Patents

Literature

136 results about "Carbon black nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon black nanoparticles are manufactured for use in rubber products, as a color pigment in plastics, paint and ink and used to model exposure to air pollution particles. These particles have been shown to have toxic effects and previous mice studies have shown that maternal exposure can affect the sperm count in male offspring.

Ultrahigh molecular weight polyethylene/carbon black nanometer composite fiber and its preparation method

InactiveCN102433600AImprove heat resistanceImprove creep resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberNanoparticle

The invention provides an ultrahigh molecular weight polyethylene / carbon black nanometer composite fiber and its preparation method. The method comprises: putting ultrahigh molecular weight polyethylene, carbon black nanoparticles and an anti-oxidant into a solvent, conducting high speed shearing and stirring by an emulsifying machine so as to be uniformly mixed, thus obtaining a mixture; then raising the temperature of the mixture to 100-120DEG C, controlling the temperature raising speed at 2-5DEG C / min, and carrying out thermal insulation for 1-4h so as to obtain a spinning solution, then employing a conventional ultrahigh molecular weight polyethylene fiber production method for preparing an ultrahigh molecular weight polyethylene / carbon black nanometer composite fiber. The ultrahigh molecular weight polyethylene / carbon black nanometer composite fiber prepared in the invention effectively improves the hear resistance and creep resistance of ultrahigh molecular weight polyethylene fibers, reduces fiber production cost, and extends the application scope of fibers. Meanwhile, the preparation method provided in the invention has concise process route and is easy to operate.

Owner:JIANGSU LIUJIA TECH CO LTD

Nano-sized carbon black heat dissipating paint and preparation method thereof

InactiveCN102250546AImprove cooling effectLow pricePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceFoaming agent

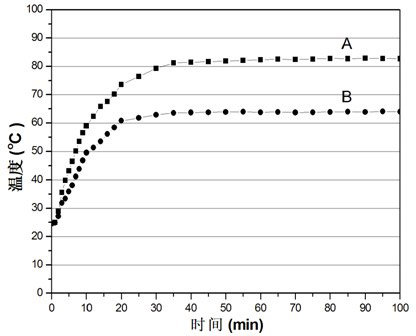

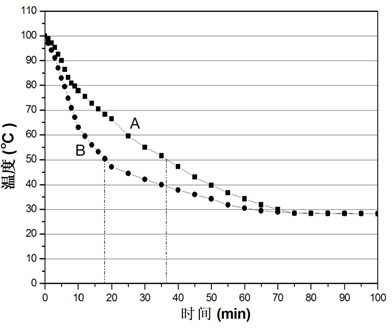

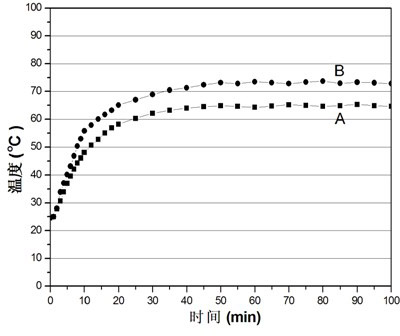

The invention relates to a nano-sized carbon black heat dissipating paint and a preparation method thereof. The paint is composed of waterborne resin, nano-sized carbon black, a dispersant of nano-sized carbon black, a waterborne leveling agent, a waterborne anti-foaming agent, and a solvent. The materials are sufficiently mixed through ball-milling, such that the heat dissipating paint is prepared. The heat dissipating paint comprises components of, by mass: 30 to 60 parts of waterborne resin, 3 to 15 parts of nano-sized carbon black, 0.5 to 2.5 parts of the dispersant of nano-sized carbon black, 0.5 to 1.5 parts of the waterborne leveling agent, 0.5 to 1.5 parts of the waterborne anti-foaming agent, and 30 to 40 parts of the solvent. The heat dissipating paint can be directly painted on heat dissipating apparatuses for increasing the heat dissipating areas of the apparatuses and improving the heat dissipating effects. The nano-sized carbon black heat dissipating paint has characteristics of highly efficient, convenient and environment friendly.

Owner:ZHEJIANG SCI-TECH UNIV

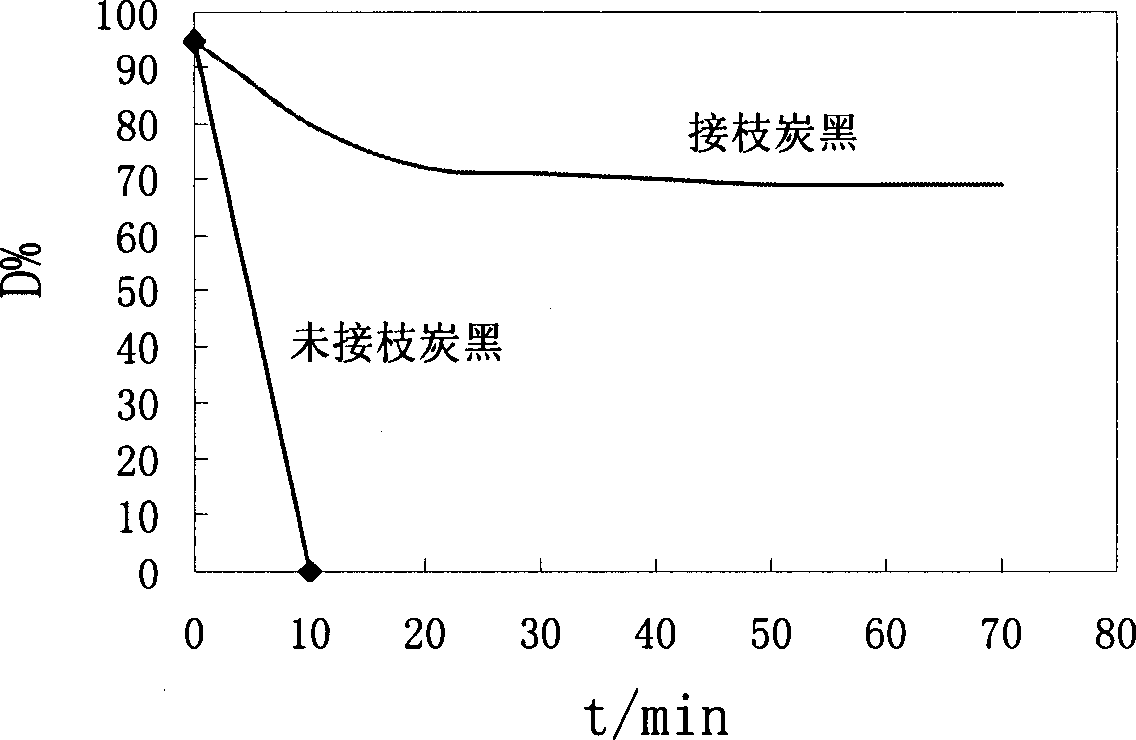

Nano carbon black with in-situ grafted organic compound and its producing method

InactiveCN1781999ASimple processLow costPigment treatment with non-polymer organic compoundsModified carbonSolvent

The present invention relates to a kind of nano carbon black with in-situ grafted organic compound and its preparation process. Under the action of mechanical shearing force field, carbon black and organic compound possessing or capable of producing active free radical are made to produce direct grafting reaction at the temperature over the smelting point forming the grafted carbon black. The obtained grafted carbon black has high dispersivity and compatibility, as well as nano effect common modified carbon black does not have. In addition, the said carbon black modifying process needs no solvent, has no pollution, simple procedure and low cost, and is suitable for continuous production.

Owner:EAST CHINA UNIV OF SCI & TECH

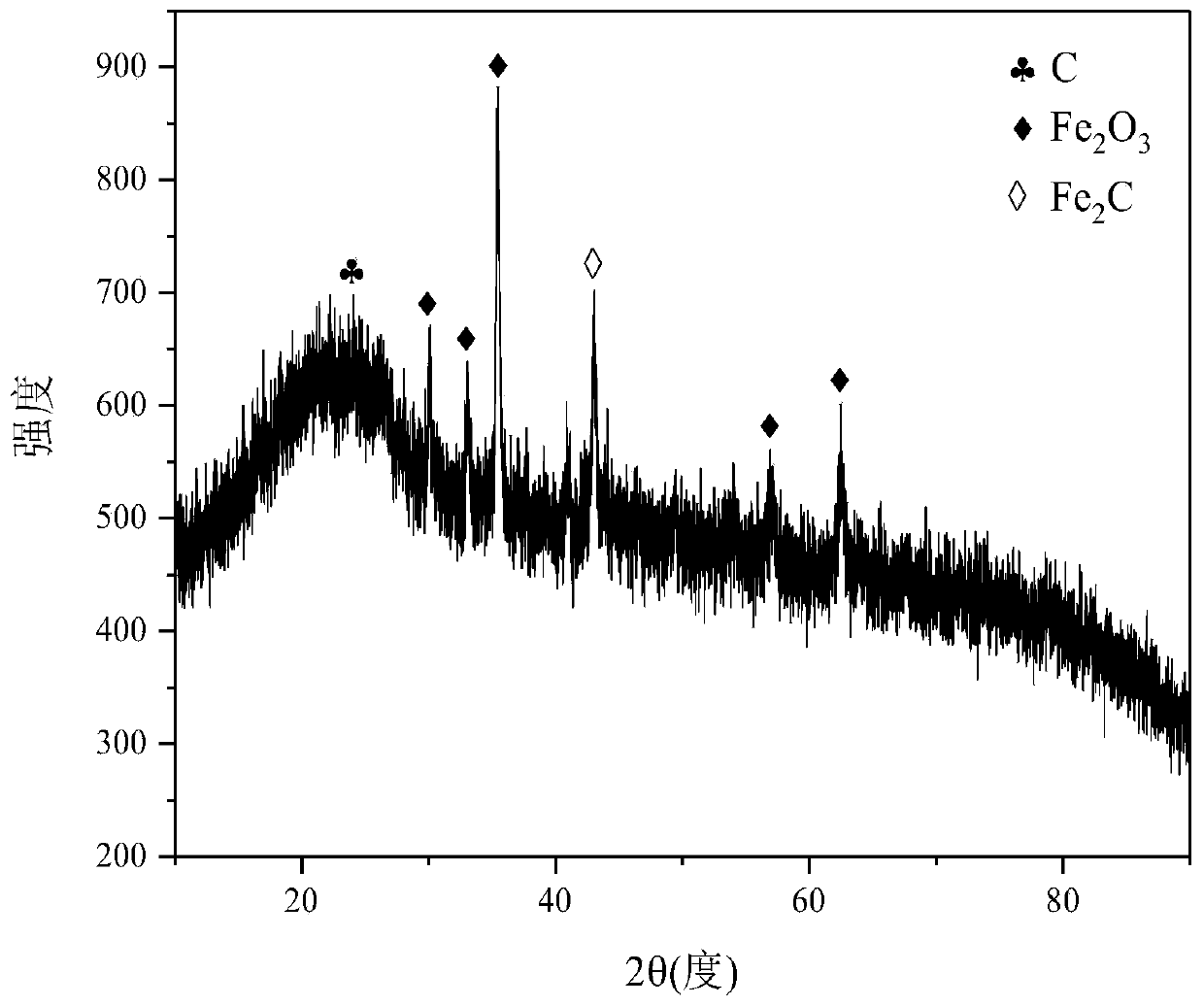

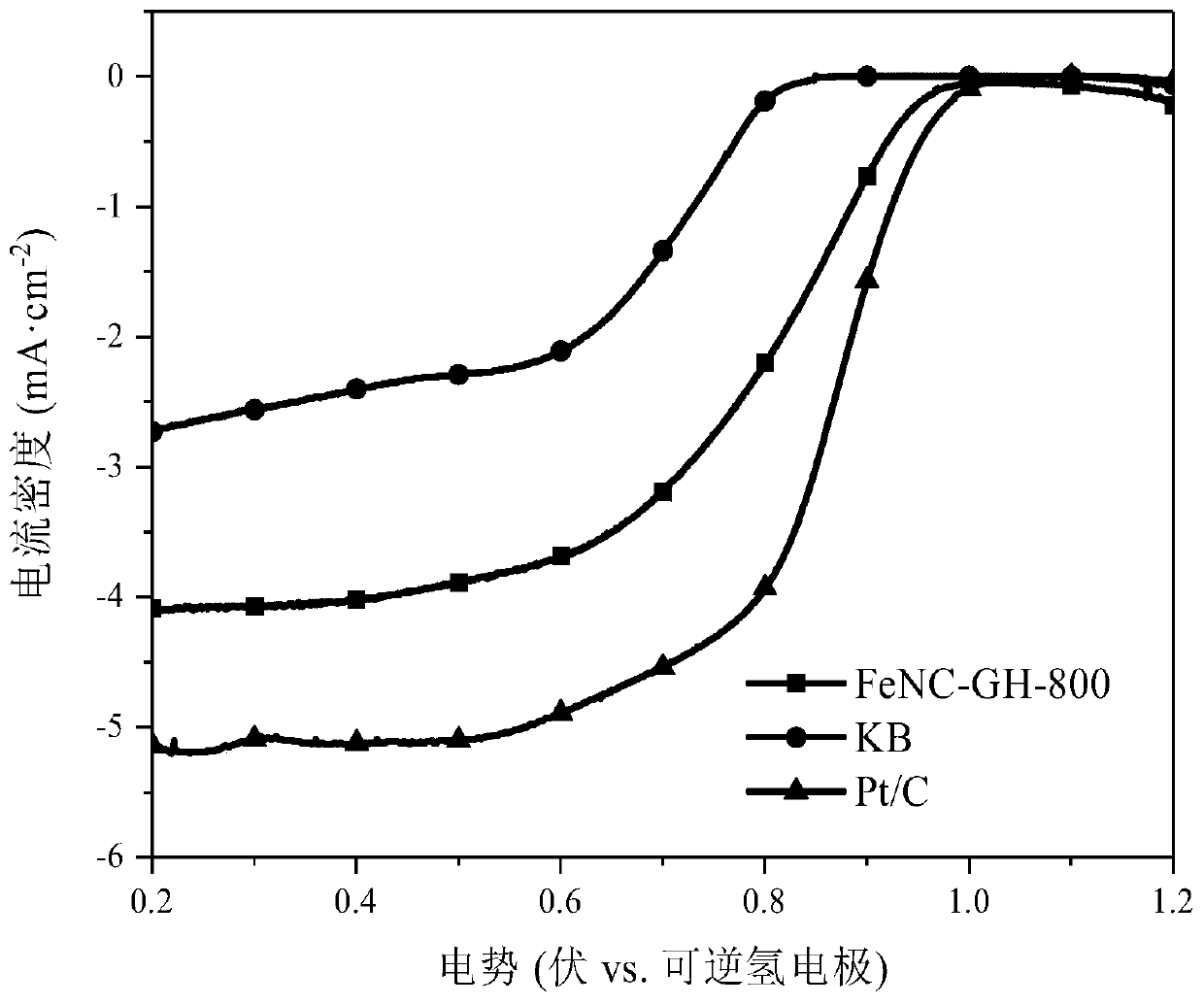

Iron and nitrogen co-doped carbon oxygen reduction catalyst and preparation method thereof

