Patents

Literature

38results about How to "Not easy to collapse and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

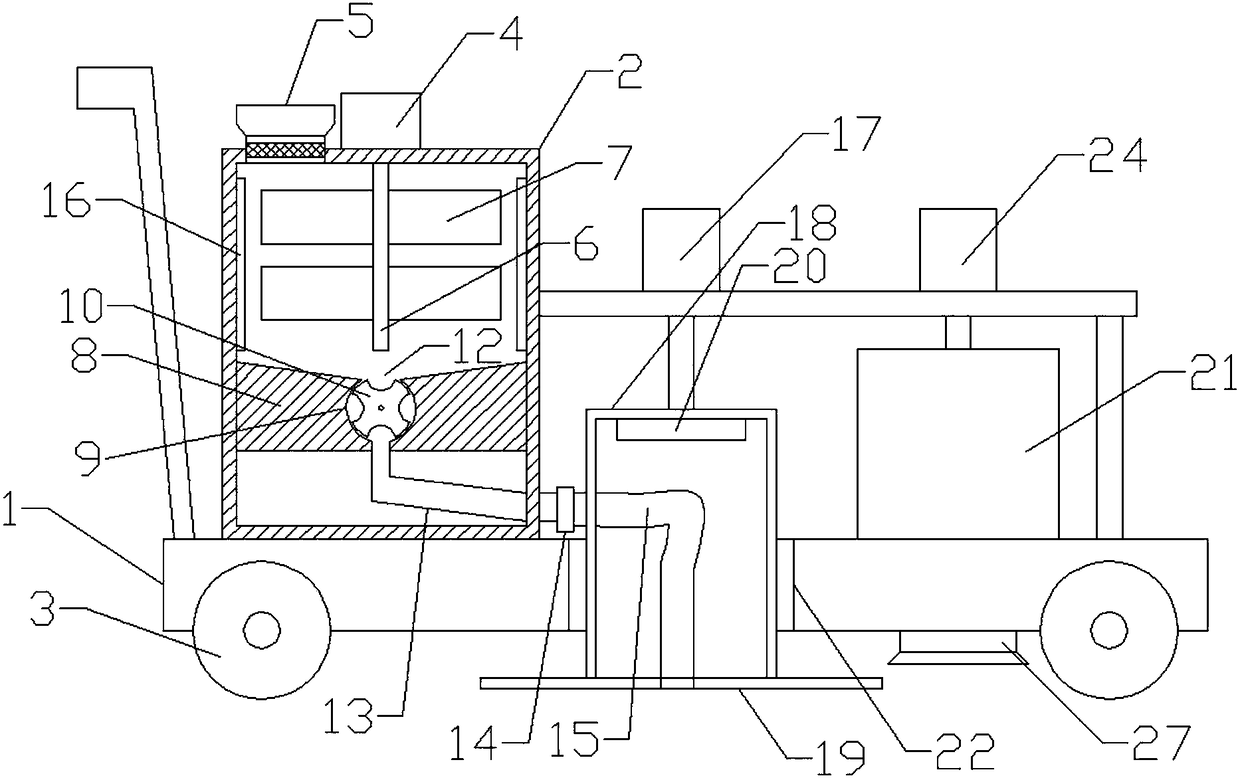

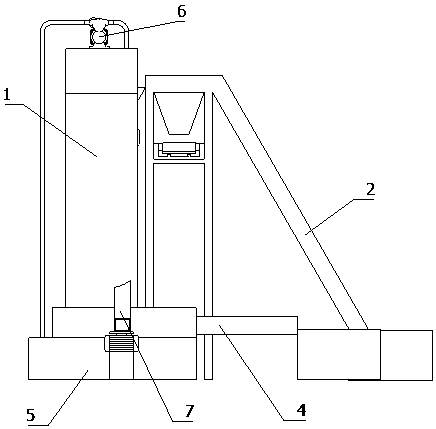

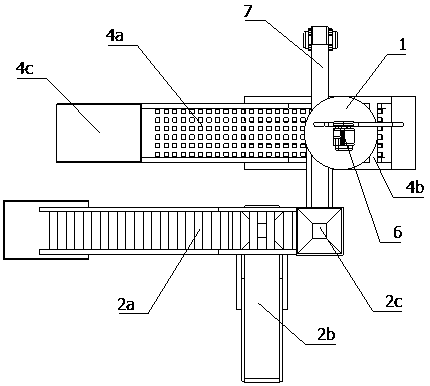

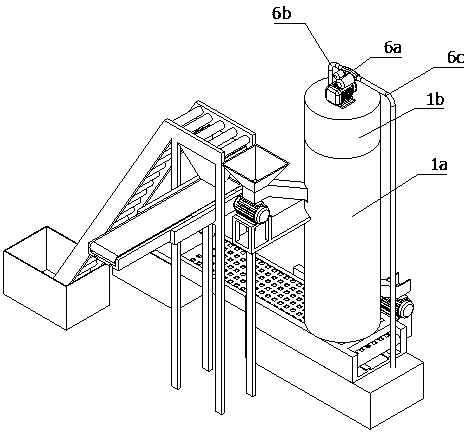

Pretreatment construction device for traffic road maintenance

InactiveCN108221619AAvoid coolingOutflow smoothlyRoad cleaningRoads maintainenceRoad surfacePre treatment

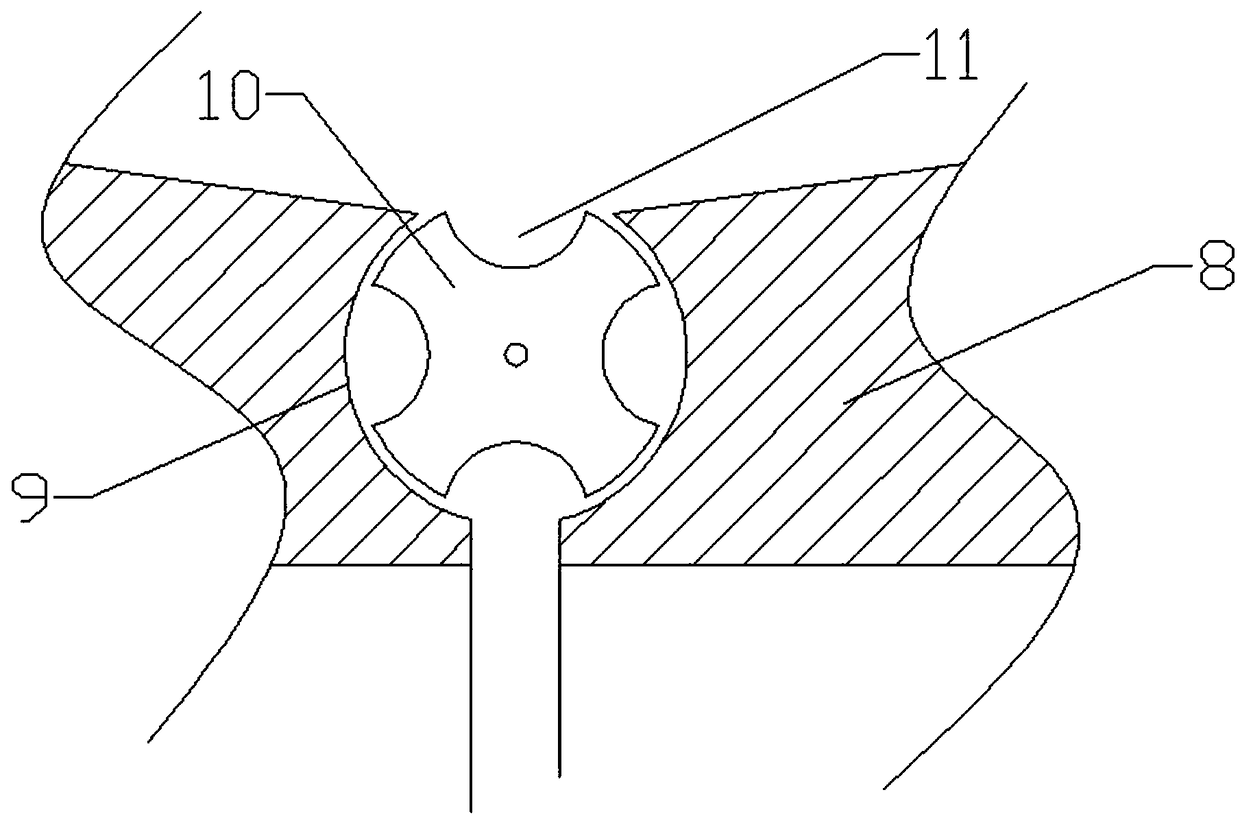

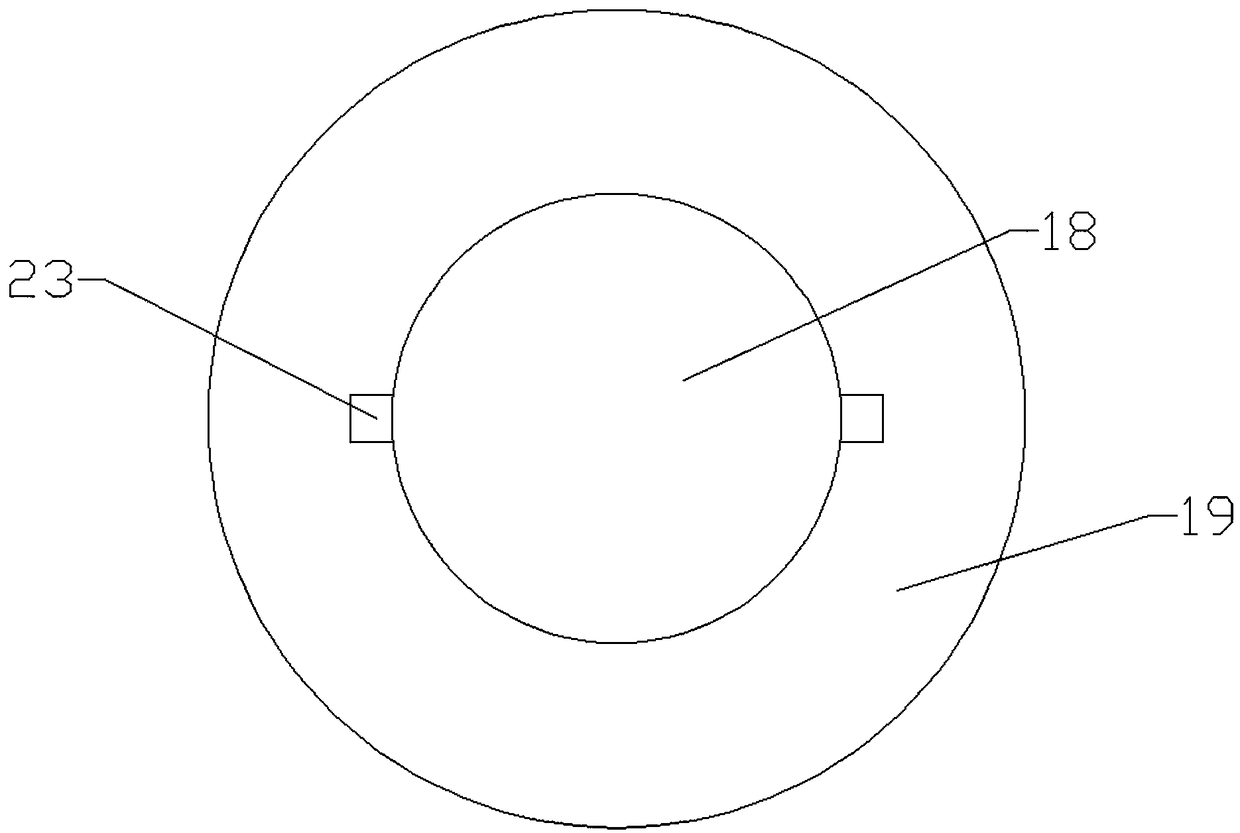

The invention discloses a pretreatment construction device for traffic road maintenance. The pretreatment construction device comprises a base, a heating box, rollers, a stirring motor and a charge hole, wherein an unloading cavity of a horizontal cylindrical structure is arranged in a separating base; a horizontal sealing column is coaxially mounted in the unloading cavity; a plurality of storageslots are uniformly formed in the side wall of the sealing column; the lower end of a lifting box is fixedly equipped with a horizontal pressure plate; a heating device for internally heating is mounted in the lifting box; a fan is further fixedly mounted on a bracket of the base; and the fan is communicated with a clearing box on the base through a pipeline. According to the pretreatment construction device disclosed by the invention, the unloading cavity and the sealing column matched with the unloading cavity are arranged, so that an asphalt raw material uniformly flows out from the heating box, filling amount is easily controlled, and material waste is reduced; impurities such as dust inside are sucked before the material is complemented, so that impurities inside are quickly clearedand reduced, and therefore, the material is extruded to be more compactly, and a repaired road is guaranteed to be not liable to collapse and deform.

