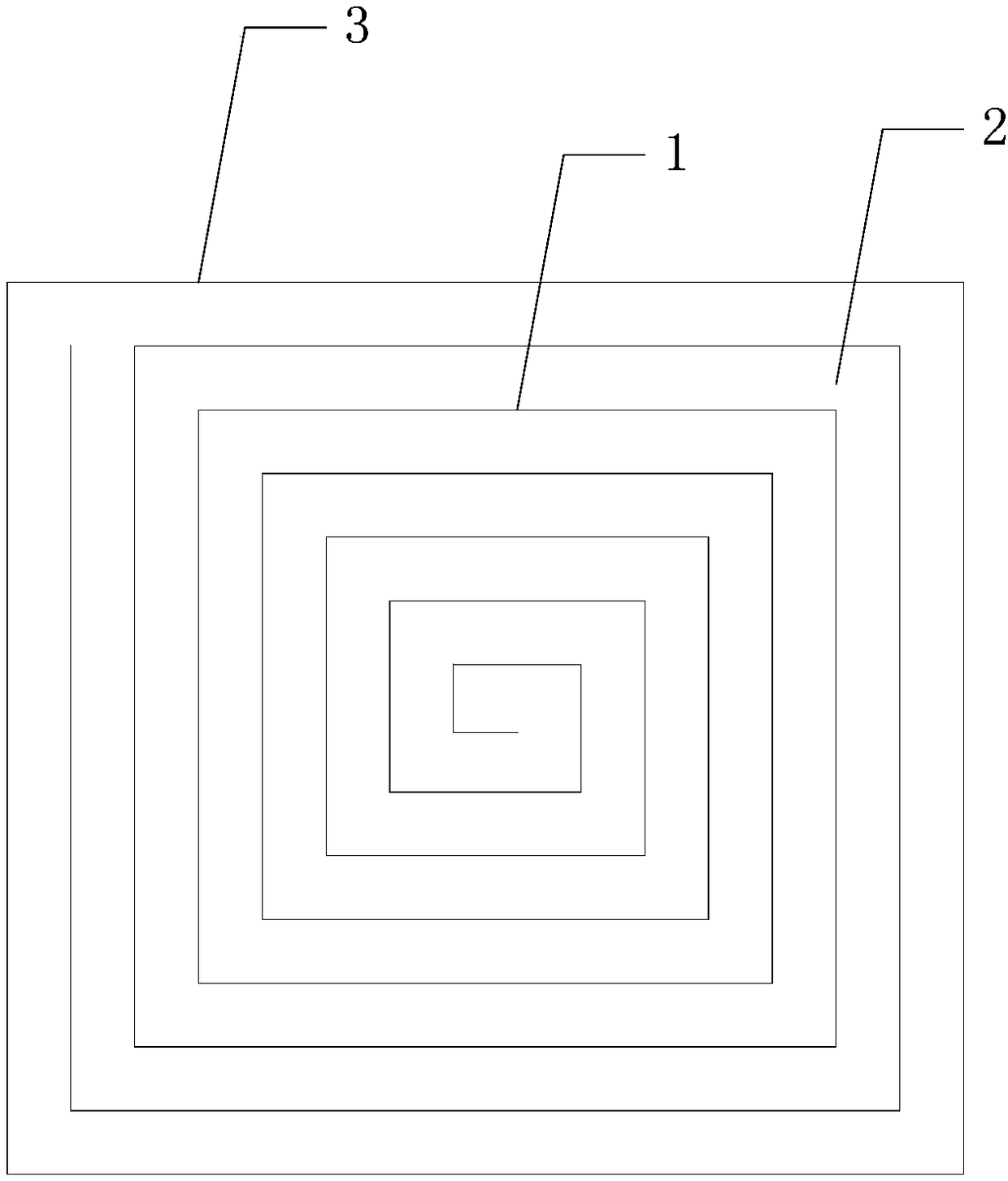

Electric heating plate and electric heating plate system

InactiveCN1694581ALow costIncrease the indoor effective use areaLighting and heating apparatusElectric heating systemElectric heatingElectricity

This invention discloses an electric heat plate including a face panel, an electric heat material, a backing and an electrode for connecting the power supply, among which, said electrode is connected with the electric heat material wrapped between the face panel and the backing, also includes a connection end led out by said electrode. In an optimum seeking plan, the material is adhered screwed or clamped with the backing and the face panel. Said plate also includes a balance layer balancing the stress of the panel set between the panel and the electric heat material and a cushion at the backing side. This invention also discloses an electric heat plate system assembled by multiple electric heart plates.

