A kind of black adhesive for aluminum-plastic film composite of lithium battery and preparation method thereof

An aluminum-plastic film, lithium battery technology, applied in the directions of adhesives, adhesive types, adhesive additives, etc., can solve the problems of destroying the bonding effect between composite layers, affecting the electrical performance of lithium batteries, and changing the concentration of electrolyte components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

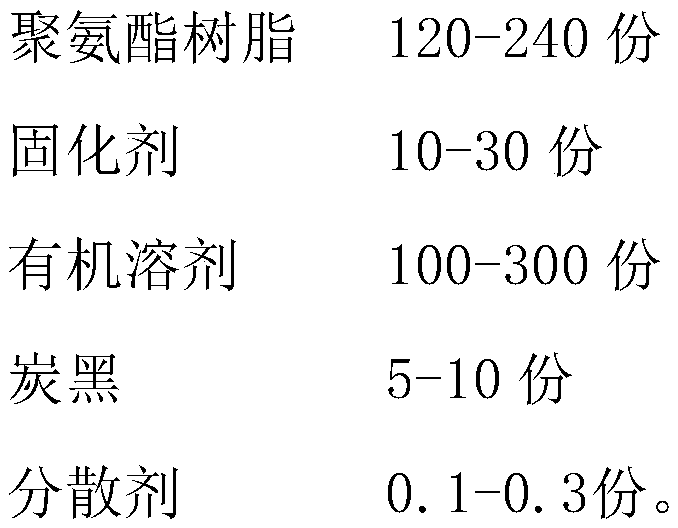

[0024] A kind of black adhesive for aluminum-plastic film composite of lithium battery, comprises the raw material of following weight part:

[0025]

[0026] Wherein, the curing agent is an aliphatic polyisocyanate curing agent.

[0027] Wherein, the -NCO content of the curing agent is 6 mol%.

[0028] Wherein, the organic solvent is composed of ethyl acetate, butanone and toluene in a weight ratio of 2:1.5:1.5.

[0029] Wherein, the carbon black is nano-carbon black, and the particle size of the nano-carbon black is 40nm.

Embodiment 2

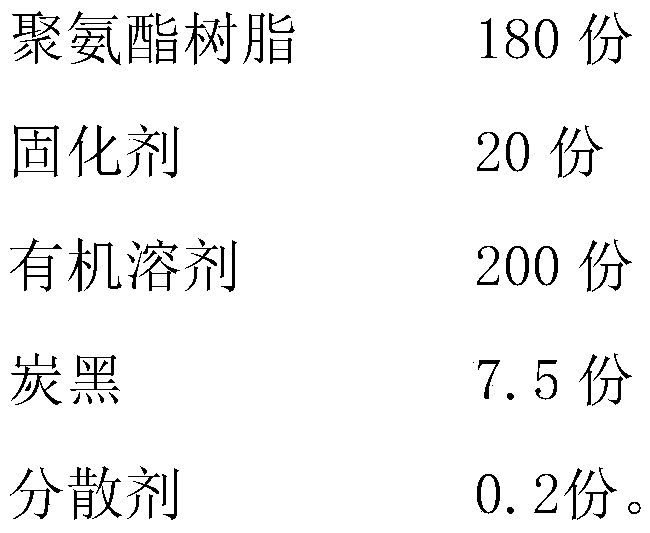

[0031] A kind of black adhesive for aluminum-plastic film composite of lithium battery, comprises the raw material of following weight part:

[0032]

[0033] Wherein, the curing agent is an aliphatic polyisocyanate curing agent.

[0034] Wherein, the -NCO content of the curing agent is 5 mol%.

[0035] Wherein, the organic solvent is composed of ethyl acetate, butanone and toluene in a ratio of 1:1:1 by weight.

[0036] Wherein, the carbon black is nano-carbon black, and the particle size of the nano-carbon black is 40nm.

Embodiment 3

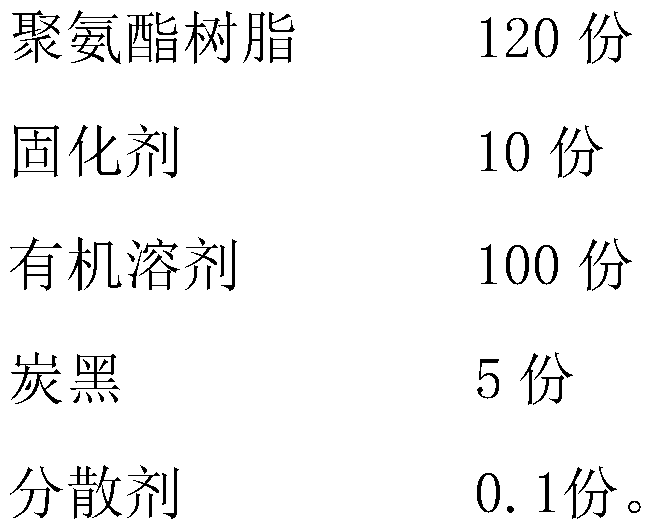

[0038] A kind of black adhesive for aluminum-plastic film composite of lithium battery, comprises the raw material of following weight part:

[0039]

[0040]

[0041] Wherein, the curing agent is an aliphatic polyisocyanate curing agent.

[0042] Wherein, the -NCO content of the curing agent is 7 mol%.

[0043] Wherein, the organic solvent is composed of ethyl acetate, butanone and toluene in a ratio of 3:2:2 by weight.

[0044] Wherein, the carbon black is nano carbon black, and the particle size of the nano carbon black is 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com