Owner:钱幼华

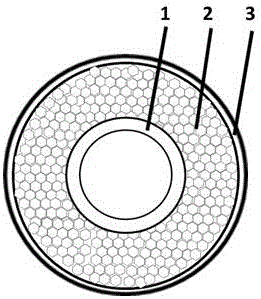

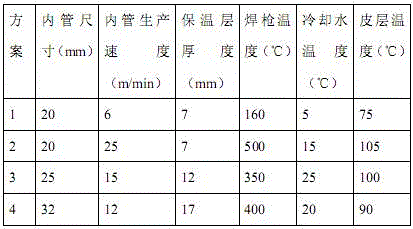

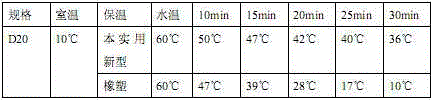

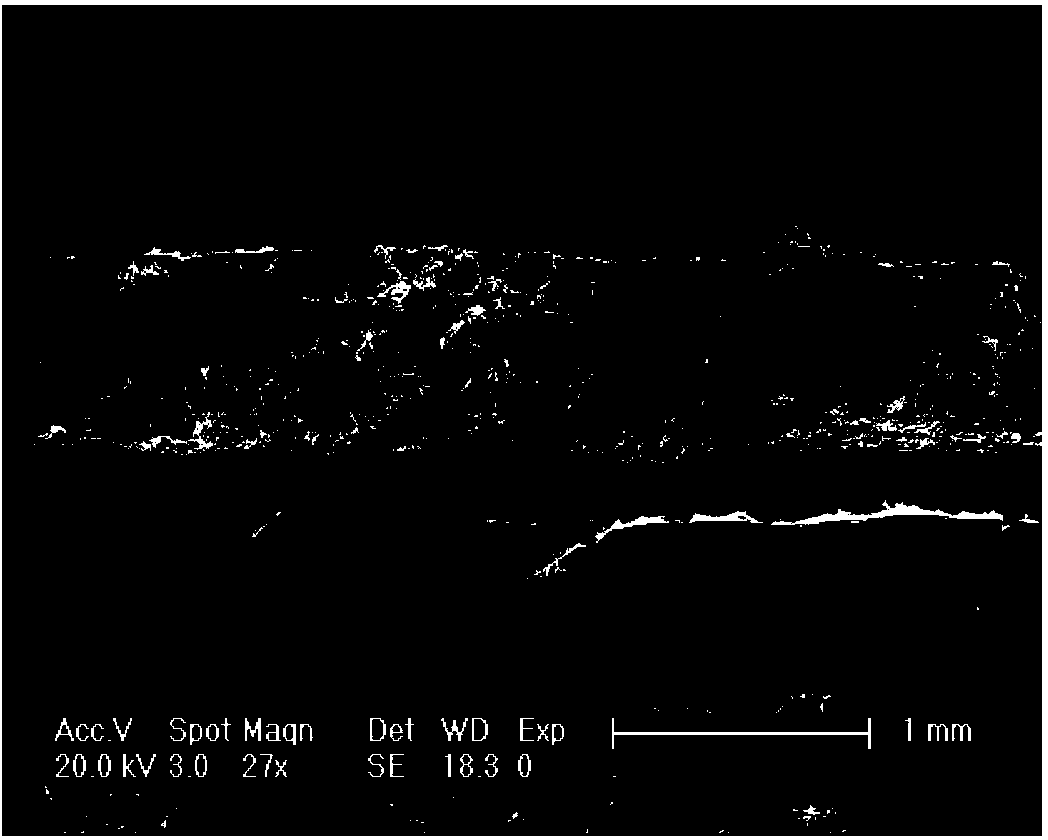

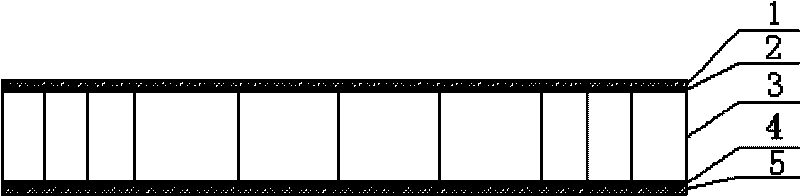

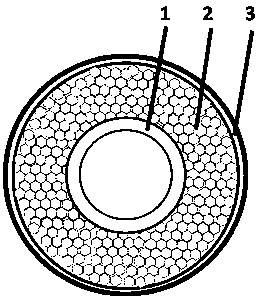

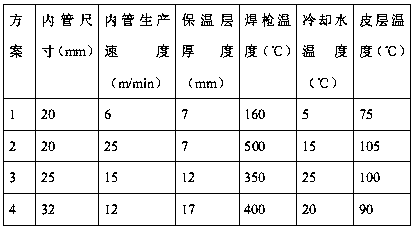

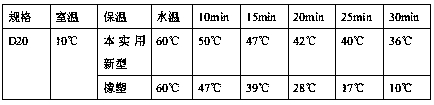

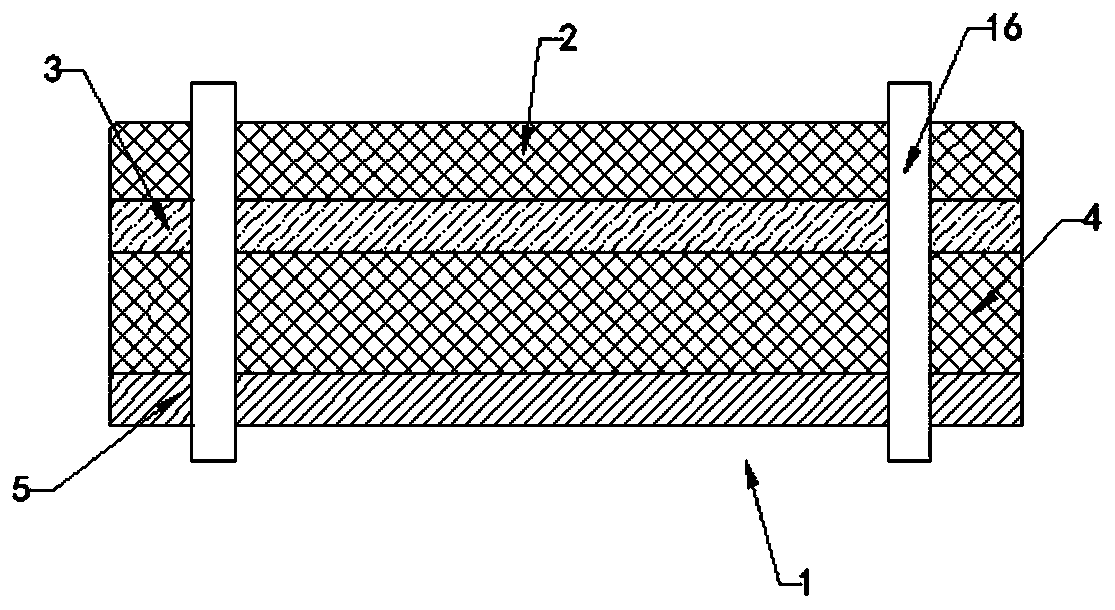

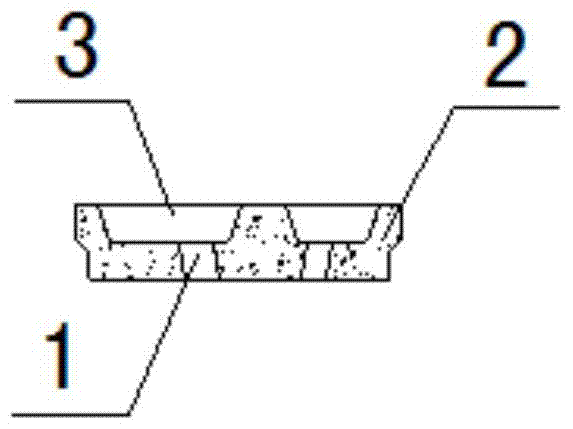

PPR insulating composite tube for home decoration and preparation method of composite tube

ActiveCN106641585ASolve the problem of scratch resistanceSolve insulation problemsThermal insulationPipe protection by thermal insulationManufacturing cost reductionProtection layer

The invention relates to a PPR insulating composite tube for home decoration and a preparation method of the composite tube. The composite tube is of a three-layer composite structure, the inner layer of a PPR or PPR aluminum-plastic composite tube is coated with an expanded polyethylene insulating layer through equipment, the expanded polyethylene insulating intermediate layer is coated with a weather-resistant and scratch-resistant outer protection layer through an extruding machine, closed-cell expanded materials are adopted by the expanded polyethylene insulating layer, the cell sizes range from 0.2 mm to 0.5 mm, and the weather-resistant and scratch-resistant layer is prepared from 60%-90% of LLDPE, 5%-15% of HDPE, 4%-20% of EVOH, 0.5%-2% of silane-modified nano-titanium dioxide and 0.5%-2% of compound additives. The expanded polyethylene insulating layer is obtained through a one-step method. The PPR insulating composite tube has the insulating and energy saving properties and the excellent weather-resistant and scratch-resistant properties, a synchronous coating molding process is adopted in the production process, the production efficiency is improved, the manufacturing cost is reduced, and the PPR insulating composite tube has a good market application prospect.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

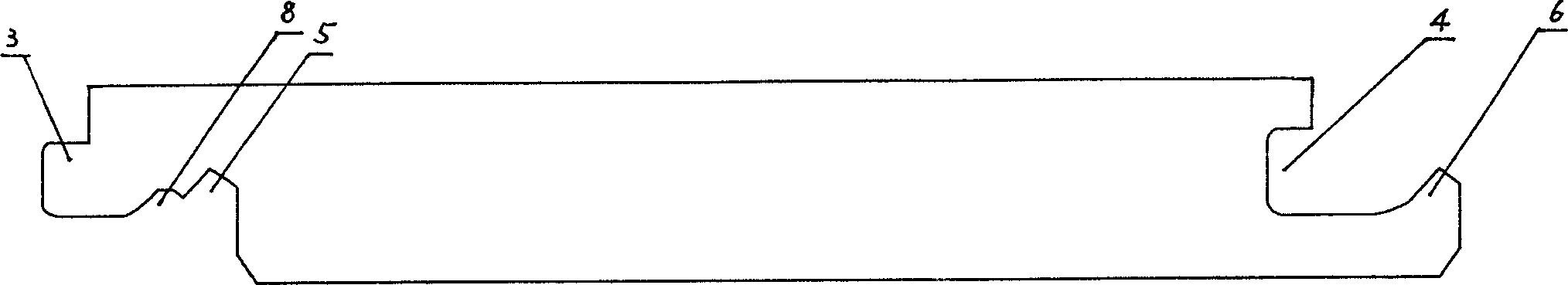

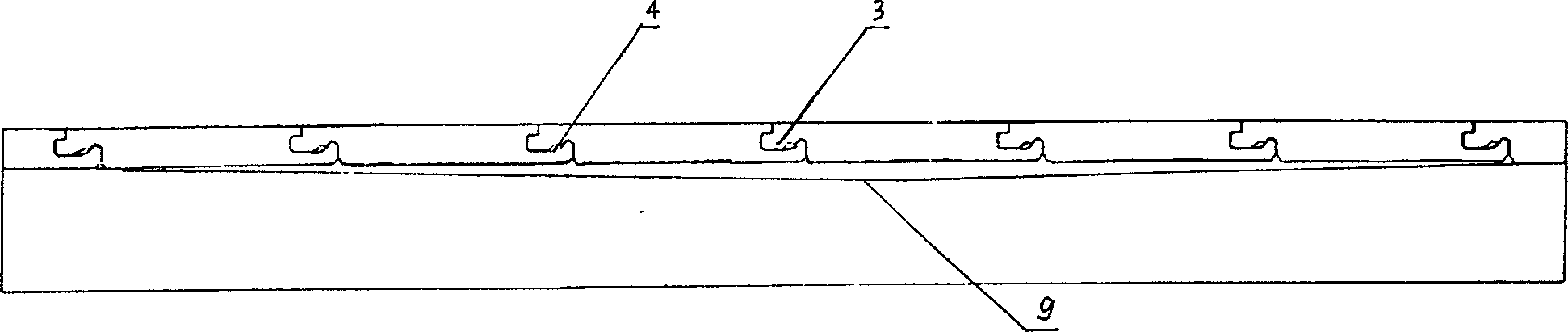

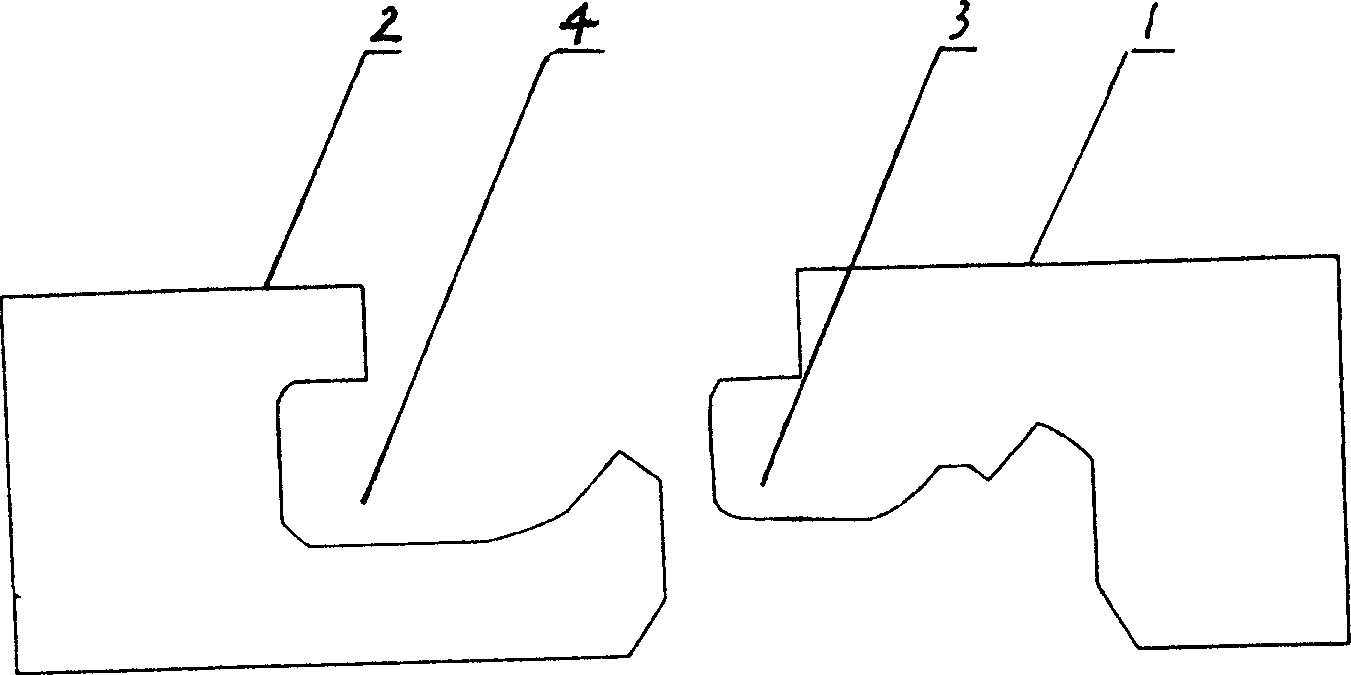

Floor joint fastening grooving

On one side of every rectangular floor board, along its length direction an inward recessed groove is cut, on the correspondent position of another side of said floor board an outward tongue is set, the forms, sizes and positions of said recessed groove and tongue must be adapted, between two floor boards the inlaying joint of recessed groove and tongue can be used for forming locking fastener. The lower groove edge of the recessed groove is extended outward and toward oblique upper direction to form hook tongue, and lower tongue edge of the tongue is extended inward and toward oblique upper direction to form hook groove, the forms, sizes and positions of hook tongue and hook groove must be adapted. Said invention utilizes the inlaying joint of recessed groove and tongue and inlaying joint of hook tongue and hook groove to make the floor boards be firmly and tightly combined together.