Owner:夏跃春

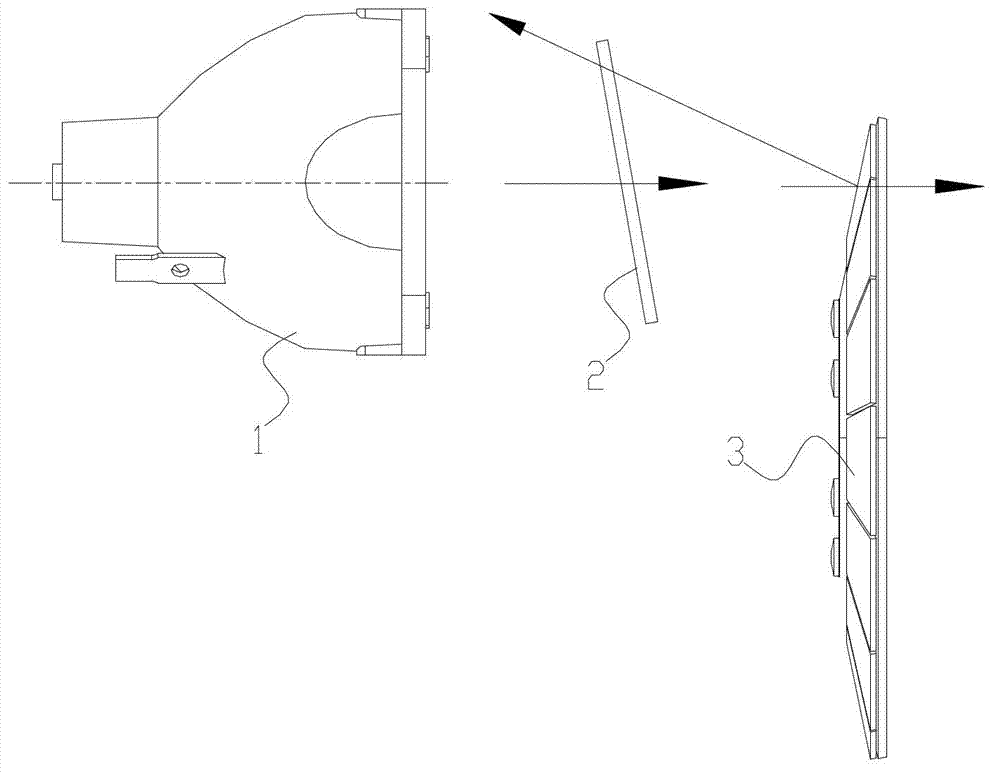

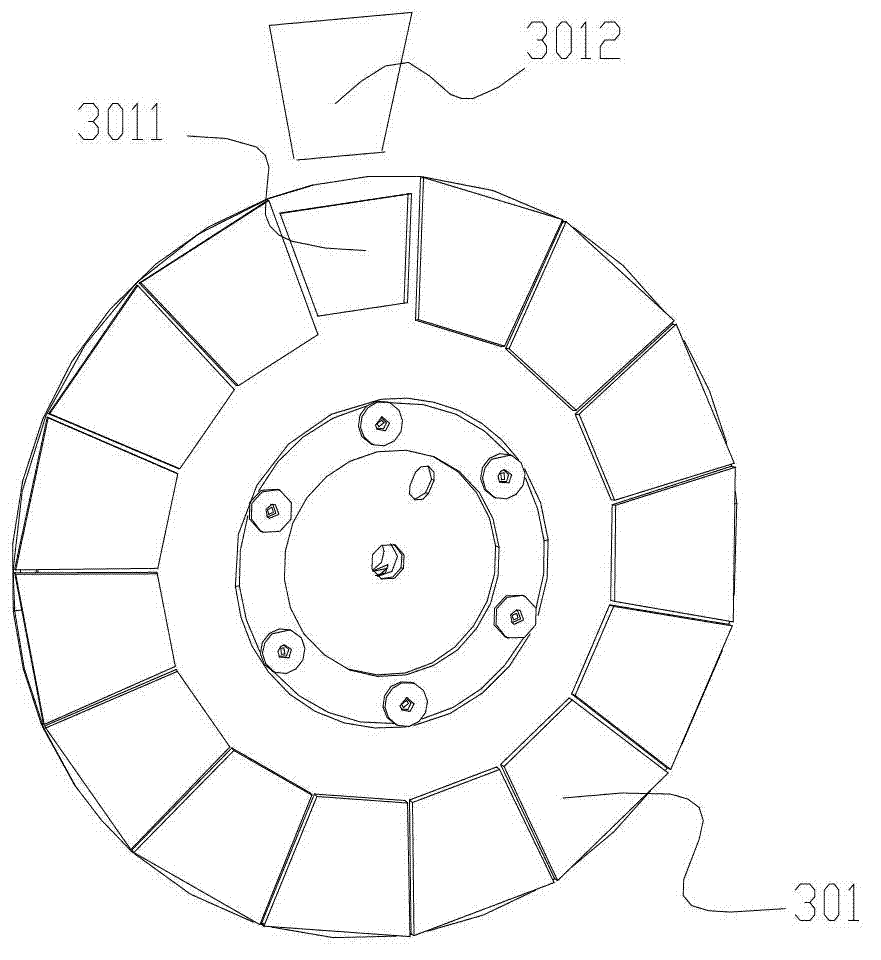

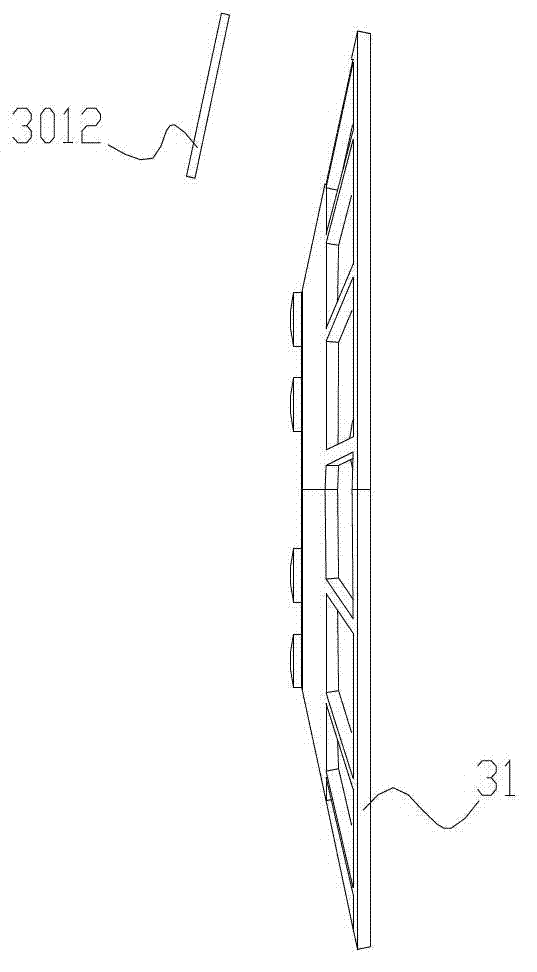

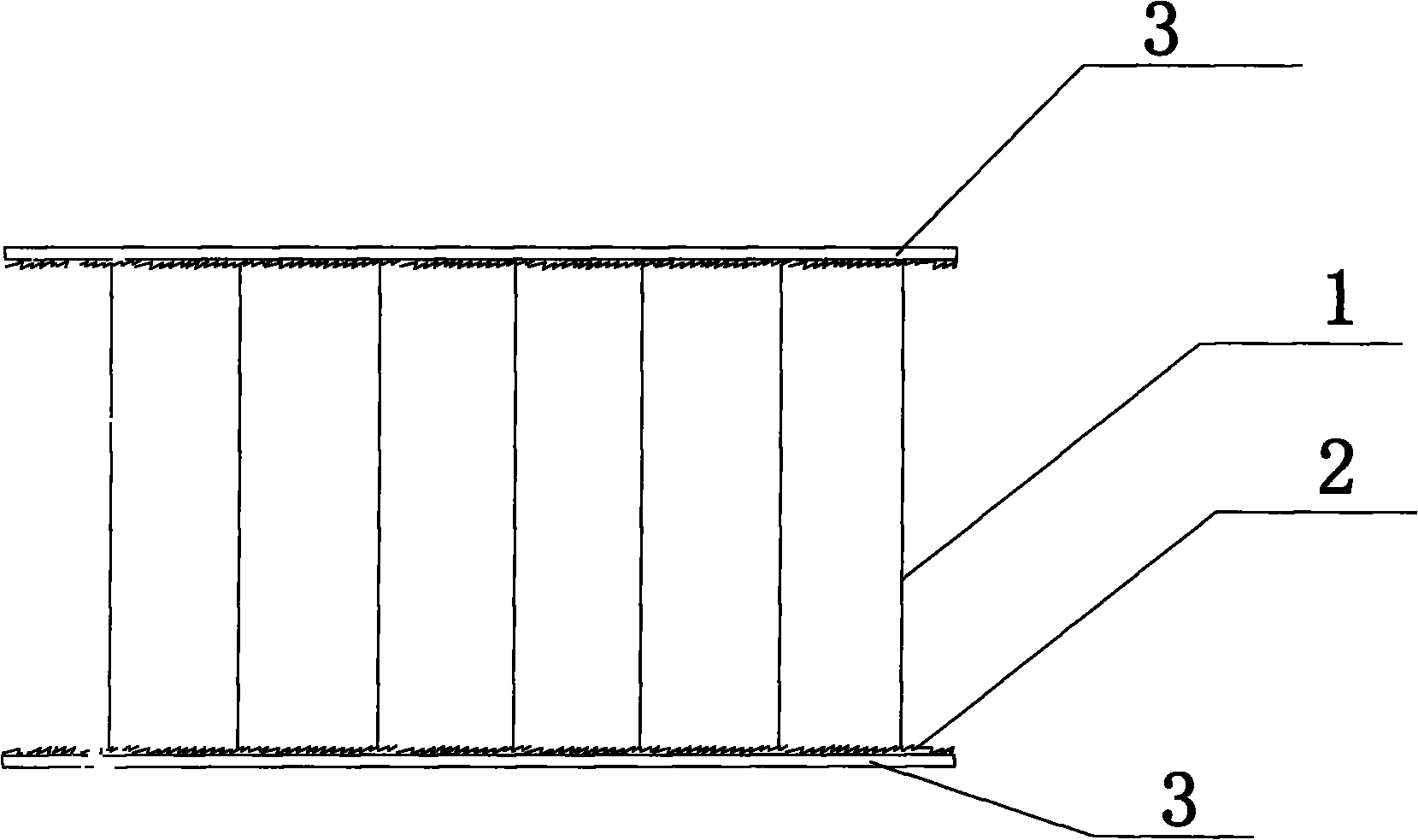

Stage lighting color filter device

ActiveCN102767792AExtended service lifeReduce the temperatureLighting heating/cooling arrangementsSpectral modifiersStage lightingEngineering

The invention discloses a stage lighting color filter device which comprises a color filter wheel and a lamp body. The color filter wheel is located in front of the lamp body, a color filter strip is arranged around the center of the color filter wheel, one end of the color filter strip close to the center of the color filter wheel serves as an inner end of the color filter strip, the inner end of the color filter strip is protruded towards one side of the lamp body, so that the color filter strip has an angle of inclination relative to the front end face of the lamp body, and the lamp body is opposite to the color filter strip. The stage lighting color filter device can lower temperature of a central zone of the lamp body and prolongs service life of the lamp body.

Owner:PR LIGHTING

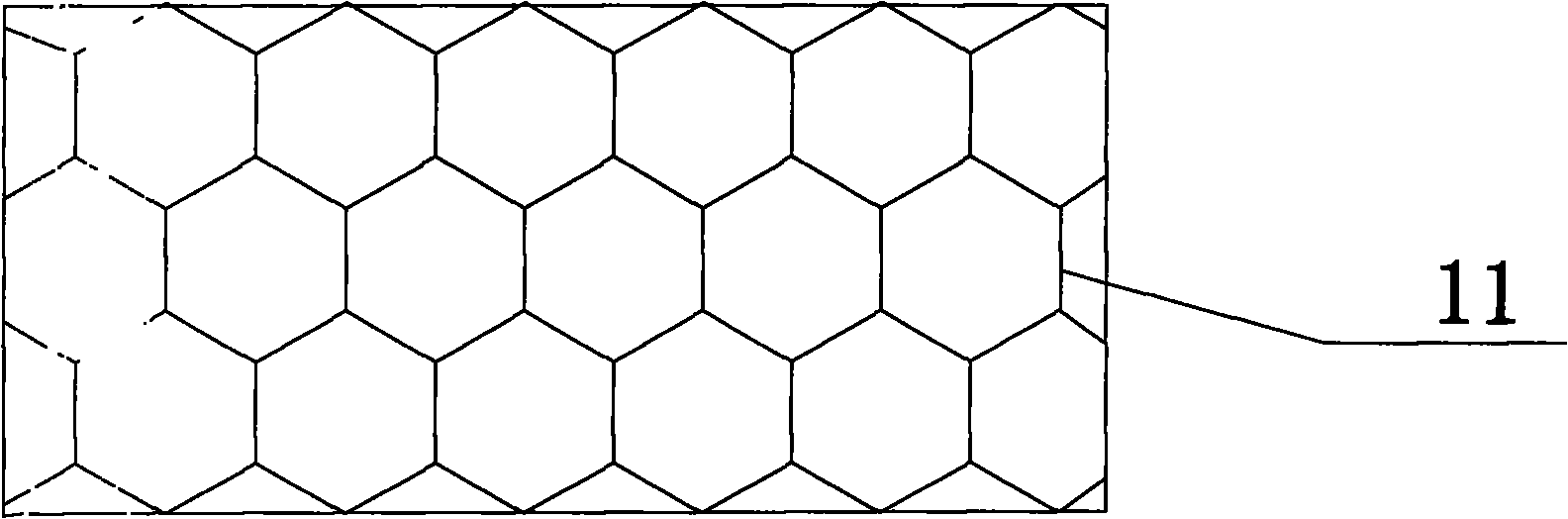

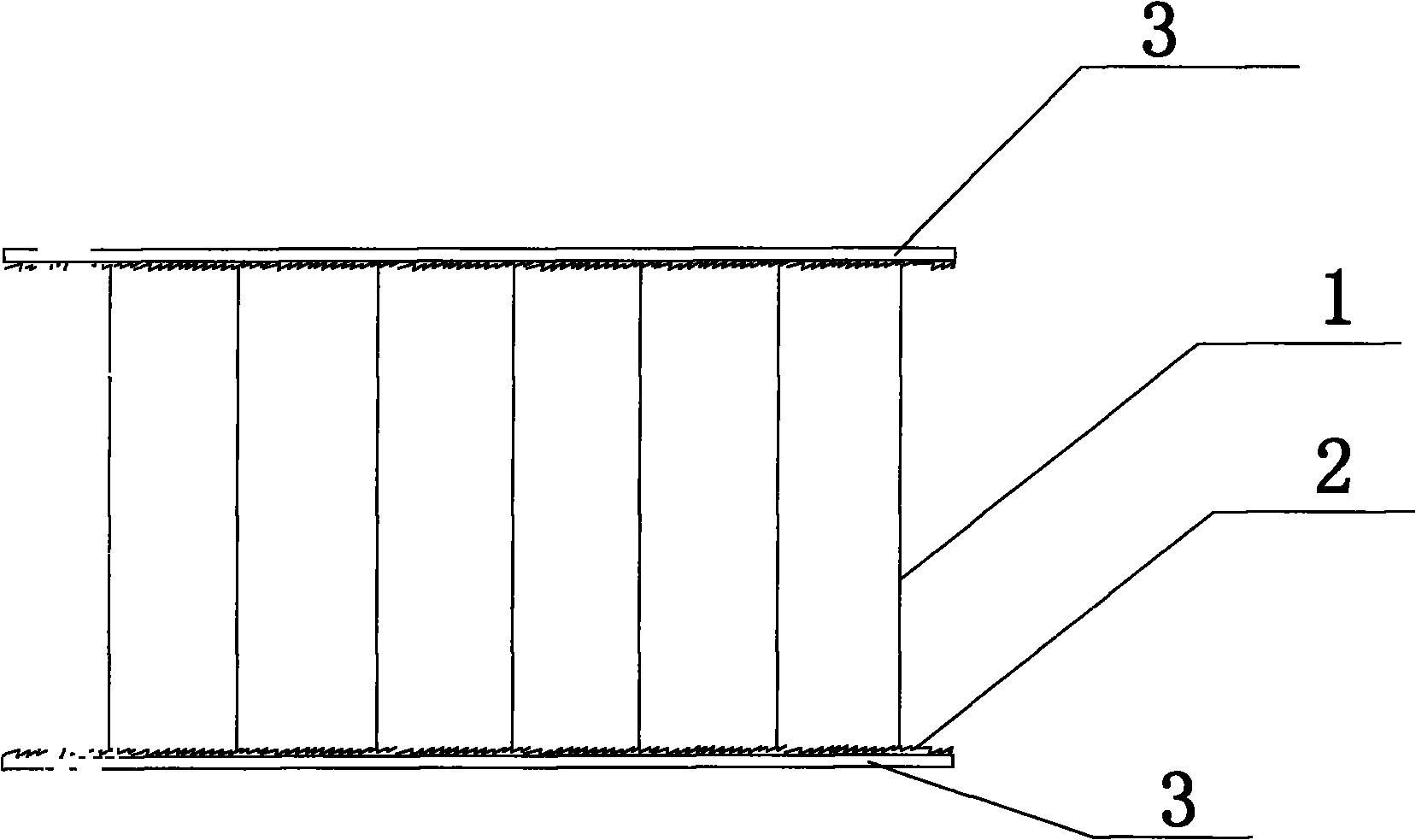

A kind of high-strength polyester fiberglass honeycomb composite board and its production process

InactiveCN102261162AHigh tensile strengthStop the flowConstruction materialCovering/liningsPolyesterThermal insulation

The invention discloses a high-strength polyester glass fiber honeycomb composite board and its production process, which comprises a three-layer structure, the middle layer is a hexagonal honeycomb core; the upper and lower sides of the hexagonal honeycomb core are provided with thin steel wire mesh; The upper and lower sides of the wire mesh are provided with polyester fiberglass boards. The invention adopts the anti-bending principle of the reinforced concrete slab, that is, on the basis of the polyester fiberglass honeycomb composite slab, a thin steel wire mesh with tensile effect is added on both sides, similar to the steel bars in the reinforced concrete slab, so that the polyester fiberglass honeycomb The tensile strength of the composite board has been doubled, and it is used for marine floors, building scaffolding, formwork, etc. Its tensile, bending and impact resistance properties are superior to ordinary boards, and it is light in weight and has a long service life. Obtaining the maximum force with the smallest material is an incomparable feature of other materials, and it is the preferred lightweight material in the construction industry at present. Because the honeycomb core in the honeycomb composite panel is divided into many closed cells, the air flow is prevented, and the heat and sound waves are greatly hindered. Therefore, it has the effect of heat insulation, heat preservation and sound insulation, and the installation is convenient and fast.