ActiveCN110534752AAperture adjustableShape is easy to controlCell electrodesUltrasonic dispersionOxidation reduction

The invention relates to an iron and nitrogen co-doped carbon oxygen reduction catalyst. The preparation method comprises steps: a carbon carrier is dissolved in an organic solvent, ultrasonic dispersion for being uniform is carried out, soluble iron salt is added under a stirring condition, and after uniform mixing, a mixed solution is obtained; the mixed solution is transferred to a reaction kettle, a reaction is carried out under the stirring condition, the reaction solution after the reaction is subjected to solid-liquid separation, washing and drying to obtain a solid material, the solidmaterial and a nitrogen source are mixed and grinded, and a pyrolysis precursor is obtained; and the pyrolysis precursor is roasted in an inert atmosphere to obtain the iron and nitrogen co-doped carbon oxygen reduction catalyst, wherein the carbon carrier is Ketjen black nano carbon black particles. Compared with the prior art, the method has the advantages of high oxidation reduction catalytic activity, good electrochemical stability, simple and controllable preparation method, short period, rich raw material reserves, low cost, capability of realizing large-scale production and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

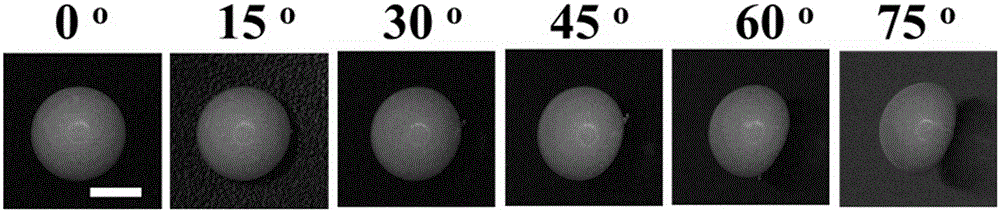

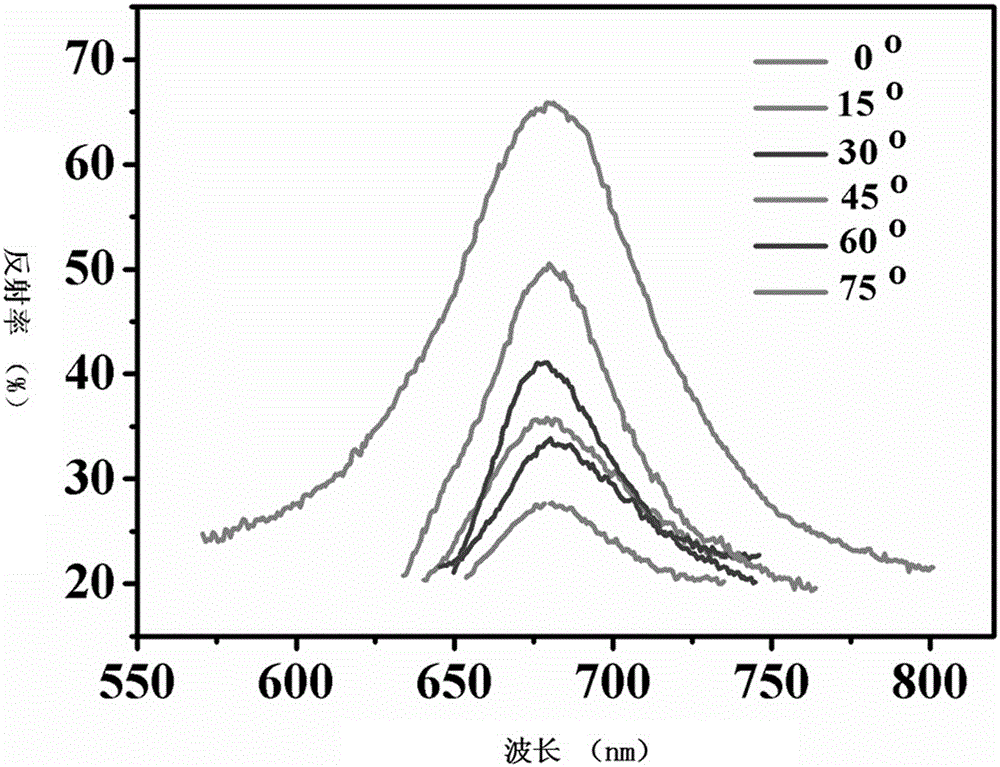

Morphology-controllable and color angle-independent photonic crystal particle and preparation method thereof

InactiveCN105177714ASimple control of shapeEliminate color angle dependenceFrom gel statePolycrystalline material growthMicrosphereSpherical shaped

The invention discloses a morphology-controllable and color angle-independent photonic crystal particle and its preparation method. The preparation method comprises the following steps: mixing Fe3O4 nanoparticles, carbon black nanoparticles, graphene nanoparticles or a mixture of the Fe3O4 nanoparticles, carbon black nanoparticles and graphene nanoparticles with an emulsion containing monodisperse colloidal microspheres; printing a mixture obtained onto a superhydrophobic substrate by a spraying, dispensing or inkjet mode so as to form emulsion droplets with diameter being 11microns -1.6 mm; and drying to obtain the ellipsoidal color angle-independent colored photonic crystal particle with its length-diameter ratio being controllable. The photonic crystal particle is colourfast and environmentally friendly and has a wide application prospect in fields of pigment, display, sensing and the like.

Owner:HEBEI NORMAL UNIV

Earthed anticorrosive conductive paint and preparation process thereof

ActiveCN102417781AImprove conductivityImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyCross-link

The invention discloses an earthed anticorrosive conductive paint and a preparation process thereof, relating to the field of earthed materials. The paint comprises the following components by mass percent: 10% to 15% of nanometer carbon black, 5% to 10% of colloidal graphite, 20% to 30% of a flexible epoxy resin, 0% to 10% of an organic silicone resin, 30% to 50% of a diluting solvent, 10% to 15% of a curing agent and 2% to 3% of a plasticizer; the sum of the mass percent of every component is 100%. The paint has high conductivity and good anticorrosive performance and closeness, which is favorable for anticorrosion, has flexibility, which is favorable for increase of a service life, and has high temperature resistance, good thermal stability and capacity of enduring impact of heavy current; the paint employs a two-component form and can improve cross-linking properties and mechanical properties of a resin after the paint is cured; the paint is applicable to a variety of earthing such as earthing for lightning protection, working earthing, protective earthing and the like having anticorrosive requirements.

Owner:武汉爱劳高科技有限责任公司

Modified carbon raw material for carbon-containing refractory material and preparation method thereof

InactiveCN102070339ASimple preparation processImprove antioxidant capacityCeramic coatingModified carbon

The invention relates to a modified carbon raw material for a carbon-containing refractory material and a preparation method thereof. The preparation method comprises the following steps: adding 5-30 wt% of a mixture of simple substance silicon powder and silicon dioxide micropowder into flake graphite fine powder or nano carbon black or multiwall carbon nanotubes; evenly stirring to obtain mixedpowder; and then, treating the mixed powder in a carbon-buried atmosphere at 800-1400 DEG C for 1-3 hours, wherein the molar ratio of the simple substance silicon powder to the silicon dioxide micropowder is (0.5-3):1. The invention has simple technique, and ceramic coatings with different thicknesses can be formed on the surface of the carbon raw material by regulating the molar ratio of the simple substance silicon powder to the silicon dioxide micropowder and regulating the percentage of the simple substance silicon powder and silicon dioxide micropowder in the carbon raw material. The oxidation resistance of the modified carbon raw material is greatly enhanced; and when being added into the carbon-containing refractory material, the modified carbon raw material can enhance the oxidation resistance of the carbon-containing refractory material, and simultaneously, the ceramic coating on the surface prevents the modified carbon raw material from reacting with the antioxidant in the carbon-containing refractory material, thereby enhancing the comprehensive properties of the carbon-containing refractory material.

