Long glass fiber reinforced polypropylene compound and preparation method thereof

A long glass fiber and polypropylene technology, applied in the field of polymer materials and their molding processing, can solve the problems of high price of scratch resistance additives, large loss of scratch resistance performance, high cost of materials, etc., to reduce the size of parts Changes and deformation problems, improved scratch resistance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

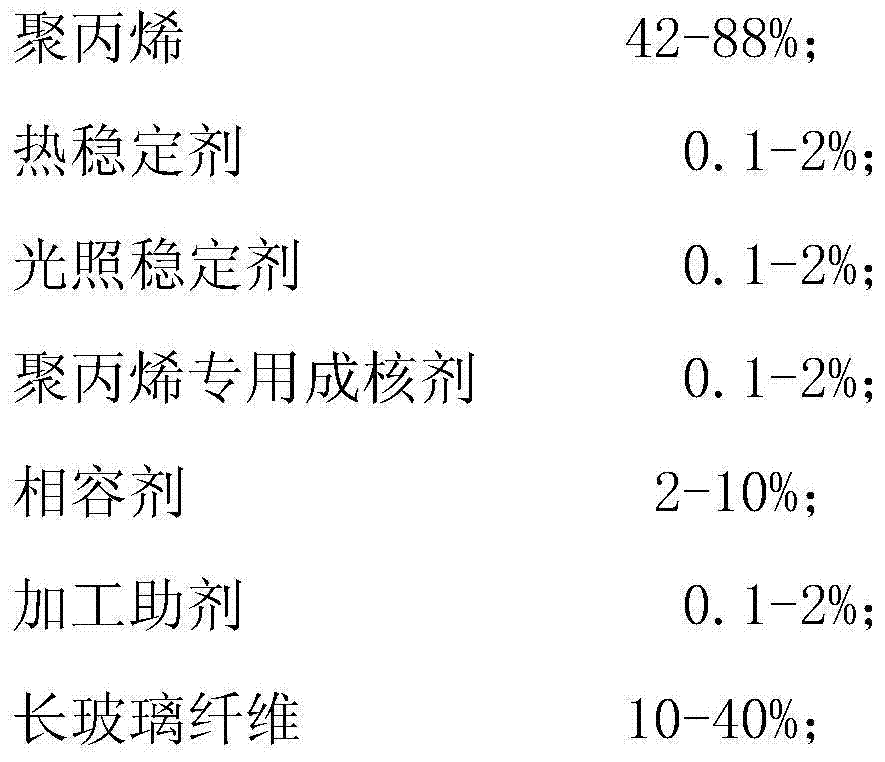

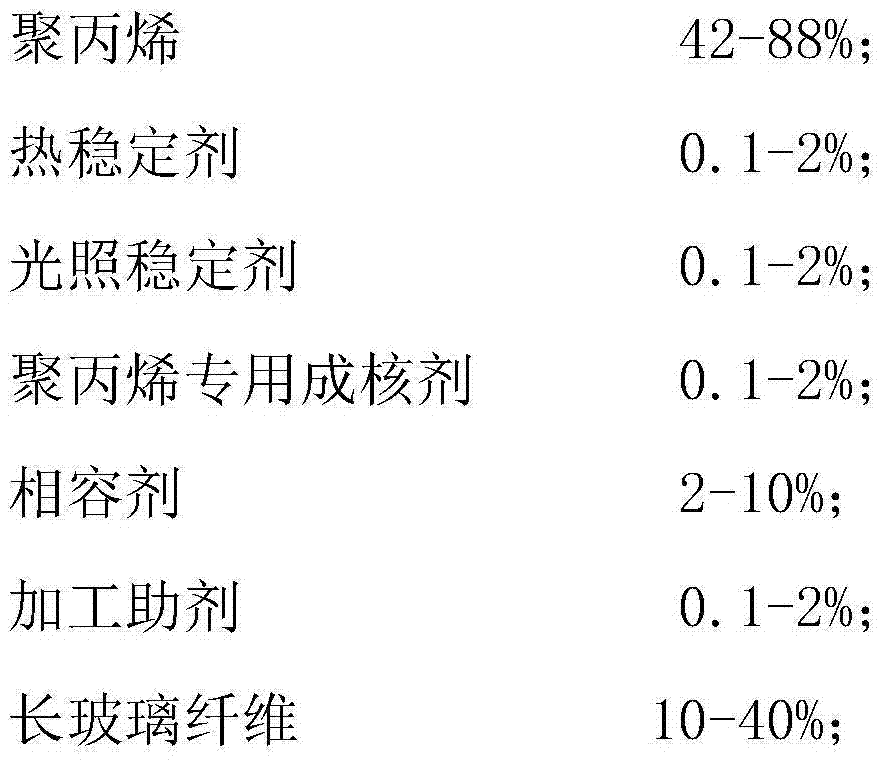

Method used

Image

Examples

Embodiment 1

[0026] The first step: 35 kg of polypropylene PP S700 (melt flow rate of 10g / 10min), 51 kg of polypropylene PP BX3920 (melt flow rate of 100g / 10min), 0.2 kg of phenolic heat stabilizer Irganox 1010, 0.3 kg Phosphite ester heat stabilizer Irganox168, 0.2 kg hindered amine light stabilizer 770, 0.3 kg polypropylene special nucleating agent TMP-5, 1 kg stearic acid complex ester processing aid ethylene bis-stearic acid amide EBS , 2 kg of maleic anhydride grafted polypropylene CA-100 is plasticized by a single screw extruder with a length-to-diameter ratio of 25:1 (rotating speed is 200r / min, and the temperature of each zone from the feeding section to the die is set to 140℃, 210°C, 245°C, 270°C, 290°C) and then transported through the LFT special die to the high temperature melt infiltration tank in the LFT special high temperature melt infiltration die. The temperature in the LFT special high temperature melt infiltration die is 290 ℃;

[0027] Step 2: Pull 10 kg of long glass fi...

Embodiment 2