Owner:青岛同力得塑料蜂巢有限公司

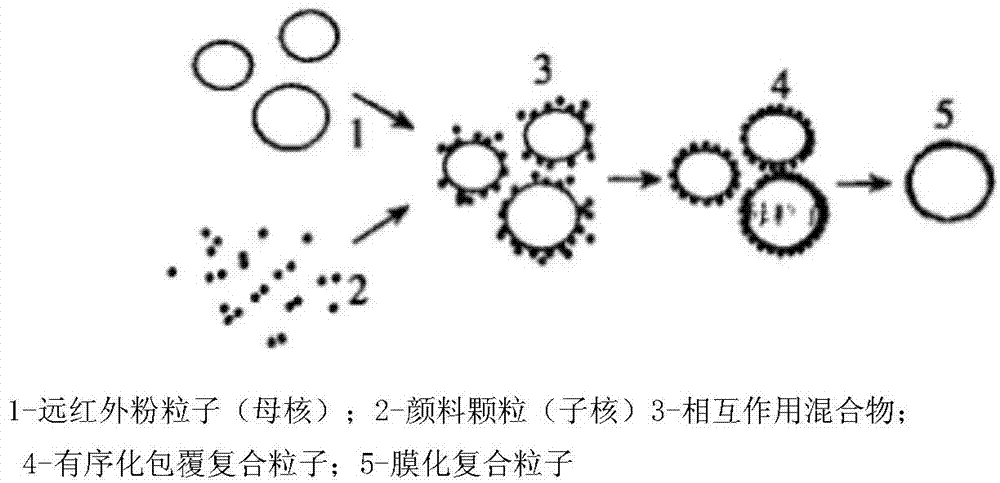

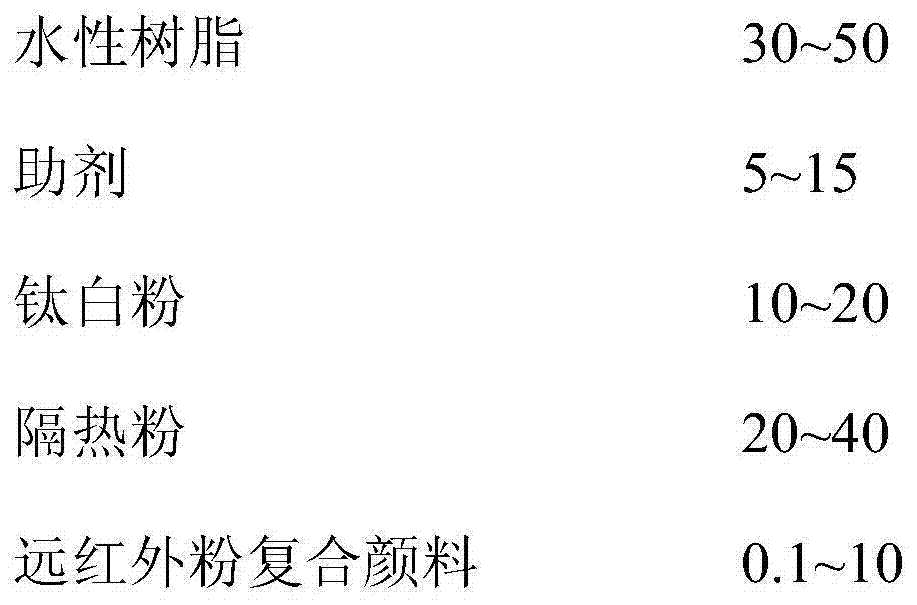

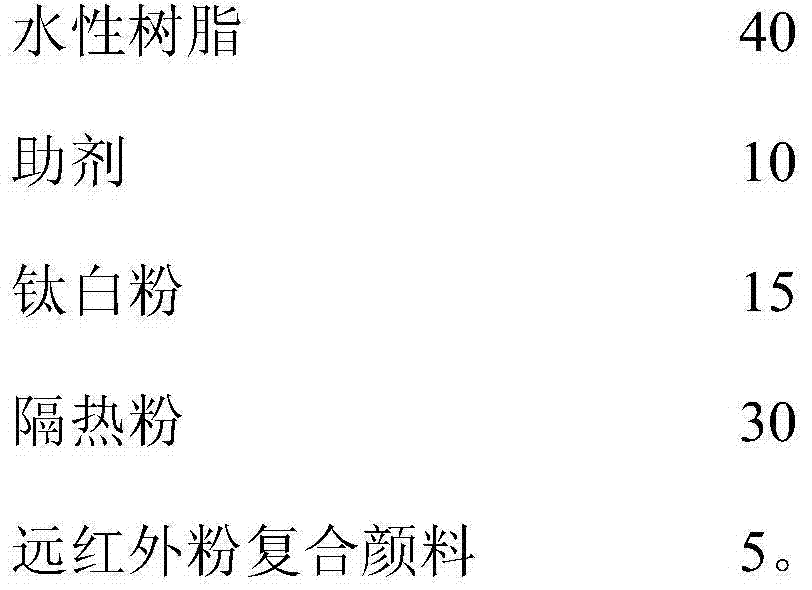

Sun-reflection heat-insulation paint and manufacturing method thereof

ActiveCN104327654ALow thermal conductivityAdditive effectPaints with biocidesPigment treatment with macromolecular organic compoundsWater basedMineral particles

The invention relates to a sun-reflection heat-insulation paint and a manufacturing method thereof. The invention aims to provide a paint with favorable heat-insulation property. The technical scheme is as follows: the sun-reflection heat-insulation paint comprises a water-based resin, assistants, titanium white, heat-insulation powder and a far-infrared powder composite pigment, wherein the water-based resin is a pure acrylic emulsion or fluorocarbon resin emulsion or silicone acrylate resin emulsion; and the assistants comprise a preservative, a bactericide, a dispersing agent, a leveling agent, a defoaming agent, a film formation assistant, a thickener and an antifreezing agent. The manufacturing method comprises the following steps: (a) proportionally and uniformly mixing porous mineral particles, silane coupling agent, dispersing agent, deionized water and anhydrous ethanol; (b) proportionally and uniformly mixing far-infrared powder, anti-phase-separating agent, water and anhydrous ethanol; (c) proportionally and uniformly mixing the liquids formed in the steps (a) and (b), and aging to obtain a gel; and (d) drying and holding the gel to obtain the composite powder.

Owner:ZHEJIANG HUADE NEW MATERIALS CO LTD

Composite environmental-friendly cushion and preparation method thereof

InactiveCN102514258AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite environmental-friendly cushion which comprises a middle layer and upper and lower surface layers. The middle layer comprises a first middle layer, a second middle layer and a bonding layer. The upper and lower surface layers are non-woven layers comprising 5 percent to 50 percent of low melting point fibers. The first and second middle layers are non-woven layers which respectively comprise the following components: bastose and 5 percent to 50 percent of low melting point fibers. The bonding layer mainly consists of the low melting point fibers. In the whole composite environmental-friendly cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the composite environmental-friendly cushion, which comprises the following steps of: respectively preparing the middle layer, the upper and lower surface layer and the bonding layer; then sequentially paving the layers; and preparing the composite environmental-friendly cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the composite environmental-friendly cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

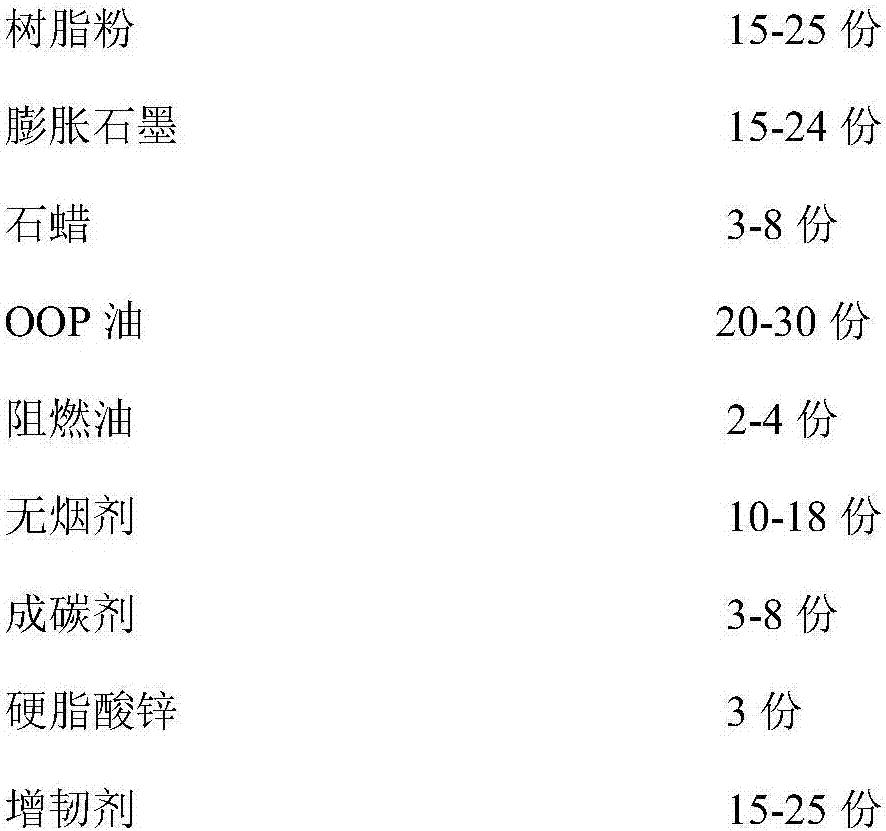

Heat-resistant flame-retardant powder coating

InactiveCN105062303AAccelerated corrosionImprove water resistancePowdery paintsPolyamide coatingsEpoxyBenzoyl peroxide

The invention discloses heat-resistant flame-retardant powder coating. The coating comprises the following raw materials: epoxy resin, carboxyl-terminated unsaturated polyester resin, nitrogen-containing phenolic resin, polyamide resin, thermoplastic styrene-butadiene rubber, ammonium polyphosphate, pentaerythritol, melamine, expansible graphite, nano-zirconia, titanium dioxide, talcum powder, diphenyl silanediol, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, octadecendioic acid, tetrahydro-1,3,4,6-tetrakis(methoxymethyl)imidazo[4,5-d]imidazole-2,5(1H,3H)-dione, benzoyl peroxide and auxiliaries. The heat-resistant flame-retardant powder coating has good heat resistance and excellent flame retardant performance, can be used for coating surfaces of kitchen ware, instrument shells, display stands, electromechanical equipment, automobile components and parts and the like, and has the advantages of good comprehensive performance and long service life.