Owner:湖南武科立达格拉菲新材料有限公司

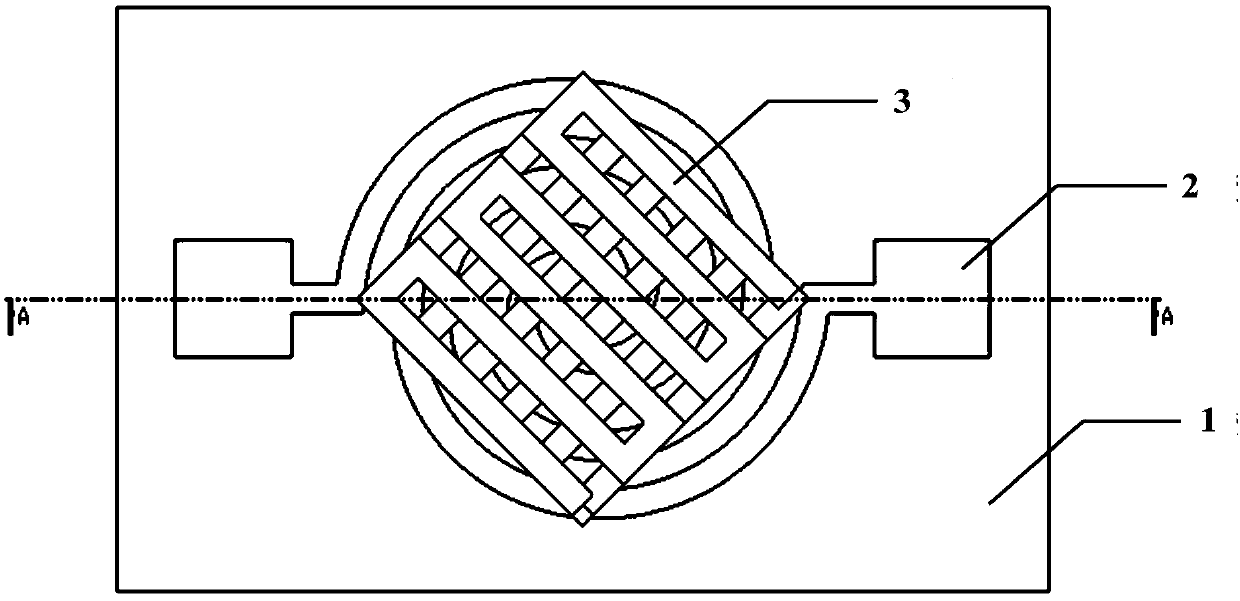

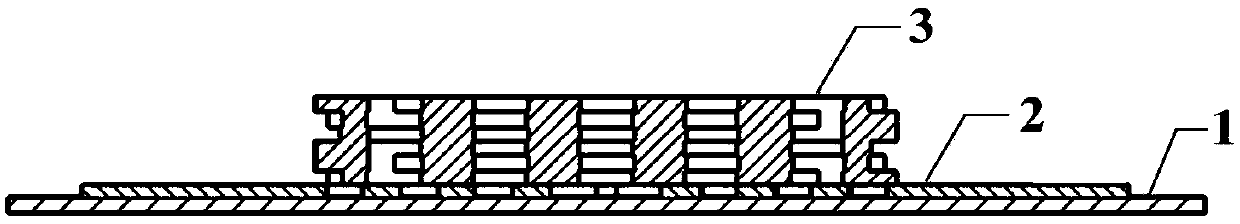

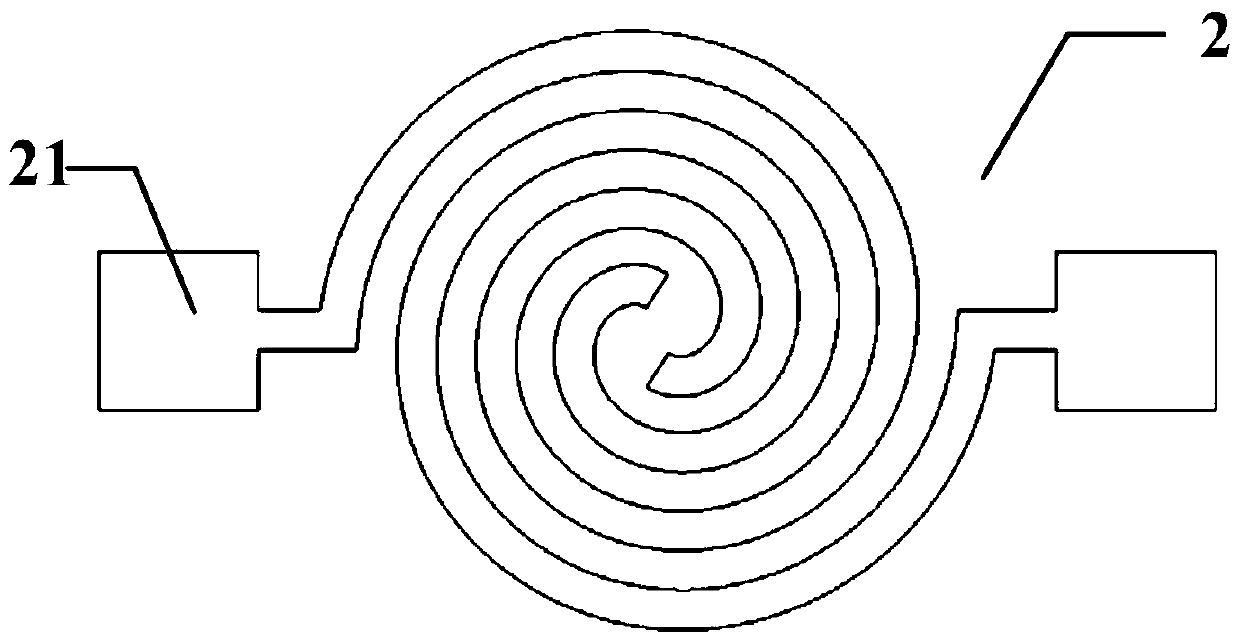

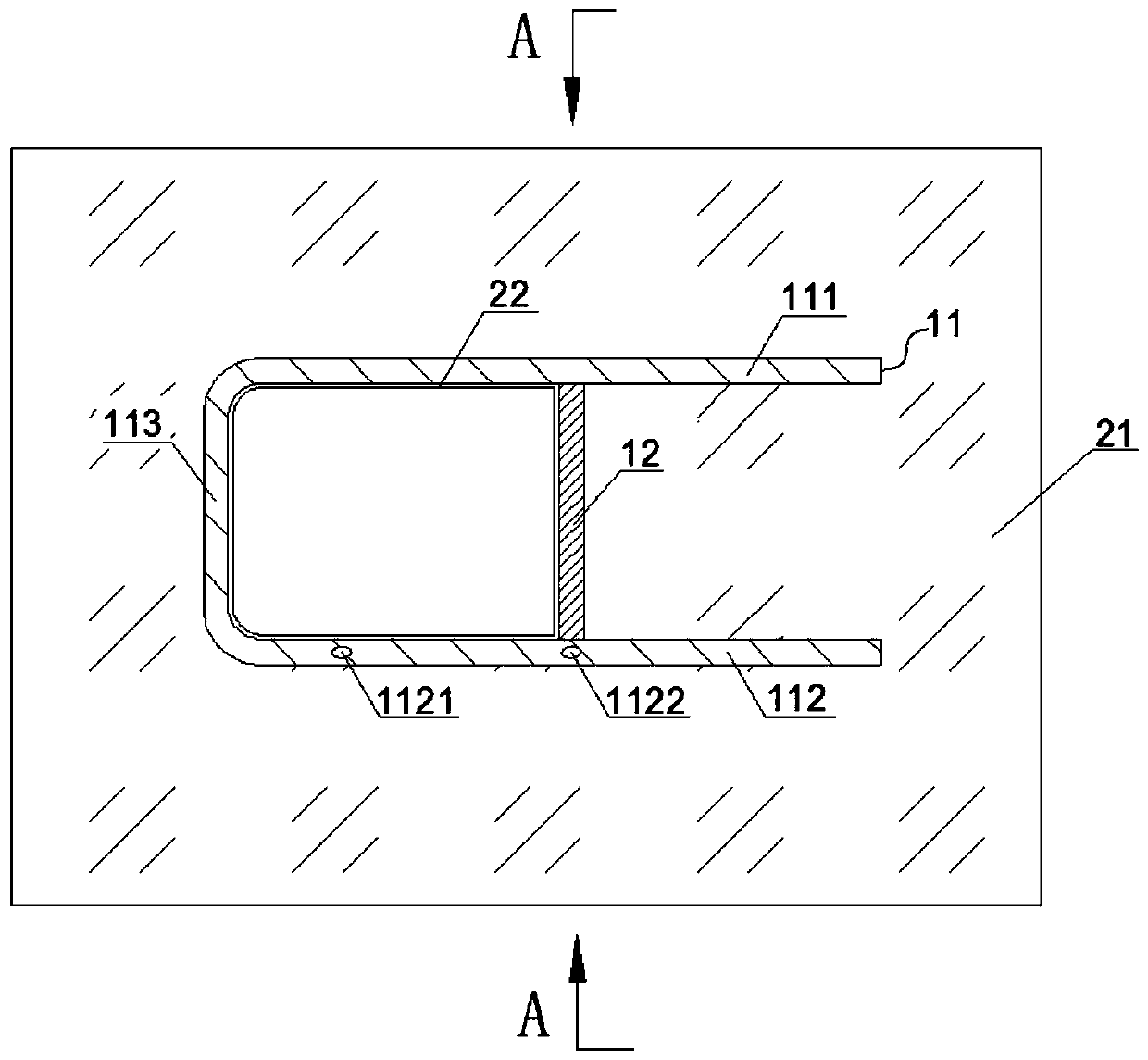

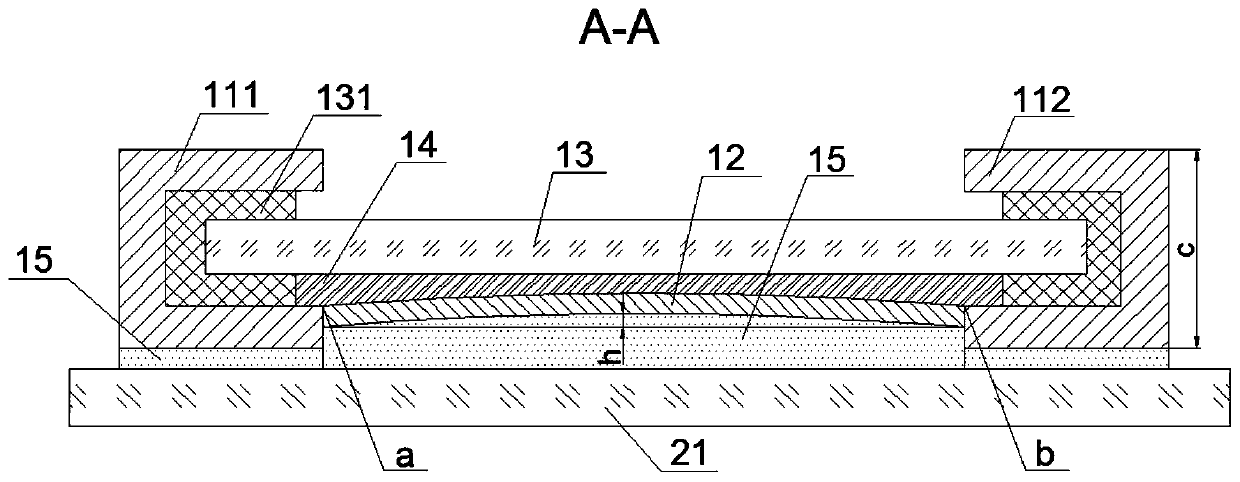

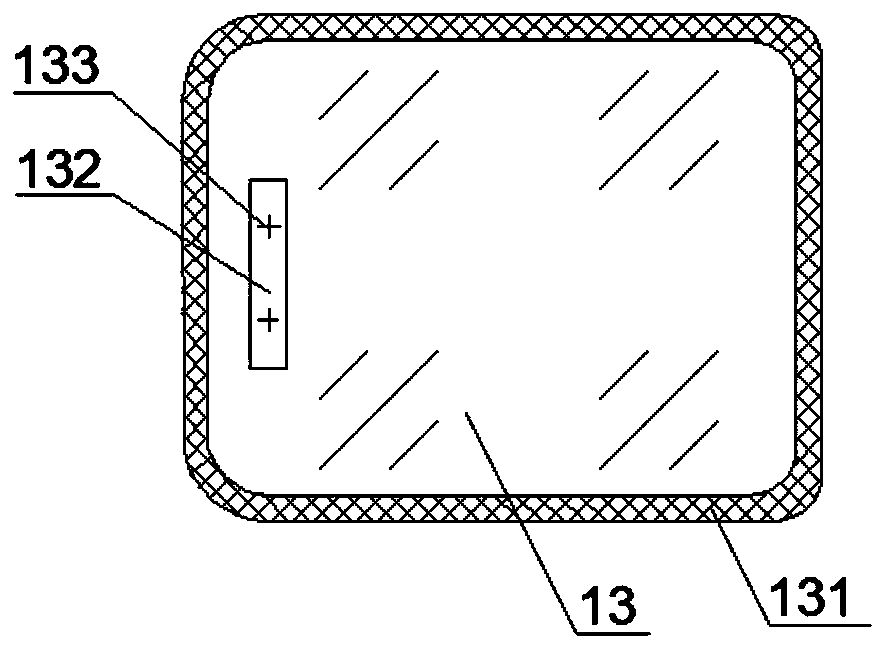

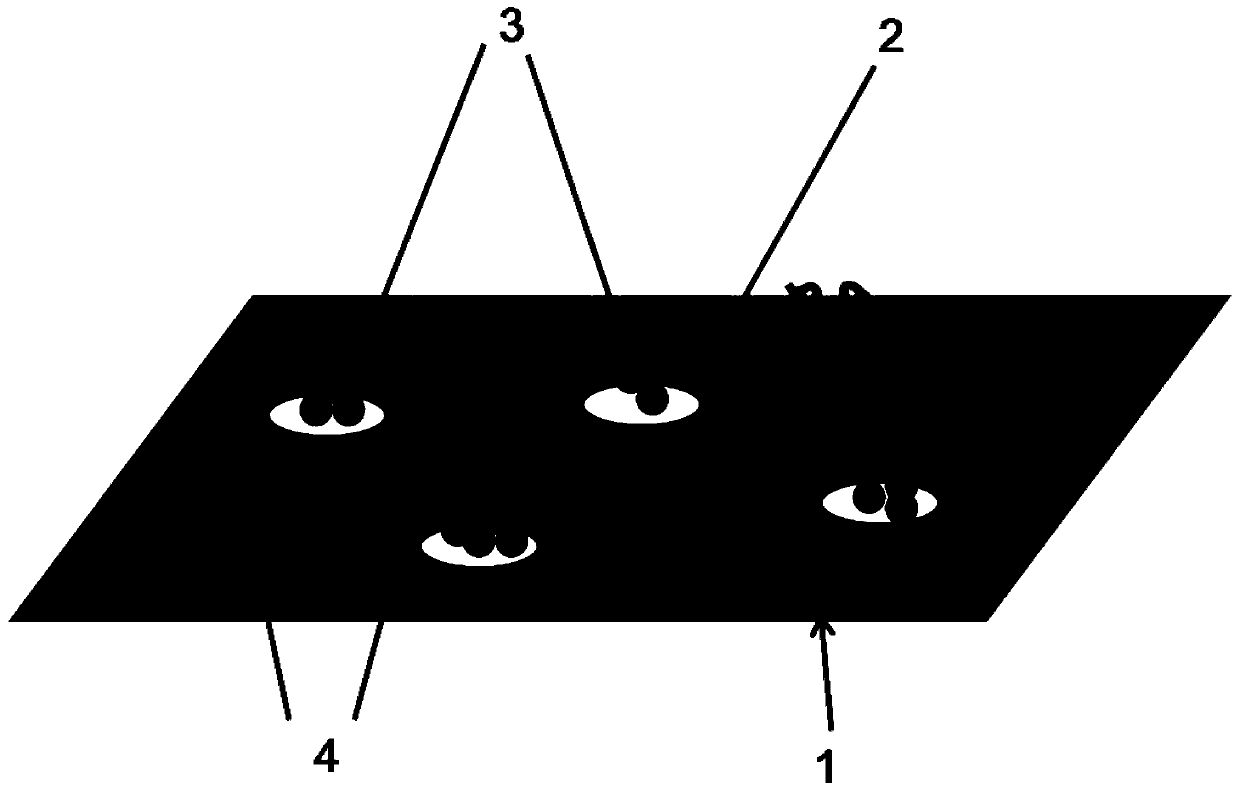

Flexible pressure sensor and flexible pressure sensing array

ActiveCN111289158AGuaranteed performanceImprove flexibilityFluid pressure measurement using ohmic-resistance variationForce measurementMicro nanoEngineering

The invention provides a flexible pressure sensor and a flexible pressure sensing array. The flexible pressure sensor comprises a substrate layer made of a flexible high-molecular polymer material, aelectrode layer, and a sensing layer. The electrode layer is arranged on the surface of the substrate layer, the flexible high-molecular polymer is adopted as a matrix of the electrode layer, and theflexible high-molecular polymer is filled with micron-sized silver sheets or other micro-nano conductive materials; and the sensing layer is electrically connected with the electrode layer, the matrixof the sensing layer adopts the flexible high-molecular polymer, and the flexible high-molecular polymer is filled with nano carbon black particles or other micro-nano conductive materials. Accordingto the invention, the geometrical shape of the electrode layer and the microstructure of the sensing layer are designed in a stretchable mode, so that the flexibility and ductility of the pressure sensor and the integration performance of the pressure sensor and the non-structural surface are effectively improved; and the structure is simple, machining is convenient, wire leading is easy, and cost is low.

