Distributed stress/temperature sensing optical fiber coordinate locating device

A technology of distributed strain and sensing optical fiber, which is applied in the direction of physical/chemical change thermometers, thermometers, measuring devices, etc., can solve problems such as difficult correspondence, measurement position deviation, elongation, etc., to facilitate handling and reduce measurement The effect of error and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

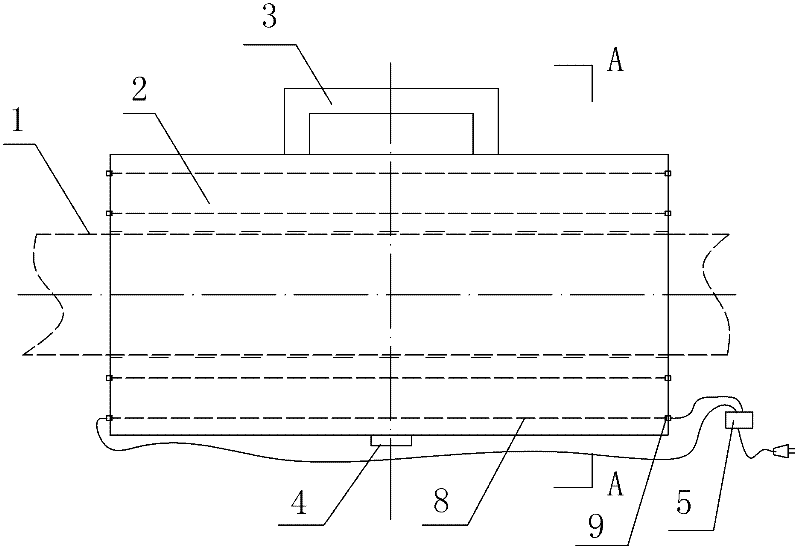

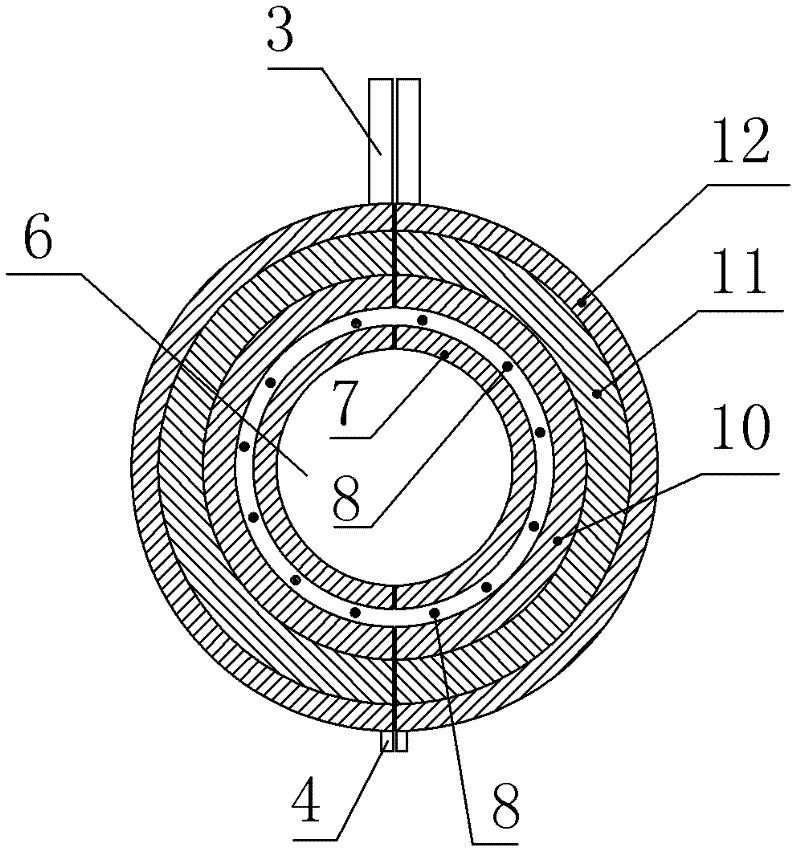

[0021] Such as figure 1 , figure 2 As shown, the distributed strain / temperature sensing optical fiber coordinate positioning device includes two semicircular ring members 2 (that is, 2 semicircular ring members 2), and the bottom ends of the two semicircular ring members are buckled by ordinary buckles. The upper ends of the two semicircular ring-shaped components are connected in a common buckle-and-latch manner (the upper ends are equipped with handles 3), and the two semicircular ring-shaped components form an optical fiber through the The ring structure of hole 6, the inner radius of two semicircular ring members is 1cm (the inner diameter of ring structure is 2cm), the outer radius of two semicircle ring members is 3cm (the outer diameter of ring structure is 6cm), two The length of the semicircular annular member is 25cm; Two semicircular annular members comprise outer skin and inner surface layer 7, and inner surface layer is positioned at outer skin (adopt plug-in co...

Embodiment 2

[0032] It is basically the same as Embodiment 1, except that the length of the two semicircular ring members is 5 cm.

[0033] Experiments were carried out according to the method described in Example 1, and the results showed that the accuracy rate reached 100%.

Embodiment 3

[0035] Basically the same as embodiment 1, the difference is: the inner radius of the two semicircular ring members is 0.3cm, the radius of the semicircle ring iron sheet is 1cm, and the outer radius of the two semicircle ring members is 2cm.

[0036] Experiments were carried out according to the method described in Example 1, and the results showed that the accuracy rate reached 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com