Owner:安徽圣德建材科技有限公司

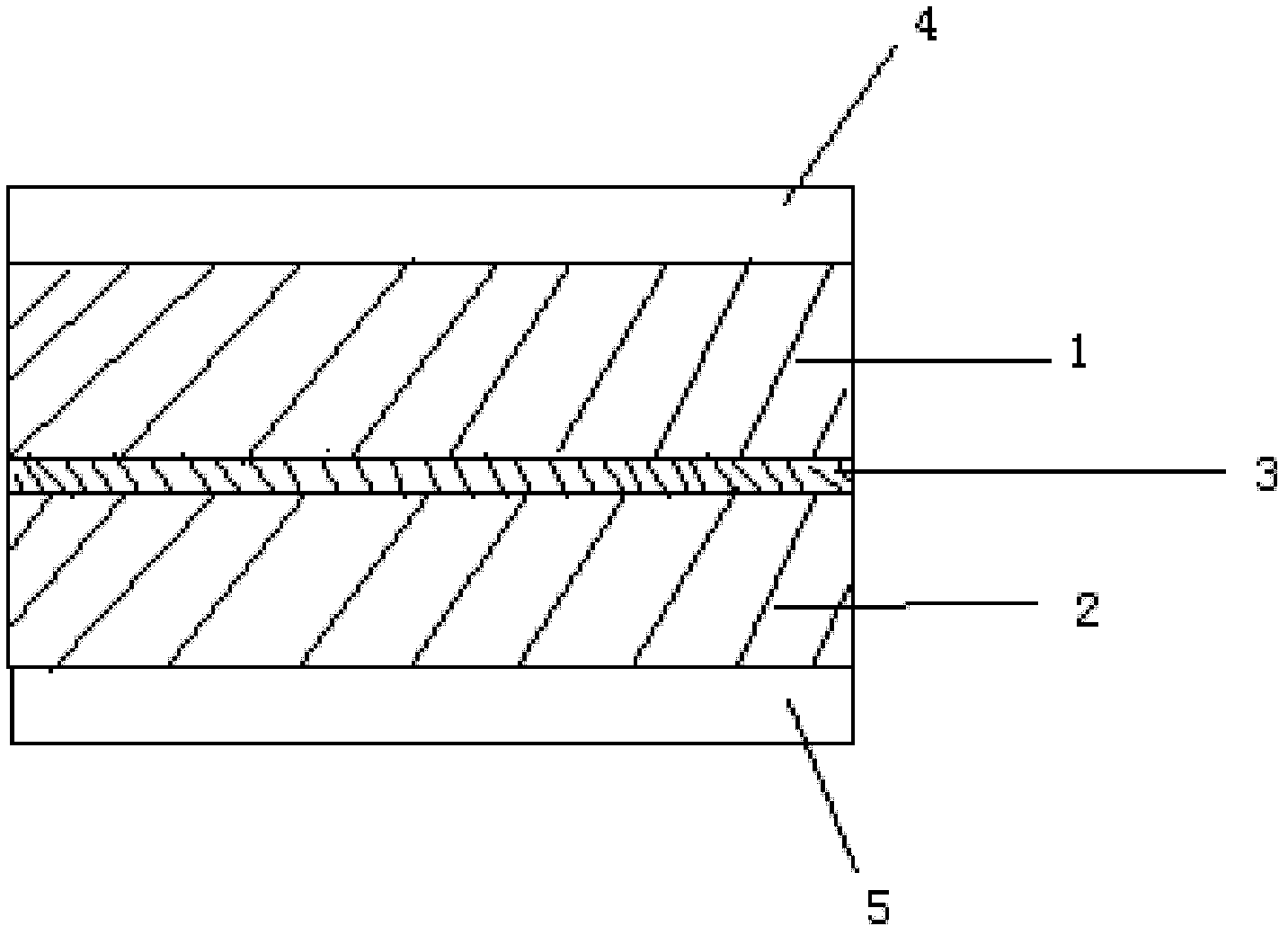

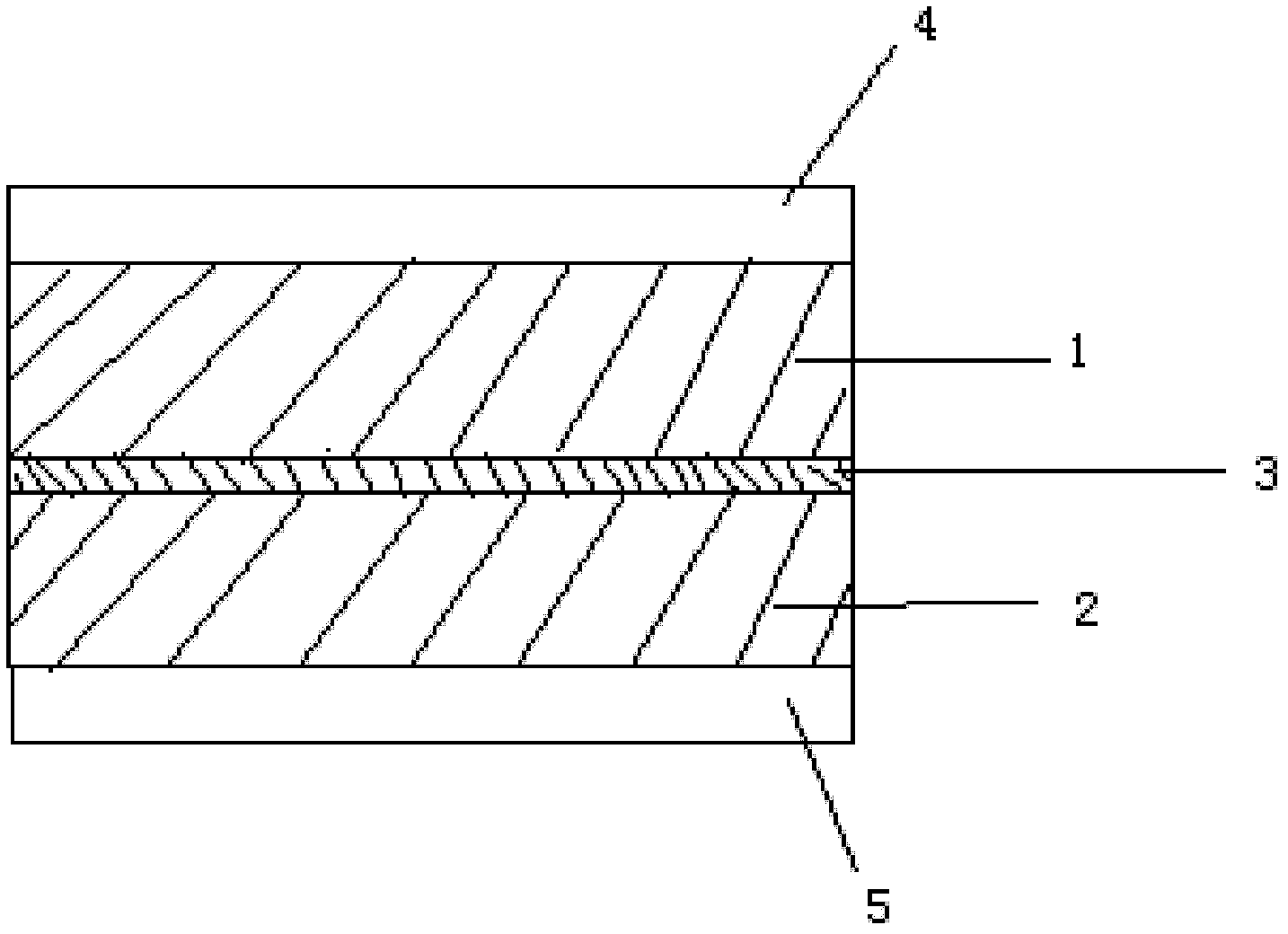

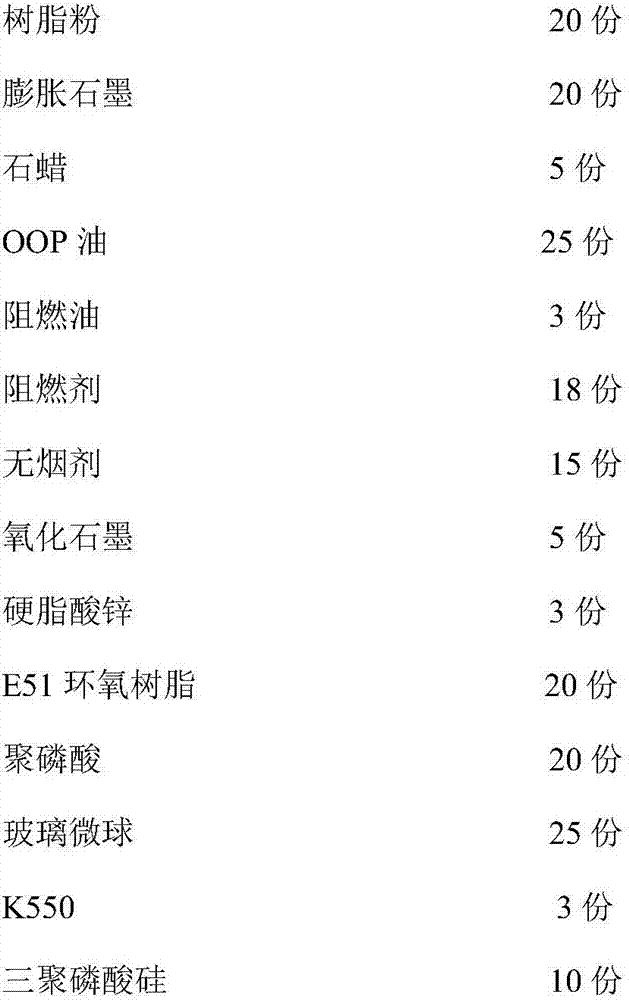

Fireproof expansion sealing strip and preparation method thereof

The invention discloses a fireproof expansion sealing strip which has the effects of shock absorption, fire protection, water resistance, sound insulation, thermal insulation, dust prevention and fixing. A sheath of the sealing strip adopts modified PVC; modified expanded graphite is formed inside the sealing strip; expanded graphite inside the fireproof sealing strip on the market can become loose and drop off after being burnt in a big fire, sealing effect is easy to lose, and black toxic smoke can be produced, so that the harm to human body in a fire scene can be improved. The fireproof sealing strip can be expanded but not become loose and drop off after being burnt in a big fire, can maintain integrity, reduce the extension of the fire, cannot generate black smoke, is good in expansibility, completeness and sealing property in case of a fire, and is good in ageing resistance at ordinary times.