Owner:SHENZHEN UNIV

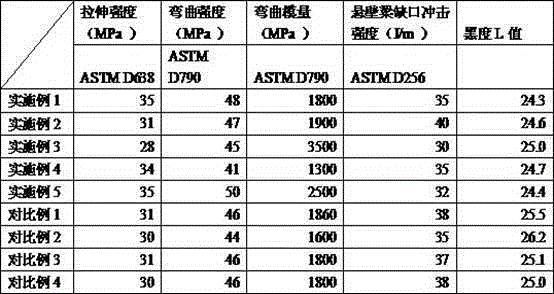

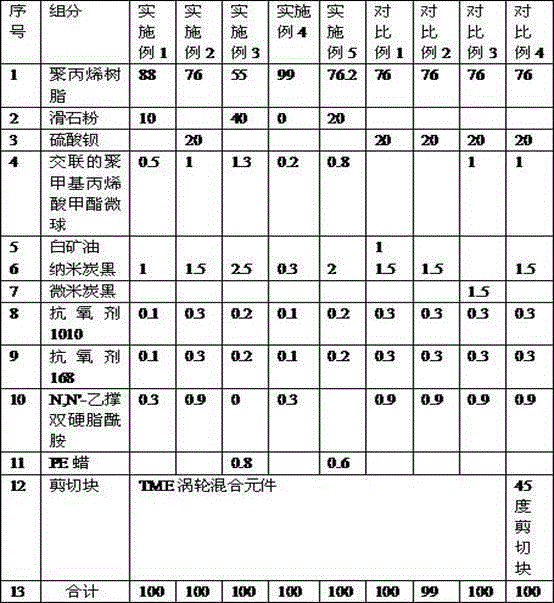

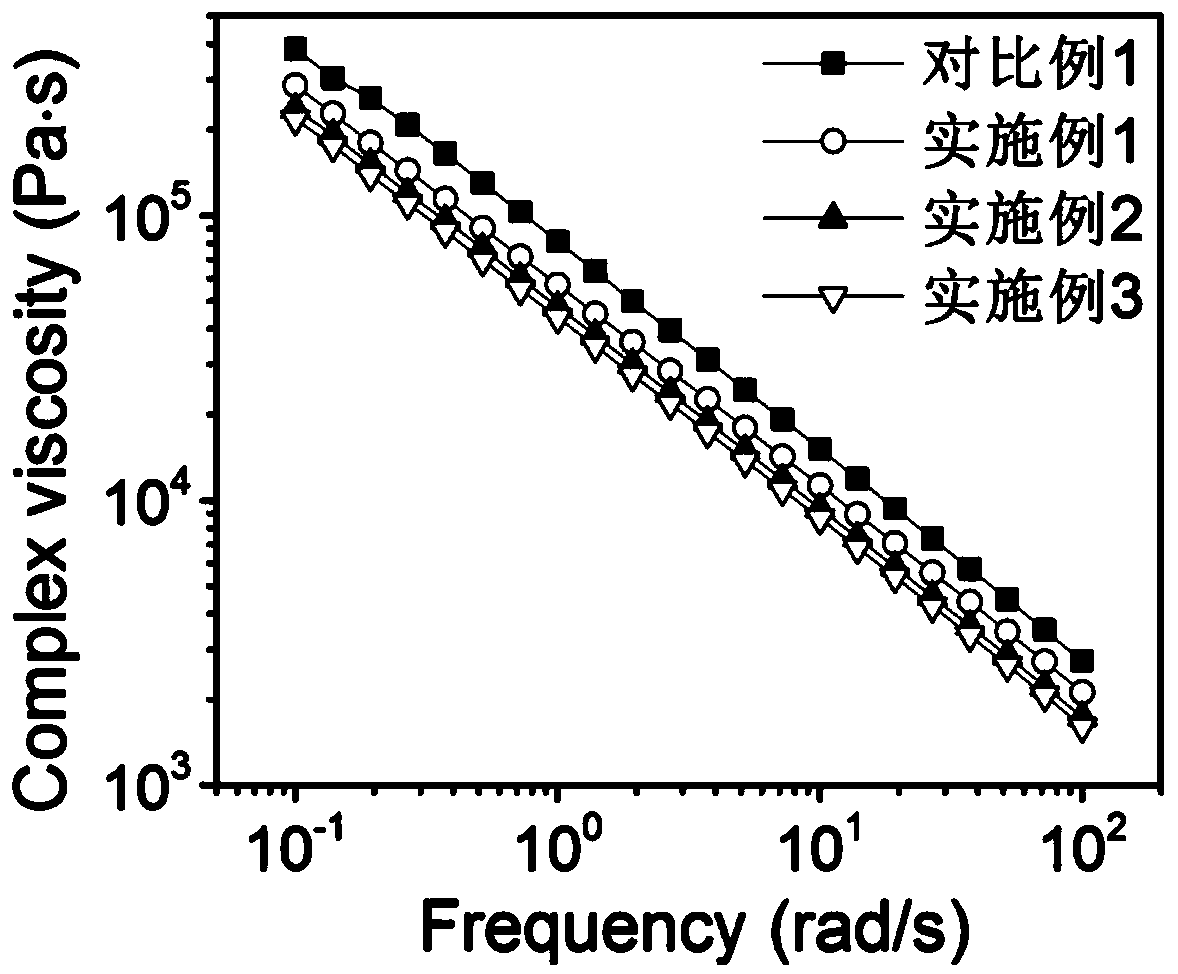

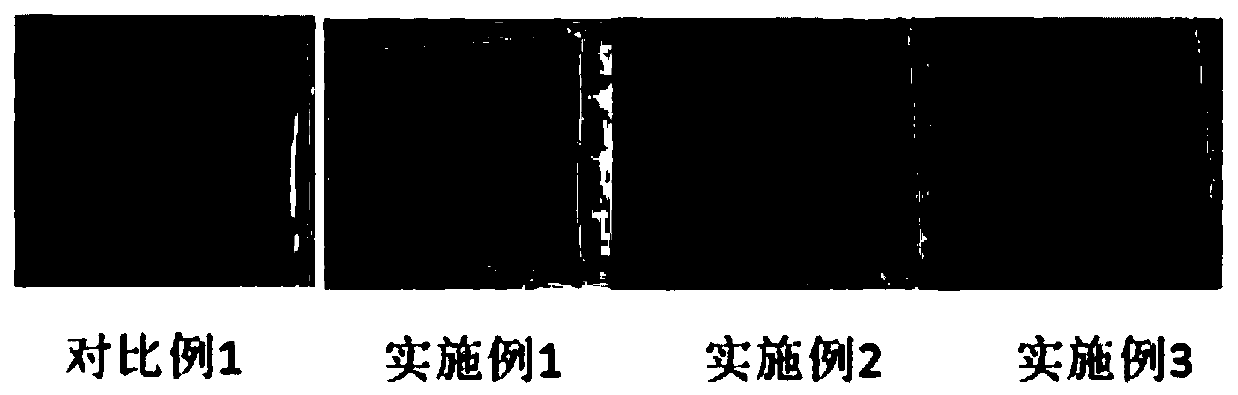

High-blackness polypropylene composition and preparation method thereof

The invention relates to the technical field of preparation of polypropylene and especially relates to a high-blackness polypropylene composition and a preparation method thereof. The high-blackness polypropylene composition is composed of following components, by weight, 55-99 parts of polypropylene resin, 0-40 parts of inorganic filling materials, 0.2-1.3 parts of crosslinked polymethyl methacrylate microspheres, 0.3-3 parts of nano carbon black and 0.4-1.5 parts of other additives. The preparation method includes the steps of feeding the polypropylene resin, the crosslinked polymethyl methacrylate microspheres and the nano carbon black into a high-speed stirrer, stirring the materials uniformly, adding other additives and filling materials, stirring the materials uniformly, and performing extrusion pelletization, melt extrusion and granulation to the uniformly-mixed materials through a double-screw extruder to prepare the high-blackness polypropylene composition. The composition is high in blackness and low in cost.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

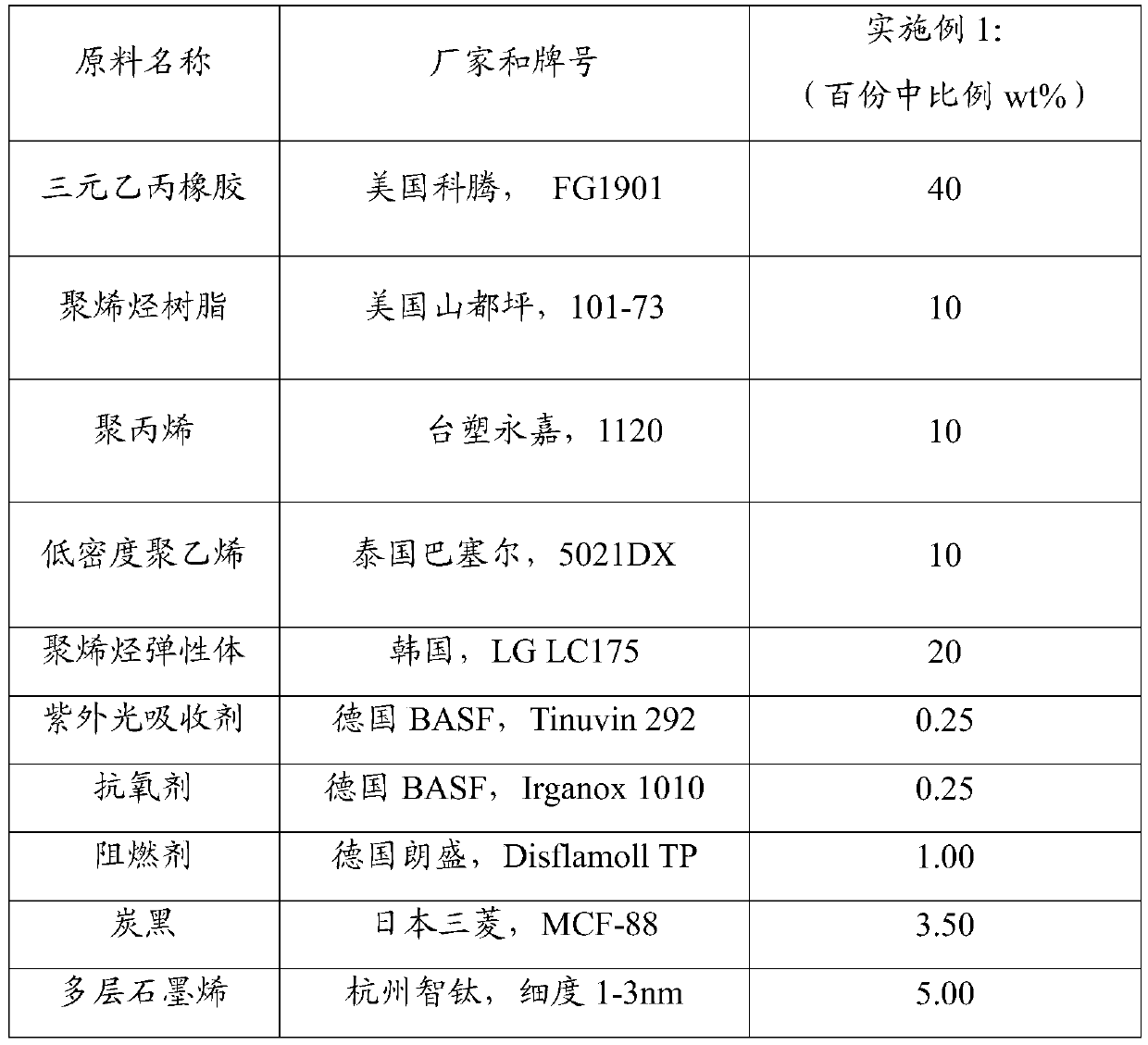

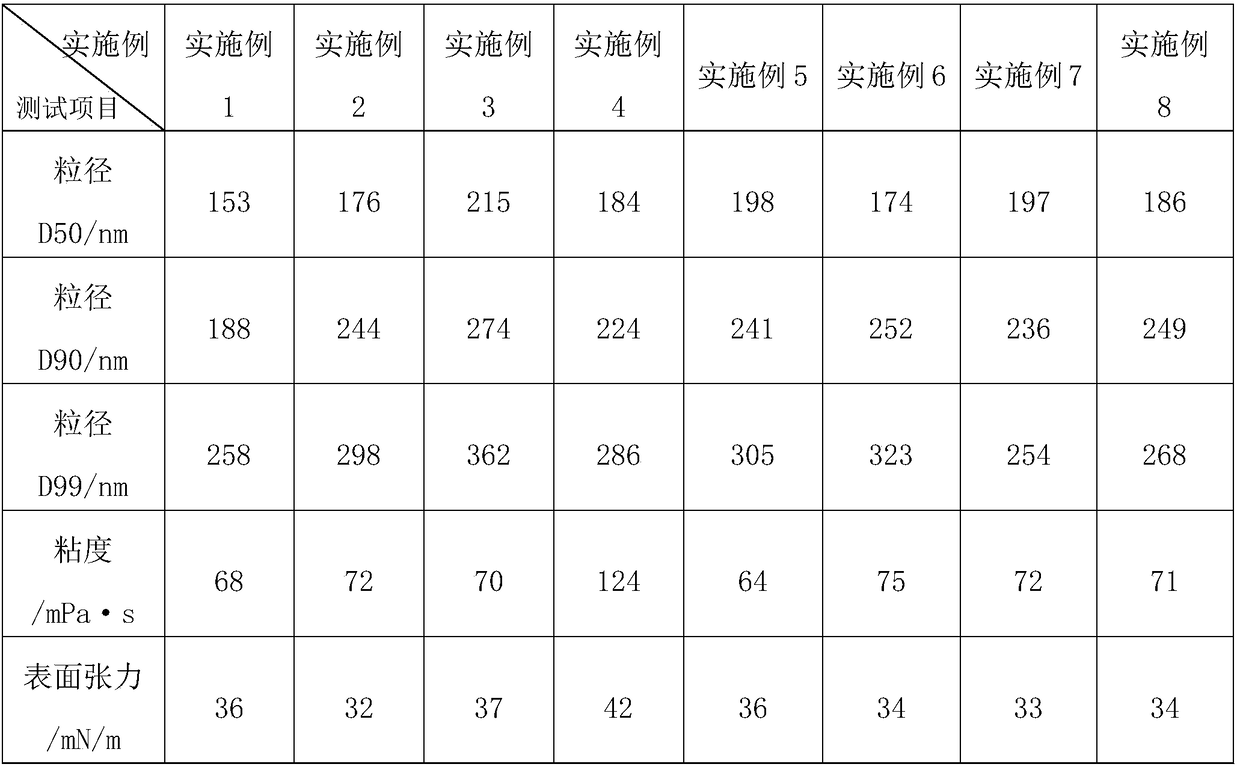

Matte TPO skin material with low processing viscosity as well as preparation method and application of TPO skin material

The invention provides a matte TPO skin material with low processing viscosity as well as a preparation method and application of the TPO skin material. The TPO skin material is formed by filling a thermoplastic polyolefin (TPO) with nanoparticles, wherein the mass ratio of the TPO to the nanoparticles is (90-99.5):(0.5-10); and the nanoparticles include one or more selected from the group consisting of multi-layer graphene, carbon nanotubes, monodisperse polystyrene microspheres, manganese oxide nanowires, iron tetroxide nanoparticles, fumed silica, and nano carbon black particles. The nanoparticles are packed in the TPO, so that the free volume of the polymer is increased, and the density of entanglement points is reduced; at the same time, interface slip occurs between the nanoparticlesand the polymer, the interface slip acts as a lubricant to reduce the viscosity of the system, so that the process temperature of operation such as mixing, calendaring and extrusion in the material processing process is reduced; the nanoparticles play a matting effect; the added nanoparticles have little effect on the mechanical properties of the material and improves the friction-resistant coefficient; and the TPO skin material provides guidance for industrial production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of oily self-dispersing nano carbon black

ActiveCN106634060AImprove placement stabilitySmall particle sizePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSilanesDouble bond

The invention discloses a preparation method of oily self-dispersing nano carbon black and belongs to the field of fine chemical industry. A silane coupling agent containing carbon-carbon double bonds is grafted on the surface of carbon black, polymerizable groups of the silane coupling agent are utilized to copolymerize with other oily monomers, the surfaces of carbon black particles are coated with a layer of polymer having both dispersing and stabilizing effects, and then the objective of self-dispersing in oily solvents is achieved.