Owner:李卫

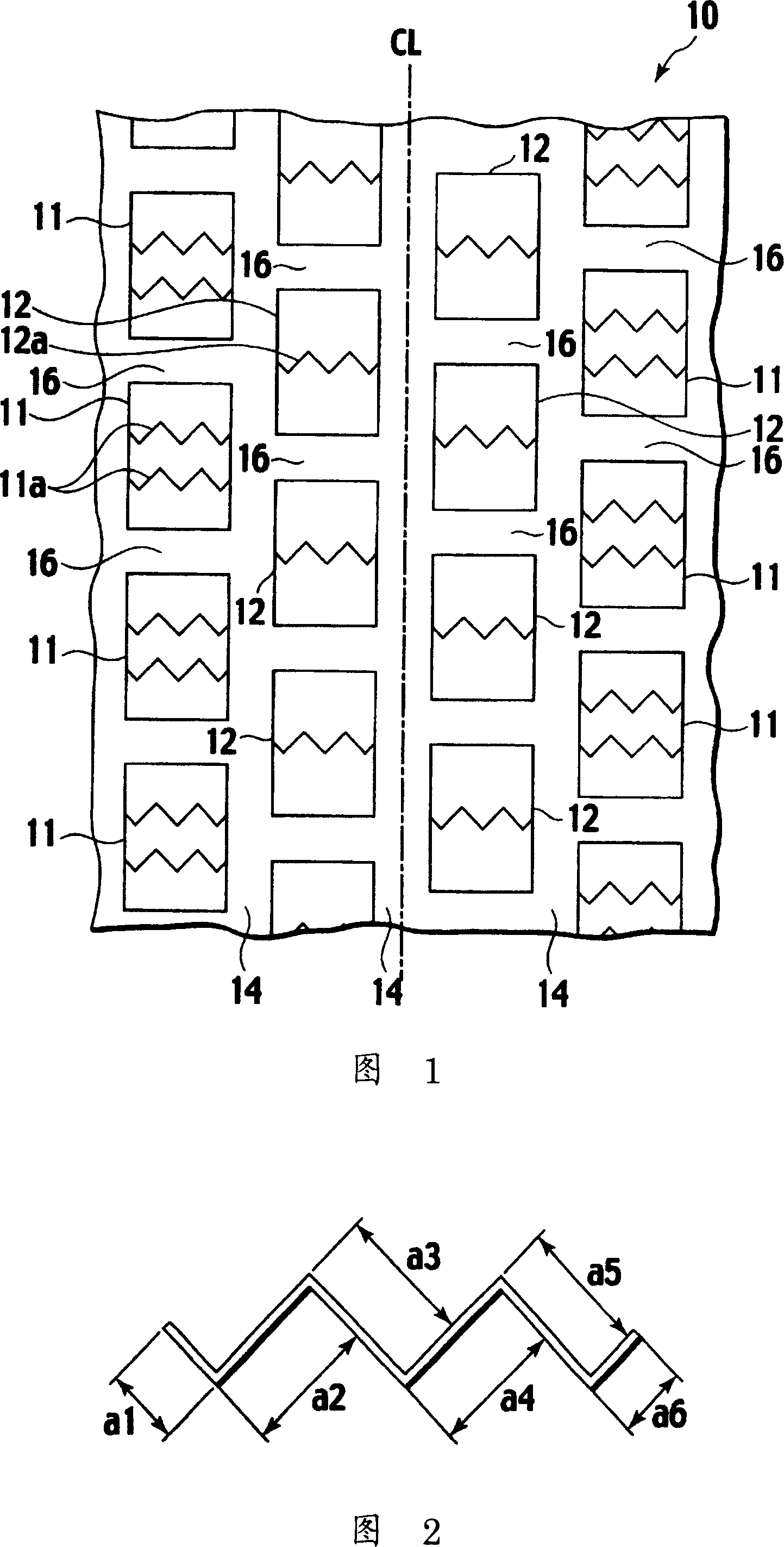

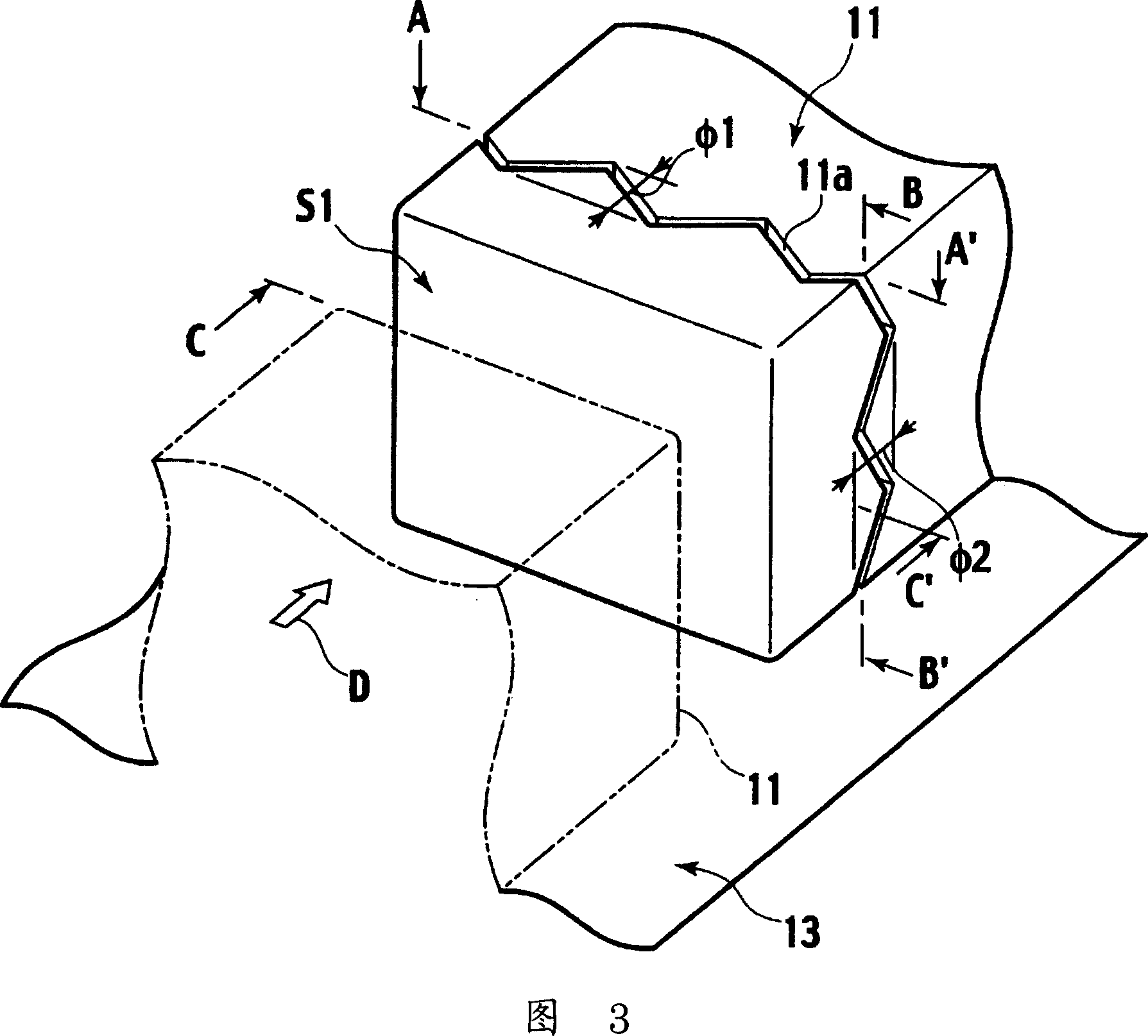

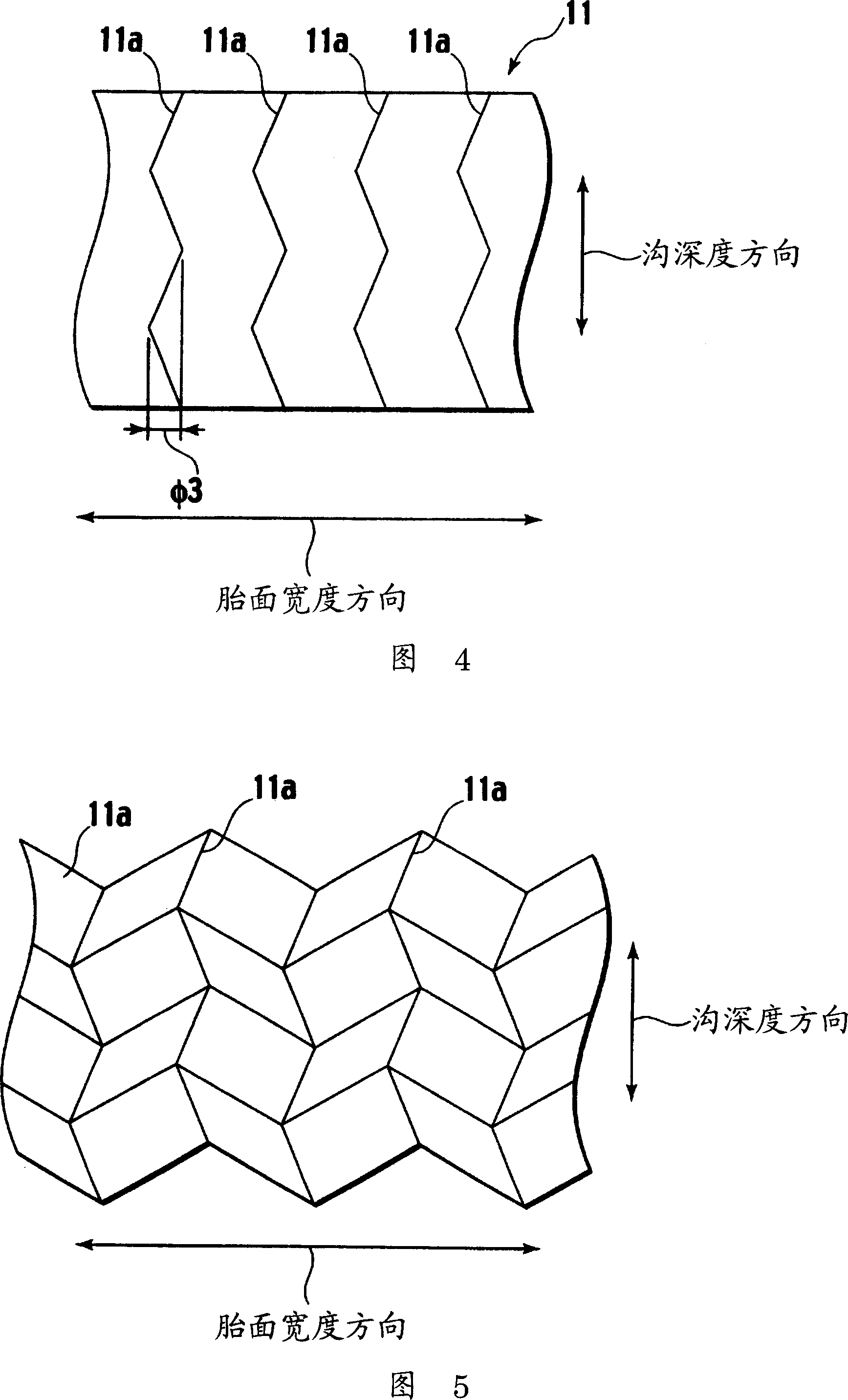

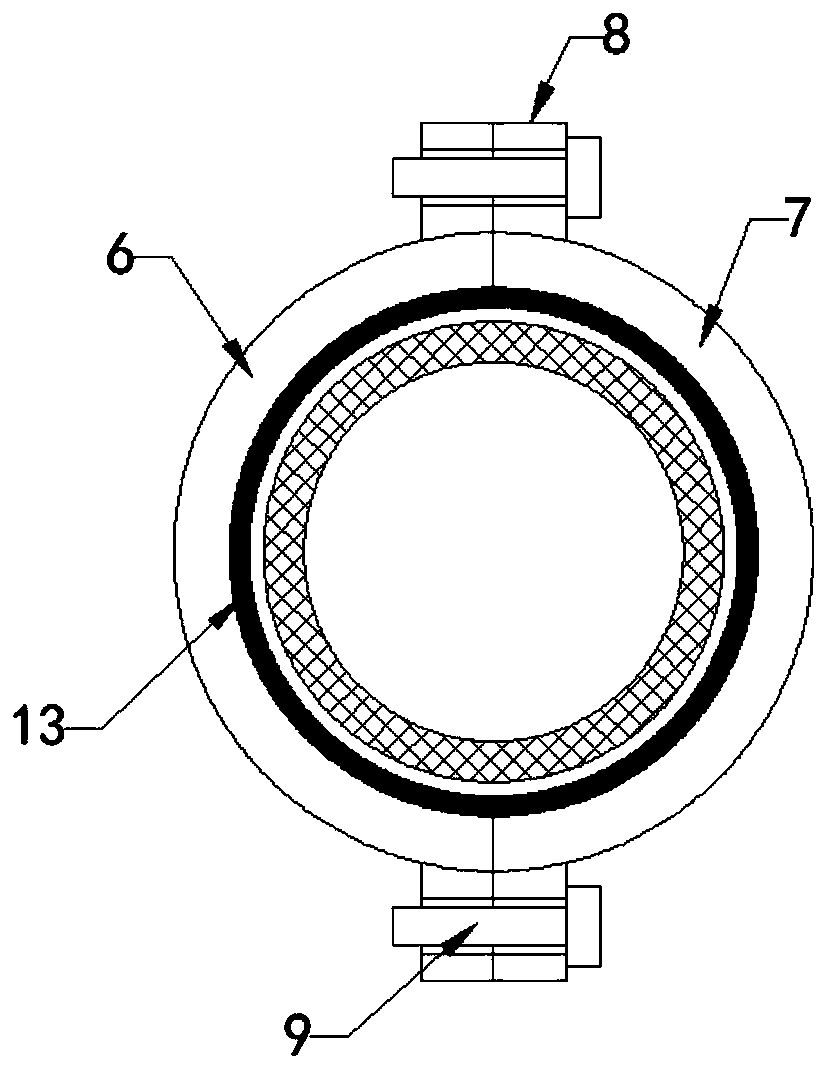

Pneumatic tire

InactiveCN1964859ARigidity does not decreaseNot easy to collapse and deformTyre tread bands/patternsEngineeringMechanical engineering

Owner:BRIDGESTONE CORP

Modified alkaline phenolic resin self-hardening sand for high-precision pump valve castings and preparation method of self-hardening sand

InactiveCN105436393ALow viscosityImprove bonding strengthFoundry mouldsFoundry coresSelf hardeningBonding strength

The invention discloses modified alkaline phenolic resin self-hardening sand for high-precision pump valve castings. A modified phenolic resin adhesive adopted by the resin self-hardening sand has the advantages of being low in viscosity, high in bonding strength, good in plasticity, low in brittleness, lower in content of free phenol and free formaldehyde, fewer in usage amount, low in hardening speed and the like, and therefore the using performance and the reusing performance of the casting sand can be effectively improved; sepiolite fabric porous polypropylene fibers mixed in the sand have high thermal stability and are obvious in toughening effect and reinforcing effect, a complex and uniform meshed structure is formed by the fibers in a sand mold, so that the plasticity of the casting sand is improved, and compactness and air permeability of the casting sand are improved; moreover, the sand can be scattered and stripped more easily in the casting demolding process, so that work efficiency is improved; the modified alkaline phenolic resin self-hardening sand is compact and air-permeable in molding, resistant to molten metal scouring and erosion and small in thermal expansion coefficient, and the sand mold is not prone to deformation or scattering in the pouring process and can be used for pouring of the high-precision pump valve castings.

Owner:合肥李诺新材料贸易有限公司

Bone grafting composite material for alveolar bone augmentation

ActiveCN108283732AHave bone conduction abilityDegradableSurgeryTissue regenerationBone formationBone augmentation

The invention belongs to the technical field of medical treatment, and particularly relates to a bone grafting composite material for alveolar bone augmentation. The bone grafting composite material for alveolar bone augmentation is characterized by being divided into three layers in sequence from interior to exterior, which are an autogenous bone, a support material and a CPC / PLGA compound; the volume ratio of the autogenous bone to the support material is 1:1. The composite material combines application of the autogenous bone, the inorganic element support material, the CPC / PLGA compound andautoblood, on the basis of characteristics of autogenous bone generation and bone induction and the advantages of plasticity, biodegradability and self-solidification-strength of the CPC / PLGA compound, autoblood provides abundant growth factors for bone repair, the bone grafting composite material is ideal, bone regeneration is guided, bone formation is promoted, and the alveolar bone amount is increased.

Owner:GUANGXI MEDICAL UNIVERSITY

Degradable bone regeneration guidance biomembrane, preparation method and application thereof

InactiveCN103349796ANot easy to collapse and deformSuperior strength performance indexSurgeryPeriosteumWound dehiscence

The present invention discloses a degradable bone regeneration guidance biomembrane, a preparation method and an application thereof. According to the present invention, propylene carbonate and poly(butylene succinate) are weighed according to a certain ratio as raw materials, and are dissolved into an organic solvent to prepare a turbid solution, and a salting out method is adopted to synthesize a biomembrane; the biomembrane is mainly applicable for stomatological implant dental department, wherein a bone regeneration space can be long-lastingly maintained and bone regeneration can be promoted in the application of the stomatological department bone defect case; and compared with the biomembrane and the preparation method thereof in the prior art, the biomembrane and the preparation method thereof of the present invention have the following characteristics that: the double layer-like structure similar to the human periosteum can be synthesized through the salting out method, the biomembrane has characteristics of good physical and chemical properties, in vitro bone regeneration guidance bioactivity, low price and the like, a plurality of shortcomings of the existing clinically used biomembrane can be overcome so as to provide an effective biomembrane for stomatological implant dental department clinic and promote bon regeneration, wherein the shortcomings comprise thick biomembrane, large tissue tension in the surgery region, easy wound dehiscence and the like.

Owner:JILIN UNIV

Online pouring molding method for nozzle of heating furnace burner

ActiveCN105135888AExtended service lifeShorten construction timeLinings repairEngineeringHeating furnace

The invention discloses an online pouring molding method for a nozzle of a heating furnace burner. The method comprises the steps that nozzle molds on a burner brick are firstly manufactured; the nozzle molds are arranged at the burner position on a furnace wall during maintenance, corundum mullite castables are poured to a heat storage chamber burner nozzle and the peripheral damaged furnace wall, closing treatment is carried out on the top end closing position and the tail closing position in a high-alumina brick blocking manner, and a separation plate in a heat storage box is repaired through formwork coating materials; and finally, after slurry to be poured is solidified and meets the standard strength requirement, the nozzle molds on the burner brick are demounted, and the nozzle of the burner is molded. Under the condition that the heating furnace burner is damaged, based on the requirement that the nozzle of the burner brick is not changed, the molds are firstly manufactured according to the size of the nozzle of the burner, and then refractory matter is poured to the nozzle to repair the nozzle. The repaired burner is not prone to deforming or collapsing, the service life of the burner on a heating furnace is effectively prolonged, then, construction time is shortened, and the maintenance workload is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