Owner:尹书祥

Bulletproof composite armor and preparation method thereof

ActiveCN111319318AEvenly dispersedInhibit growthProtective equipmentSynthetic resin layered productsCarbon fibersComposite ceramic

The invention discloses a bulletproof composite armor and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method of the bulletproof composite armor comprises the following steps: 1) mixing boron carbide, high-thermal-conductivity carbon nano fibers, phenolic resin and high-purity water, uniformly stirring to obtain composite slurry, and carrying out spray granulation to obtain a composite raw material; (2) filling the composite raw material prepared in the step (1) into a carbon fiber woven bag, sewing the bag, putting the bag into a mold, carrying out cold pressing to form a green body, and carrying out high-temperature hot-pressing and sintering on the green body to obtain a composite ceramic plate; and 3) hot-pressing and compounding the composite ceramic plate prepared in the step 2), aramid fiber cloth and an ultra-high molecular weight polyethylene back plate in a high-temperature autoclave to obtain the bulletproof composite armor. The cracking of the ceramic plate in all directions can be prevented, and the high-temperature resistance of a crack stopping layer is improved.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Waterborne polyurethane thermal-insulating sound-absorbing coating and preparation method thereof

InactiveCN104789107AExtend your lifeLow shrinkagePolyurea/polyurethane coatingsSolventAbsorption effect

The invention discloses waterborne polyurethane thermal-insulating sound-absorbing coating and a preparation method thereof. The waterborne polyurethane thermal-insulating sound-absorbing coating comprises a polyurethane prepolymer, N-hydroxymethyl acrylamide, phthalic acid dibutyl ester, a zirconium-aluminic acid ester coupling agent, rutile titanium dioxide, methylsilicone oil, a mixed solvent and a sound-absorbing material. The preparation method comprises the following steps: dissolving every 1 kg by weight of N-hydroxymethyl acrylamide in 2 kg of 50-70% ethanol in volume concentration, mixing with the polyurethane prepolymer in a reaction kettle, enabling the components to react for 1 hour at 80-150 DEG C, and adding the zirconium-aluminic acid ester coupling agent to continuously react for 2-5 hours; subsequently adding the phthalic acid dibutyl ester, rutile titanium dioxide, methylsilicone oil, mixed solvent and sound-absorbing material, and uniformly mixing, thereby obtaining a waterborne polyurethane thermal-insulating sound-absorbing coating product. The waterborne polyurethane thermal-insulating sound-absorbing coating can insulate heat and absorb sound, and is good in chemical resistance, good in temperature resistance, good in weather resistance, long in film service life, free of toxicity or smell, safe and environment-friendly and good in sound absorption effect.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH +1

High-strength flame-retardant elastic fabric and preparation method thereof

ActiveCN110607684AImprove flame retardant performanceHigh breaking strengthWeft knittingFlame-proof filament manufacturePolyethylene terephthalate glycolMicrosphere

The invention discloses a high-strength flame-retardant elastic fabric and a preparation method thereof, and belongs to the technical field of fabric and processing thereof. The preparation method includes co-reacting layered hydroxide, sodium alginate and ammonium polyphosphate to obtain modified microspheres, blending the modified microspheres with the polytrimethylene terephthalate for extruding, carrying out melt extrusion with polyethylene terephthalate to obtain an extruded material, spinning and cooling the extruded material, drawing to obtain a composite fiber, mixing the composite fiber with dopamine hydrochloride solution, adding graphene oxide, mixing and soaking to obtain a composite flame-retardant fiber, and finally weaving the composite flame-retardant fiber into a fabric that is the high-strength flame-retardant elastic fabric. The high-strength flame-retardant elastic fabric prepared by the invention has excellent flame retardance and breaking strength.

Owner:汕头市兴裕泰纺织有限公司

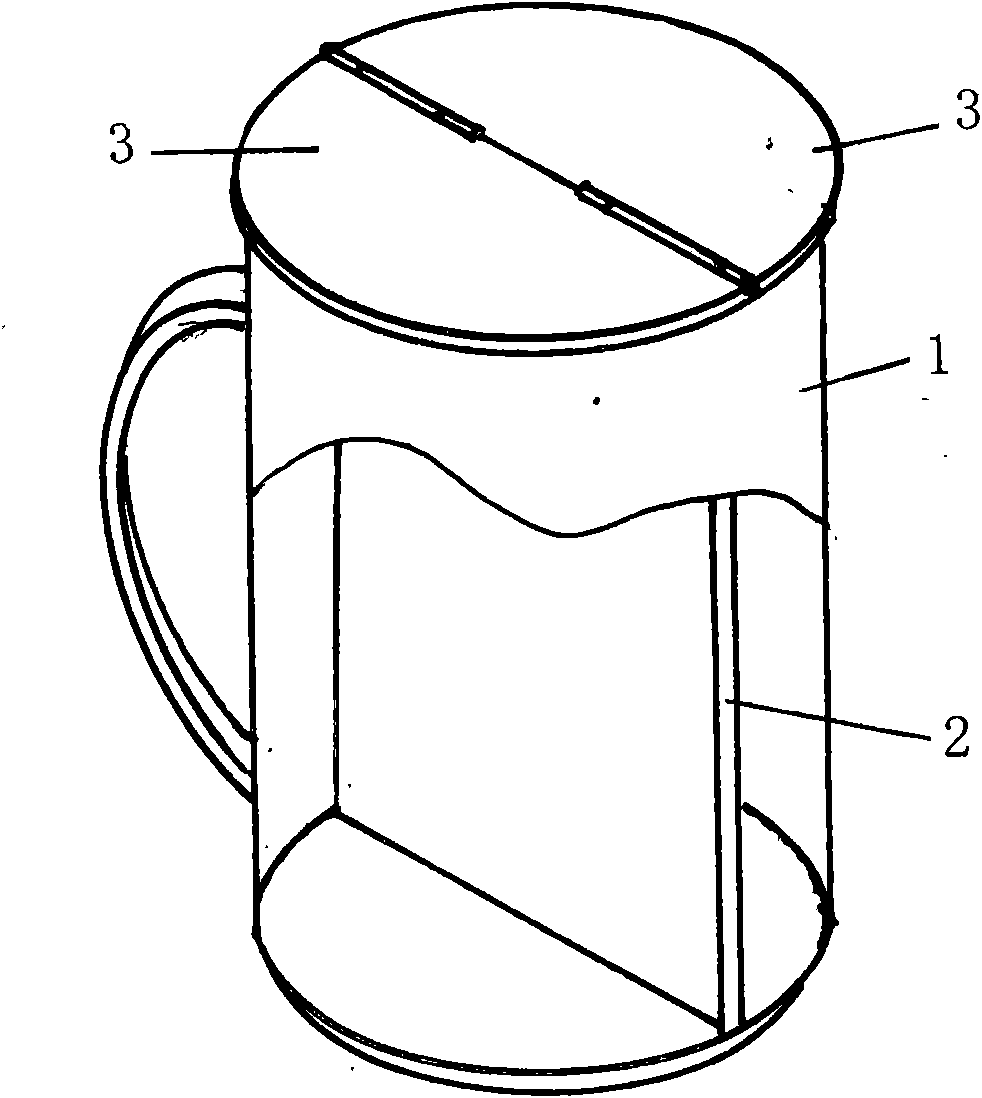

Dual-body water glass

The invention provides a dual-body water glass. A vertical double-layer clapboard is arranged in a glass body of the water glass; and the upper part of the glass body is provided with separately arranged flaps corresponding to the vertical clapboard in the glass body. When the dual-body water glass is used, the water glass can be respectively filled with hot boiling water and cooled boiled water or two different beverages for people with different requirements to drink; and the arranged double-layer clapboard can play a role in insulating heat, so that the cold and hot water cannot transfer heat mutually.

Owner:董文涛

Natural fiber health-care board and preparation method thereof

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

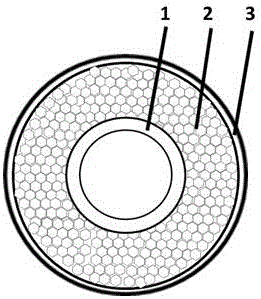

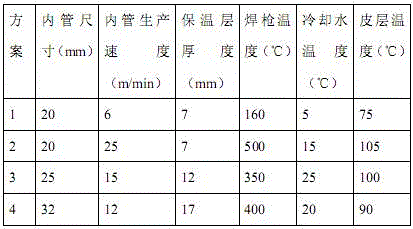

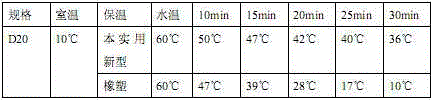

PPR insulating composite tube for home decoration and preparation method of composite tube

ActiveCN106641585ASolve the problem of scratch resistanceSolve insulation problemsThermal insulationPipe protection by thermal insulationManufacturing cost reductionProtection layer

The invention relates to a PPR insulating composite tube for home decoration and a preparation method of the composite tube. The composite tube is of a three-layer composite structure, the inner layer of a PPR or PPR aluminum-plastic composite tube is coated with an expanded polyethylene insulating layer through equipment, the expanded polyethylene insulating intermediate layer is coated with a weather-resistant and scratch-resistant outer protection layer through an extruding machine, closed-cell expanded materials are adopted by the expanded polyethylene insulating layer, the cell sizes range from 0.2 mm to 0.5 mm, and the weather-resistant and scratch-resistant layer is prepared from 60%-90% of LLDPE, 5%-15% of HDPE, 4%-20% of EVOH, 0.5%-2% of silane-modified nano-titanium dioxide and 0.5%-2% of compound additives. The expanded polyethylene insulating layer is obtained through a one-step method. The PPR insulating composite tube has the insulating and energy saving properties and the excellent weather-resistant and scratch-resistant properties, a synchronous coating molding process is adopted in the production process, the production efficiency is improved, the manufacturing cost is reduced, and the PPR insulating composite tube has a good market application prospect.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Ultra-bright negative ion glazed brick and production process thereof

ActiveCN108331281AEvenly distributedSufficient and balanced bonding areaCovering/liningsBrickUltra fine

The invention discloses an ultra-bright negative ion glazed brick. The negative ion concentration of the ultra-bright negative ion glazed brick is 5-10 times higher than that of a common glazed brick,and at the same time, a crystal structure reflects light to enable the glazed brick more bright. The glazed brick comprises a bottom layer green body, a sound-insulation insulating layer, a top layergreen body, a base glaze layer, a functional layer and an overglaze layer; the bottom green body and the top green body comprise stone powders, sand, ultra-fine negative ion powders, diatom mud, mud,waste residues and broken mud of ceramic and water; the sound-insulation insulating layer includes a polyamide mesh, asbestos fibers and gypsum powders; the base glaze layer includes potassium sodiumfeldspar, quartz, alumina, washed soil, burnt talc, zirconium silicate and ultra-fine negative ion crystals; the functional layer includes ultra-fine negative ion crystals, activated carbon, diatom mud and glass beads; and the overglaze layer includes potassium sodium feldspar, barium carbonate, dolomite, zinc oxide, burnt talc, burnt soil, washed soil, corundum, nanometer titanium dioxide, and ultra-fine negative ion crystals.