Owner:JIANGNAN UNIV

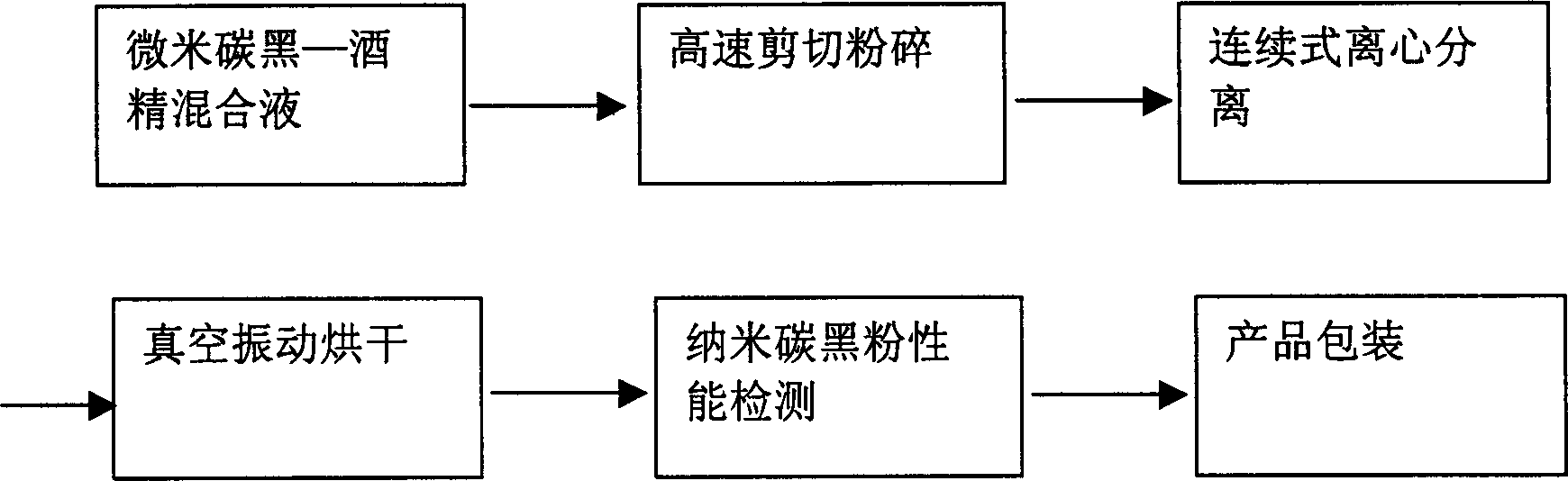

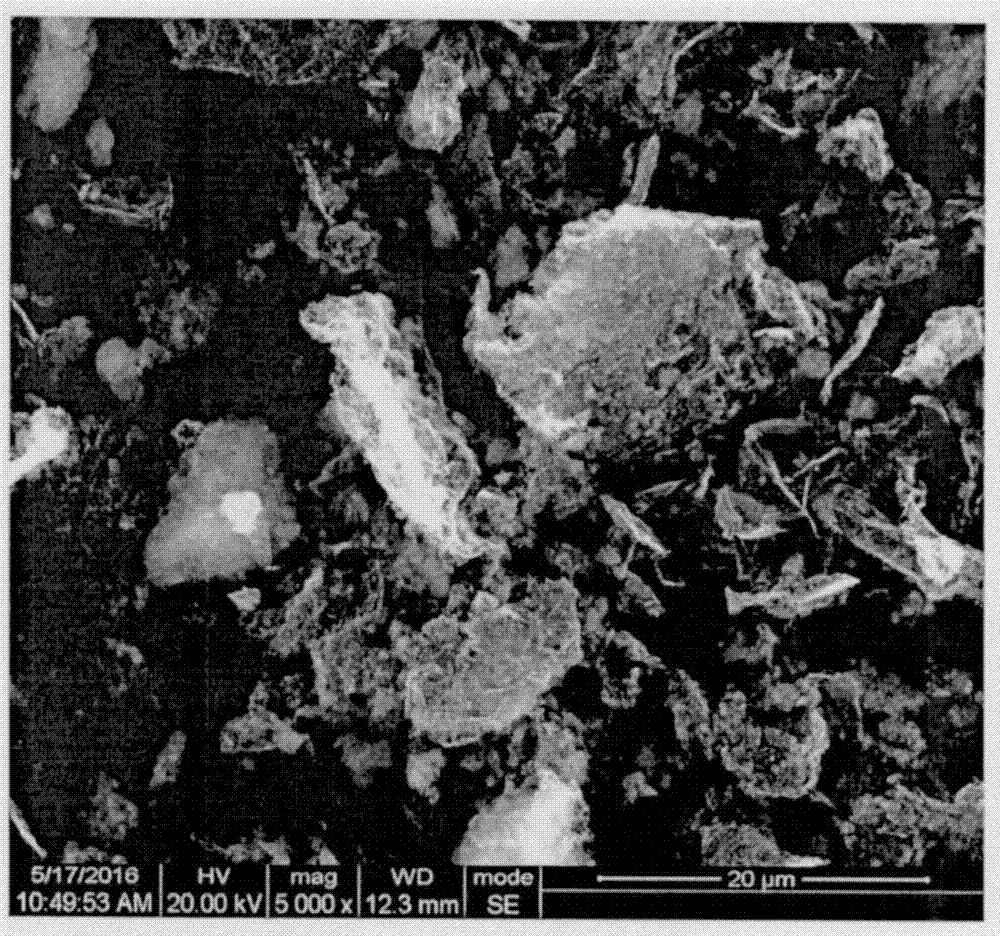

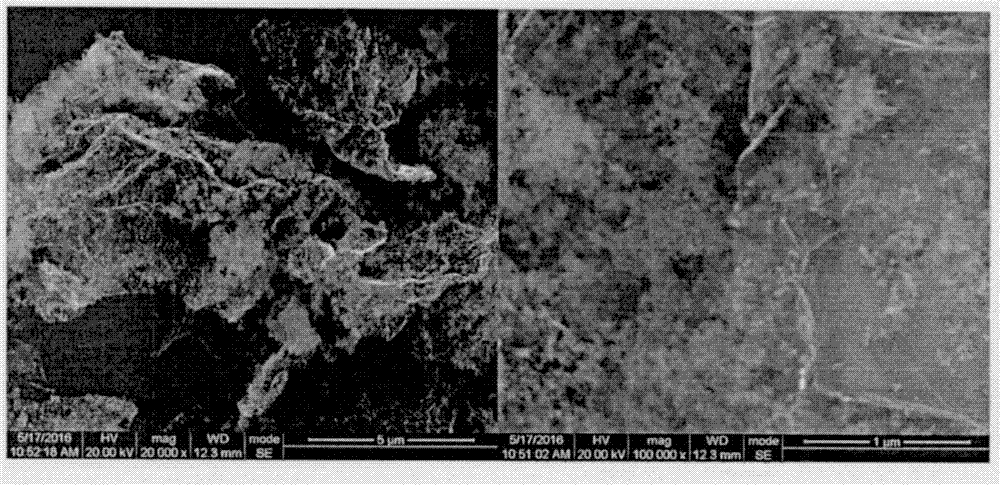

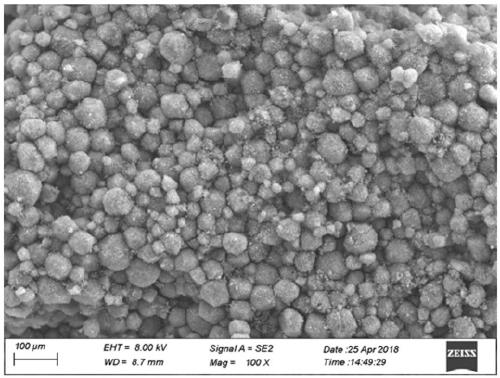

Method for preparing nanometer carbon black powder

InactiveCN1552621ASmall median particle sizeUniform particle sizeOther chemical processesAlcoholNanostructured carbon

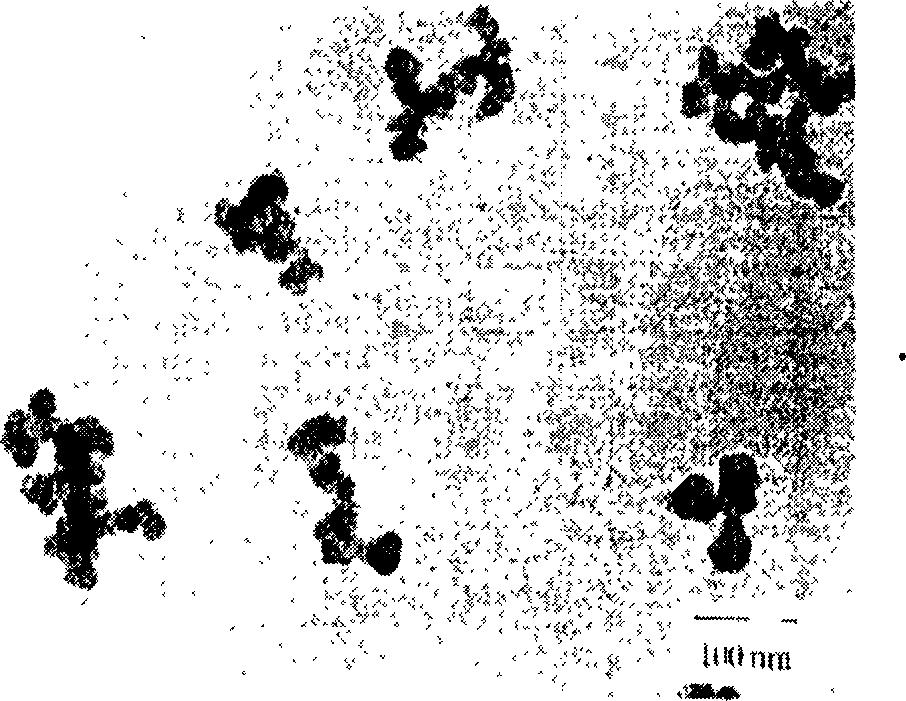

A process for preparing carbon black nanoparticles from its micro-class particles includes such steps as high-speed (1000-20000 rpm) shearing under the protection of industrial alcohol, centrifugal separating of alcohol, and baking while vacuum vibrating. Its particle diameter is less than or equal to 10 nm.

Owner:UNIV OF SCI & TECH BEIJING

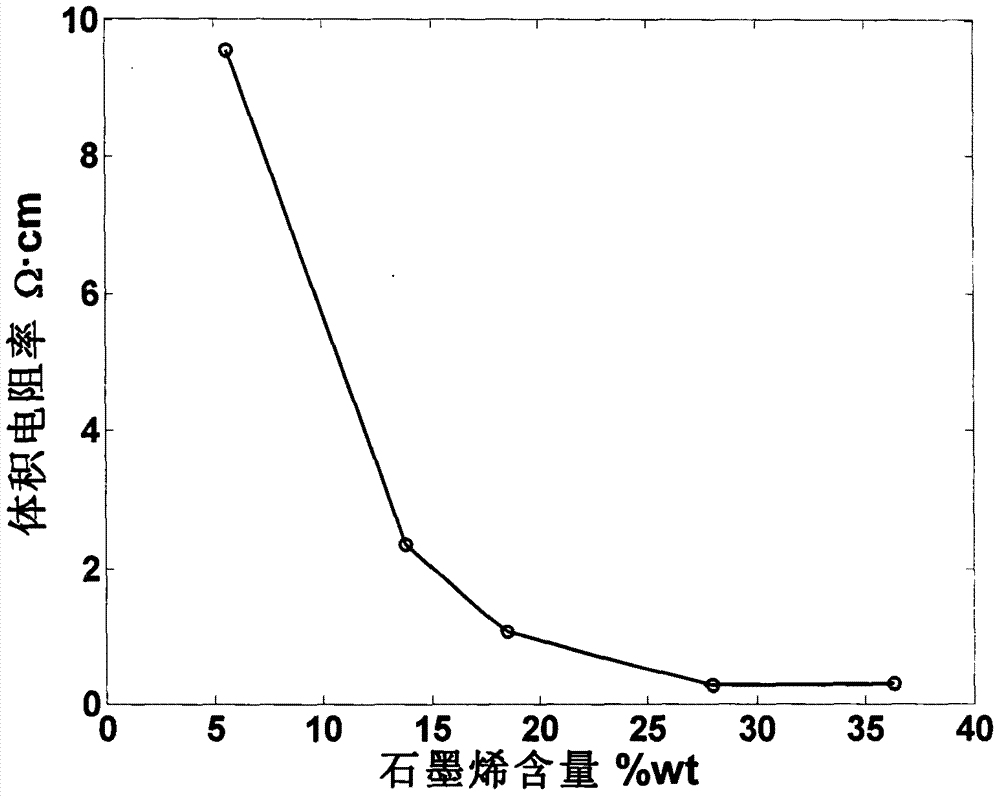

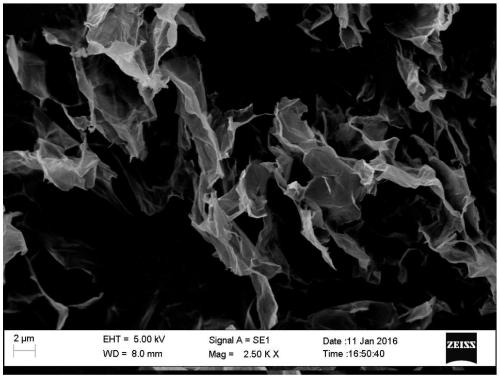

Graphene-white carbon black composite powder and preparation technology thereof

InactiveCN107541096AMaintain Monolayer DispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySlurry

The invention relates to graphene-white carbon black composite powder and a preparation technology thereof. The preparation technology comprises dispersing a graphene oxide aqueous solution and whitecarbon black powder in water at a high speed to obtain uniform mixed aqueous slurry, adding a gelling agent and a surfactant into mixed aqueous slurry, adjusting pH of the solution so that graphene oxide-white carbon black hydrogel is obtained, filtering and drying the graphene oxide-white carbon black hydrogel to obtain graphene oxide-white carbon black aerogel and calcining the graphene oxide-white carbon black aerogel at a high temperature in the inert atmosphere to reduce the graphene oxide so that the graphene-white carbon black composite powder is obtained. The preparation technology issimple and reliable and realizes a low cost. The graphene-white carbon black composite powder has powder resistivity less than 100 omega. cm, graphene in the composite material has good single layer dispersity, rich pore structures are formed through layer enwinding, the white carbon black nano-particles are uniformly dispersed on the surface of the graphene layer, and the composite material has excellent electrical conductivity and thermal conductivity and can be widely used in the fields of coatings, rubber products and plastic.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

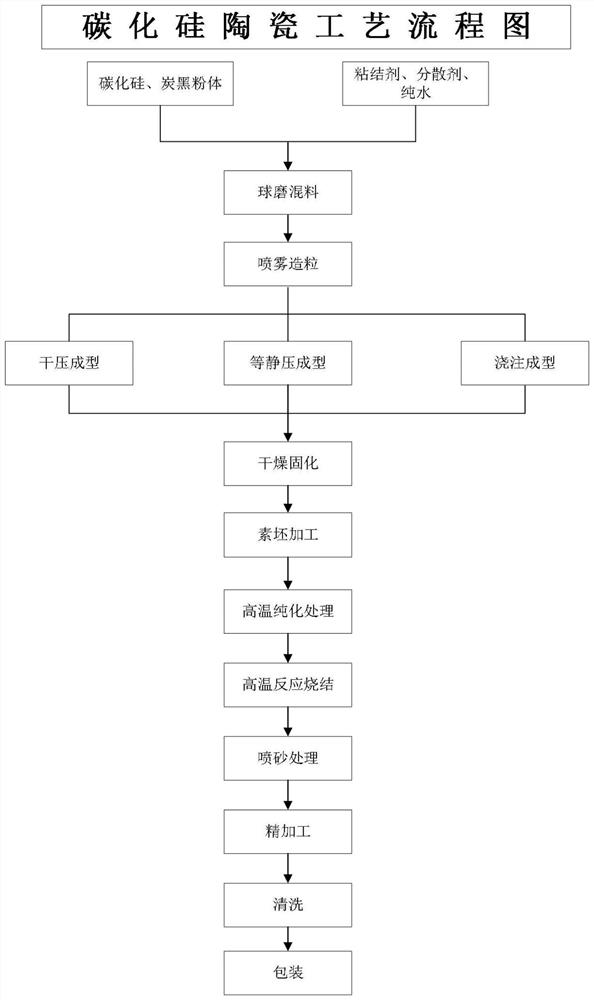

High-purity high-density silicon carbide ceramic and manufacturing method thereof