[0032] The first step: 71 kg of polypropylene PP YPJ3860 (melt flow rate is 60g / 10min), 0.5 kg of phenolic heat stabilizer 1010, 0.5 kg of phosphite ester heat stabilizer 627A, 0.6 kg of hindered amine light stabilizer 622, 0.4 kg of polypropylene special nucleating agent HPN-20E, 1 kg of stearic acid complex ester processing aid ethylene bisstearic acid amide EBS, 5 kg of maleic anhydride grafted polypropylene CA-100 passed 25:1 The single-screw extruder is plasticized (rotating speed is 220r / min, and the temperature of each zone from the feeding section to the head is set to 140℃, 220℃, 260℃, 280℃, 300℃) and then transported to the LFT dedicated die through the LFT dedicated die In the high temperature melt infiltration tank in the high temperature melt infiltration die, the temperature in the LFT special high temperature melt infiltration die is 300℃;

[0033] The second step: the 21 kilograms of long glass fiber Tufrov 4599 produced by PPG company is drawn into the high-tempe...

Embodiment 3

[0038] The first step: 42 kg of polypropylene PP EP540V (melt flow rate is 100g / 10min), 1 kg of phenolic heat stabilizer 1010, 1 kg of thioester heat stabilizer 412S, 2 kg of hindered amine light stabilizer 770, 2 kg of polypropylene special nucleating agent Millad 3988, 2 kg of stearic acid complex ester processing aid ethylene bis-stearic acid amide EBS, 10 kg of maleic anhydride grafted polypropylene Bondyram 1001CN through 25:1 single screw extrusion After being plasticized (rotation speed is 260r / min, the temperature of each zone from the feeding section to the machine head is set to 140℃, 260℃, 280℃, 310℃, 330℃) and then transported to the LFT special high temperature melt through the LFT special die In the high temperature melt infiltration tank in the infiltration die, the temperature in the LFT special high temperature melt infiltration die is 330℃;

[0039] The second step: the 40 kilograms of long glass fiber Tufrov 4599 produced by PPG company is pulled into the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com