Owner:GUANGDONG BAIQIANG CERAMICS CO LTD

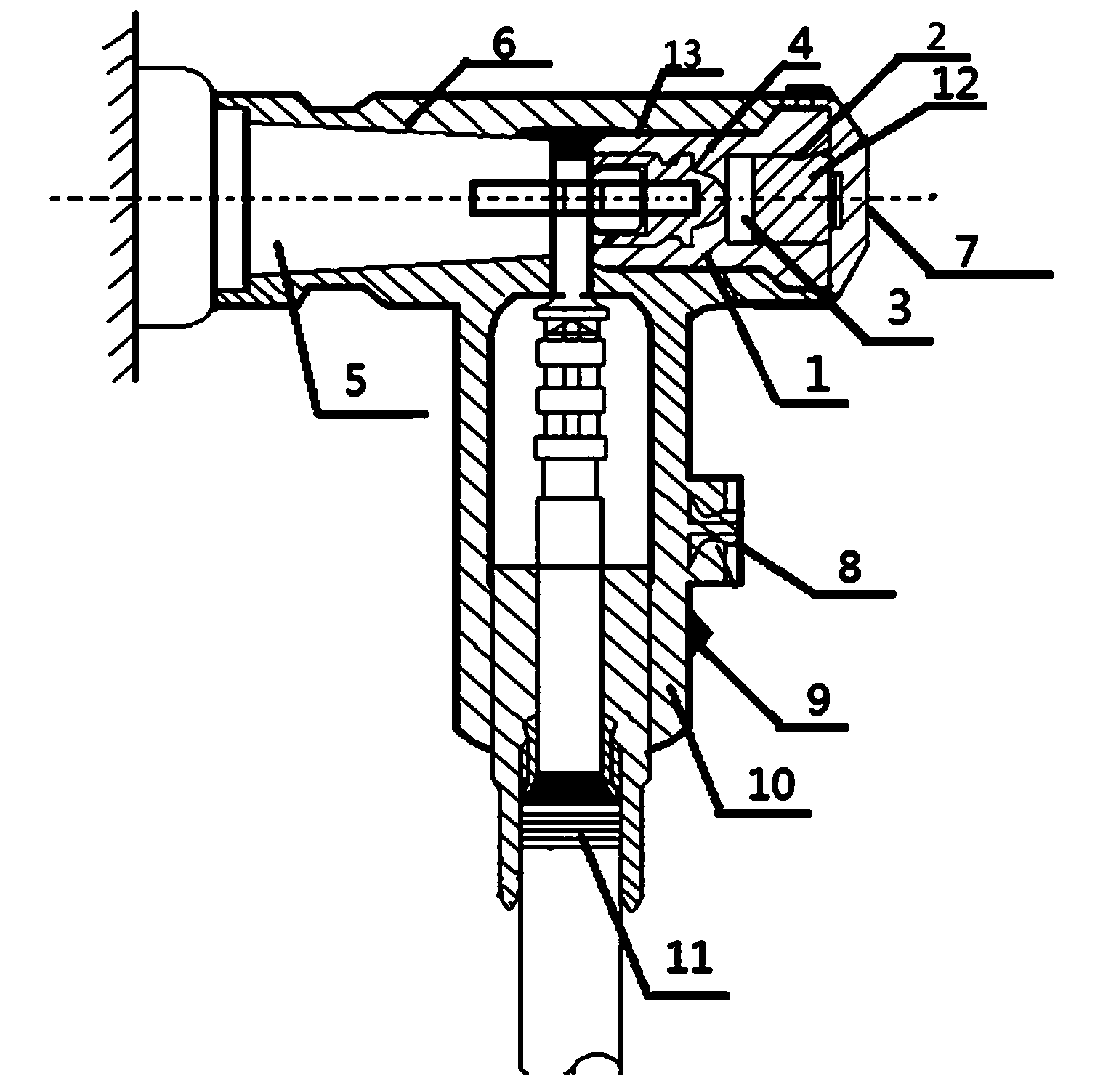

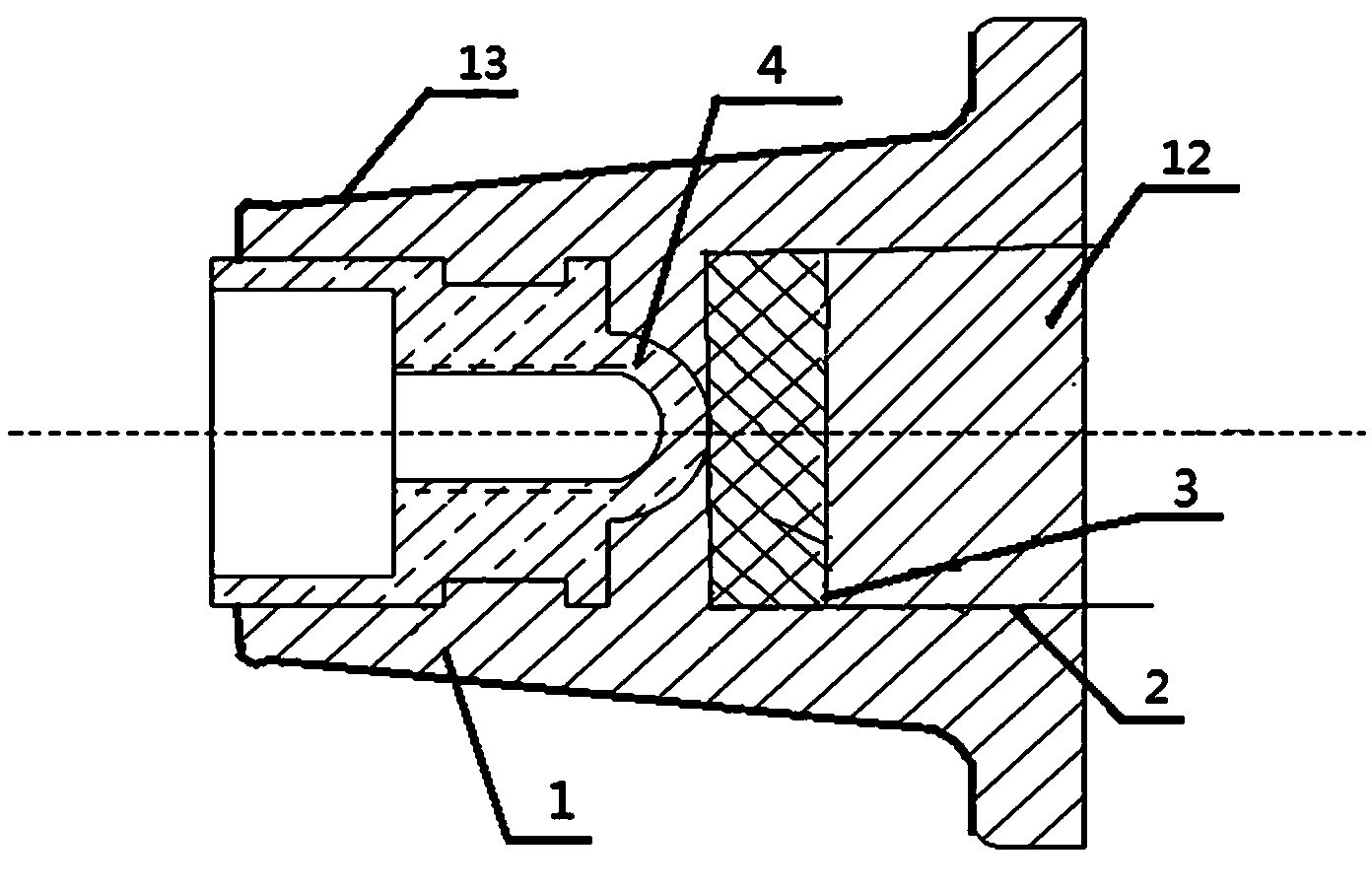

On-line temperature measuring device for monitoring connecting portion between ring main unit and 10 kV cable head

InactiveCN103983377ATimely processingEnsure safetyThermometer detailsThermometer applicationsEpoxyWireless transmission

Provided is an on-line temperature measuring device for monitoring the connecting portion between a ring main unit and a 10 kV cable head. A wireless temperature sensor is arranged at the connecting position of the cable head and makes direct contact with a metal heating unit for acquiring data, the data are transmitted to an information collector arranged on the inner wall of the ring main unit through a wireless transmission technology, and the data are sent to a main control chamber through the wireless transmission technology after being processed by the information collector, wherein according to the arrangement structure of the wireless temperature sensor, a temperature measuring hole is formed in the rear of an European-type plug at the connecting position of the 10kV cable head, the bottom of the temperature measuring hole makes direct contact with threads of the European-type plug and is connected with the back of a metal conductor, the wireless temperature sensor is placed at the bottom of the temperature measuring hole and closely attached to the back of the metal conductor, and a hole between the wireless temperature sensor and the opening of the temperature measuring hole is filled with epoxy resin to ensure insulativity. The device overcomes the defect that in the prior art, contact-type temperature measurement can not be performed while the ring main unit operates, and the accuracy and the reliability for temperature measurement are greatly improved.

Owner:潘晨

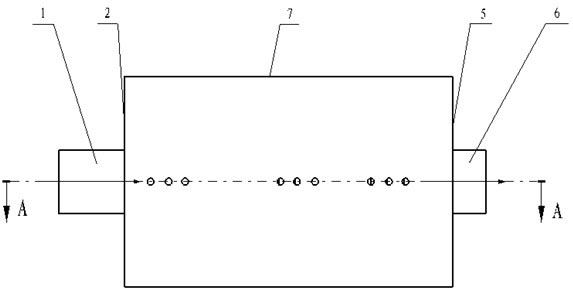

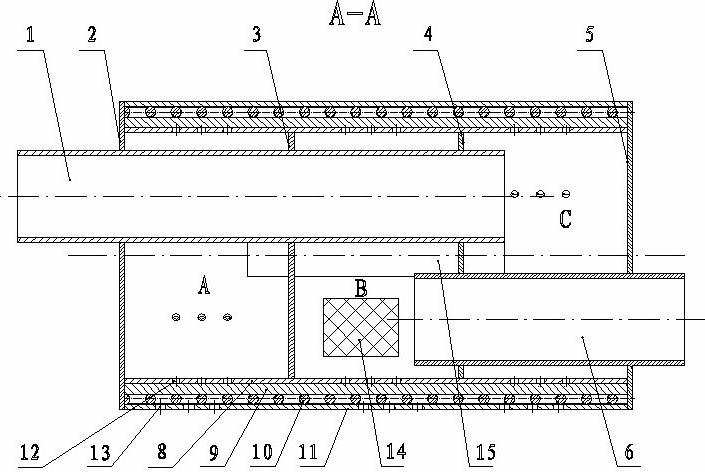

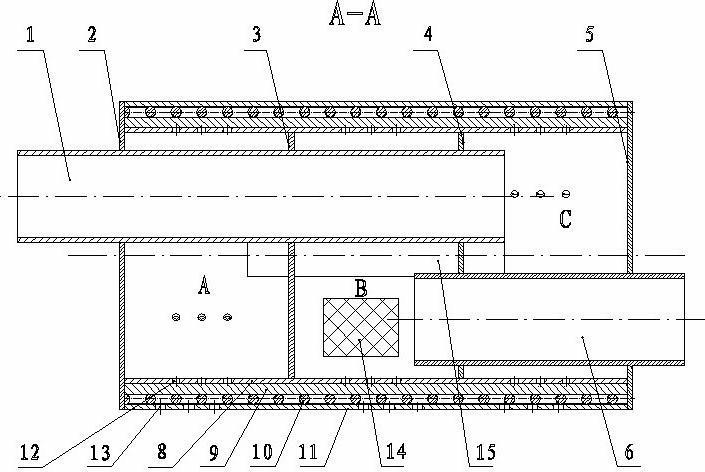

Main silencer for air exhaust system of automotive engine

ActiveCN102146826AAvoid shockReduce vibrationSilencing apparatusMachines/enginesMesh gridProduct gas