The invention discloses a high-purity high-density silicon carbide ceramic and a preparation method thereof, silicon carbide ceramic powder with different particle sizes is used as a main raw material, graphite powder and nano carbon black are used as binders, resin is used as a binder, a spray granulation process is used for uniform mixing. The preparation method comprises the following steps: carrying out dry pressing molding, isostatic pressing molding or casting molding to obtain a ceramic green body, drying and curing the green body, carrying out primary high-temperature purification heattreatment and secondary reaction siliconizing heat treatment, and finally carrying out surface treatment to obtain the high-purity high-density silicon carbide ceramic. The silicon carbide ceramic prepared by the process is high in purity, the content of various metal impurities is lower than 200 ppm, the density of the material reaches 99% or above, and the silicon carbide ceramic can be widelyapplied to the application fields of photovoltaics, LEDs or semiconductors with high purity and strength requirements.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

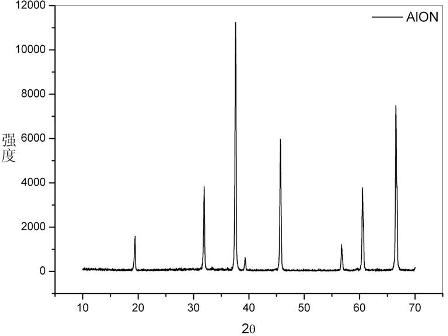

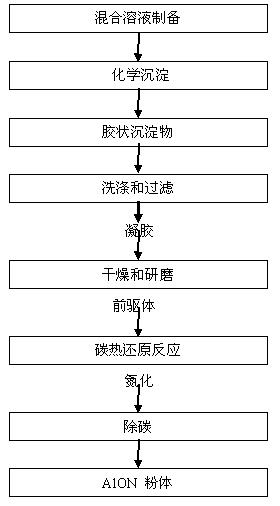

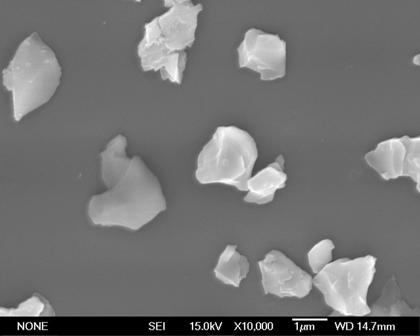

Method for preparing doped-cerium-terbium gamma-AlON radical luminous powder

InactiveCN102020988AAvoid uneven mixingAvoid reunionLuminescent compositionsCerium nitrateNitrogen gas

The invention relates to a method for preparing gamma-AlON radical ceramic luminous powder by using a co-precipitation method, belonging to the field of synthesis and preparation of phosphor powder materials. The method is characterized by comprising the following steps of: using aluminum nitrate, cerium nitrate, terbium nitrate, urea and nano carbon black as raw materials, using PEG as a dispersing agent, using ammonium bicarbonate and ammonia water as a precipitating agent, and precipitating and reacting to obtain a precursor; precipitating and washing the precursor, and grinding after drying; after processing for 2-4 hours under the nitrogen protection condition at 700 DEG C, keeping warm for 2-4 hours under the condition of nitrogen flow of 0.5L / min at 1750 DEG C; after naturally cooling in air, removing carbon under the condition of 700 DEG C, and finally obtaining AlON radical phosphor powder doped with Tb3+ / Ce3+luminous irons. The particle size of the powder is in the range of 1-2mu and is uniform. After the components are optimized, the AlON powder co-doped with Tb3+ / Ce3+ irons is excited to have good luminous properties under the condition of 275nm, and the luminous intensity is as ten times as that of AlON phosphor powder singly doped with Tb3.

Owner:SHANGHAI UNIV

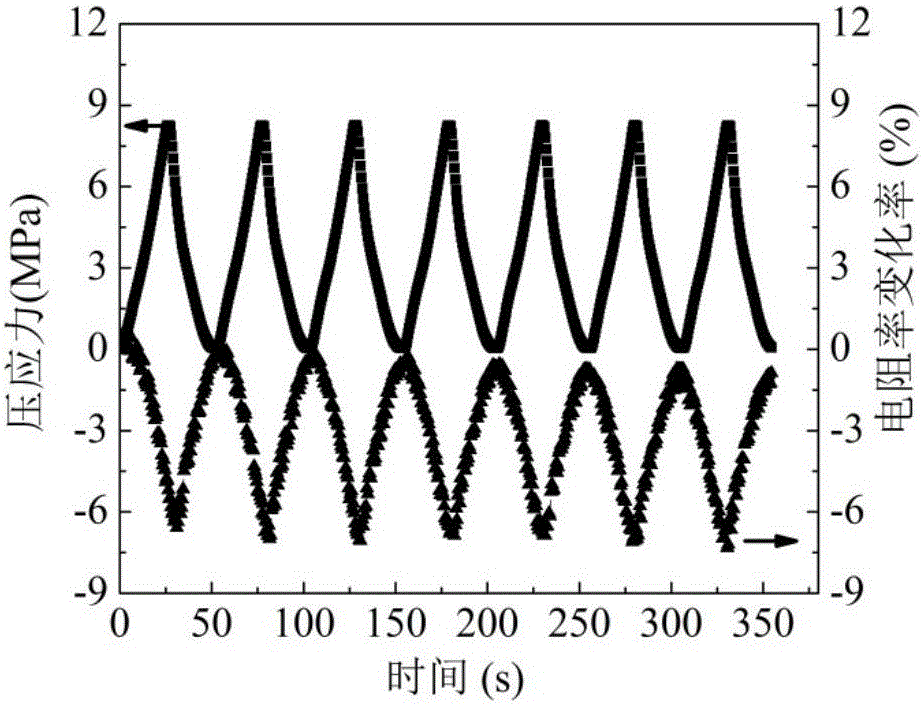

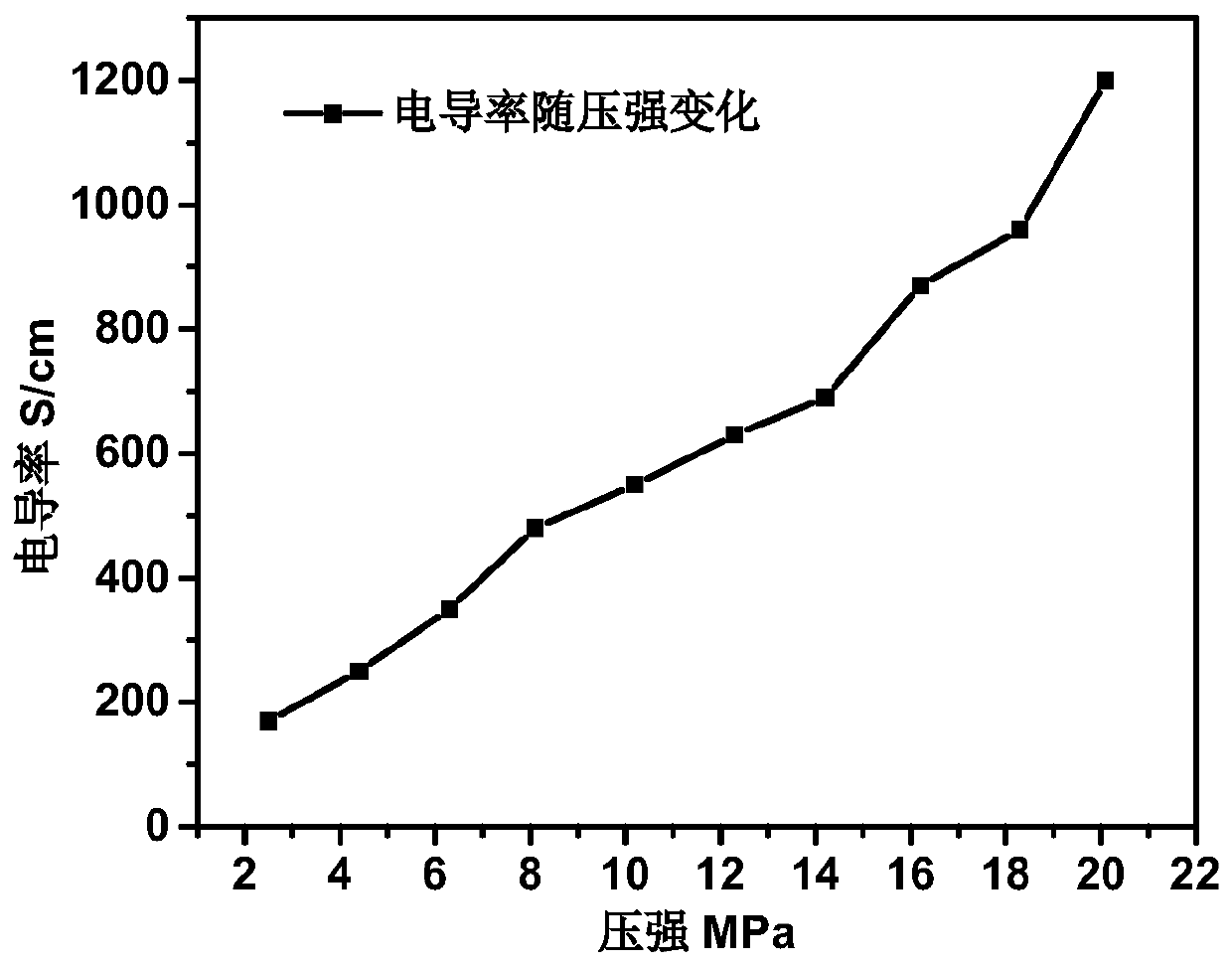

Electrostatic self-assembly carbon nano tube/nano-carbon black composite mortar as well as preparation method and application thereof

The invention discloses electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar. Raw materials of the mortar comprise cement, silica fume, electrostatic self-assembly carbon nano tubes / nano-carbon black, a water reducing agent, sand and water. The minimum static resistivity of the mortar reaches 0.45 omega*m, the range of an absolute value of the resistivity change rate is 3.3%-22.1%, the change range of stress sensitivity is 0.40%-2.69% / MPa, and the change range of the strain sensitivity is 105-704. Compared with the prior art, the electrostatic self-assembly carbon nano tube / nano-carbon black composite mortar and the preparation method thereof solve the problem about dispersion of nanofiller in the mortar very well, and the carbon nano tubes and the nano-carbon black have the collaborative conductive effect, so that the mortar can acquire very low static resistivity and has excellent pressure-sensitivity by the aid of a small mixing amount of electrostatic self-assembly carbon nano tubes / nano-carbon black.

Owner:DALIAN UNIV OF TECH

Decorating interior sound insulation material

The invention relates to a decorating interior sound insulation material, which is prepared from the following raw materials in parts by weight: 42-56 parts of thermoplastic phenol resin, 20-25 parts of expanded vermiculite, 4-6 parts of polystyrene foamed plastic, 2-3 parts of a silane coupling agent, 1-1.5 parts of nano carbon black, 8-10 parts of polymethyl methacrylate, 0.1-0.2 part of an antioxidant, 0.1-0.2 part of a foaming agent, 0.2-0.3 part of magnesite, 2-3 parts of silica sol with the solid content of 10%-15%, 20-40 parts of 100-200-mesh montmorillonoid, 10-12 parts of a water-based polyurethane emulsion with the solid content of 8%-10%, 10-20 parts of collagenous fiber, 20-30 parts of waste felt and 2-5 parts of an assistant. The prepared expanded vermiculite-polyurethane composite emulsion-wrapped thermoplastic phenol resin nonwoven sound insulation material is light in weight, small in thickness and good in sound insulation effect, and has a good market prospect.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +3

