PPR insulating composite tube for home decoration and preparation method of composite tube

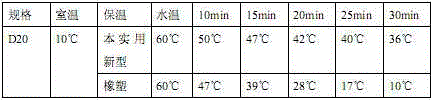

The technology of thermal insulation composite and aluminum-plastic composite pipe is applied in the field of plastic pipeline thermal insulation, which can solve the problems of rubber and plastic materials, which are easy to absorb moisture and have poor thermal insulation effect, the thermal insulation effect is not affected by the tight fit, and the service life is easy to age, so as to achieve easy pipeline maintenance , good thermal insulation effect, high cell strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

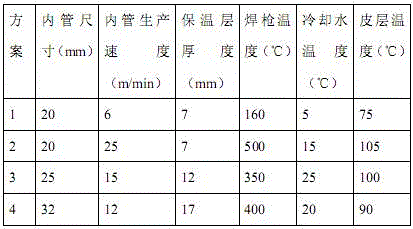

[0031] Embodiment 1-4: A kind of production technology of PPR thermal insulation composite pipe for home improvement of the present invention comprises the following steps:

[0032] 1) Inner tube forming: the inner PPR or PPR composite tube is first extruded on the pipe equipment;

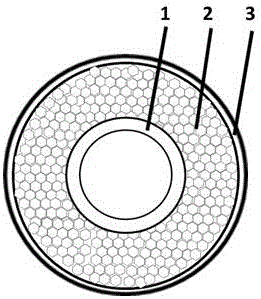

[0033] 2) Insulation layer cutting and cladding welding section: cut the foamed polyethylene pipe in the axial direction and wrap it on the continuously extruded PPR or PPR composite pipe in step 1), and pass through a welding torch with a heat welding temperature of 120-500°C Glue the slits and tightly cover the PPR or PPR composite pipe to form a foamed polyethylene insulation middle layer 2;

[0034] 3) The weather-resistant layer is extruded to cover the shaping section

[0035] 3.1) The weather-resistant and scratch-resistant outer layer 3 is composed of the following components in weight percent: 60-90% LLDPE, 5-15% HDPE, 4-20% EVOH, 0.5-2% silane-modified nano titanium dioxide and 0.5- 2% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com