Main silencer for air exhaust system of automotive engine

A technology of automobile engine and exhaust system, which is applied in the direction of engine components, machines/engines, mufflers, etc., can solve the problems of reducing the service life of the main muffler, failure, corrosion of the main muffler, etc., to shorten the residence time and improve the service life , to prevent the effect of direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

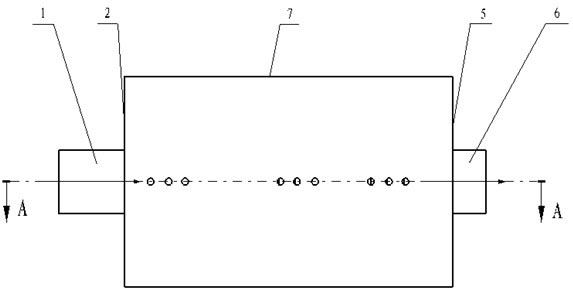

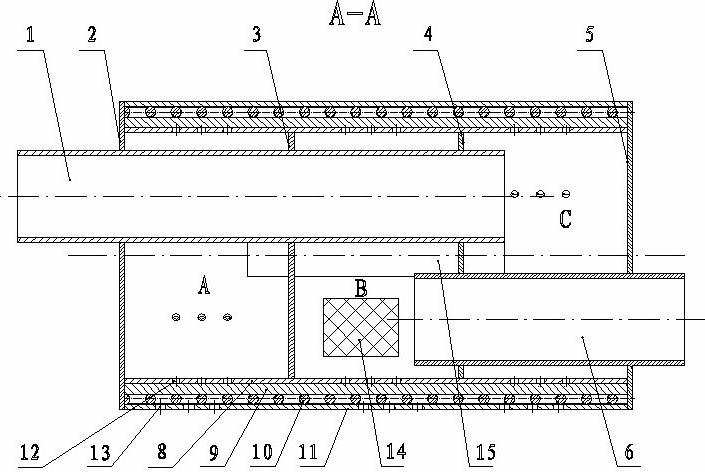

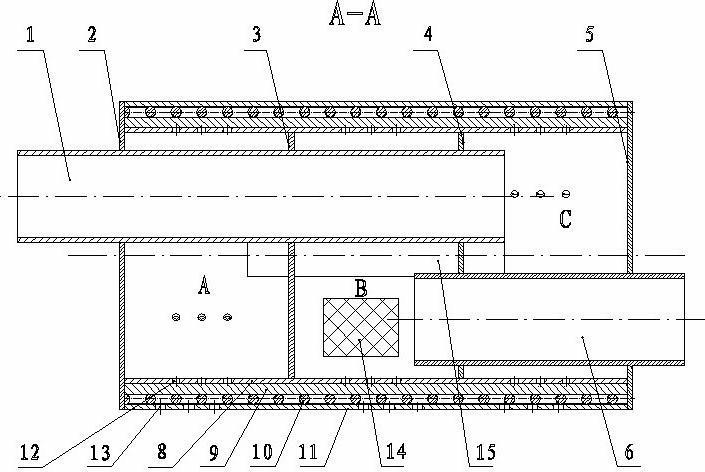

[0014] Such as figure 1 , figure 2 As shown, the multi-grid main muffler of the present invention is mainly composed of intake pipe 1, front end cover 2, first partition 3, second partition 4, rear end cover 5, exhaust pipe 6, cylinder 7 and other components. The cylinder body 7 is composed of an inner cylinder body 8 , a first mesh layer 9 , a second mesh layer 10 and an outer cylinder body 11 . The first grid layer 9 and the second grid layer 10 are sandwiched between the inner cylinder 8 and the outer cylinder 11 in the form that the grids cross each other and the two layers overlap each other, and the whole is pressed into a cylindrical shape by wrapping structure, the inner cylinder 8 and the outer cylinder 11 are divided into countless tiny space units by the first mesh layer 9 and the second mesh layer 10, and there is a certain gap between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com