Garbage classification device

A garbage sorting and garbage technology, applied in magnetic separation, filtration separation, solid separation, etc., can solve the problem that metal garbage, non-metal garbage and liquid garbage cannot be separated at the same time, and achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

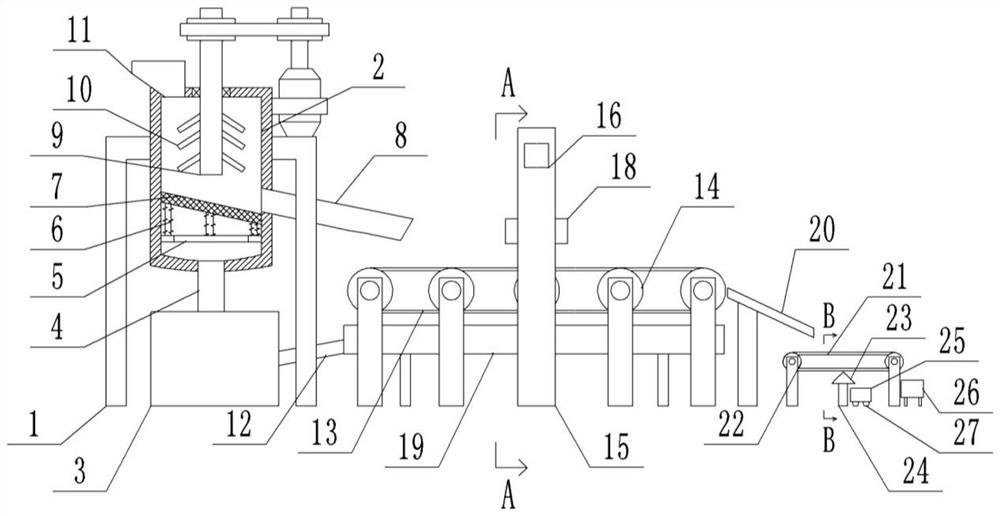

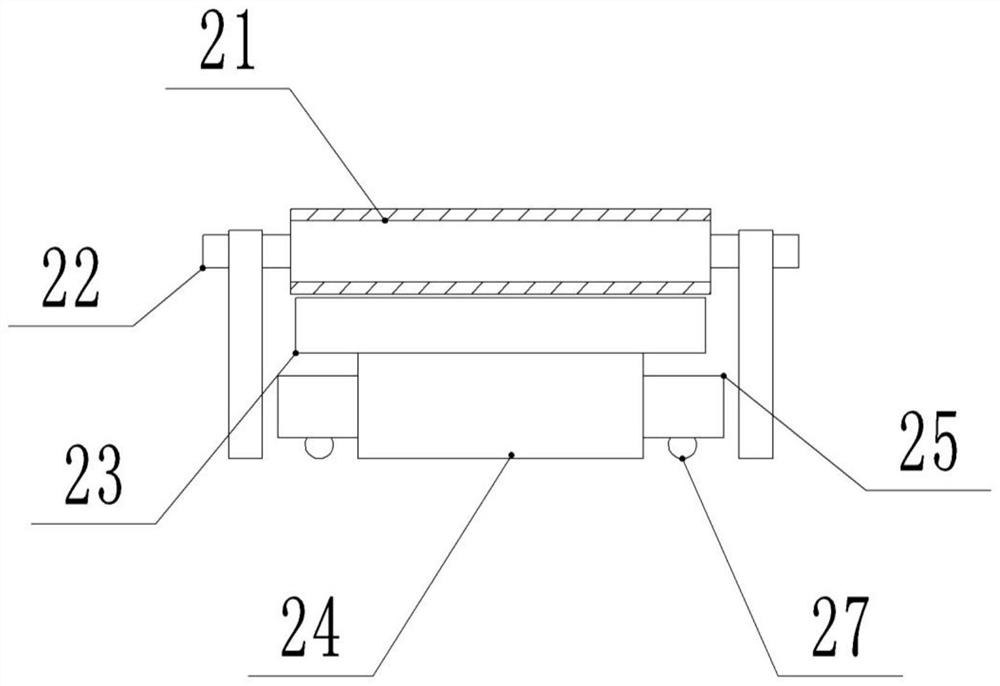

[0024] like figure 1 and image 3 Shown: a garbage sorting device, including a liquid garbage separation mechanism, a metal garbage separation mechanism and a transmission mechanism for transferring solid waste separated by the liquid garbage separation mechanism to the metal garbage separation mechanism. The liquid garbage separation mechanism includes a separation box 2, The filter screen 7 and the support 1 for supporting the separation box 2, the top of the separation box 2 is fixedly provided with a feed hopper 11, the filter screen 7 is slidingly connected with the inner wall of the separation box 2, and the separation box 2 is fixedly connected with a ring-shaped The second support plate 5, the second support plate 5 is positioned at the below of the filter screen 7, the spring 6 is connected between the filter screen 7 and the second support plate 5, and the side wall of the separation box 2 is fixedly provided with a discharge pipe 8, and The connecting end of the ma...