The invention proposes a main silencer for an air exhaust system of an automotive engine, which comprises a barrel body, an air inlet pipe, an air exhaust pipe, a medium-voltage cavity A, a low-voltage cavity B and a high-voltage cavity C; the barrel body consists of an inner barrel body, a first grid layer, a second grid layer and an outer barrel body; the first grid layer and the second grid layer are mutually crossed in a grid manner and are clamped between the inner barrel body and the outer barrel body in a two-layer superposition manner; a ventilation and drainage hole is arranged on the inner barrel body; and a drainage hole is arranged on the outer barrel body. The main silencer can prevent direct impact caused by high temperature and high pressure gas to the outer wall of the outer barrel body, reduce the vibration, the radiation noise and the effect on indoor comfort and simultaneously prevent the water accumulation generated in the inner barrel body to prevent a clapboard, an end cover, the air inlet pipe and the air exhaust pipe from being corroded by the water accumulation. Therefore, the comfort of the entire main silencer is improved, the maintenance cost of a user is saved, and the service life of the main silencer is greatly improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

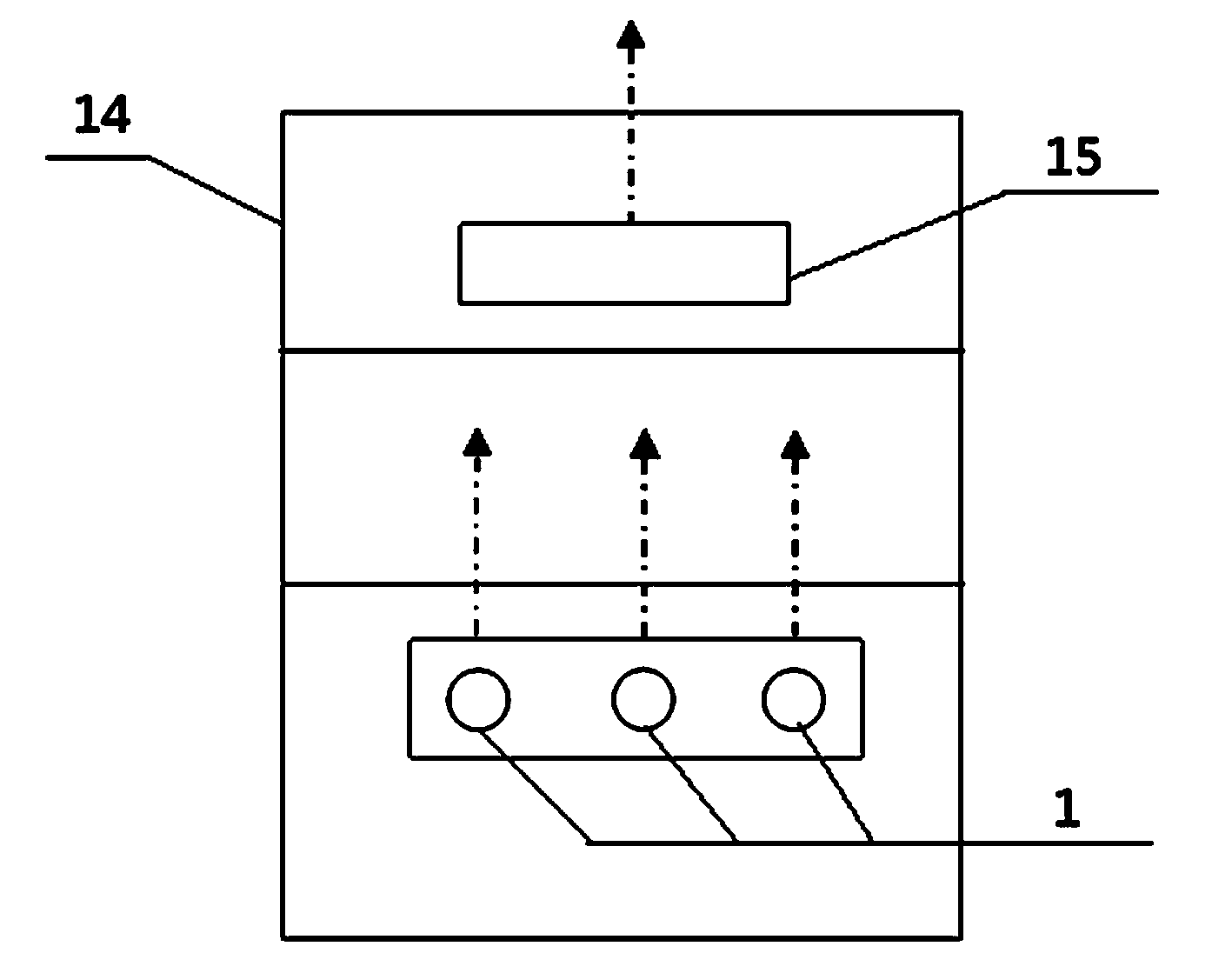

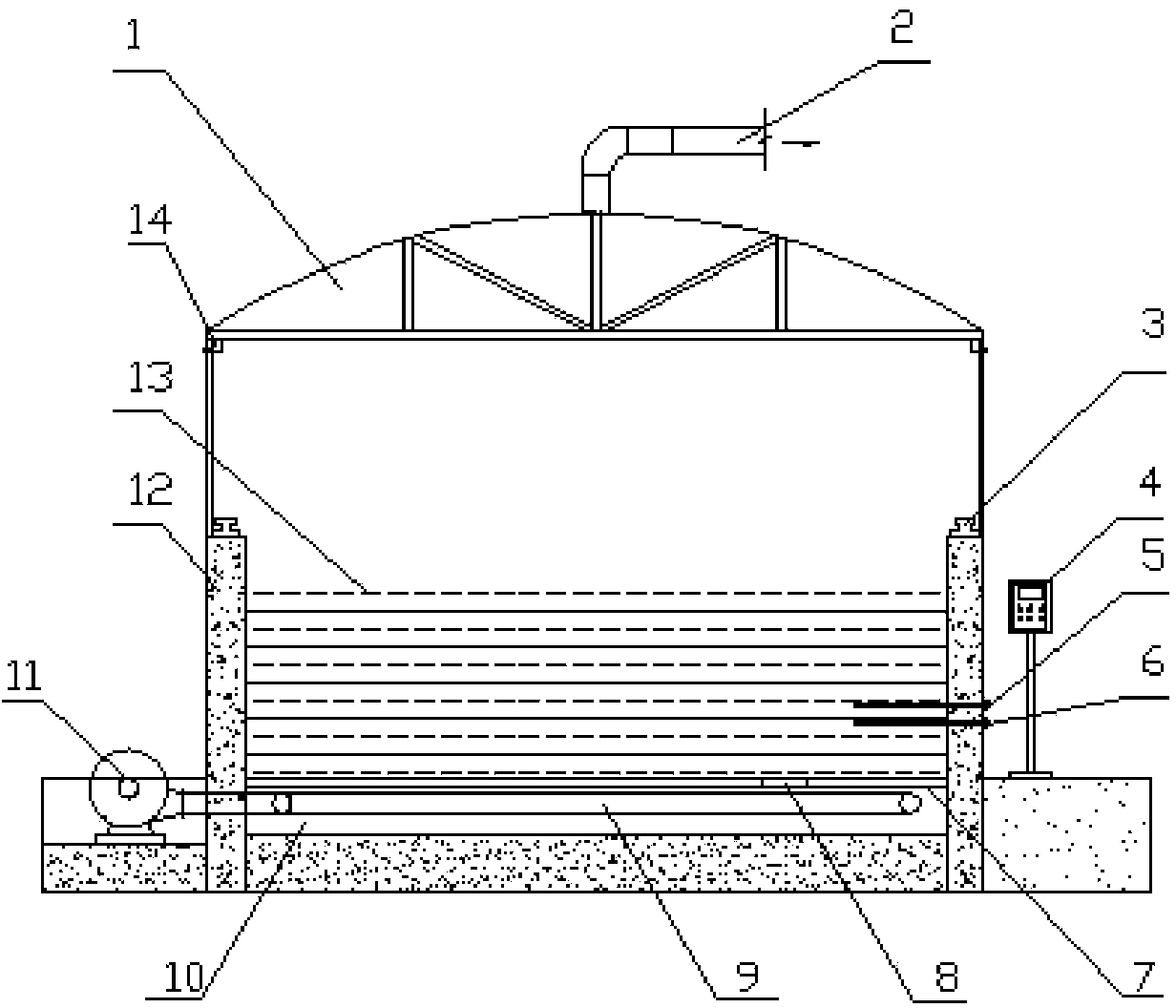

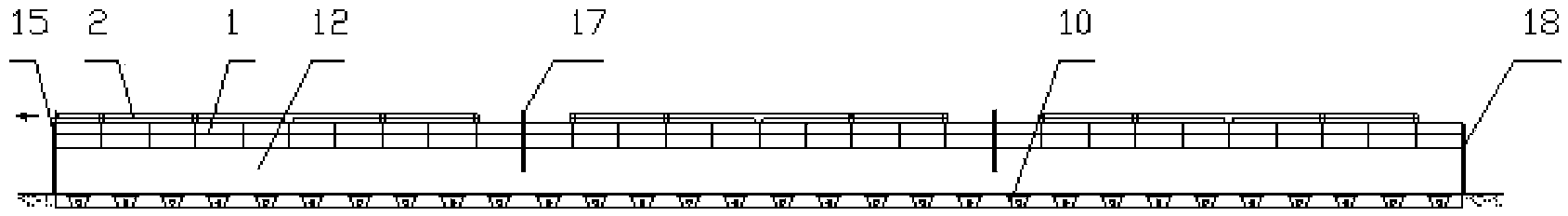

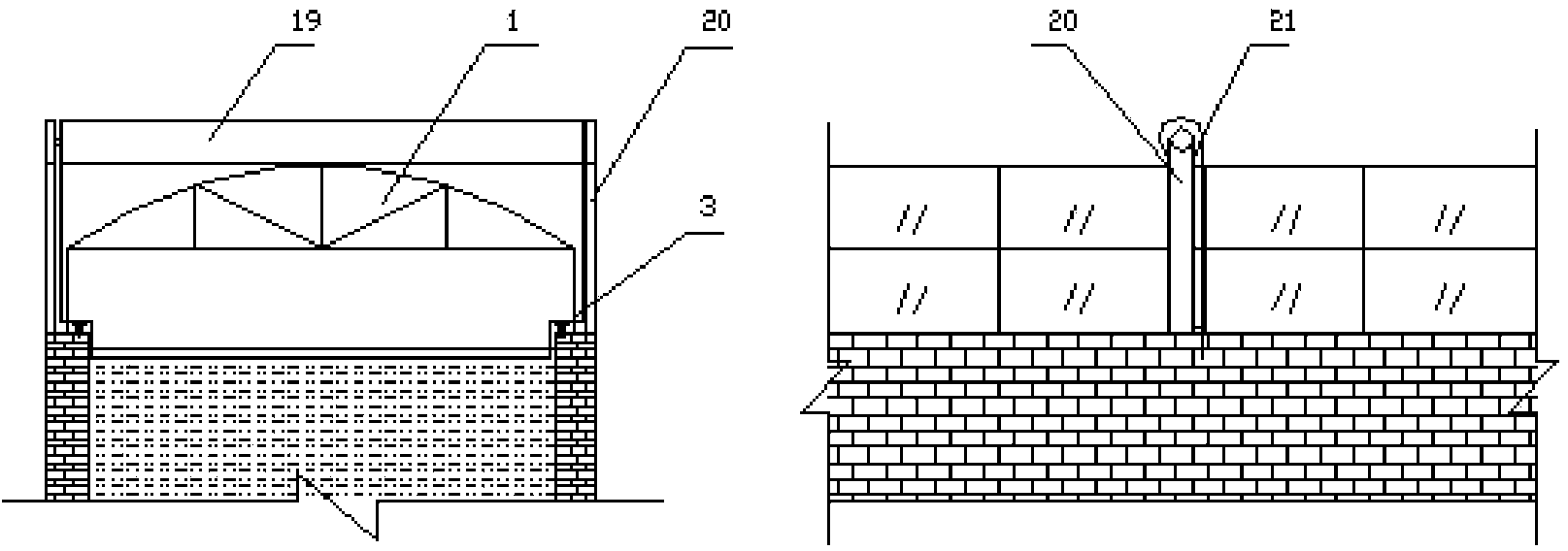

Sludge unit enclosed tank type OAR treatment system

ActiveCN103708692APrevent odor from escapingReduce energy consumptionSludge processingEnergy based wastewater treatmentAutomatic controlHeat conservation

The invention relates to a sludge unit enclosed tank type OAR treatment system. The system comprises fermentation tanks, a stone filter interlayer, a unit glasshouse, an aeration system and an automatic control system. The sludge unit enclosed tank type OAR treatment system has the beneficial effects that 1, the unit enclosed structure is capable of sufficiently utilizing the solar energy and the biological energy, and also capable of achieving the effects of heat preservation, thermal insulation, odor spillover prevention and the like, and the energy consumption is reduced and the operating cost