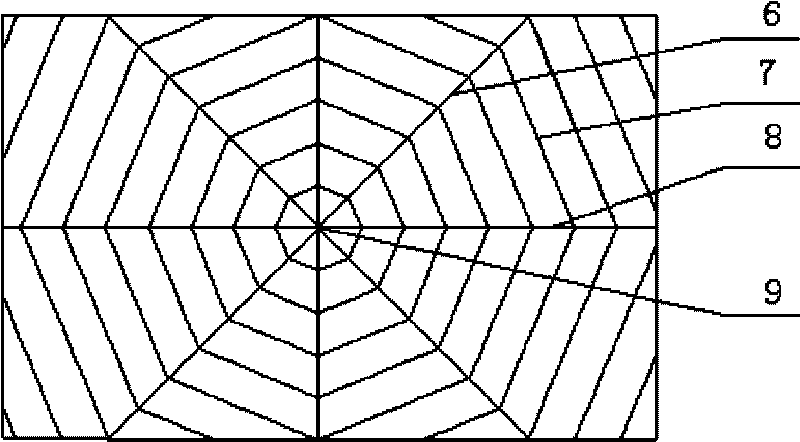

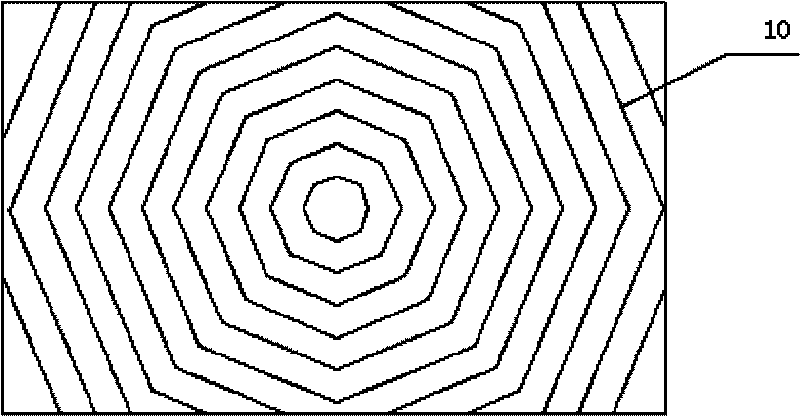

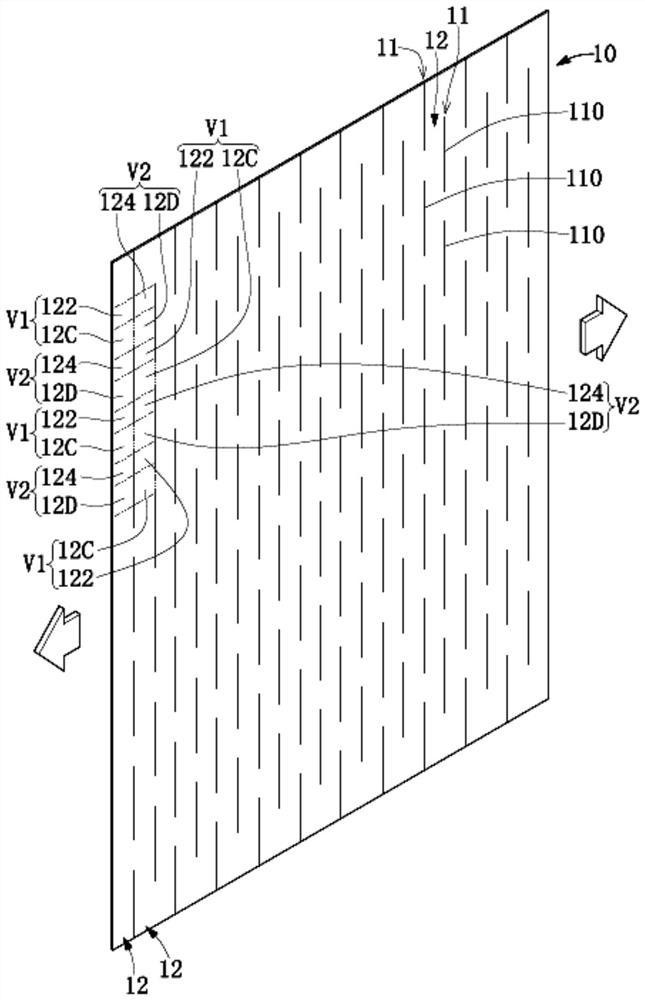

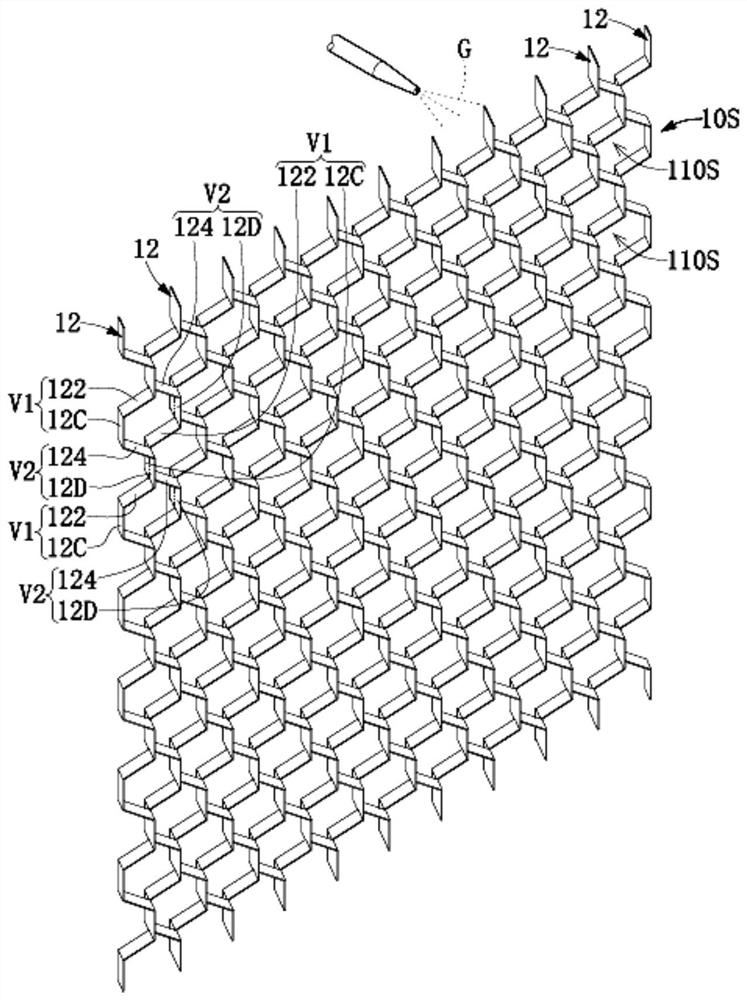

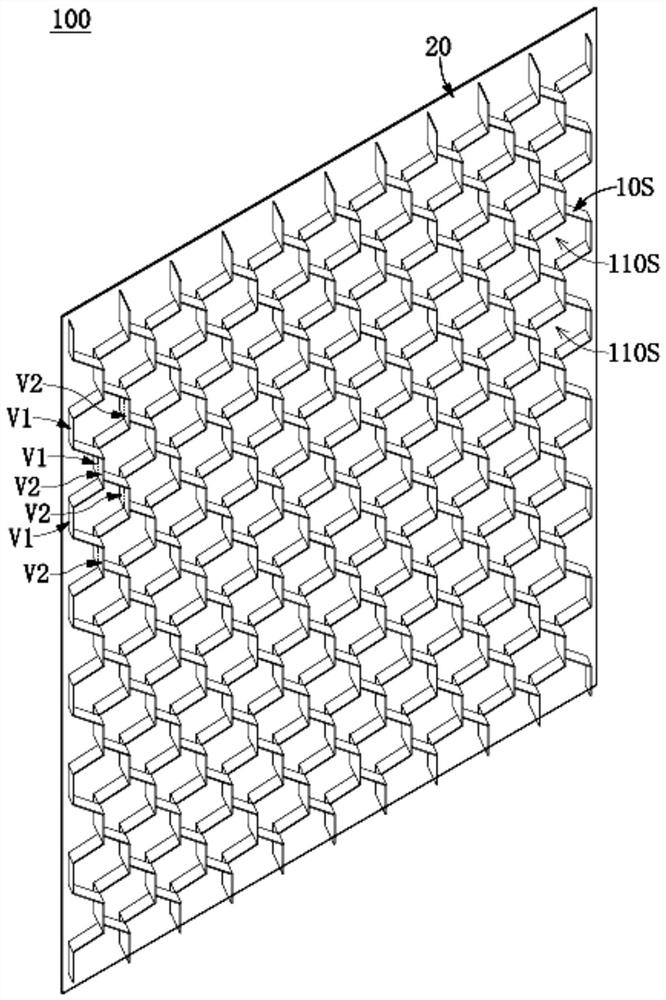

Araneose corrugated board

InactiveCN101705643AExcellent edge compressive strengthHigh composite strength between layersSpecial paperPaper/cardboardCardboardHoneycomb

The invention discloses an araneose corrugated board, which comprises an outer layer panel, a bottom layer panel and two adhesive films, wherein an araneose paper honeycomb core is clamped between the two layers of adhesive films; the araneose paper honeycomb core is formed by adhering honeycomb corrugated paper according to a cobweb structure; outer layer paper is adhered to the araneose paper honeycomb core through the adhesive film; and bottom layer paper is adhered to the araneose paper honeycomb core through the adhesive film. The araneose corrugated board has the advantages of the conventional corrugated board and a honeycomb board, has a simple structure, high strength, impact resistance, high interlayer combined strength, heat insulation, sound adsorption, simple manufacture and low cost, so the araneose corrugated board is particularly suitable for the shipping package of general large workpiece merchandise, especially for a buffering cushion and a box bottom board.

Owner:李新桥

Device used for automatic peeling of potatoes

InactiveCN108741125AAvoid getting stuckImprove efficiencyVegetable peelingFood treatmentSpiral bladeWater flow

The present invention relates to the field of automatic processing and particularly relates to a device used for automatic peeling of potatoes. A material loading mechanism is arranged on a side of atank body; an output end of the material loading mechanism passes through the tank body and is connected with an input end of a peeling device; a waste cleaning device is arranged under the tank body;a filtering device is arranged under the waste cleaning device; a circulation device is arranged above the tank body and connected with the tank body and the filtering device; a material dischargingmechanism is arranged at the side of the tank body; besides, an input end of the material discharging mechanism passes through the tank body and is connected with an output end of a peeling device; the peeling device comprises a water pipe and spiral blades arranged around the water pipe; the water pipe and the spiral blades are hollow; besides, the water pipe communicates with the inside spaces of the spiral blades; and the lower ends of the spiral blades are provided with a plurality of spraying holes. The peeling machine can automatically conduct material feeding; automatic material discharging is conducted after peeling by high-pressure water stream; the high-pressure water stream used for the peeling of the potatoes is filtered; the filtered high-pressure water stream is then reused by the circulation device; and potato peels produced after the peeling can be automatically cleaned to a waste basket.

Owner:刘永萍

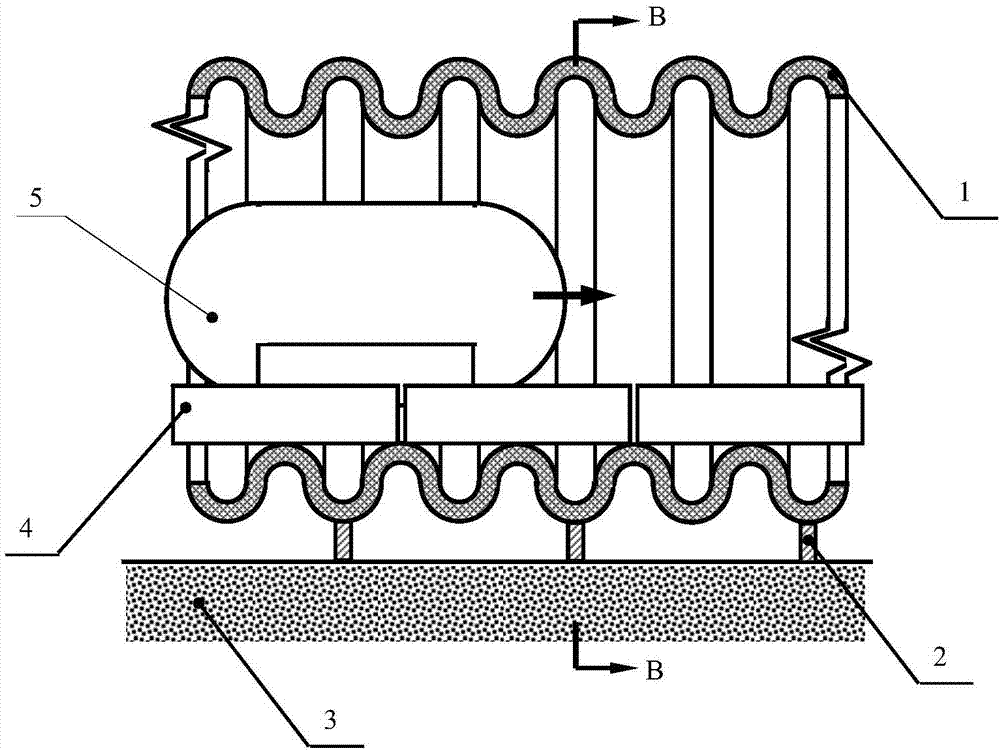

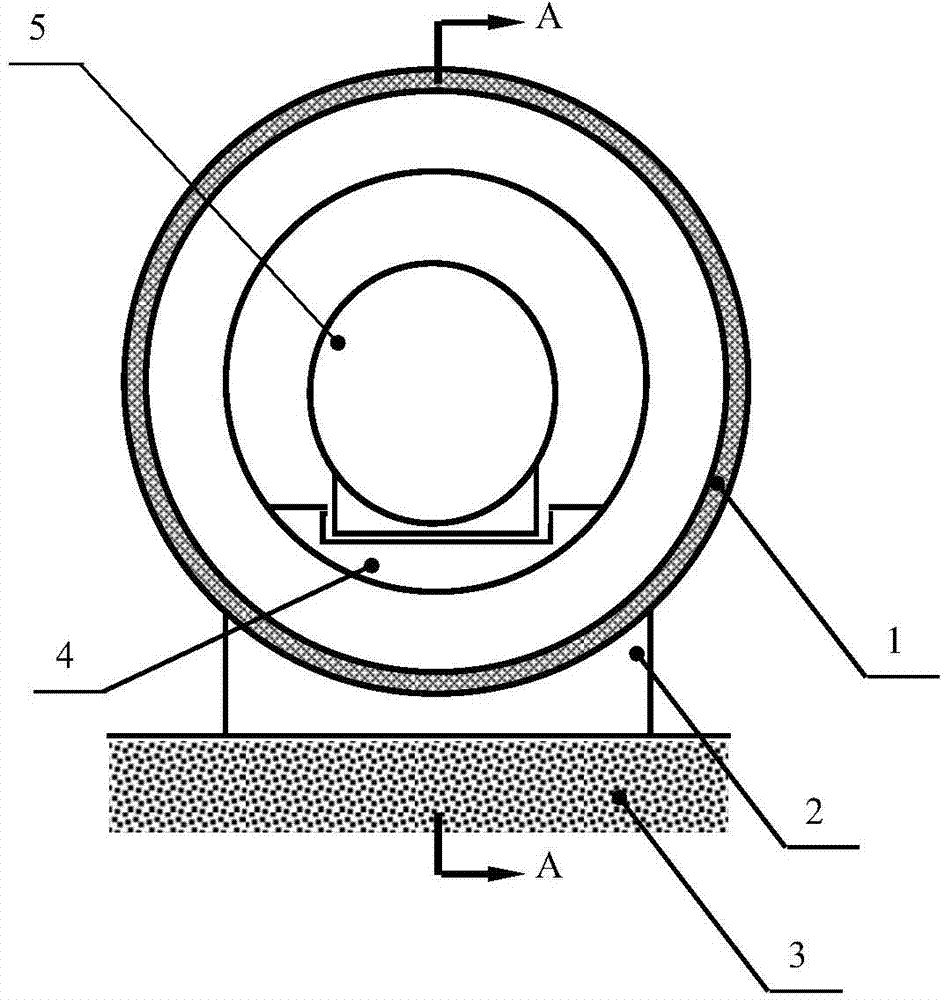

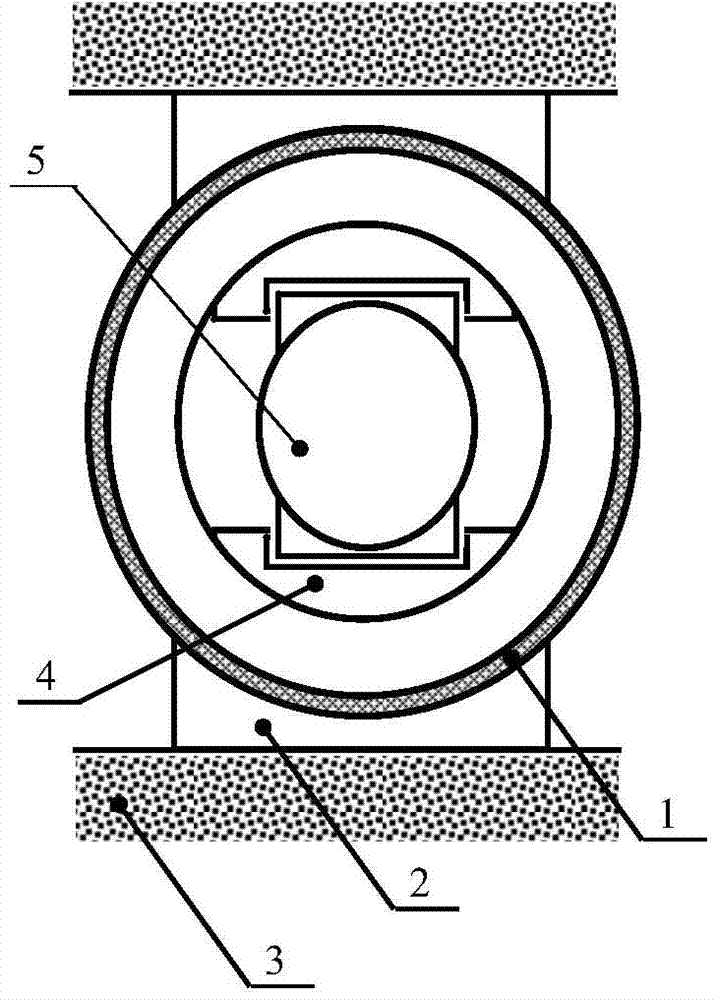

Vacuum magnetic levitation tunnel

ActiveCN103661421AReduce uniformity impactLongitudinal stiffness is smallRailway tunnelsWave crestLevitation

The invention relates to a vacuum magnetic levitation tunnel which comprises a tunnel shell, supports, a roadbed and magnetic levitation blocks for being fixed on the tunnel shell to be suspended and driving a levitation vehicle. The vacuum magnetic levitation tunnel is characterized in that the longitudinal profile of the tunnel shell is a corrugated pipe hook face, and a transverse profile is in a circle or oval shape; one ends of the magnetic levitation blocks are fixed at the positions of the inner side of the bottom of the tunnel shell at equal longitudinally-striding wave pitch number interval, and the other ends of the magnetic levitation blocks are used for sliding supporting; the supports are installed at the positions, at the wave crests equal distance away from the longitudinally-fixing positions of the magnetic levitation blocks, on the outer side of the bottom of the tunnel shell, and the supports are fixed on the roadbed. The buttock line of the corrugated pipe hook face of the tunnel shell is a sine curve and the like. Obviously, fewer materials can be used in the vacuum magnetic levitation tunnel, the longitudinal rigidity of the vacuum magnetic levitation tunnel is reduced to convert the longitudinal internal stress generated by temperature changes into longitudinal elastic deformation, meanwhile, the radial rigidity of the vacuum magnetic levitation tunnel is increased to enable deformation to be not prone to being caused when vacuum and track loads are borne, the temperature change stress is averagely divided by the supports, the uniformity influences of the temperature change stress on magnetic buoyancy and magnetic driving force are reduced, and the components are widely applied to the vacuum magnetic levitation tunnel.