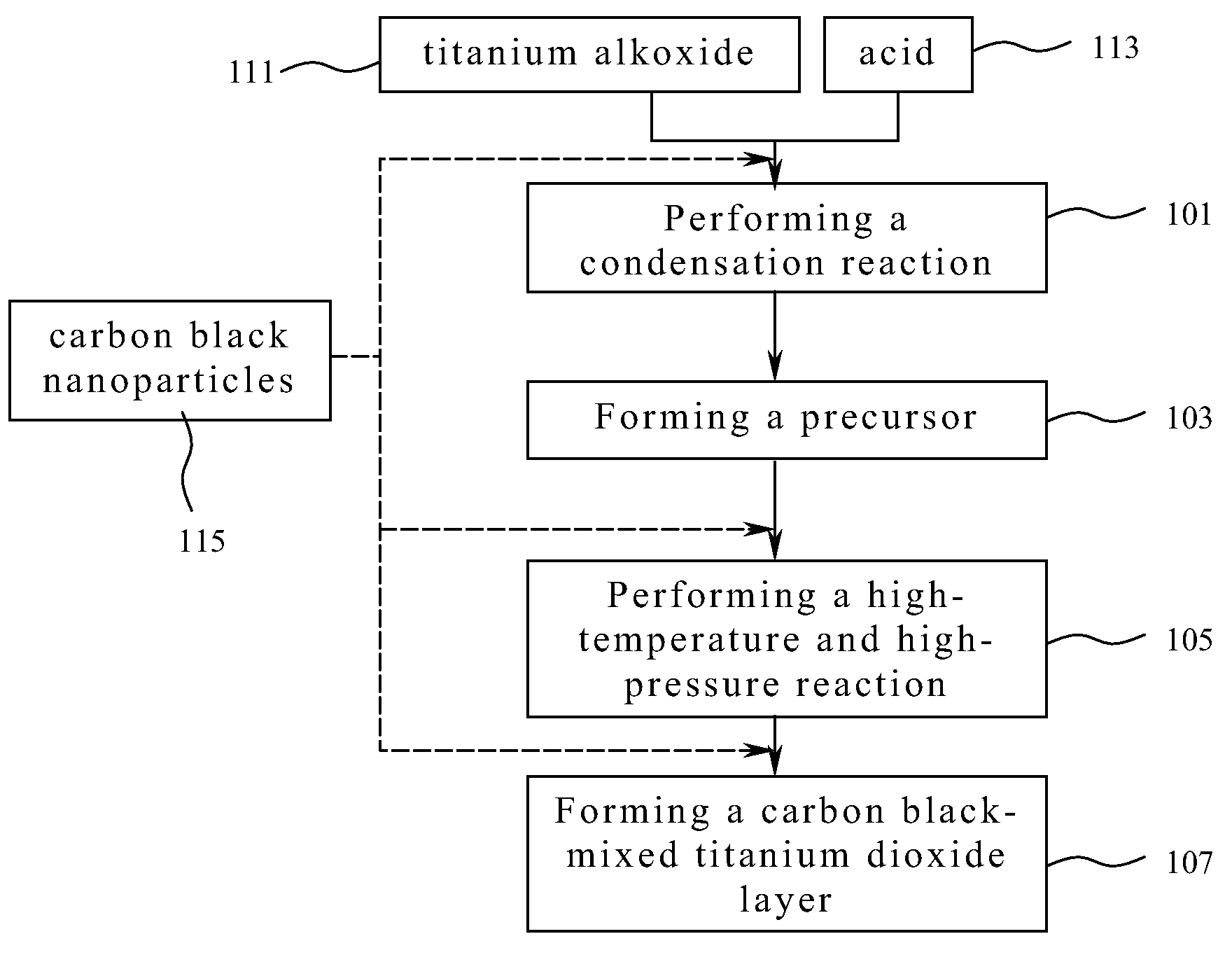

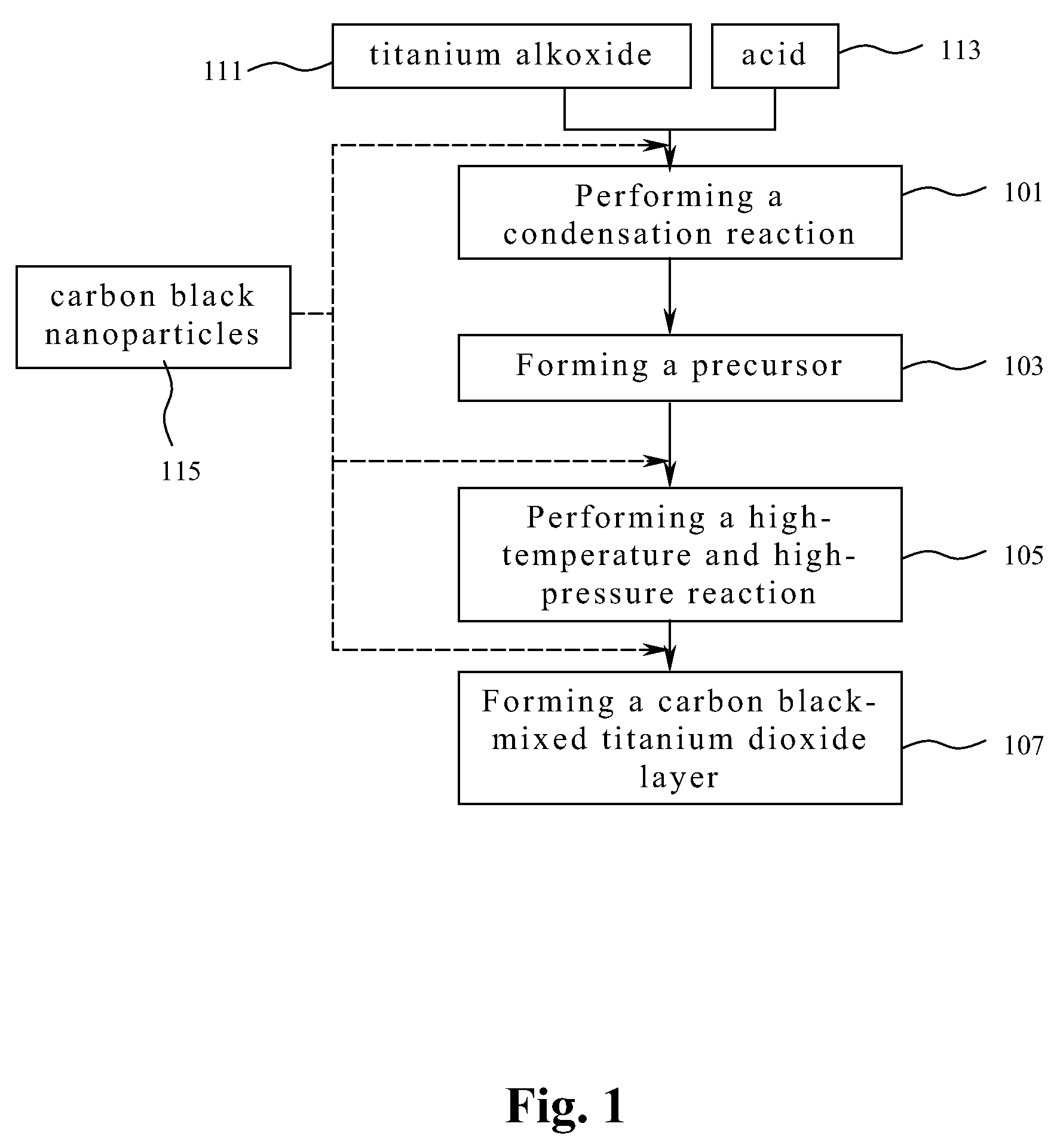

Dye-sensitized solar cell, anode thereof, and method of manufacturing the same

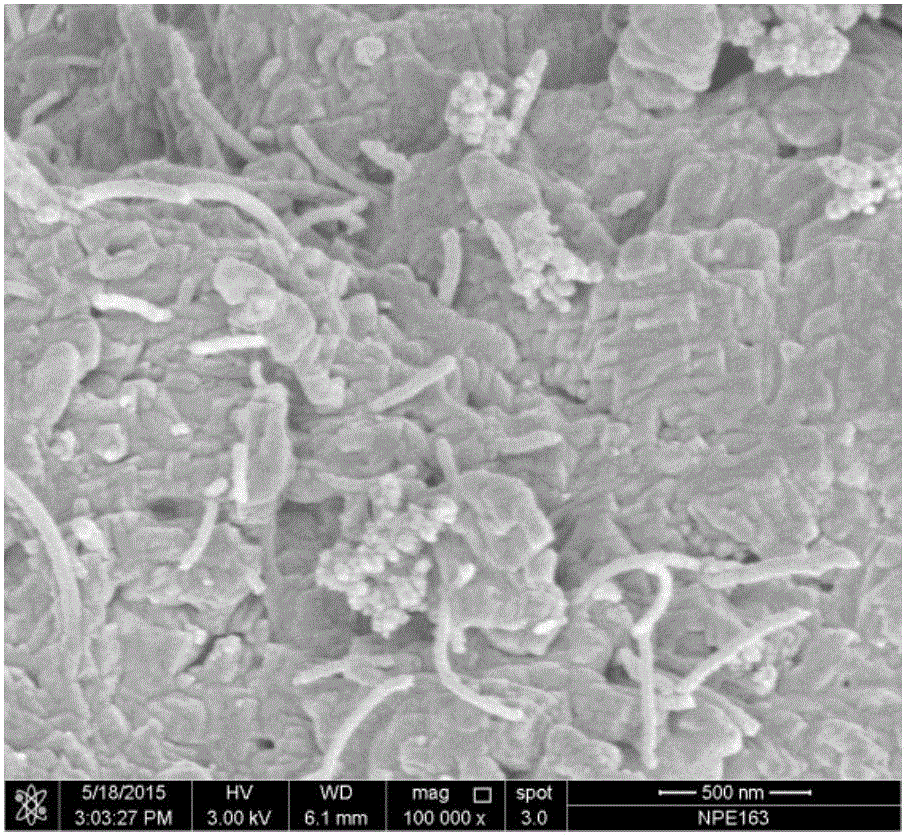

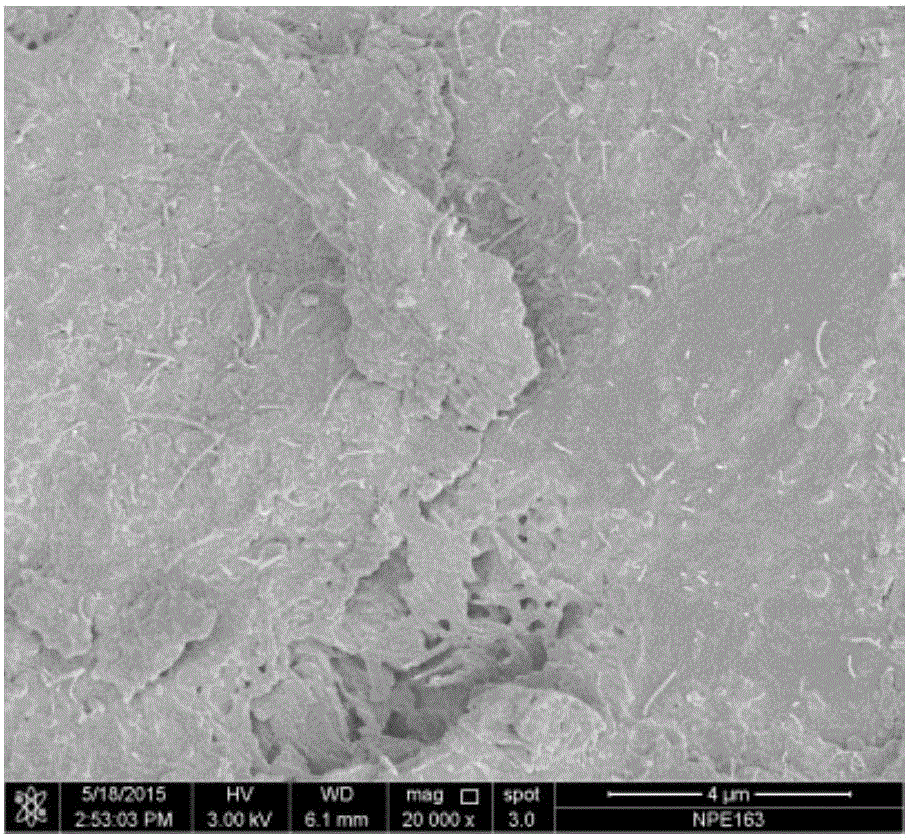

InactiveUS20100154880A1Improve conductivityImprove conversion efficiencyElectrolytic capacitorsFinal product manufactureElectricityElectrical battery

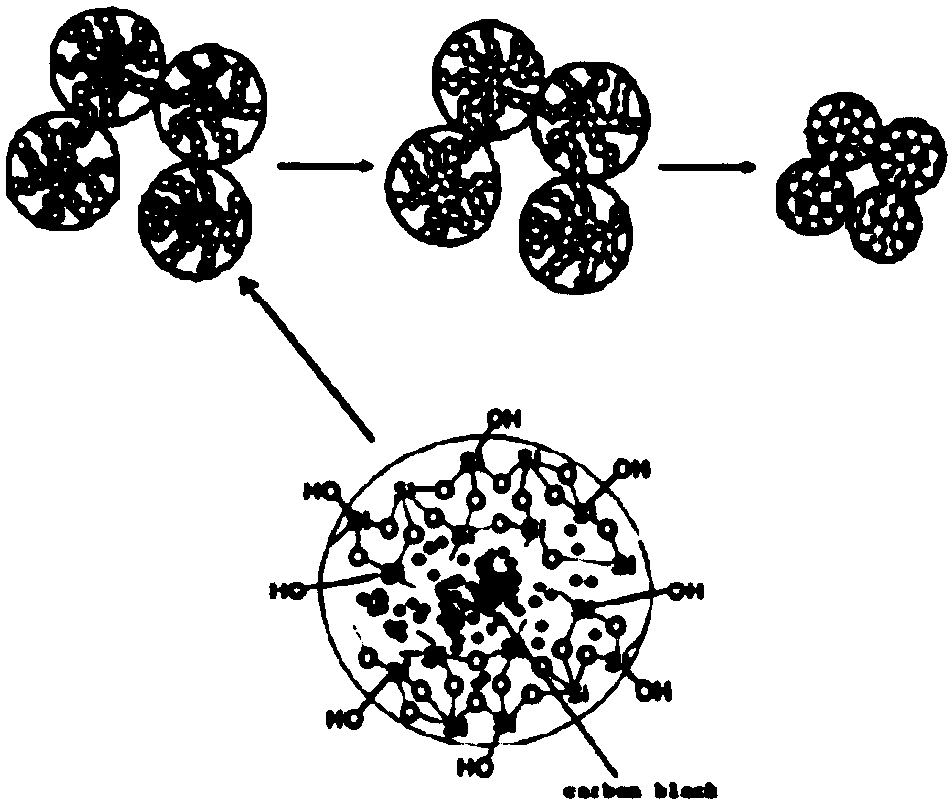

A dye-sensitized solar cell (DSSC), anode thereof, and method of manufacturing the same are disclosed. The anode has a titanium dioxide layer mixed with a desired ratio of carbon black nanoparticles to increase the conductivity of the anode. Thereby, the conversion efficiency of the solar energy to electricity for the DSSC is effectively improved.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

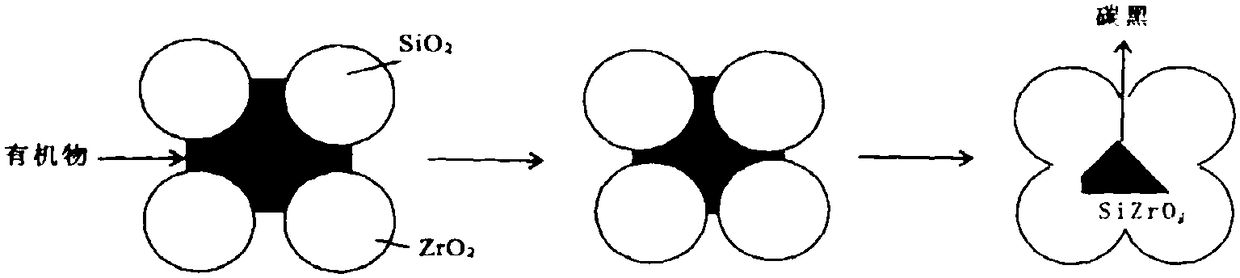

Preparation method of ceramic printing ink containing carbon black

The invention discloses a novel preparation method of ceramic printing ink containing carbon black. The preparation method comprises the steps of carbon black modification, preparation of modified carbon black sol, preparation of silica sol, preparation of zirconia sol, preparation of zirconium silicate containing carbon black precursor, preparation of zirconium silicate containing carbon black powder, and the preparation of zirconium silicate containing carbon black ceramic printing ink. The ceramic ink containing carbon black utilizes zirconium silicate containing carbon black nanoparticlesinstead of cobalt, chromium and other heavy metal elements in the prior art, being environmentally friendly without pollution. The cheap carbon black is used to replace the expensive cobaltous oxide in the existing black ceramic pigment material, greatly reducing the cost of black ceramic ink. The ceramic ink containing carbon black is in deep and pure color, and has good high temperature stability. The average particle size D50 of zirconium silicate containing carbon black nanoparticles in ceramic inkcontaining carbon black is less than 300nm, meeting the requirement of almost all ceramic nozzles for the fineness of ink particles in the market.

