Garden garbage can capable of preventing peculiar smell from diffusing

A technology for garbage cans and gardens, applied in the directions of garbage cans, garbage collection, separation methods, etc., can solve the problems of food rot and odor, and achieve the effect of preventing odor from escaping and preventing food from rotting and odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

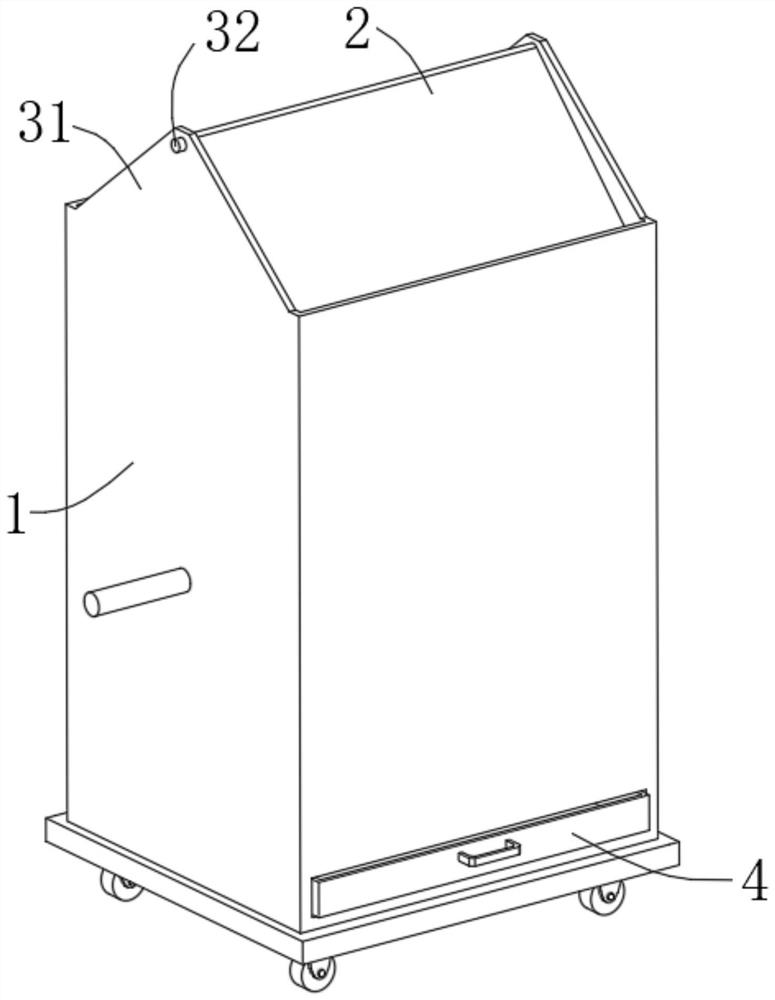

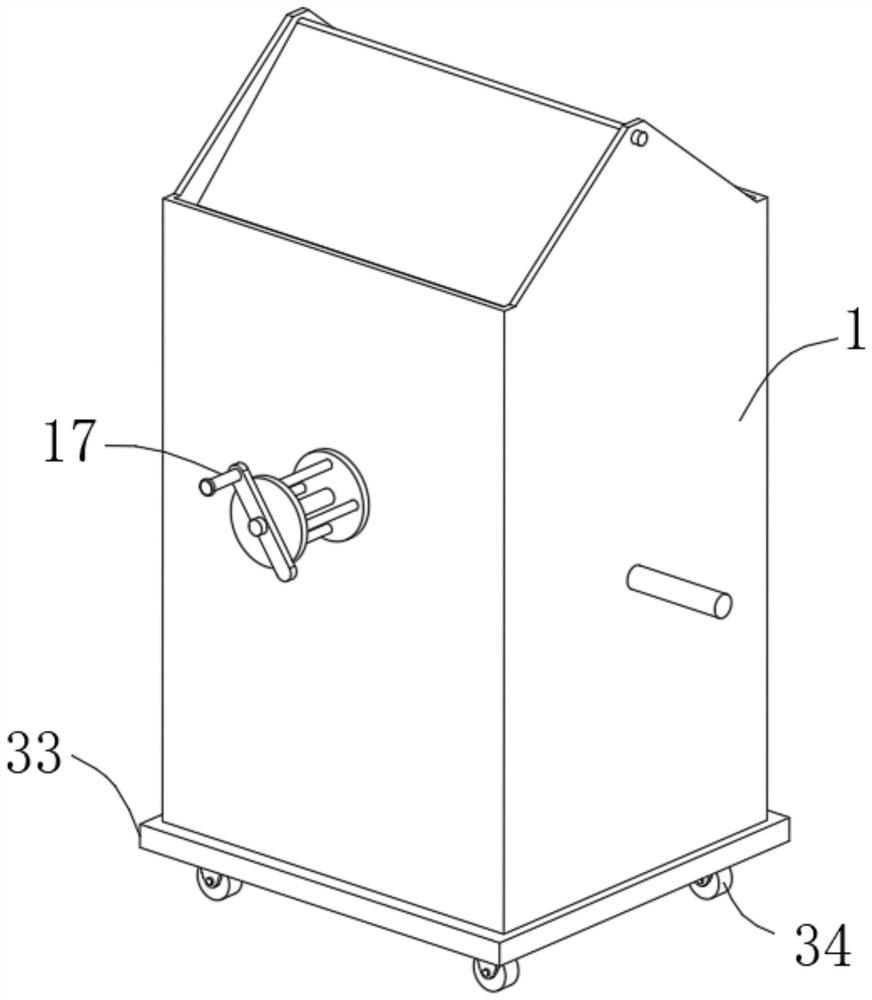

[0027] see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 7 , a garden trash can that can prevent odors from escaping in the illustration, including a barrel body 1, a rotatable cover plate 2 is installed on the top of the barrel body 1, and a filter plate 3 is provided at the bottom of the barrel body 1, and the filter plate The bottom of the filter plate 3 is slidably connected with a water storage box 4, and both sides of the filter plate 3 are slidably connected with an extruding plate 5, and a transmission device 6 is provided between the extruding plates 5 to make the extruding plates 5 approach or move away from each other , Elastic pieces 7 are provided between the extrusion plate 5 and the inner wall of the barrel body 1 .

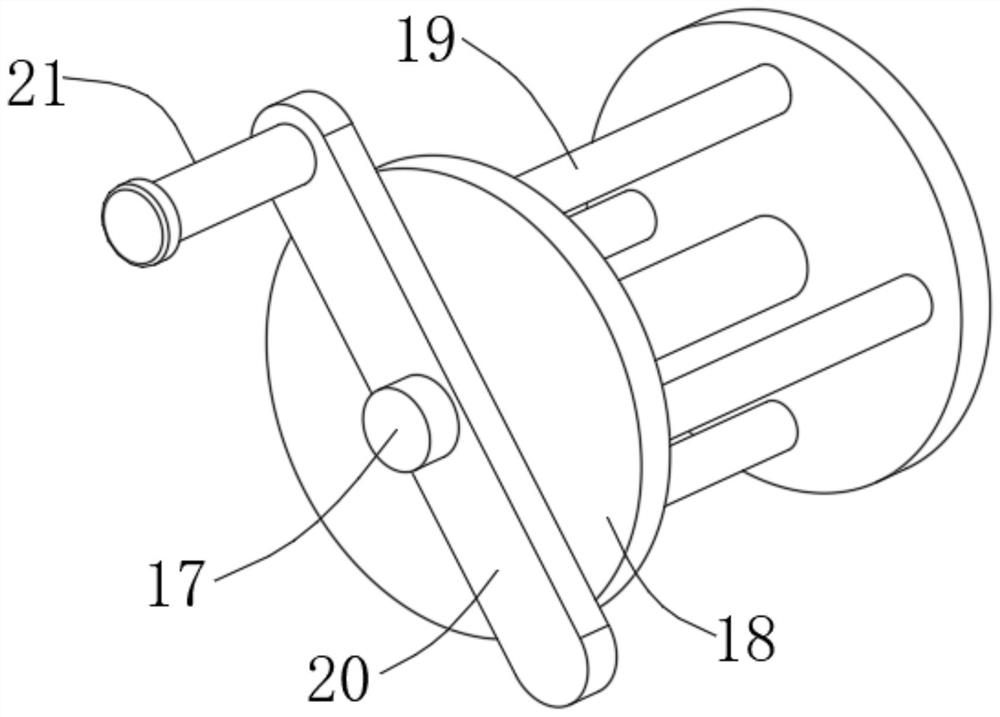

[0028] see Figure 7 , the elastic member 7 includes a sliding shaft 29, one end of the sliding shaft 29 is fixed on the extrusion plate 5, and the end away from the sliding shaft 29 passes through the side wall of the staving 1, be...

Embodiment 2