Embodiment 2

[0028] like figure 1 Shown: the difference between embodiment 2 and embodiment 1 is that the liquid garbage separation mechanism in a garbage sorting device also includes a stirring unit, the stirring unit includes a third motor and a stirring shaft 9, and the third motor is fixed on the bracket 1 , the bottom end of the stirring shaft 9 runs through the top of the separation box 2, and extends to the inside of the separation box 2, the top of the stirring shaft 9 and the separation box 2 is connected by bearing rotation, and the part of the stirring shaft 9 located in the separation box 2 is evenly distributed with stirring The blade 10, the output shaft of the third motor and the stirring shaft 9 are all provided with pulleys, and the two pulleys are connected by a belt.

[0029] The implementation mode of embodiment 2 is: before sorting the garbage, first start the third motor, the third motor starts to drive the stirring shaft 9 to rotate, and the stirring shaft 9 drives t...

Embodiment 3

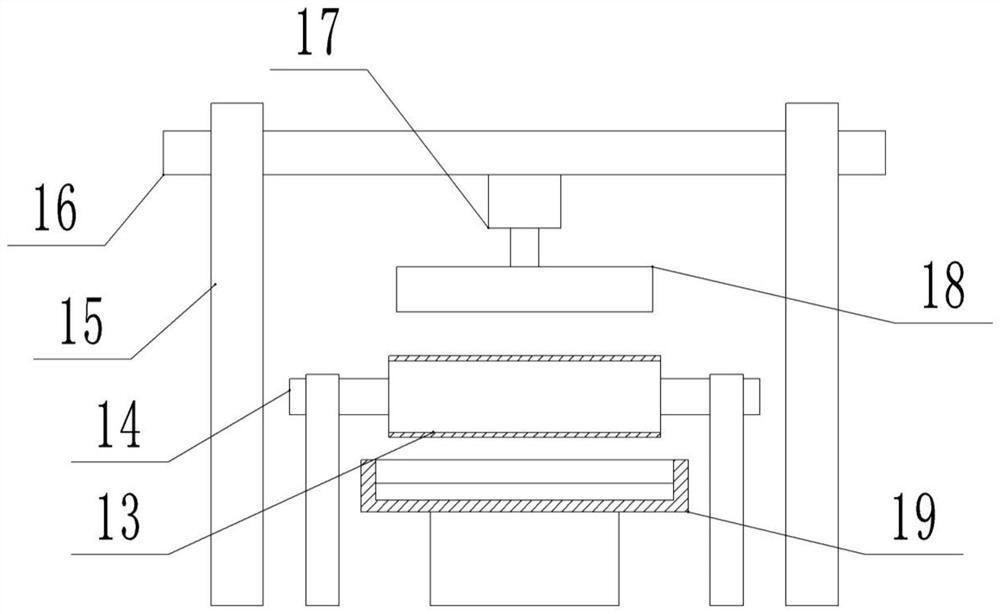

[0032] like figure 1 , figure 2 and Figure 4 Shown: the difference between Embodiment 3 and Embodiment 1 is that a garbage sorting device also includes an extrusion mechanism for squeezing the moisture in the garbage on the first conveyor belt 13, the extrusion mechanism includes an electric push rod 17 and two vertical plate 15, the bottom ends of the two vertical plates 15 are fixed on the ground, and the two vertical plates 15 are arranged on the front side and the rear side of the first conveyor belt 13, and the third support plate 16 is fixedly connected between the two vertical plates 15 , the electric push rod 17 is fixedly arranged on the third support plate 16, and the free end of the electric push rod 17 is fixedly connected with an extruding plate 18, and the extruding plate 18 is located directly above the first conveyor belt 13. In this scheme, the electric push rod 17 The model number is DTZ100.

[0033] In addition, the difference between embodiment 3 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com