Owner:王昕鑫

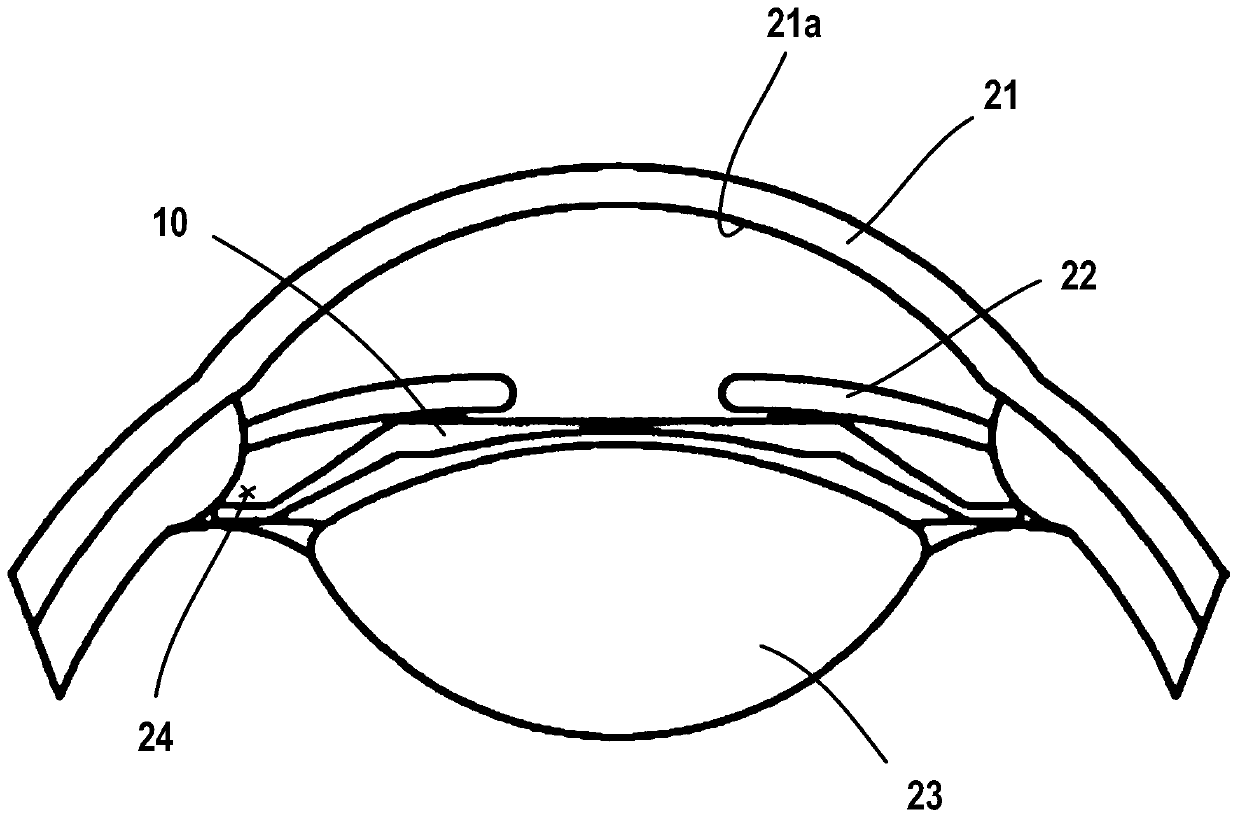

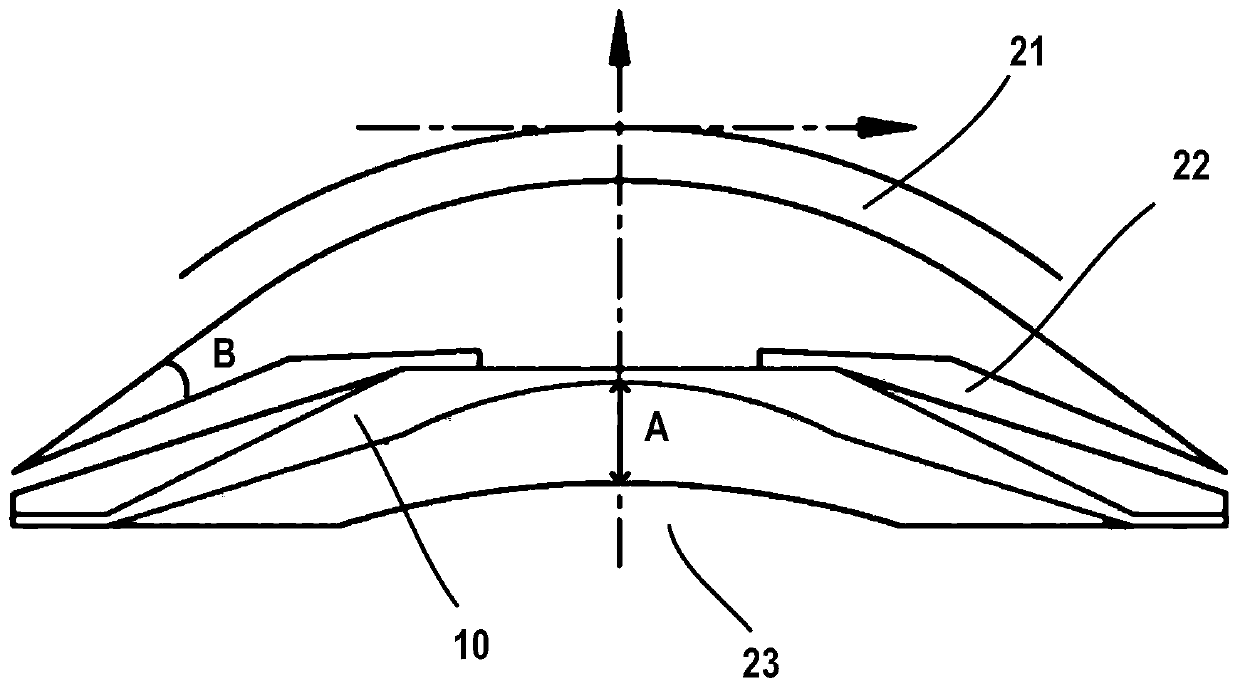

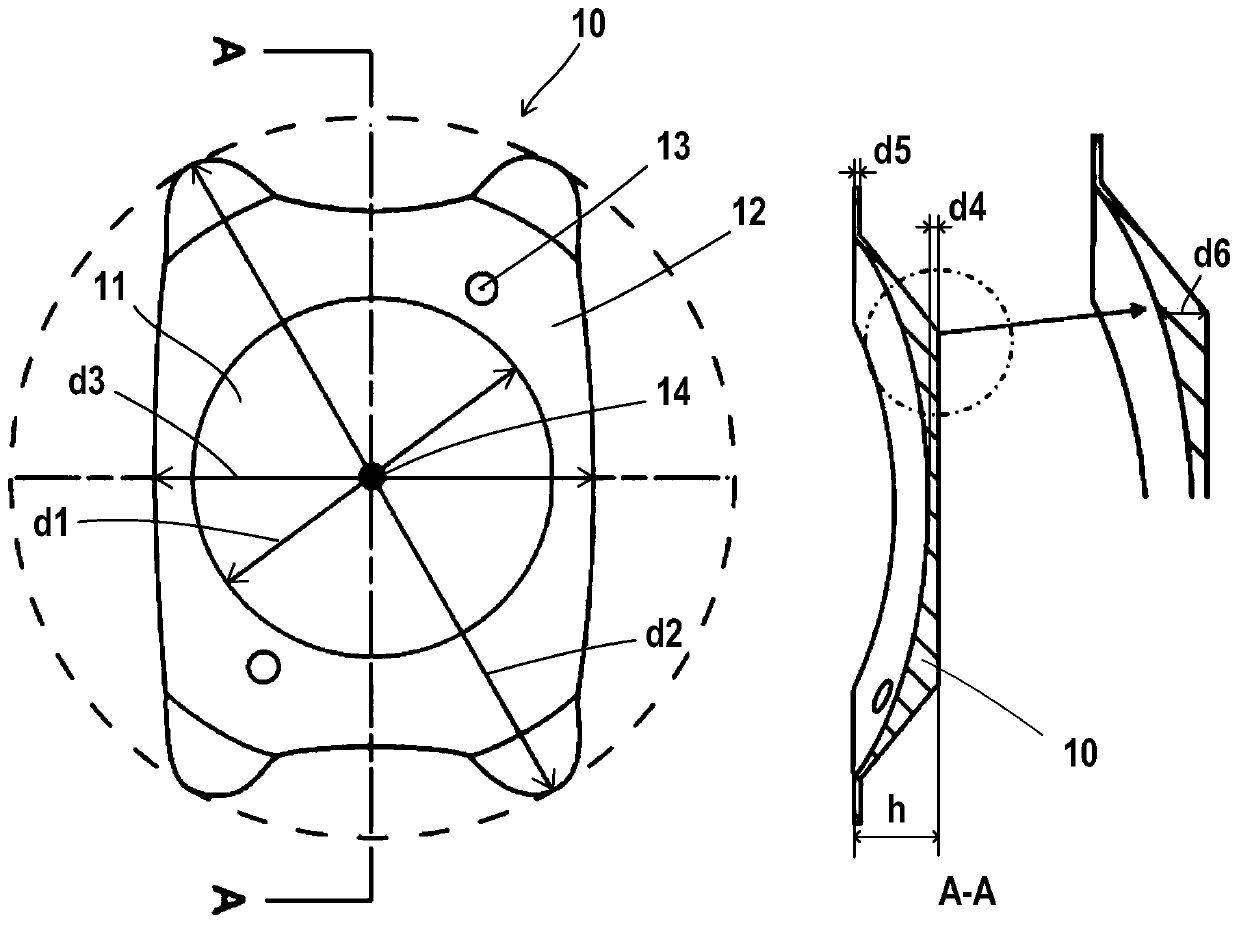

Phakic intraocular lens

PendingCN111358594AExcellent deformation stabilityHigh elastic modulusIntraocular lensOphthalmologyTissue damage

The invention provides a phakic intraocular lens which can maintain stable arch height in eyes. The phakic intraocular lens of the present invention has the following structure. The center thickness of the optical part of the phakic intraocular lens is 0.05-0.25 mm, preferably 0.05-0.20 mm, and more preferably, 0.08-0.18 mm; the thickness of the support part edge is 0.05-0.25 mm, preferably 0.05-0.20 mm, and more preferably, 0.08-0.18 mm; the thickness of the thickest part is 0.1-0.8 mm, preferably 0.15-0.75 mm, and more preferably, 0.15-0.70 mm. By adopting the above structure, as explained in the following embodiments, the phakic intraocular lens of the present invention can maintain stable arch height through the above special size design. The intraocular lens can be kept the arch height, so as not to collapse deformation, and not to cause damage to intraocular tissue due to excessive hardness.