[0033] see Figure 3-Figure 6 , the present embodiment further explains the embodiment 1, the transmission device 6 in the figure includes a moving block 8, a connecting rod 9 is slidably connected to the moving block 8, and a connecting plate 10 is fixed on the top of the connecting rod 9, and the two connecting plates 10 Both ends are fixed on the inner wall of the barrel body 1, and both ends of the moving block 8 are fixed with a pole 11, and both ends of the pole 11 are rotatably connected with a rotating plate 12, and the end of the rotating plate 12 is far away from the end of the pole 11 and extruded The plates 5 are rotationally connected, the top of the moving block 8 is fixed with a moving part 13, the bottom of the connecting plate 10 is fixed with a protective cover 35, the bottom of the protective cover 35 is fixed on the top of the filter plate 3, and the protective cover 35 is provided with a The through groove 36 through which the pole 11 slides.

[0034] see...

Embodiment 3

[0037] see Figure 8 and Figure 9 , the present embodiment further explains the embodiment 1, the transmission device 6 in the figure includes a moving block 8, a connecting rod 9 is slidably connected to the moving block 8, and a connecting plate 10 is fixed on the top of the connecting rod 9, and the two connecting plates 10 Both ends are fixed on the inner wall of the barrel body 1, and both ends of the moving block 8 are fixed with a pole 11, and both ends of the pole 11 are rotatably connected with a rotating plate 12, and the end of the rotating plate 12 is far away from the end of the pole 11 and extruded The plates 5 are rotationally connected, the top of the moving block 8 is fixed with a moving part 13, the bottom of the connecting plate 10 is fixed with a protective cover 35, the bottom of the protective cover 35 is fixed on the top of the filter plate 3, and the protective cover 35 is provided with a The through groove 36 through which the pole 11 slides.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com