Composite material for manufacturing dry powder fire extinguisher nozzle and method for manufacturing nozzle using same

A fire extinguisher nozzle and composite material technology, which is applied in the field of composite materials, can solve the problems of powder cannot be sprayed smoothly, high cost of rubber materials, and poor smoothness, so as to improve the utilization rate of dry powder, not easy to deform and collapse, and return to the original position Excellent elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

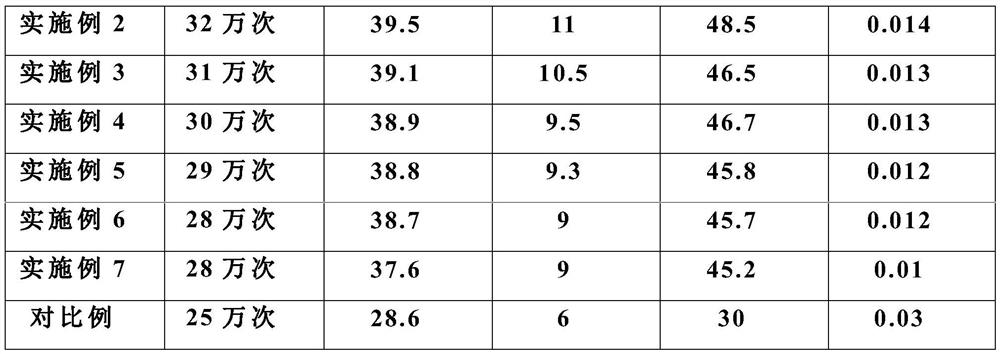

Examples

Embodiment 1

[0037] Embodiment 1: A kind of composite material that is used to manufacture dry powder fire extinguisher nozzle, it is made up of the following raw materials in parts by mass: 100 parts of the mixture of silicone rubber and CPVC resin; 35 parts of plasticizers; 8 parts of heat stabilizers; 9 parts of toughening agent; 15 parts of hot melt adhesive; 4 parts of crosslinking agent; 10 parts of accelerator; 8 parts of external lubricant; 0.6 parts of internal lubricant; 8 parts of flame retardant; 15 parts of filler A, 20 parts of filler B .

[0038] Among them, the silicone rubber is 110-2 type methyl vinyl silicone rubber with a polymerization degree of 8000 and a molecular weight of 450000-500000, and the vinyl content in the raw rubber is 0.18wt%. The mass ratio of the above-mentioned silicone rubber to CPVC resin is 1:6. The plasticizer is trialkyl phosphate, the heat stabilizer is calcium zinc composite heat stabilizer, the toughening agent is nitrile rubber, the crosslin...

Embodiment 2

[0043] Embodiment 2: a kind of composite material that is used to manufacture dry powder fire extinguisher nozzle, it is made up of the following raw materials in parts by mass: 100 parts of the mixture of silicone rubber and CPVC resin; 30 parts of plasticizer; 6 parts of heat stabilizer; 8 parts of toughening agent; 14 parts of hot melt adhesive; 4 parts of crosslinking agent; 10 parts of accelerator; 6 parts of external lubricant; 0.4 parts of internal lubricant; 6 parts of flame retardant; .

[0044] Among them, the silicone rubber is 110-2 methyl vinyl silicone rubber with a degree of polymerization of 10,000 and a molecular weight of 500,000-700,000, and the vinyl content in the raw rubber is 0.30 wt%. The mass ratio of the above-mentioned silicone rubber to CPVC resin is 1:6. Plasticizer is dioctyl adipate, heat stabilizer is rare earth heat stabilizer, toughener is nitrile rubber, crosslinking agent is sulfur and 2-dibutylamine-4,6 dithiol-s-triazine According to the...

Embodiment 3

[0049] Embodiment 3: a kind of composite material that is used to manufacture dry powder fire extinguisher nozzle, it is made up of the following raw materials in parts by mass: 100 parts of the mixture of silicone rubber and CPVC resin; 40 parts of plasticizer; 8 parts of heat stabilizer; 10 parts of toughening agent; 16 parts of hot melt adhesive; 4 parts of crosslinking agent; 10 parts of accelerator; 8 parts of external lubricant; 0.6 parts of internal lubricant; 10 parts of flame retardant; 15 parts of filler A, 20 parts of filler B .

[0050] The silicone rubber is 110-2 methyl vinyl silicone rubber with a degree of polymerization of 10,000 and a molecular weight of 450,000-500,000, and the vinyl content in the raw rubber is 0.35 wt%. The mass ratio of the above-mentioned silicone rubber to CPVC resin is 1:6. The plasticizer is a mixture of dioctyl phthalate and diisononyl phthalate in a mass ratio of 1:1, the heat stabilizer is an organic antimony heat stabilizer, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com