Owner:EYEBRIGHT MEDICAL TECH BEIJING

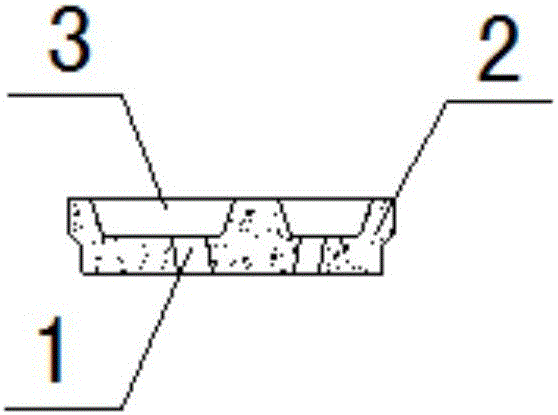

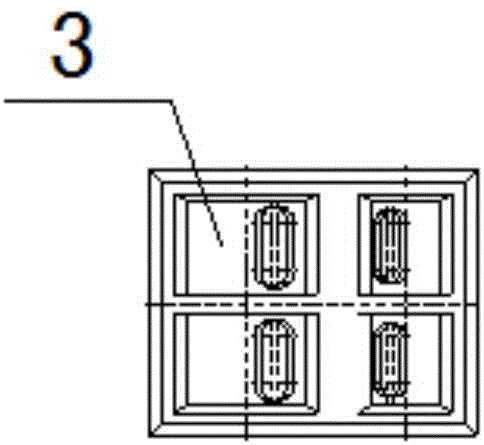

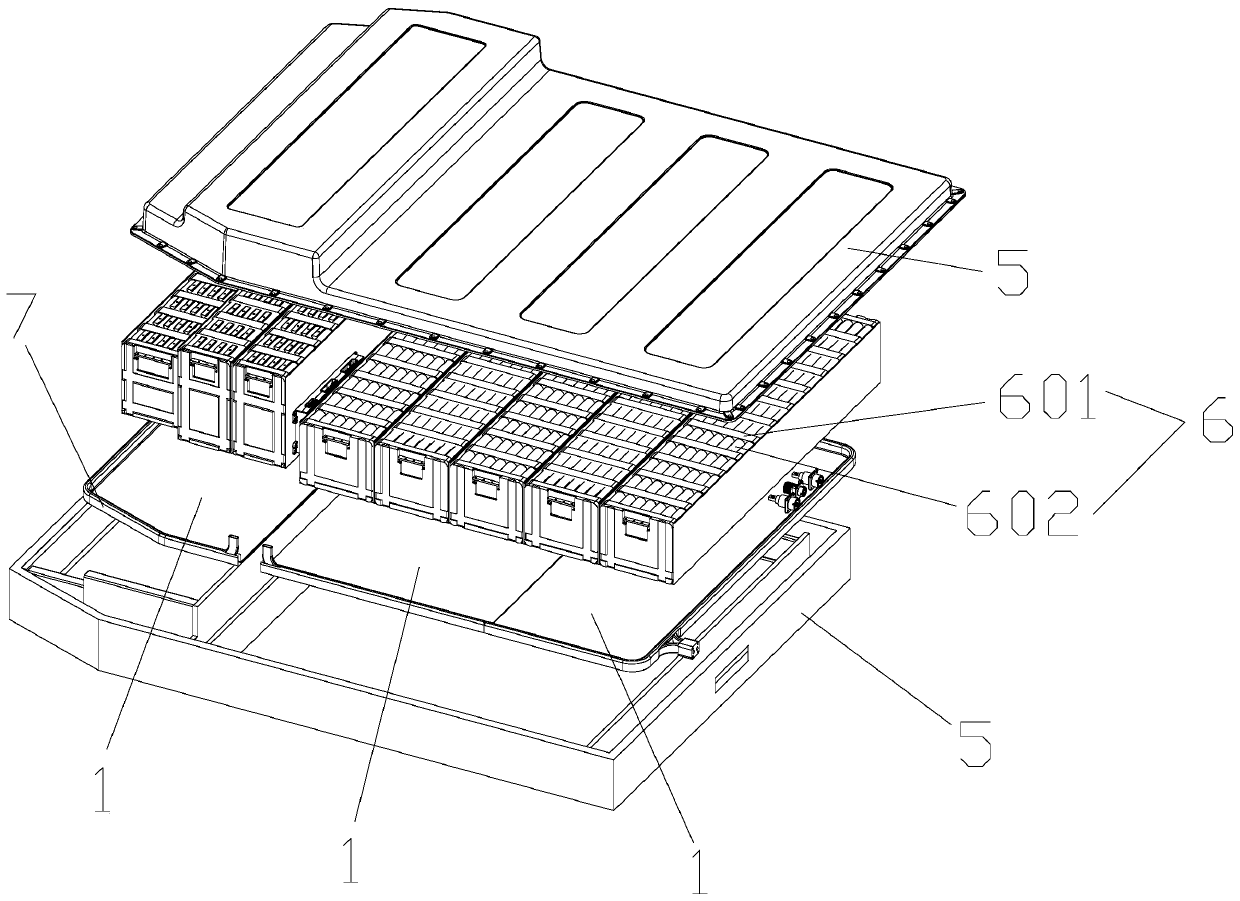

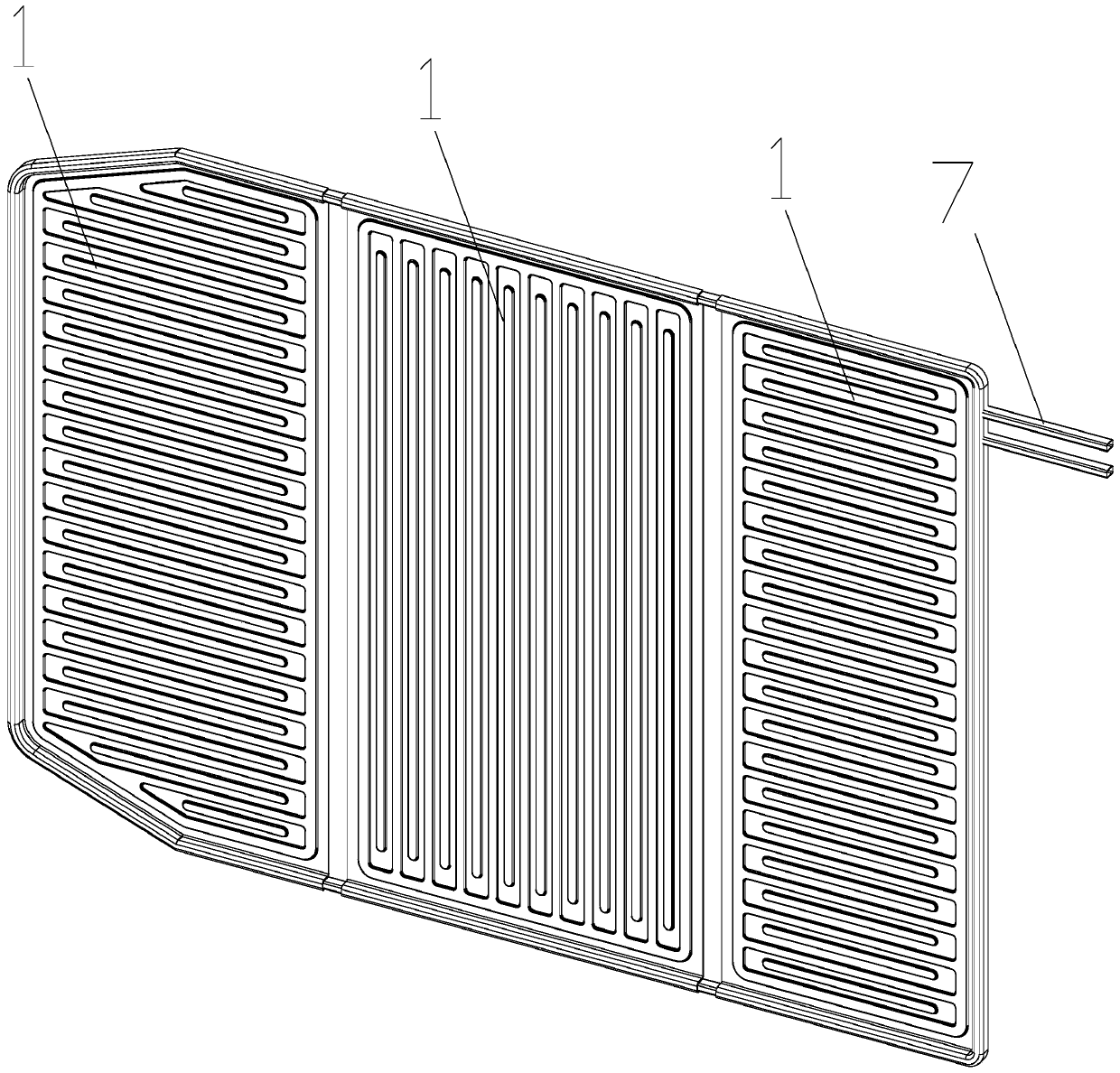

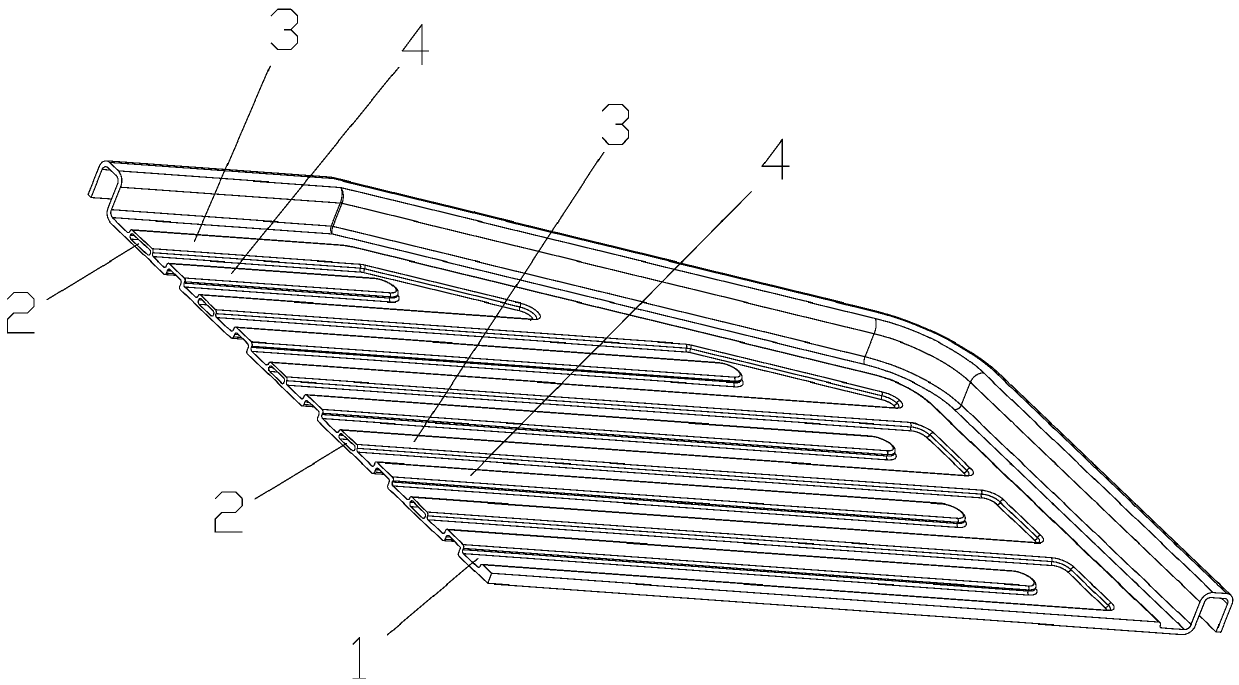

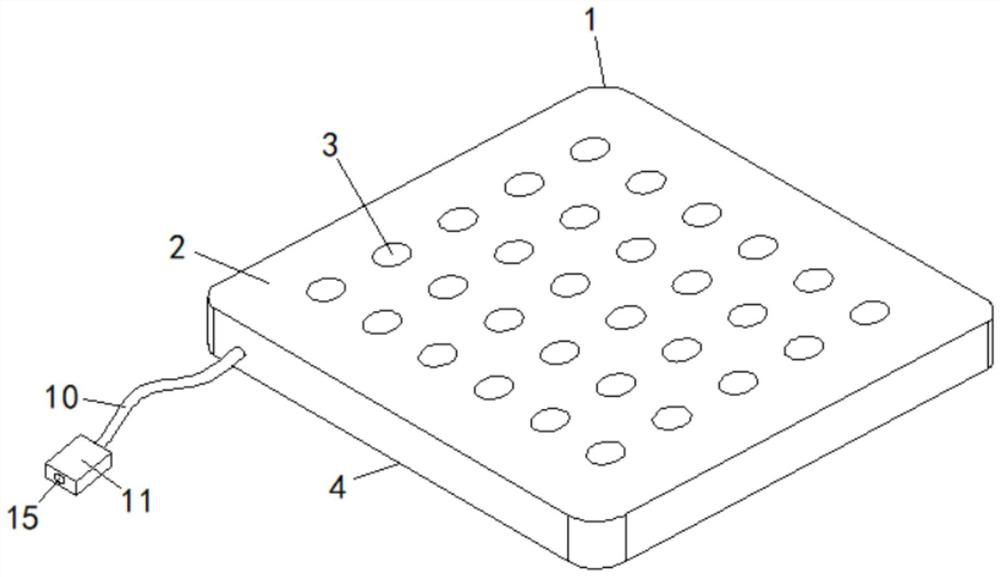

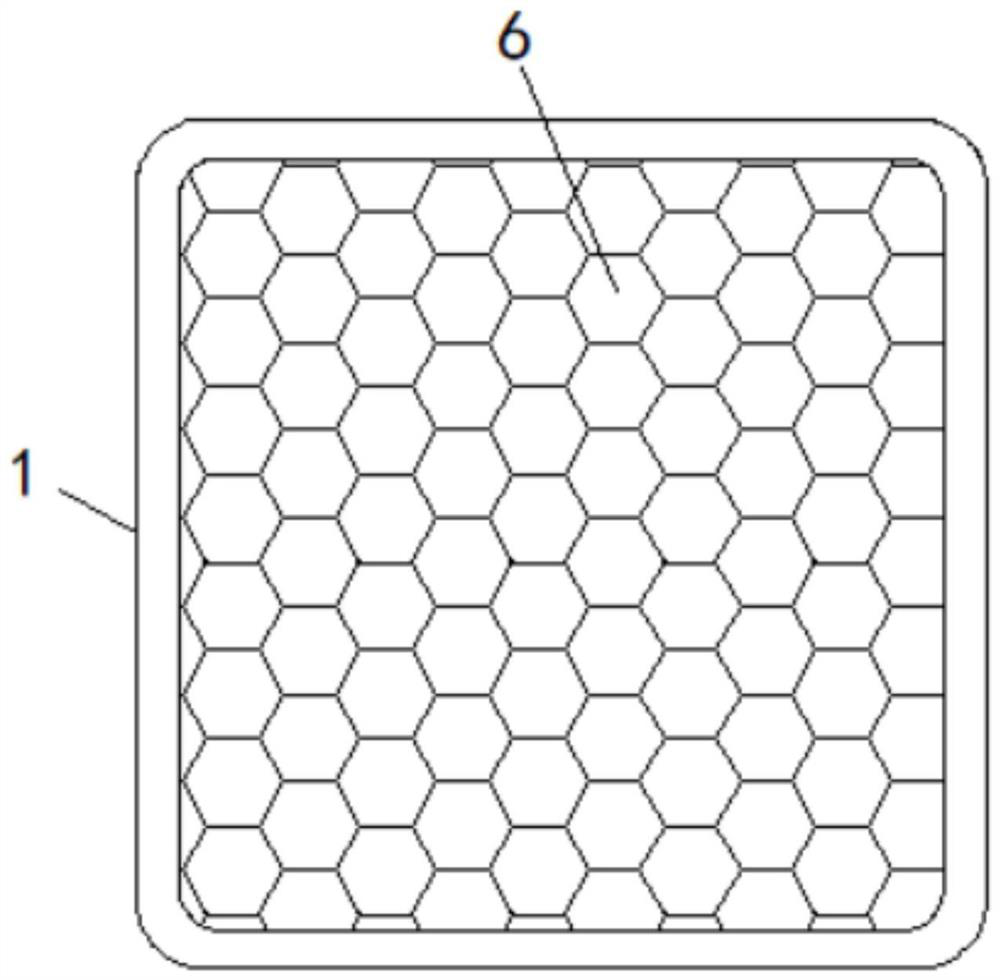

Blow-up type uniform temperature board and battery pack

PendingCN109786893AIncreased load-bearing capacityNot easy to collapse and deformSecondary cellsCell component detailsElectrical and Electronics engineeringBattery pack

The invention discloses a blow-up type uniform temperature board and a battery pack, wherein the blow-up type uniform temperature board comprises a horizontally arranged board body, and a hollow embossment formed at an upper surface of the board body, wherein the inside of the hollow embossment is a blow-up flow channel; the upper surface of the board body is also provided with a load-bearing embossment which is formed through punching the board body and is higher than the hollow embossment. The blow-up type uniform temperature board provided by the invention has very high load-bearing anti-deformation capability.

Owner:SUZHOU ANKAO ENERGY

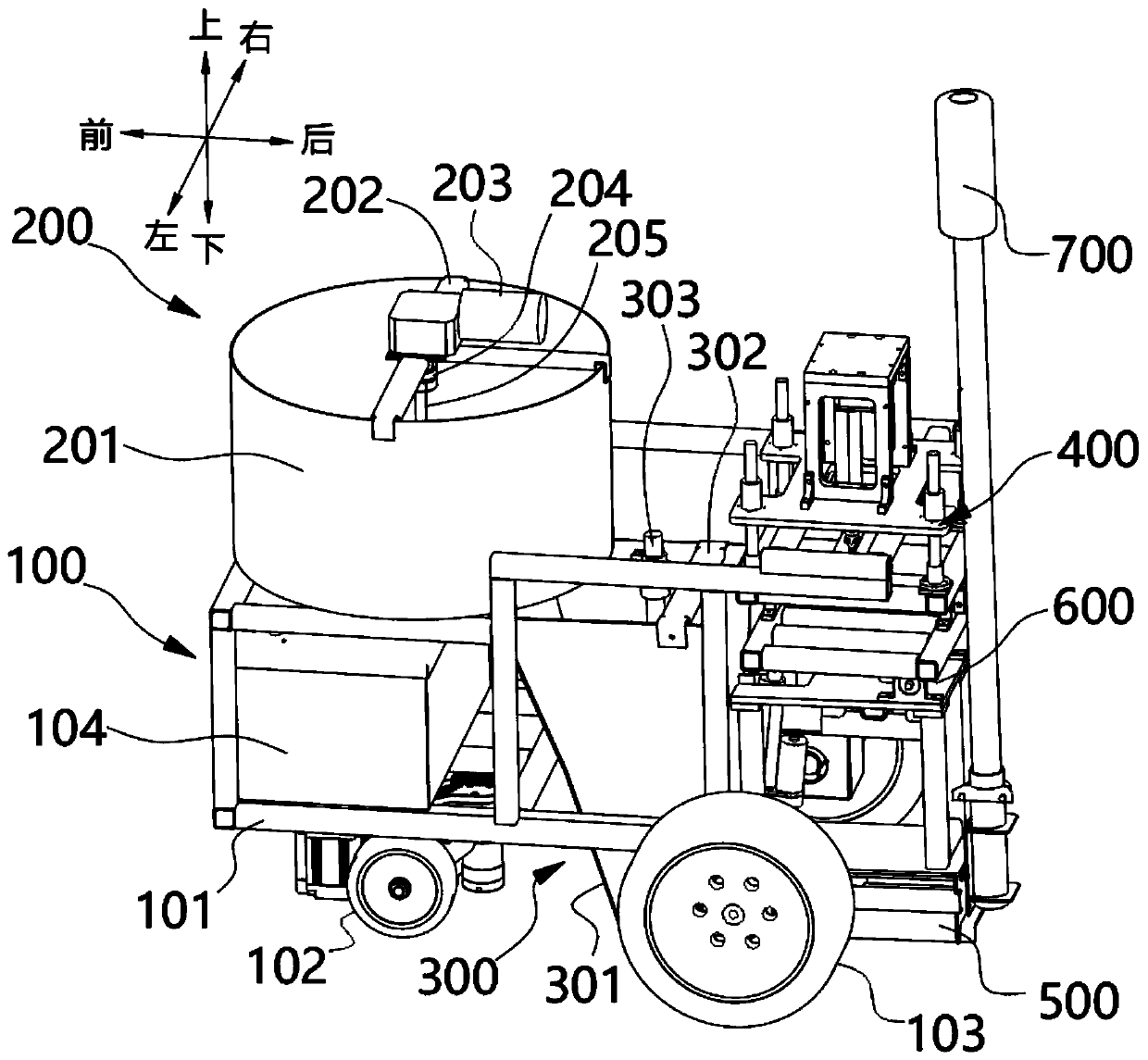

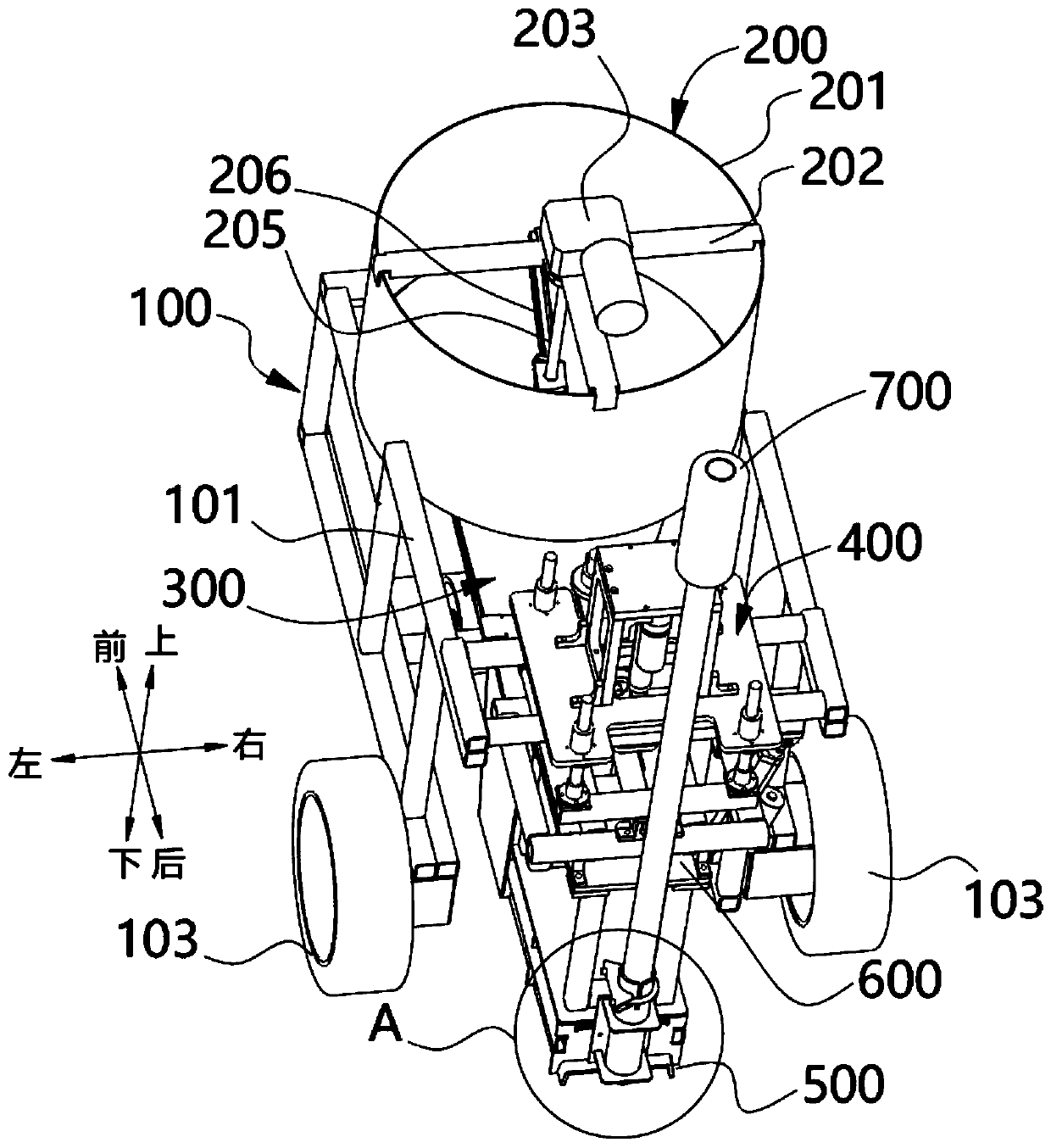

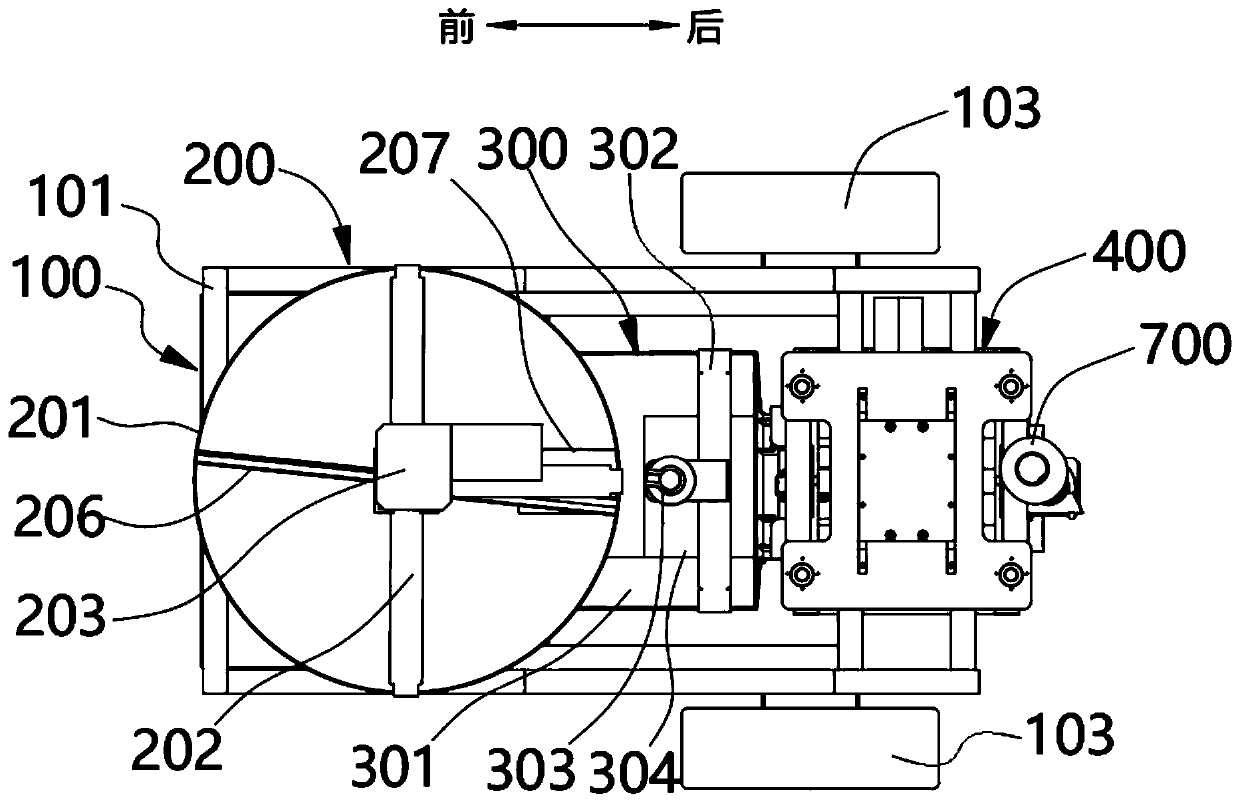

Reference strip generation device and leveling robot

InactiveCN111350335AFast scraping speedQuick levelingMixing operation control apparatusBuilding constructionsMaterials preparationCement slurry

The invention relates to the field of building construction equipment, and particularly relates to a reference strip generation device and a leveling robot. The reference strip generation device comprises a vehicle body, and walking wheels are arranged at the bottom of the vehicle body, wherein a material preparation device is installed on the vehicle body and used for applying cement slurry to the ground; and a reference generation mold positioned behind the material preparation device is further installed on the vehicle body, and when the reference strip generation device moves forwards, thereference generation mold can level and shape the cement slurry output by the material preparation device so as to form a reference strip on the ground. According to the reference strip generation device, the cement slurry is output to the ground through the material preparation device, along with advancing of the vehicle body, the reference generation mold is utilized for leveling and shaping the cement slurry into a strip shape, the reference strip generation speed is high, after the reference strip is hardened, a scraper abuts against the reference strip and moves along the reference strip, and then mortar on the ground can be leveled; and in the leveling process, the adjacent ground does not need to be repeatedly compared or the reference surface does not need to be repeatedly compared, the leveling speed is high, and the efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Corn starch-based foaming material and preparation method thereof

The invention discloses a corn starch-based foaming material and a preparation method thereof. The preparation method includes the steps: (1) uniformly stirring and mixing starch, hydrogen peroxide, ferrous sulfate, water and citric acid, heating mixture to perform oxidation reaction, and cooling and discharging the mixture to obtain a component A for standby application; (2) uniformly stirring and mixing polyvinyl alcohol (PVA), plasticizers and sodium hydrogen carbonate to obtain a component B for standby application; (3) uniformly stirring and mixing the component A, the component B, amideadditives, ethylene-acrylic acid (EAA) copolymers and talcum powder, extruding mixture by a single screw extruder with high compression ratio to obtain the starch-based foaming material. The starch-based foaming material has high resilience ratio and foaming ratio, the compression resilience ratio is higher than or equal to 95% when relative humidity is lower than or equal to 50%, the compressionresilience ratio is higher than or equal to 80% when relative humidity is higher than or equal to 90%, and the overall foaming ratio is higher than or equal to 25 times.

