Sludge unit enclosed tank type OAR treatment system

A treatment system and closed tank technology, applied in sludge treatment, biological sludge treatment, energy and wastewater treatment, etc., can solve the problems of inability to reasonably control the active environment of sludge microorganisms, low degree of automation, long fermentation cycle, etc. The effect of shortening the fermentation cycle, reducing labor intensity and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

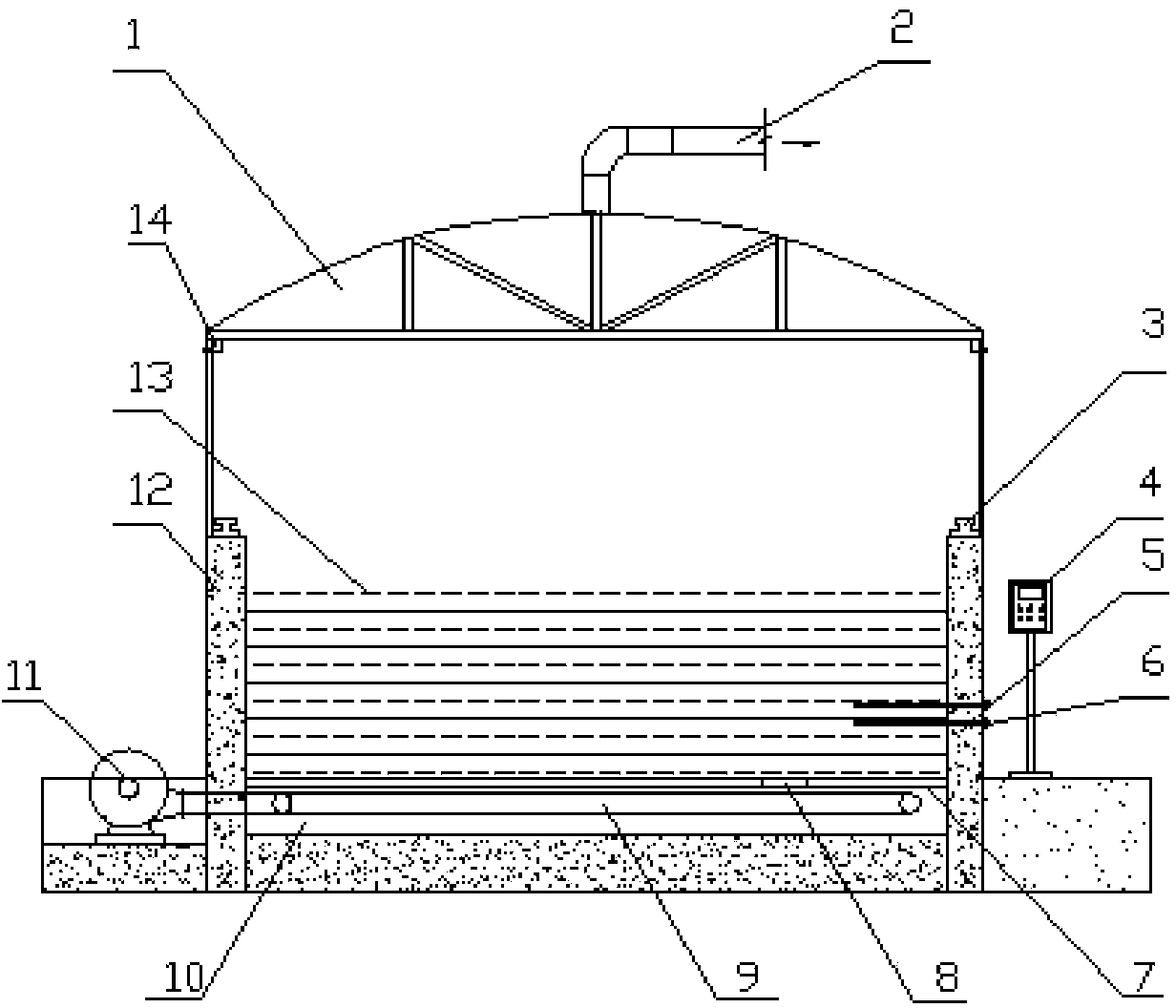

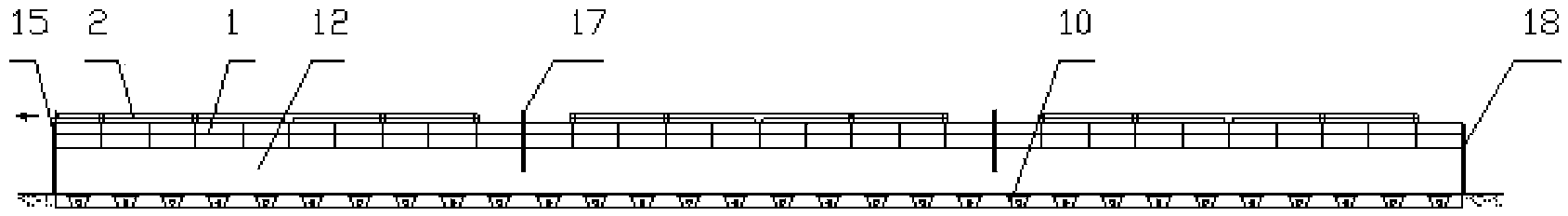

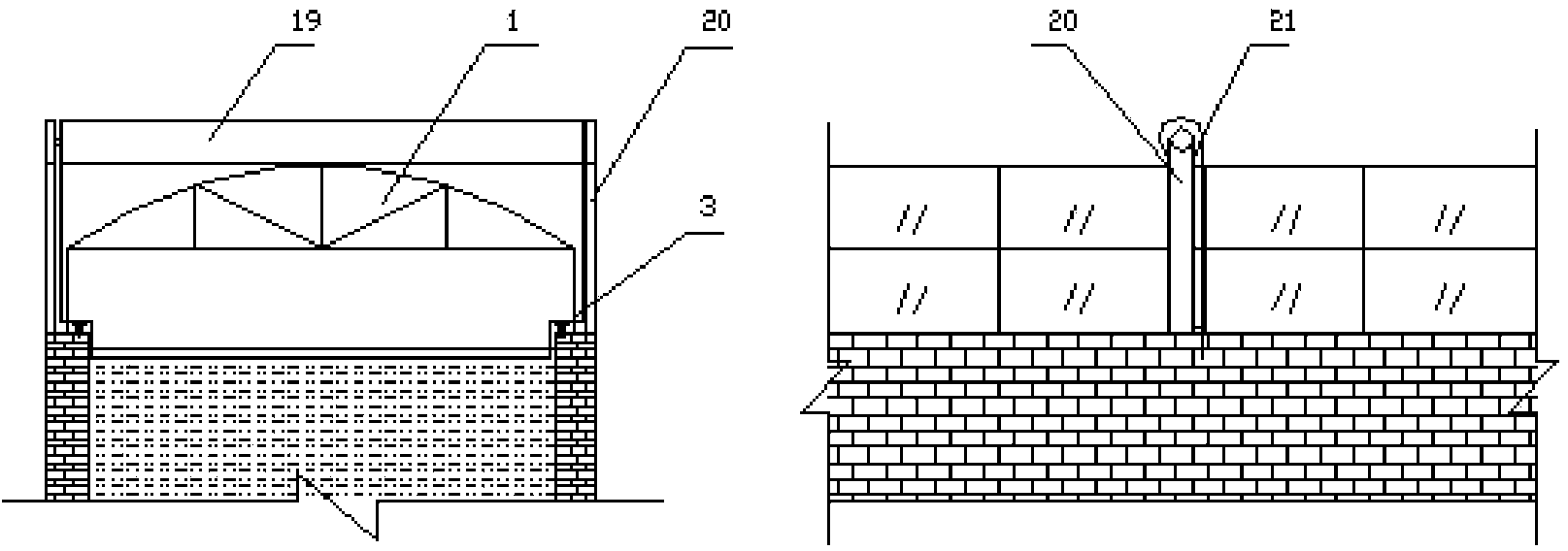

[0045] according to figure 1 Construction and production of unit closed tank OAR treatment system for sludge fermentation.

[0046] The design height of stockpile is 1.5m, and the number of long slots is 4. Each fermentation tank is 60m in length, 6m in width and 4m in height, and the long tank is divided into 3 units by 2 partition doors. The unit sunshine shed adopts sunshine board and light steel structure, galvanized chain plate partition door; exhaust gas collection and negative pressure aeration pipe adopts PVC pipe; 1000mmx500mmx70mm; aeration device high-pressure centrifugal fan, secondary aeration pipeline, UPVC series pipe fittings; automatic control system adopts self-made PLC and self-made temperature probe, three units set different aeration process parameters according to the process; each unit is controlled locally The instrument is networked to the central control room. The compost turner adopts a track-type roller compost turner.

[0047] The working proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com