is reduced, 2, the design of an obstruction door is advantageous for the hierarchical control of the material fermentation process and also advantageous for shortening the fermentation period and improving the processing capacity, 3, the feedback of a plurality of parameters and the adoption of the variable frequency technology are capable of realizing automatic accurate control of fermentation oxygen supply amount, and the controllers of a plurality of chambers can be networked to form a central control system, so that the labor intensity is greatly reduced, the efficiency is improved and the labor cost is reduced, 4, the number of the fermentation tanks can be increased or decreased according to the desired processing capacity, and the fermentation units are arranged flexibly to achieve the desired design requirements and to be suitable for large-scale sludge treatment, and 5, the processes are smooth in transition, simple to operate and simple and easy to maintain.

Owner:北京圣海林生态环境科技股份有限公司 +2

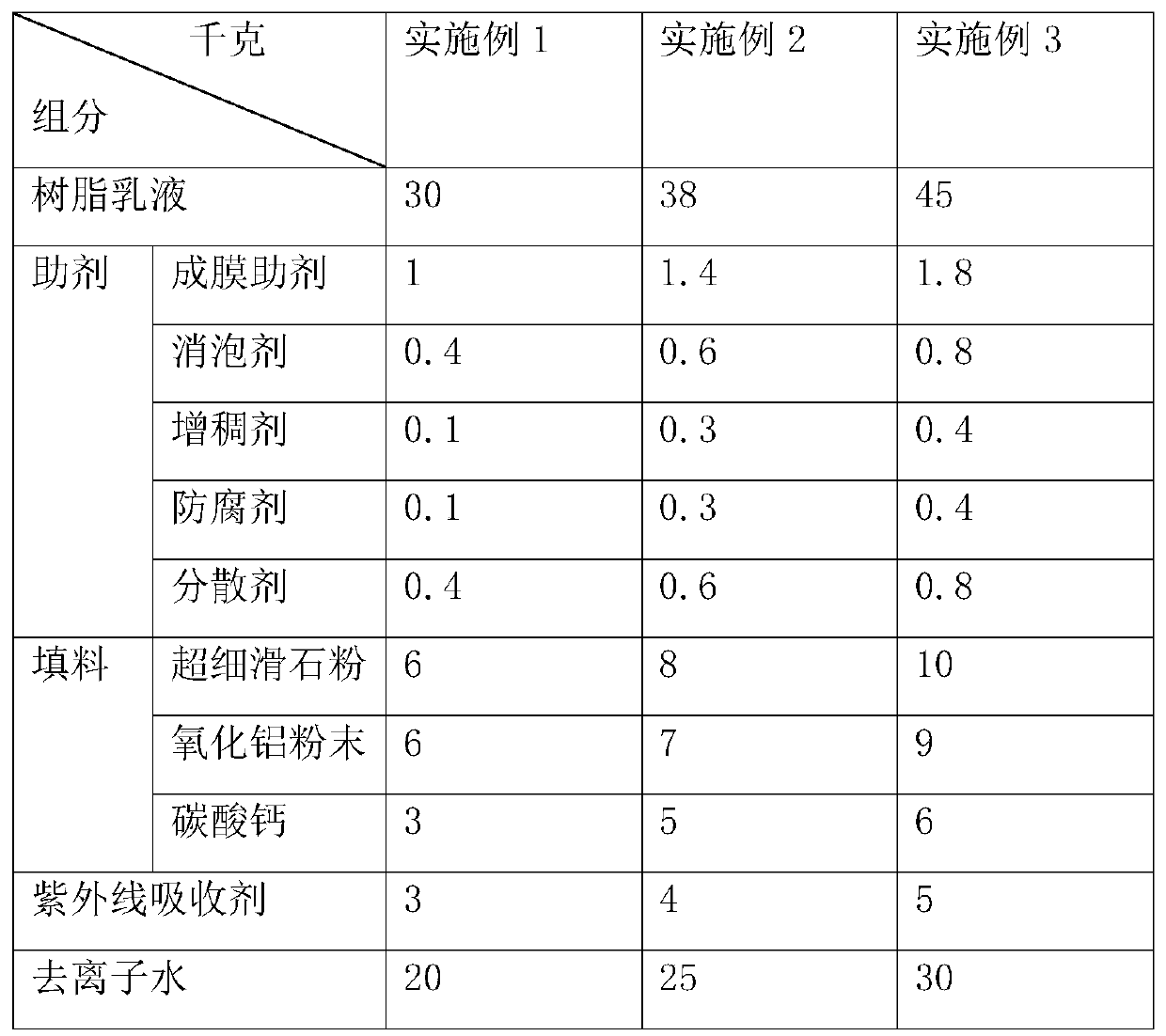

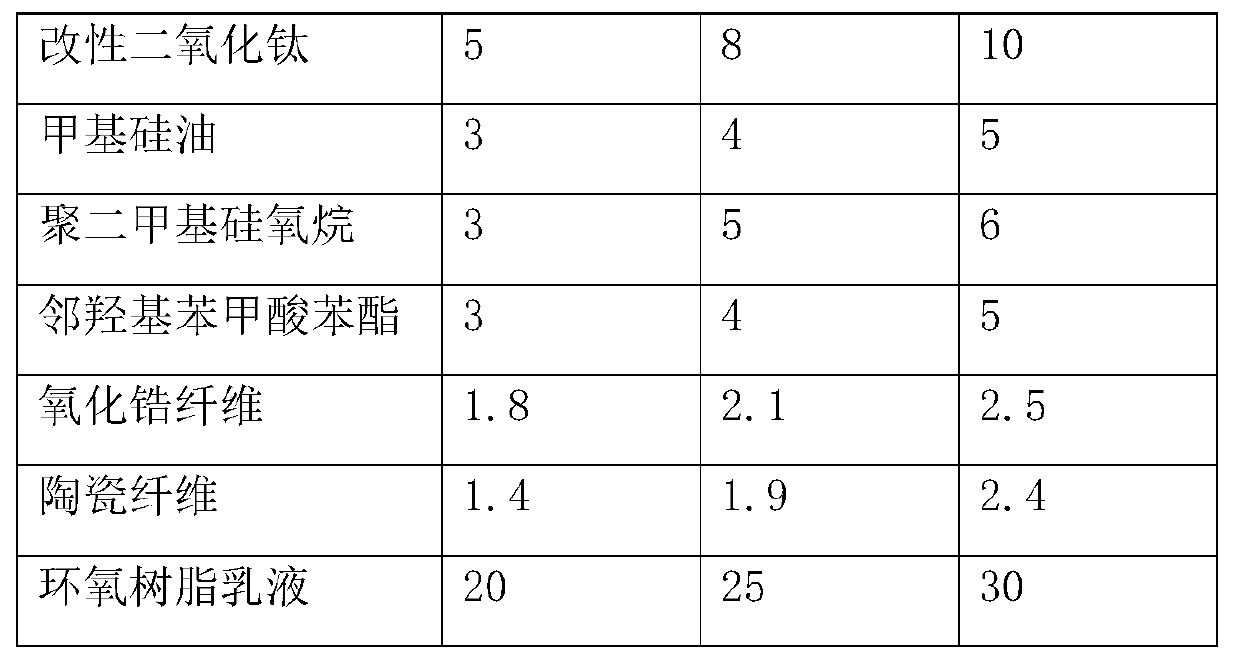

Anti-ultraviolet paint for cosmetic packing bottles and preparation method and application technique thereof

InactiveCN110054982AGood dispersionImprove adhesionLiquid surface applicatorsAnti-corrosive paintsEpoxyFiber

The invention discloses an anti-ultraviolet paint for cosmetic packing bottles and a preparation method and application technique thereof. The anti-ultraviolet paint is made from, by weight, 30-45 parts of resin emulsion, 4-8 parts of an aid, 6-10 parts of a filling material, 3-5 parts of an ultraviolet absorbent, and 20-30 parts of deionized water. The resin emulsion is made by mixing a silica-modified acrylate, polyurethane acrylate and hollow glass beads in a mass ratio of 1:(0.8-1):(0.5-0.8); the ultraviolet absorbent comprises, by weight, 5-10 parts of modified titania, 3-5 parts of methyl silicone oil, 3-6 parts of polydimethylsiloxane, 3-5 parts of phenyl salicylate, 1.8-2.5 parts of zirconia fiber, 1.4-2.4 parts of ceramic fiber, and 20-30 parts of epoxy resin emulsion. The anti-ultraviolet paint for cosmetic packing bottles has good heat insulation effect and high ultraviolet resistance.

Owner:广州澳盈日化包装用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com