Araneose corrugated board

A corrugated cardboard and spider web technology, applied in the field of corrugated cardboard, can solve the problems of edge compressive strength, low peel strength, flat compressive strength, poor impact resistance, and high manufacturing labor cost, and achieve high impact resistance, easy processing, and excellent quality. The effect of edge compression strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

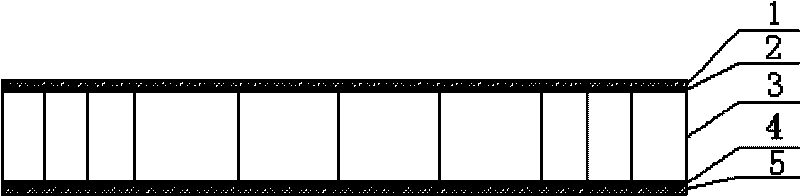

[0017] refer to figure 1 , the present embodiment comprises outer surface paper 1, glued film I 2, glued film II 4, bottom surface paper 5, between glued film I 2 and glued film II 4, spider web-like paper crest nest core 3 is sandwiched; the spider The net-like paper peak core 3 is made of honeycomb corrugated paper bonded according to the spider web structure; the outer layer paper 1 and the spider-web-like paper peak core 3 are bonded together by an adhesive film I 2; the bottom surface paper and the spider-web-like paper peak core glued together by glue film II 4;

[0018] The outer surface paper 1 and the bottom surface paper 5 are selected from sandboard or kraft paper, and the adhesive film I 2 and the adhesive film II 4 are adhesive films formed by special glue for honeycomb paperboard.

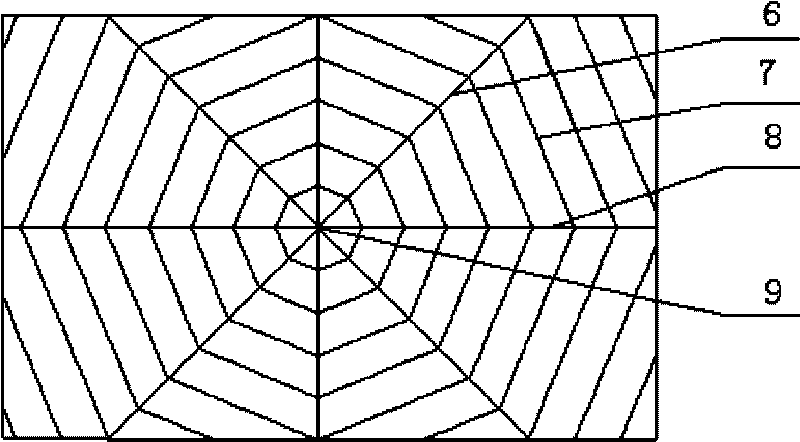

[0019] refer to figure 2 , the spider web-like paper peak nest core 3 is composed of eight main ribs passing through the center 9 to form an overall skeleton, and each adjacent mai...

Embodiment 2

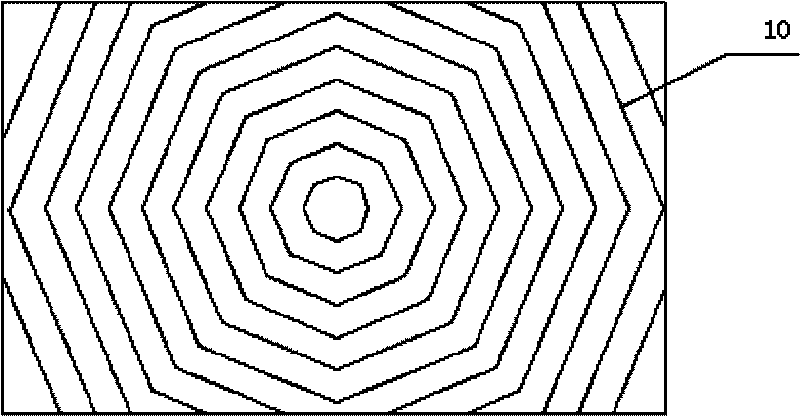

[0021] refer to image 3 , the difference between this embodiment and Embodiment 1 is that the spider web-shaped paper peak nest core 3 has no main edge, but the overall skeleton is formed by each edge 10, starting from the center of the paper peak nest core, each edge forms a concentric A regular octagon with equal distances between adjacent edges. This embodiment has a simpler structure, more convenient processing and production, and is suitable for packaging and transportation of general commodities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com