A kind of highly scratch-resistant two-component nano-modified acrylic varnish and its preparation method

A technology of acrylic varnish and nano-modification, which is applied in coatings, polyurea/polyurethane coatings, etc., and can solve problems such as unknown, no explanation for the improvement of scratch resistance, and reduced brightness changes at scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

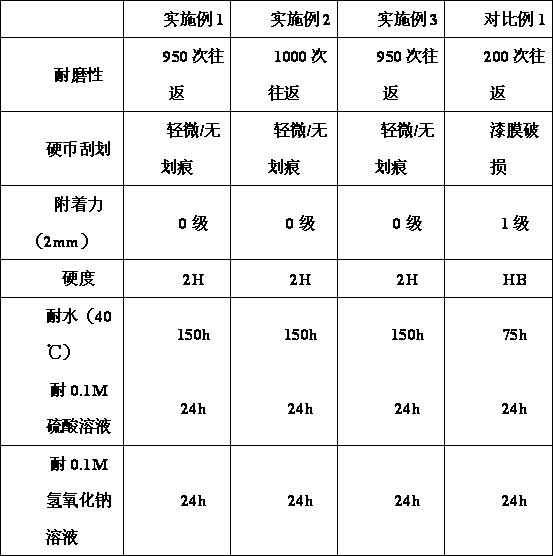

Examples

Embodiment 1

[0012] In a clean and standard container, weigh 15 parts of acrylic resin a (solid content 70%, acid value 6mgKOH / g, hydroxyl content 4.2%), acrylic resin b (solid content 50%, acid value 3mgKOH / g, hydroxyl Content 2.0%) 20 parts, acrylic resin c (solid content 70%, acid value 9mgKOH / g, hydroxyl content 2.24%) 22 parts, nano silicon dioxide 20 parts and 6 parts propylene glycol methyl ether acetate, start the disperser, in Stir at a medium speed at a speed of 700r / min and disperse evenly for 5 minutes to obtain a pre-dispersed resin; then add 5 parts of xylene, 9.5 parts of 100 # Solvent oil, 0.3 parts of substrate wetting agent, 0.5 parts of leveling agent, 1.1 parts of ultraviolet absorber, 0.6 parts of light stabilizer, stir and disperse at a medium speed at a speed of 800r / min for 1 hour to obtain component A; group B One part needs to be obtained by adding 70 parts of HDI trimer curing agent and 30 parts of dehydrated n-butyl acetate into a clean container, stirring until...

Embodiment 2

[0015] In a clean and standard container, weigh 16 parts of acrylic resin a (solid content 70%, acid value 6mgKOH / g, hydroxyl content 4.2%), acrylic resin b (solid content 50%, acid value 3mgKOH / g, hydroxyl Content 2.0%) 21 parts, acrylic resin c (solid content 70%, acid value 9mgKOH / g, hydroxyl content 2.24%) 23 parts, nano silicon dioxide 17 parts and 8 parts propylene glycol methyl ether acetate, start the disperser, in Stir at a medium speed at a speed of 700r / min to disperse evenly for 5 minutes to obtain a pre-dispersed resin; then add 6 parts of xylene, 7 parts of 100 # Solvent oil, 0.2 parts of substrate wetting agent, 0.4 parts of leveling agent, 0.9 parts of ultraviolet absorber, 0.5 parts of light stabilizer, stir and disperse at a medium speed at a speed of 800r / min for 1 hour to obtain component A; component B It is necessary to add 70 parts of HDI trimer curing agent and 30 parts of dehydrated n-butyl acetate into a clean container, stir until it is evenly disper...

Embodiment 3

[0017] In a clean and standard container, weigh 18 parts of acrylic resin a (solid content 70%, acid value 6mgKOH / g, hydroxyl content 4.2%), acrylic resin b (solid content 50%, acid value 3mgKOH / g, hydroxyl content Content 2.0%) 21 parts, acrylic resin c (solid content 70%, acid value 9mgKOH / g, hydroxyl content 2.24%) 25 parts, nano silicon dioxide 15 parts and 8.5 parts propylene glycol methyl ether acetate, start the disperser, in Stir at a medium speed at a speed of 700r / min to disperse evenly for 5 minutes to obtain a pre-dispersed resin; then add 6.3 parts of xylene, 5 parts of 100 # Solvent oil, 0.1 part of substrate wetting agent, 0.2 part of leveling agent, 0.6 part of ultraviolet absorber, 0.3 part of light stabilizer, stir and disperse at a medium speed at a speed of 800r / min for 1 hour to obtain component A; component B It is necessary to add 70 parts of HDI trimer curing agent and 30 parts of dehydrated n-butyl acetate into a clean container, stir until it is evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com