Owner:JIAXING BOFA NEW PLASTIC CO LTD

A kind of PPR thermal insulation composite pipe for home improvement and preparation method thereof

ActiveCN106641585BImprove insulation effectExtended service lifeThermal insulationPipe protection by thermal insulationManufacturing cost reductionThermal insulation

The invention relates to a PPR insulating composite tube for home decoration and a preparation method of the composite tube. The composite tube is of a three-layer composite structure, the inner layer of a PPR or PPR aluminum-plastic composite tube is coated with an expanded polyethylene insulating layer through equipment, the expanded polyethylene insulating intermediate layer is coated with a weather-resistant and scratch-resistant outer protection layer through an extruding machine, closed-cell expanded materials are adopted by the expanded polyethylene insulating layer, the cell sizes range from 0.2 mm to 0.5 mm, and the weather-resistant and scratch-resistant layer is prepared from 60%-90% of LLDPE, 5%-15% of HDPE, 4%-20% of EVOH, 0.5%-2% of silane-modified nano-titanium dioxide and 0.5%-2% of compound additives. The expanded polyethylene insulating layer is obtained through a one-step method. The PPR insulating composite tube has the insulating and energy saving properties and the excellent weather-resistant and scratch-resistant properties, a synchronous coating molding process is adopted in the production process, the production efficiency is improved, the manufacturing cost is reduced, and the PPR insulating composite tube has a good market application prospect.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

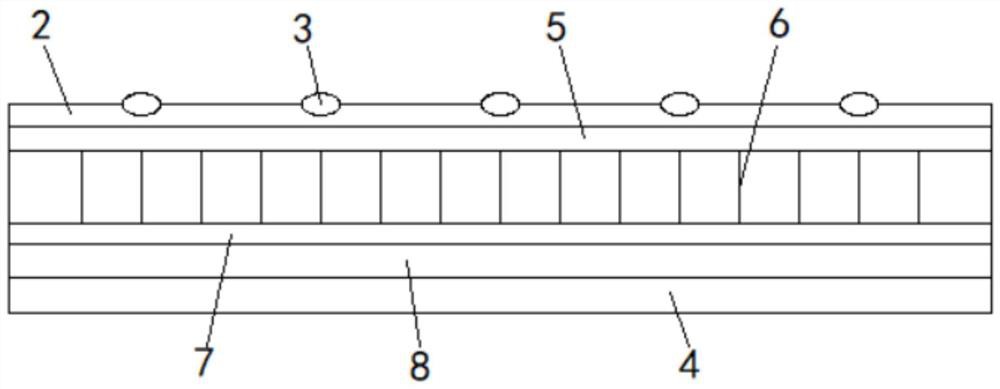

Heat-insulating sound-absorbing baffle and production process thereof

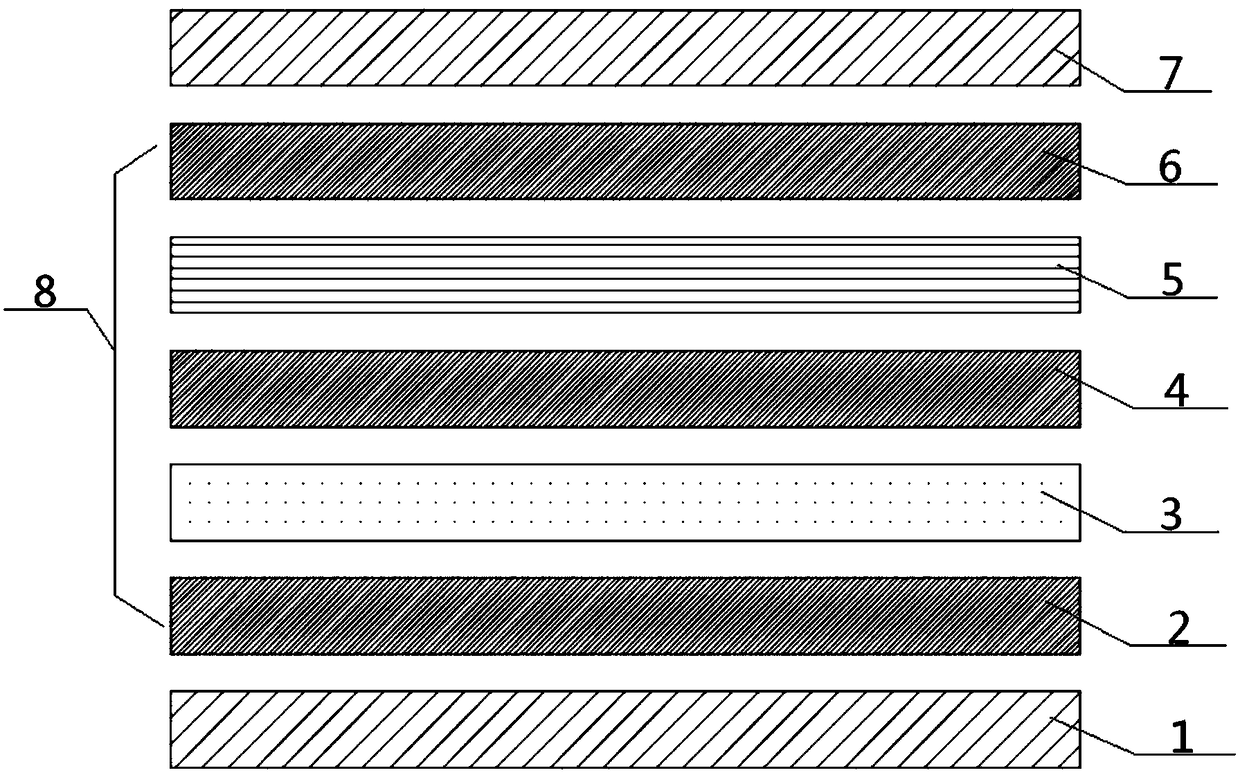

PendingCN109228573AStrong heat/sound insulationStrong firmnessSynthetic resin layered productsLaminationGlass fiberHoneycomb

The invention discloses a heat-insulating sound-absorbing baffle. The heat-insulating sound-absorbing baffle sequentially comprises a bottom plate layer, a first macromolecular film layer, an aluminium silicate layer, a second macromolecular film layer, a support plate layer, a third macromolecular film layer and a face plate layer, wherein the bottom plate layer, the first macromolecular film layer, the aluminium silicate layer, the second macromolecular film layer, the support plate layer, the third macromolecular film layer and the face plate layer are adhered layer by layer; the support plate layer is a light plate layer, preferably a polypropylene hemp fiber plate or a polypropylene honeycomb plate; a fiber porous structure is arranged in the aluminium silicate layer; the bottom platelayer and the face plate layer are aluminum foil layers; the macromolecular film layers are hot melt type adhesive films; and the shapes of the bottom plate layer, the aluminium silicate layer, the support plate layer, the face plate layer, the first macromolecular film layer, the second macromolecular film layer and the third macromolecular film layer are planar or curved. According to the design, glass fibers are not adopted, collapse and deformation are difficult, and the heat insulation and sound absorption effects are strong; and moreover, a connection way has smaller limitation on a layer structure, the rigid support effect is better, the lightweight effect is stronger, and the heat-insulating sound-absorbing baffle is easy to produce and the price performance is higher.

Owner:DONGFENG COMML VEHICLE CO LTD

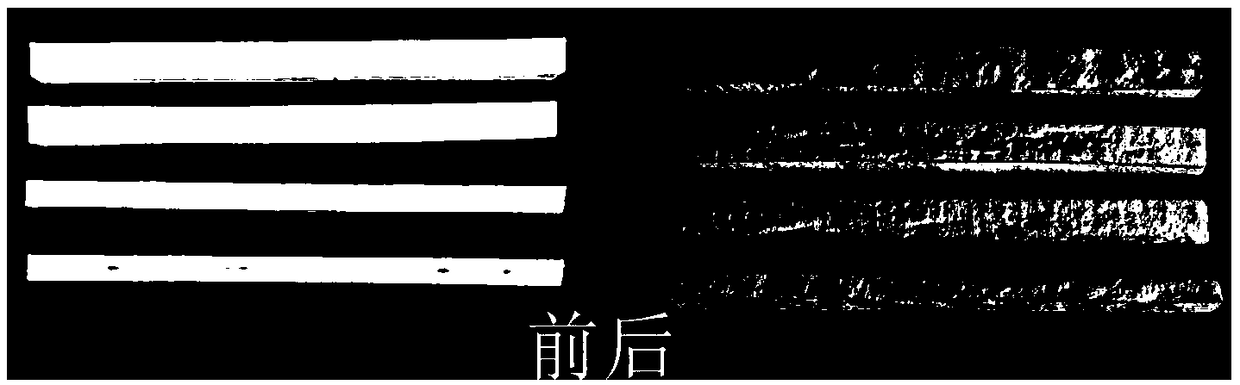

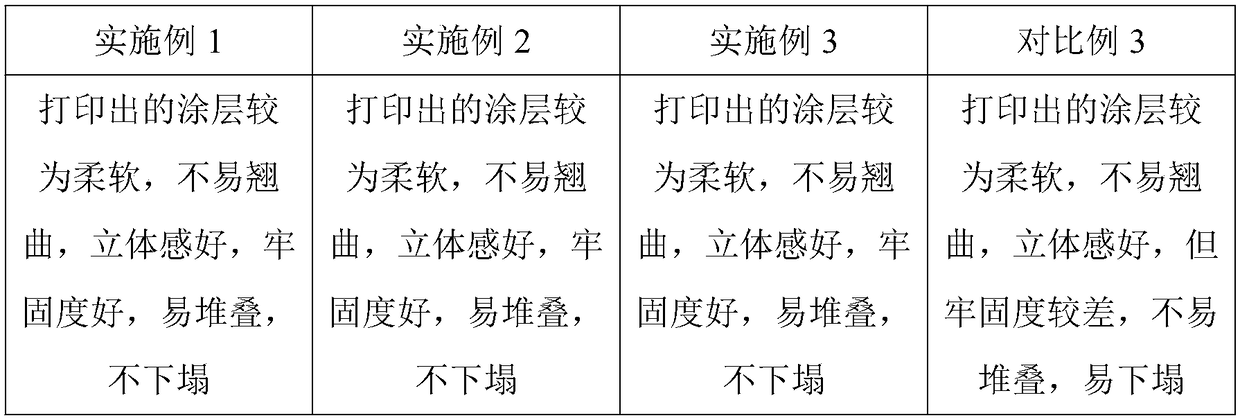

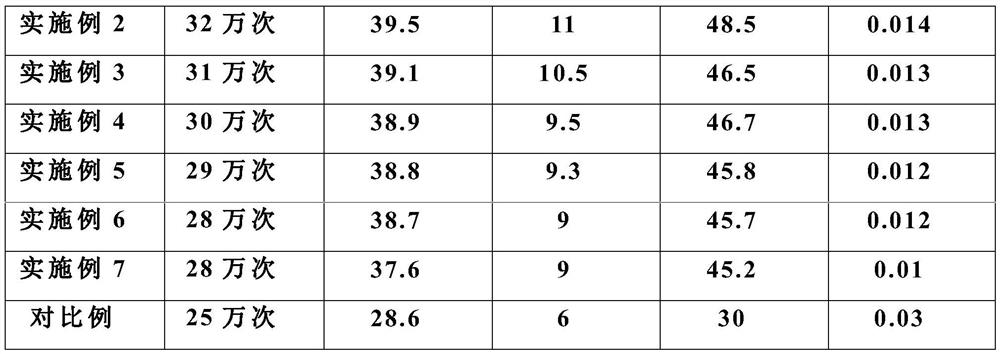

A kind of acrylic resin for water-based 3D printing ink and preparation method thereof

The invention belongs to the technical field of 3D printing materials, and in particular relates to an acrylic resin for water-based 3D printing ink and a preparation method thereof. The acrylic resin for water-based 3D printing ink provided by the present invention comprises the following components and parts by mass: 38-45 parts of monomer mixture, 0.2-0.5 parts of initiator, 15-36 parts of n-butanol, glycidyl methacrylate 3.6-4.8 parts of ether, 5-12 parts of fumed silica, 1-2 parts of carboxymethyl chitosan active substance and 30-40 parts of deionized water. The acrylic resin for water-based 3D printing ink provided by the present invention can prepare a coating on the surface of textiles by printing, and the prepared coating has a good three-dimensional effect, high efficiency, good firmness, easy stacking, and no collapse.

Owner:广东立得新材料科技有限公司

A bone graft composite material for alveolar bone augmentation

ActiveCN108283732BEnough supportNot easy to collapse and deformSurgeryTissue regenerationBone formationBone augmentation

The invention belongs to the technical field of medical treatment, and particularly relates to a bone grafting composite material for alveolar bone augmentation. The bone grafting composite material for alveolar bone augmentation is characterized by being divided into three layers in sequence from interior to exterior, which are an autogenous bone, a support material and a CPC / PLGA compound; the volume ratio of the autogenous bone to the support material is 1:1. The composite material combines application of the autogenous bone, the inorganic element support material, the CPC / PLGA compound andautoblood, on the basis of characteristics of autogenous bone generation and bone induction and the advantages of plasticity, biodegradability and self-solidification-strength of the CPC / PLGA compound, autoblood provides abundant growth factors for bone repair, the bone grafting composite material is ideal, bone regeneration is guided, bone formation is promoted, and the alveolar bone amount is increased.

Owner:GUANGXI MEDICAL UNIVERSITY

Composite material for manufacturing dry powder fire extinguisher nozzle and method for manufacturing nozzle using same

Owner:苏州厚利春塑胶工业股份有限公司

Preparation method of velvet foaming mattress

The application discloses a preparation method of a velvet foaming mattress. The preparation method comprises the step of weighing velvet, triethylamine, polyether triols, methane dioxide, purified water, an AC foaming agent, silicone oil, ethylenediamine polyether, white oil, barium stearate, petroleum jelly, methylbenzotriazole, tetrabromoethane, butane and phenolsulfonic acid; the velvet foaming mattress has the characteristics that the relative density is low, the compressive strength is 290 to 330 MPa, the tear strength is 5 to 9 N / cm and the low-temperature resistance is realized; in addition, the velvet foaming mattress has the disability of 60 to 80 percent, and the product is soft, high in durability, low in possibility of collapse and deformation, high in bearing performance andlow in water absorption; the elongation is 260 to 440 percent, and the product has the advantages of antibacterial property, mildew resistance, good process stability, long service life, low possibility of worm damage and off-fire self-extinguishing; furthermore, the product has no change when being put into a high temperature-resisting oven at the temperature of 150 DEG C for 8 to 12 hours, the tensile strength is 460 to 480 MPa, and the bonding strength is 340 to 440 MPa.

Owner:苏州市苏真床垫有限公司

A kind of starch-based foaming material and preparation method thereof

The invention discloses a starch-based foam material and a preparing method thereof. The preparing method comprises the steps of 1, stirring starch, hydrogen peroxide, ferrous sulfate, water and citric acid to be uniformly mixed, afterwards, heating to conduct an oxidizing reaction, and cooling for discharging to obtain a component A for use; 2, stirring polyvinyl alcohol (PVA), plasticizer and sodium bicarbonate to be uniformly mixed to obtain a component B for use; 3, stirring the component A, the component B, amide-type additives, ethylene-acrylic acid (EAA) and talcum powder to be uniformly mixed, extruding the mixture through a single screw extruder with a high compression ratio to be foamed and formed, and obtaining the starch-based foam material. The starch-based foam material has ahigh resilience rate and a high foaming ratio, and when the relative humidity is smaller than or equal to 50%, the compression resilience ratio is larger than or equal to 95%; when the relative humidity is larger than or equal to 90%, the compression resilience ratio is larger than or equal to 80%, and the overall foaming rate is larger than or equal to 25 times.

