Floor joint fastening grooving

A joint lock and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of low tensile strength and high installation requirements, and achieve the effects of improved tensile strength, less deformation and collapse, and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

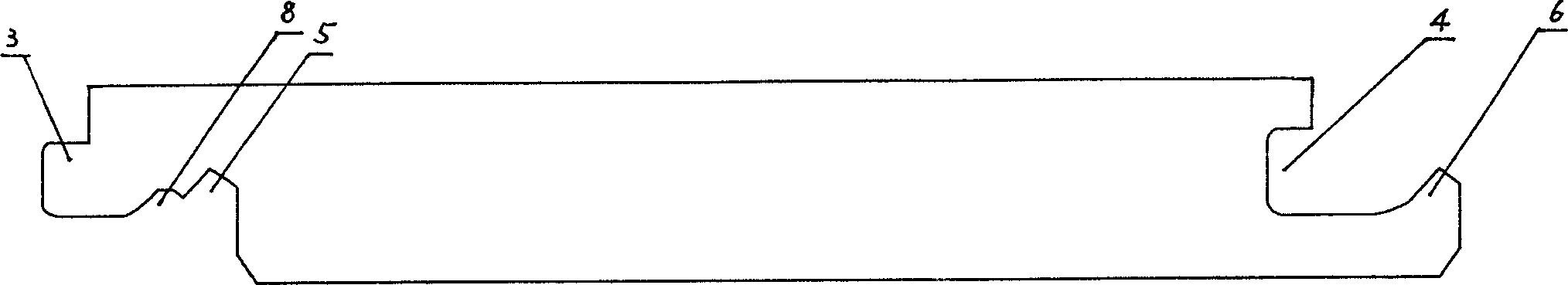

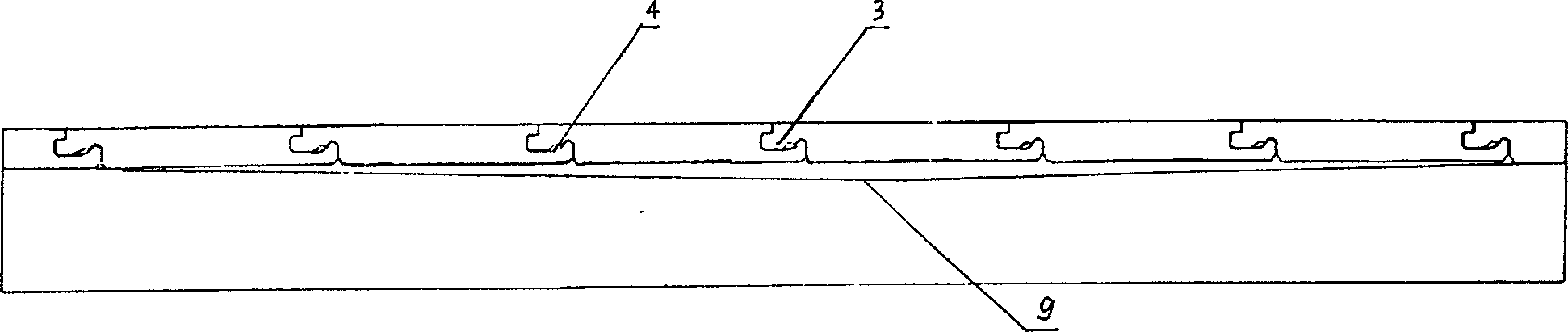

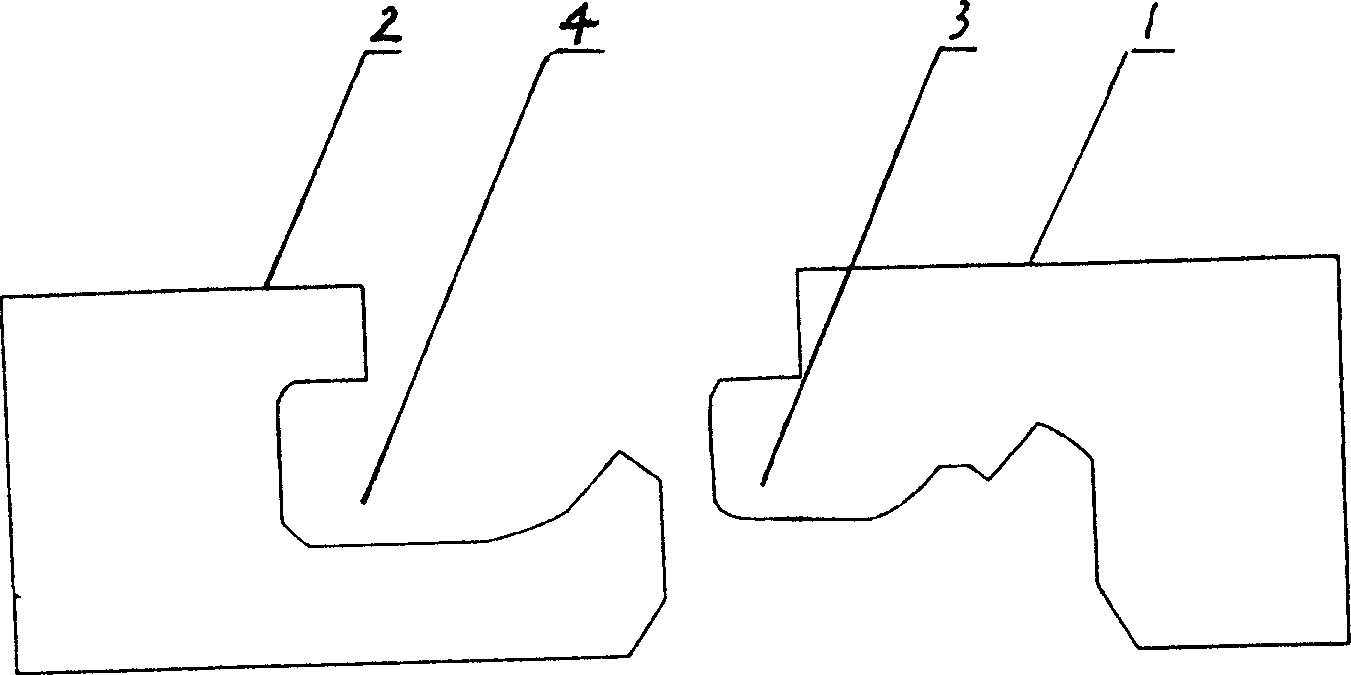

[0019] figure 1 Shown is an embodiment of the floor joint lock tongue and groove of the present invention, which includes two identical rectangular floor sheets I1 and rectangular floor sheets II2, on one side of each rectangular floor, and below the top surface, There is a groove 4 inward along its length direction, and a tenon 3 is arranged outward at the corresponding position on the other side of the floor. The shape, size and position of the groove 4 and the tenon 3 are all adapted , The groove 4 and the tenon 3 are inlaid to form a lock between the two floors, and the two floors are tightly combined. In this embodiment, the groove 4 is a rectangular groove, and the lower edge of the groove extends outward and obliquely upward to form a tenon 6; the tenon 3 is a rectangular tenon corresponding to the groove 4, The lower edge of the tenon extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com