Owner:SOUTH CHINA UNIV OF TECH

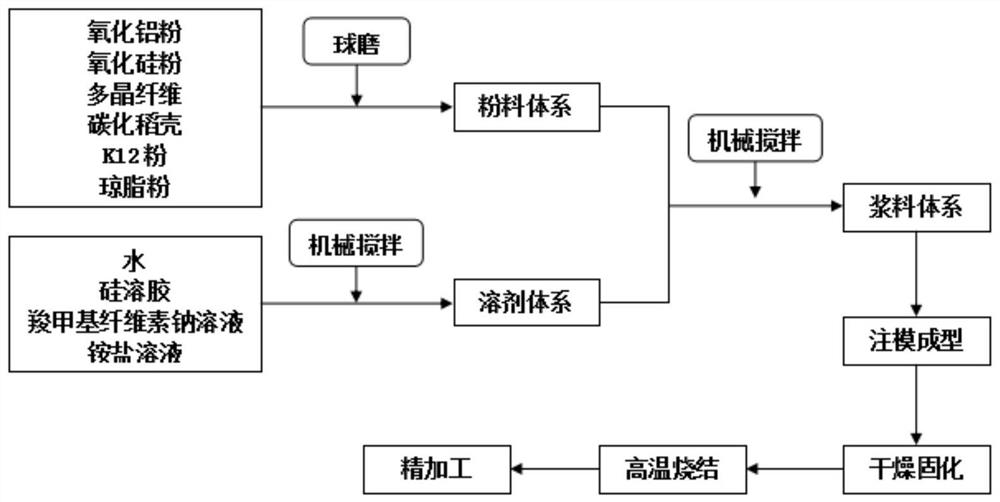

A kind of preparation method of microporous high temperature resistant lightweight refractory brick

ActiveCN111302830BLow densityGood heat insulation and energy saving effectCeramicwareCelluloseMullite

The invention discloses a preparation method of a microporous high temperature resistant lightweight refractory brick, and relates to the technical field of refractory bricks. The microporous high temperature resistant lightweight refractory brick is made of refractory grade alumina powder, polycrystalline mullite fiber and silicon powder It is ceramic aggregate, carbonized rice husk is used as pore-forming agent, water is used as solvent, silica airgel is used as binder, sodium carboxymethyl cellulose solution is used as foam stabilizer, and ammonium salt solution is used as dispersion agent. Agent, K12 powder is used as foaming agent, and agar powder is used as molding agent. The structure of this product is simple to manufacture, and the cost is low. The microporous lightweight brick produced has low density, low thermal conductivity, good heat insulation and energy saving effect, strong acid and alkali corrosion resistance, and long service life.

Owner:张家港市盛澳电炉科技有限公司

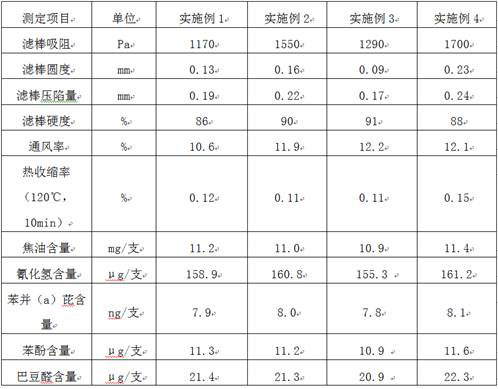

A polylactic acid tow for cigarettes, its preparation method and its application

ActiveCN110656396BGood deformation resilienceNot easy to collapse and deformTobacco smoke filtersMonocomponent polyesters artificial filamentCelluloseThermoplastic

The invention provides a polylactic acid tow for cigarettes, which is made of the following raw materials in parts by weight: L-lactide, stannous octoate, polyene thermoplastic PP masterbatch, food-grade silica gel masterbatch, oligomeric lactic acid-β-ring Dextrin, food grade sodium carbonate, polyethylene glycol oleate, hydroxymethylcellulose, deionized water. The present invention also provides a preparation method of polylactic acid tobacco tow, including rinsing, drying, direct melting, melt extrusion, polymerization, extrusion devolatilization, melting, mixing, microwave treatment, spinning, cooling, Winding, drawing, curling, drying. The invention also provides the application of making the polylactic acid tobacco tow into a cigarette filter. The invention has beneficial effects: the cigarette filter tip has moderate suction resistance range, good adsorption effect on harmful substances in smoke, good deformation resilience, moderate ventilation rate, good thermal shrinkage performance and good physical properties.

Owner:孔令孝 +1

Sandwich type cushion packaging material and manufacturing method thereof

PendingCN113428505ANot easy to collapse and deformStable supportContainers to prevent mechanical damagePack materialSandwich type

The invention discloses a sandwich type cushion packaging material. The material comprises a support cushion layer and at least one outer surface layer, wherein the support buffer layer comprises a plurality of cutting lines and a plurality of ribs; one rib is formed between every two adjacent cutting lines; each rib is provided with a plurality of first side convex parts and a plurality of second side convex parts which extend in a staggered mode; the first side convex part of one rib of two adjacent ribs is partially connected to the second side convex part of the other rib. and the at least one outer surface layer is adhered to the plurality of first side convex parts of the support buffer layer or the plurality of second side convex parts of the support buffer layer. The invention further provides a manufacturing method of the sandwich type cushion packaging material.

Owner:KUNSHAN AIRBAG PACKING CORP

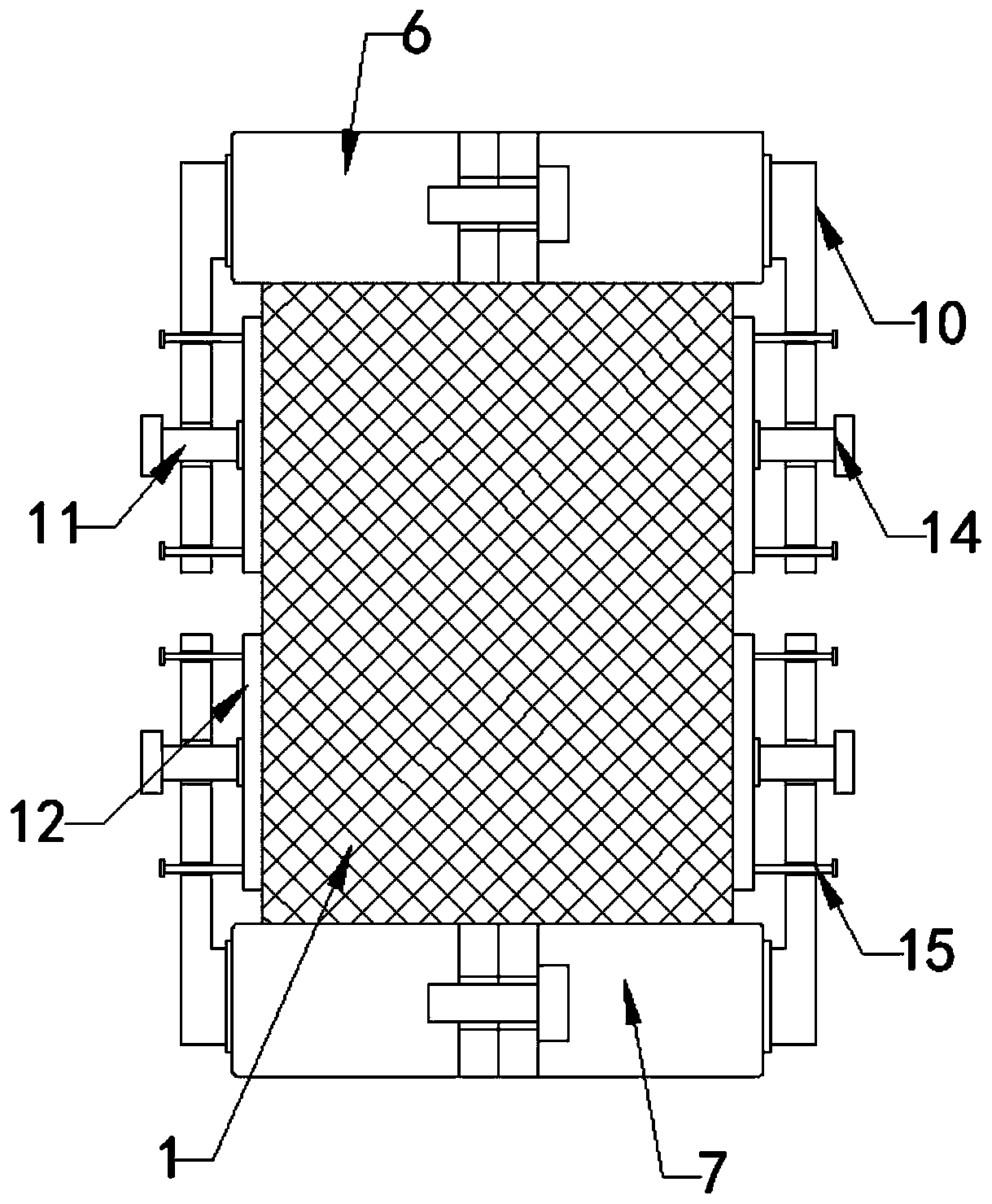

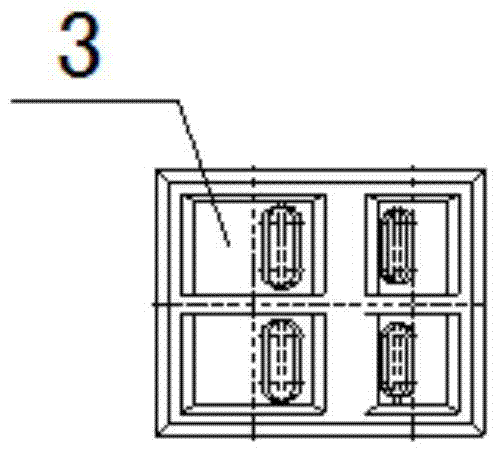

Filter element and manufacturing method thereof

InactiveCN111481981AEfficient killingNot easy to collapse and deformSynthetic resin layered productsFiltration circuitsThreaded rodFilter element

The invention discloses a filter element and a manufacturing method thereof. The filter element comprising a filter element body, wherein the filter element body comprises a framework fiber layer; a rough filtration fiber layer is arranged on the inner side of the framework fiber layer; an adsorption fiber layer is arranged on the inner side of the rough filtration fiber layer; a refined filtration fiber layer is arranged on the inner side of the adsorption fiber layer; a first fixing plate and a second fixing plate are arranged on the two sides of the two ends of the filter element body correspondingly. Locking plates are fixedly connected to the two ends of the first fixing plate and the two ends of the second fixing plate correspondingly. A locking rod is inserted between the two locking plates; a connecting rod is fixedly connected to the outer side walls of the first fixing plate and the second fixing plate; a threaded rod is inserted into the connecting rod in threaded mode, oneend of the threaded rod is rotationally connected with a positioning plate, and one side of the positioning plate abuts against the outer wall of the filter element body; collapse and deformation arenot likely to happen, the filtering precision is high, activated carbon fibers can effectively kill bacteria, the purifying effect is improved, the filter element is stable in the using process, and the filtering effect is improved.

Owner:YANSHAN UNIV

Pottery clay particle cushion capable of eliminating fatigue

PendingCN111802854AHave a relaxing massage effectEffective relaxing massage effectStuffed mattressesChiropractic devicesMotor vibrationClassical mechanics

The invention discloses a pottery clay particle cushion capable of eliminating fatigue, which comprises a cushion body, an upper cushion surface and a lower cushion surface, wherein massage pottery clay particles are fixedly connected to the outer surface of the upper cushion surface; an upper elastic buffer layer is fixedly connected below the upper cushion surface; an elastic supporting pad is fixedly connected to the lower portion of the upper elastic buffer layer, the elastic supporting pad is a honeycomb hole-shaped silica gel pad, a balance vibration plate is fixedly connected to the lower portion of the elastic supporting pad, a motor vibration plate is fixedly connected to the lower portion of the balance vibration plate, and the lower portion of the motor vibration plate is fixedly connected with the lower cushion surface.The seat cushion can be conveniently used, the relaxing effect of the seat cushion is remarkably enhanced, the body is further relaxed through the vibrationfunction, fatigue is eliminated, and the practicability is high.

Owner:陕西新容康医疗器械有限公司

Preparation method of coconut palm fiber foaming mattress

The invention discloses a preparation method of a coconut palm fiber foaming mattress. Coconut palm fiber, hexahydrotriazine, isocyanate, triethylenediamine, methyl diisocyanate, triethanolamine, water-soluble silicone oil, pure water, dibutyltin dilaurate, an AC foaming agent, DCP, decabromodiphenyl ether, fatty acid amide, butyl acetate and acetic anhydride are weighed; the preparation method is simple, the cost is low, the maneuverability is strong, the compressive strength is 280-320MPa, the rebound rate is 99% to 99.8%; the tear strength is 5 to 7N / cm, the product is soft, high in durability, not easy to collapse and deform, and high in supporting performance; the elongation is 200 to 240%, and the mattress is antibacterial, mildew-proof, good in process stability, long in service life, and not easy to eat by moth; the tensile strength is 230 to 330MPa, the bond strength is 220 to 280MPa, and the raw material is wide in source, and can be widely produced and continue to replace existing materials.

Owner:苏州市苏真床垫有限公司

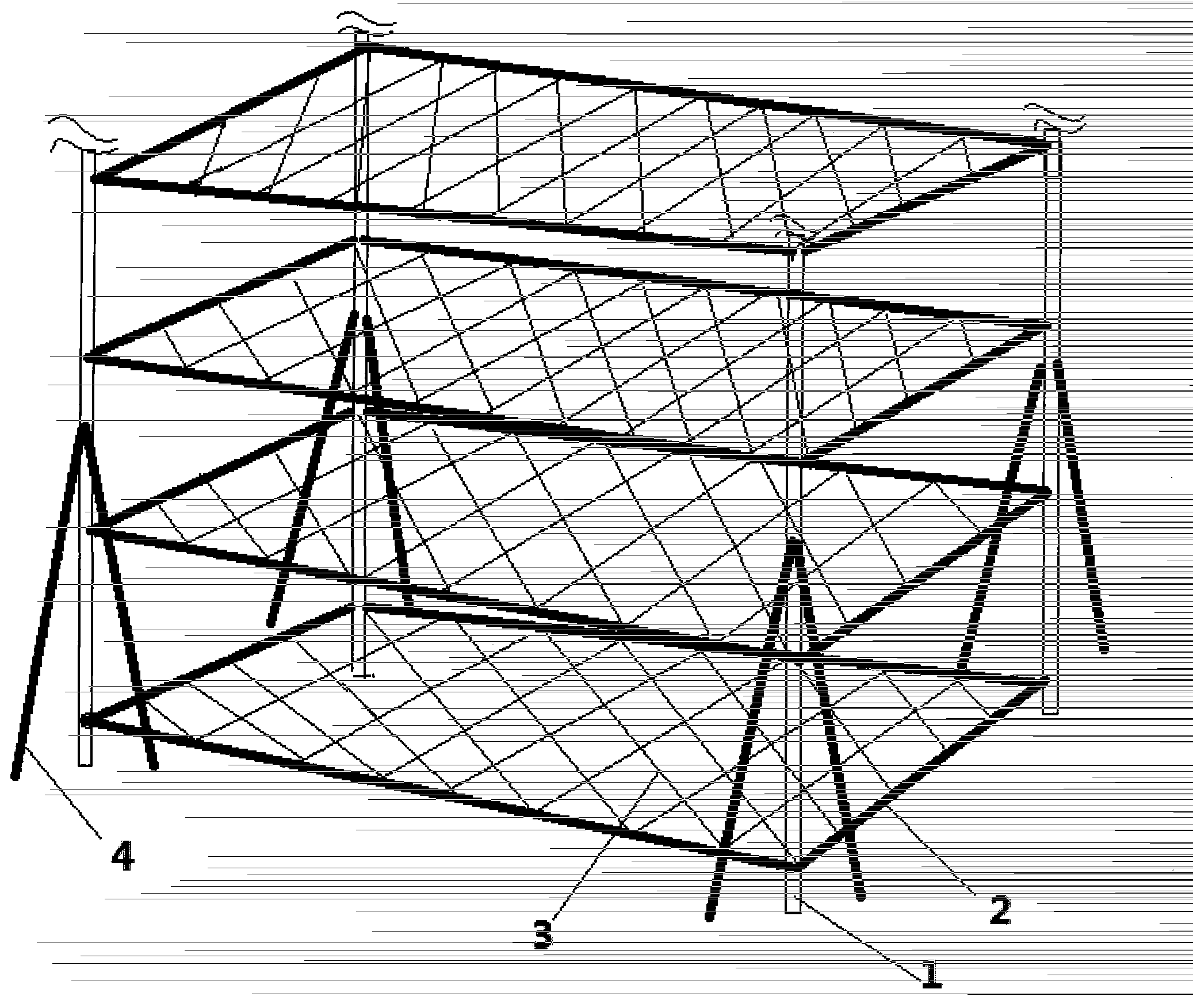

Cultivating frame for cultivating flammulina velutipes

The invention provides a cultivating frame for cultivating flammulina velutipes. The cultivating frame comprises wood standing columns and plastic crossbeams. The standing columns and the crossbeams are fixedly connected through bolts. Diagonal supports are disposed on two sides of each standing columns. A grid shelf weaving by metal wires or plastic cords is disposed between every two crossbeams. Flammulina velutipes cultivating bottles are disposed on the grid shelf between every two crossbeams, sufficient circulation of air, moisture, carbon dioxide and the like is facilitated, and growth of flammulina velutipes is promoted. The cultivating frame is firm in structure, lightweight, less prone to collapse, long in service life, and convenient and flexible in demounting, mounting and size adjusting.

Owner:解波

On-line pouring molding method for burner nozzle of heating furnace

The invention discloses an online pouring molding method for the burner nozzle of a heating furnace. Firstly, the nozzle mold on the burner brick is made, and the nozzle mold is set at the position of the burner on the furnace wall during maintenance, and then the burner nozzle of the regenerator is installed. The damaged furnace wall and the surrounding area are poured with corundum mullite casting material, and at the same time, the closing part of the top and the tail is closed with high alumina bricks, and the partition plate in the heat storage box is covered with formwork. Make repairs. Finally, after the poured slurry is solidified and meets the strength standard requirements, the nozzle mold on the burner brick is removed, and the burner nozzle is formed. In the case of damage to the burner of the heating furnace, based on the requirement that the nozzle of the burner brick remains unchanged, the present invention firstly makes a mold according to the size of the nozzle of the burner, and then repairs it by casting the nozzle with a refractory material. The burner repaired by the invention is not easy to deform and collapse, effectively prolongs the service life of the burner on the heating furnace, and further shortens the construction time and maintenance engineering amount.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com