Owner:佛山市扬子颜料有限公司

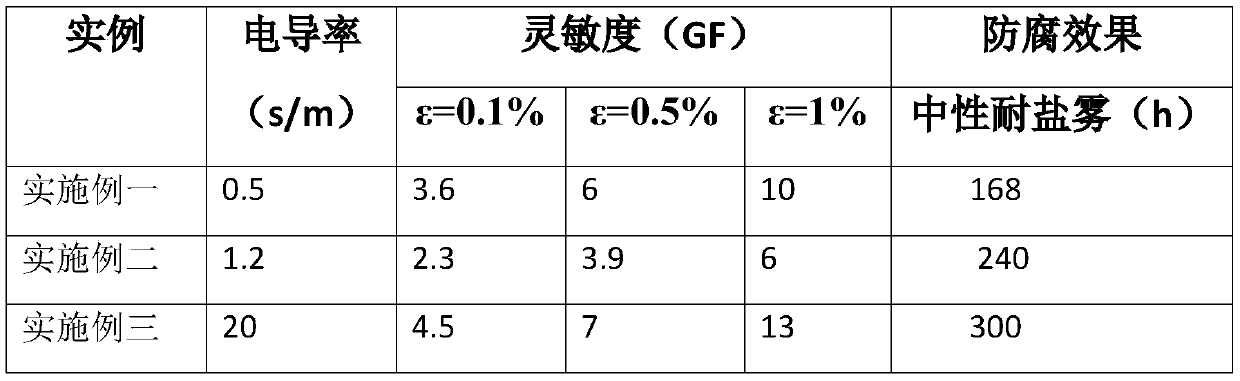

Bio-based water-based anticorrosive conductive coating for bridge building protection and health monitoring and preparation method thereof

ActiveCN111303770AProduction environmental protectionSustainable developmentAnti-corrosive paintsElectrically-conductive paintsConductive coatingNano carbon

The invention discloses a bio-based water-based anticorrosive force-sensitive conductive coating for bridge building protection and health monitoring, which comprises a bio-based resin, an assistant,deionized water, a cosolvent, a pigment and a conductive filler, and the conductive filler comprises nano carbon black, carbon nanotubes, Mxene, silver nanowires or nickel nanowires. Bio-based resin is used as a main film forming matter, so that the production of the product is environmentally friendly and in line with sustainable development. The conductive filler is added, so that the prepared bio-based water-based anti-corrosion force-sensitive conductive coating not only has corrosion resistance, but also has conductivity and sensitive sensitivity, thereby being used for stress detection or bridge deformation detection.

Owner:ZHEJIANG HUANZHOU POLYMER MATERIAL TECH CO LTD

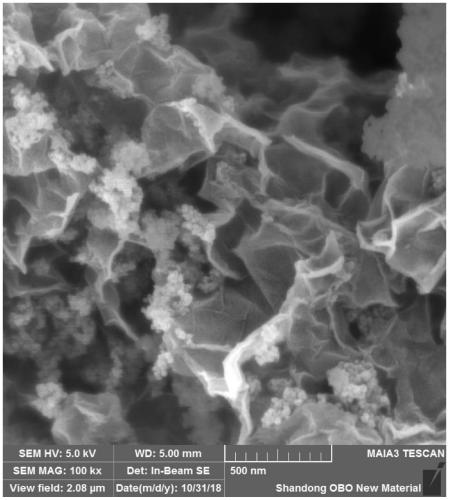

Graphene/white carbon black nanometer composite material and preparation method thereof

The invention provides a graphene / white carbon black composite material. The graphene / white carbon black composite material comprises a graphene material and white carbon black, wherein the white carbon black is grafted on lamellas of the graphene material through chemical bonds. The graphene / silane coupling agent / white carbon black composite material with a novel structure is obtained by bondingthe graphene material and the white carbon black through chemical bonds. In the composite material provided by the invention, the graphene material and the white carbon black are interspersed, mutualagglomeration can be inhibited, and white carbon black nanoparticles are uniformly compounded and grafted on the surfaces of the lamellas of the graphene material, so the graphene material can keep abasic lamellar structure and maintains good single-layer dispersity in the composite material, and the material is a nano-scale highly-dispersed material. Meanwhile, the white carbon black on the surface of the graphene can improve the rigidity of the graphene lamellas, prevent the graphene from curling and folding due to high-temperature shearing in a rubber mixing process and improve the dispersity of the graphene in a rubber matrix.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

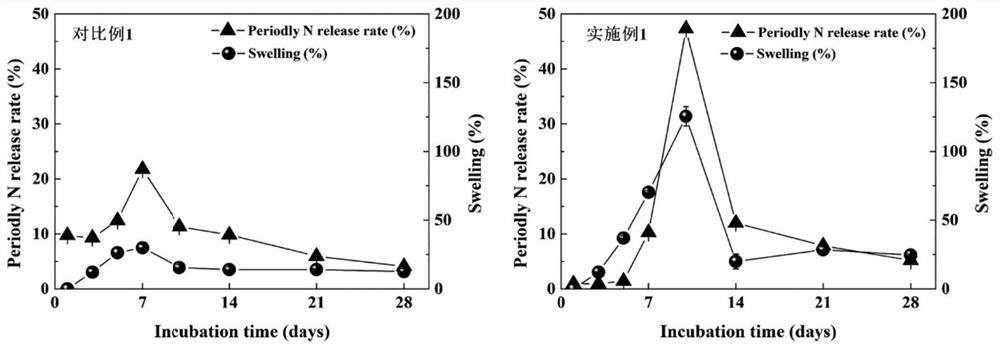

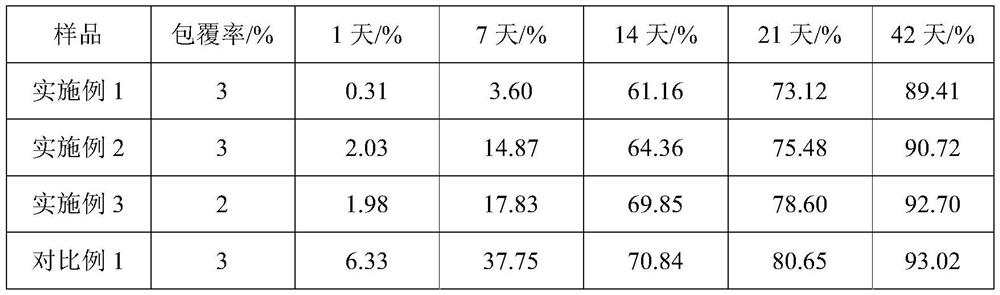

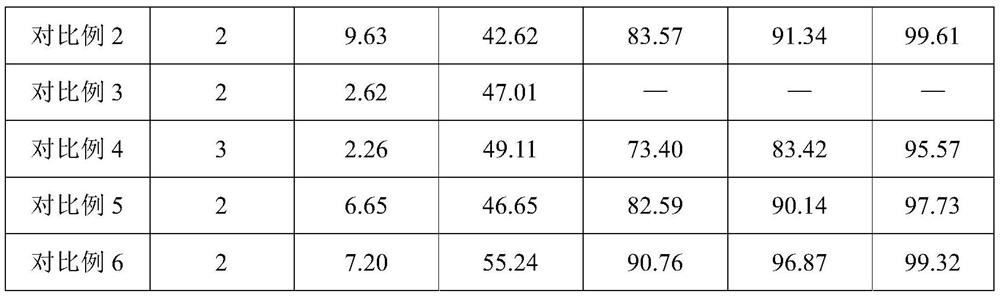

Vegetable oil-based polyurethane coated fertilizer and preparation method thereof

ActiveCN112159269ASuperhydrophobicImprove surface hydrophobicityUrea compound fertilisersLayered/coated fertilisersMicro nanoVegetable oil

The invention discloses a vegetable oil-based polyurethane coated fertilizer and a preparation method thereof. The vegetable oil-based polyurethane coated fertilizer comprises fertilizer particles anda vegetable oil-based polyurethane coating, wherein the modified vegetable oil-based polyurethane coating comprises an inner layer coating, a middle layer coating and an outer layer coating which aresequentially coated from inside to outside; the inner layer coating and the outer layer coating are prepared from a vegetable oil-based polyurethane coating solution, and the middle layer coating isprepared from a vegetable oil-based polyurethane coating solution and nano carbon black. According to the fertilizer and the preparation method disclosed in the invention, nano carbon black which is low in surface energy, low in price and easy to obtain is doped into a plant oil-based polyurethane coating to construct a micro-nano super-hydrophobic coating, so that the plant oil-based polyurethanecontrolled-release fertilizer with an ultralow coating rate is prepared, and the nutrient content of the controlled-release fertilizer per unit mass is increased; the purposes of prolonging the controlled release effect of the coated fertilizer and reducing the dosage of the coating material can be achieved, the cost is relatively low, and the environment-friendly effect is achieved.

Owner:SOUTH CHINA AGRI UNIV

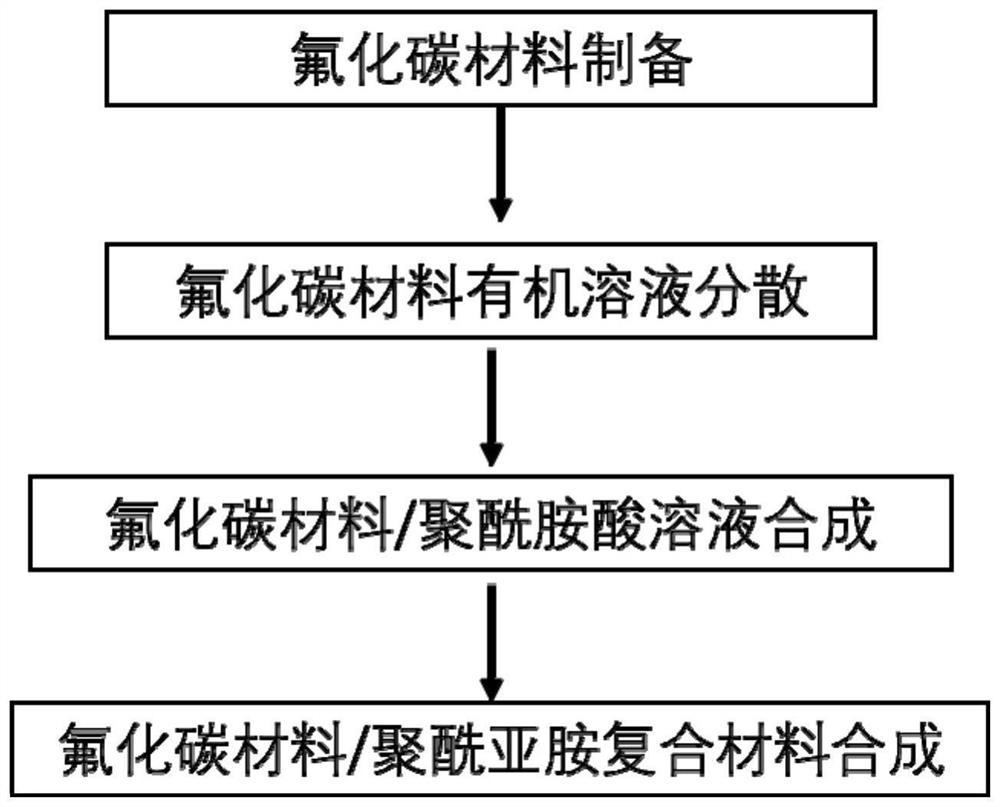

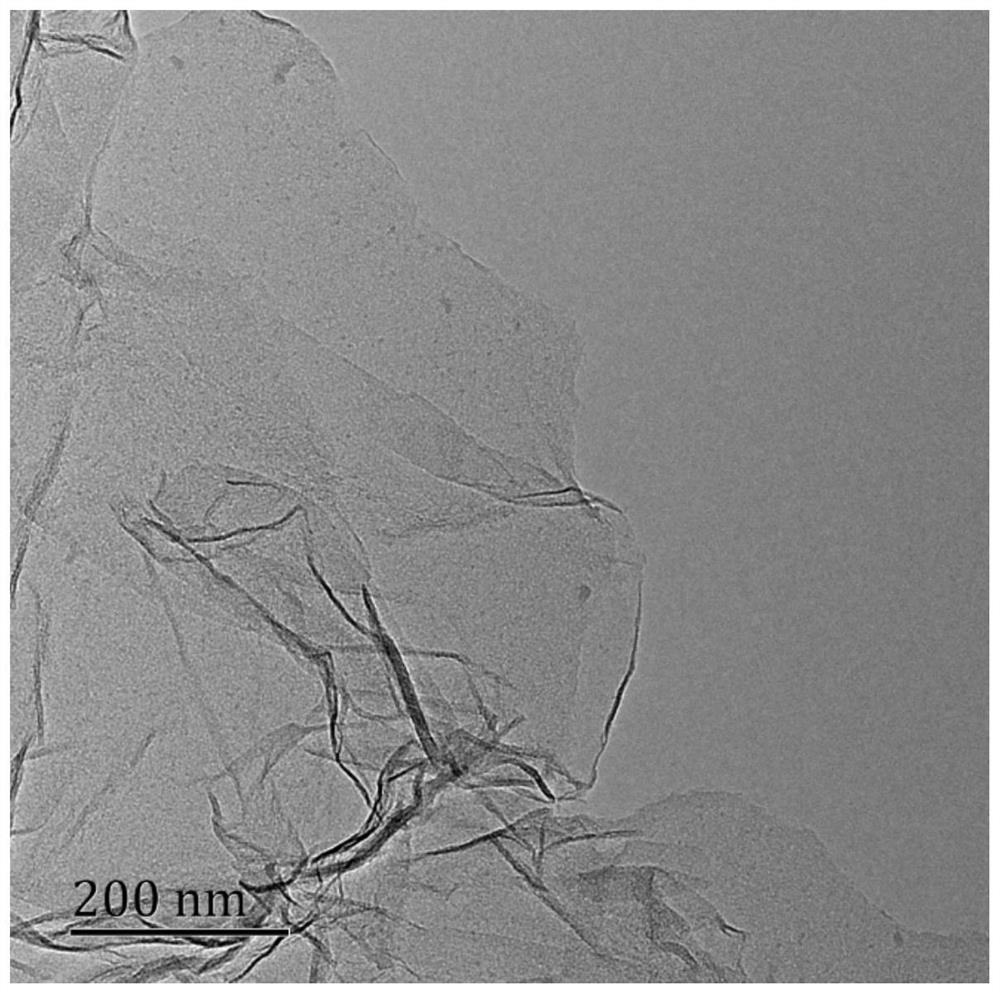

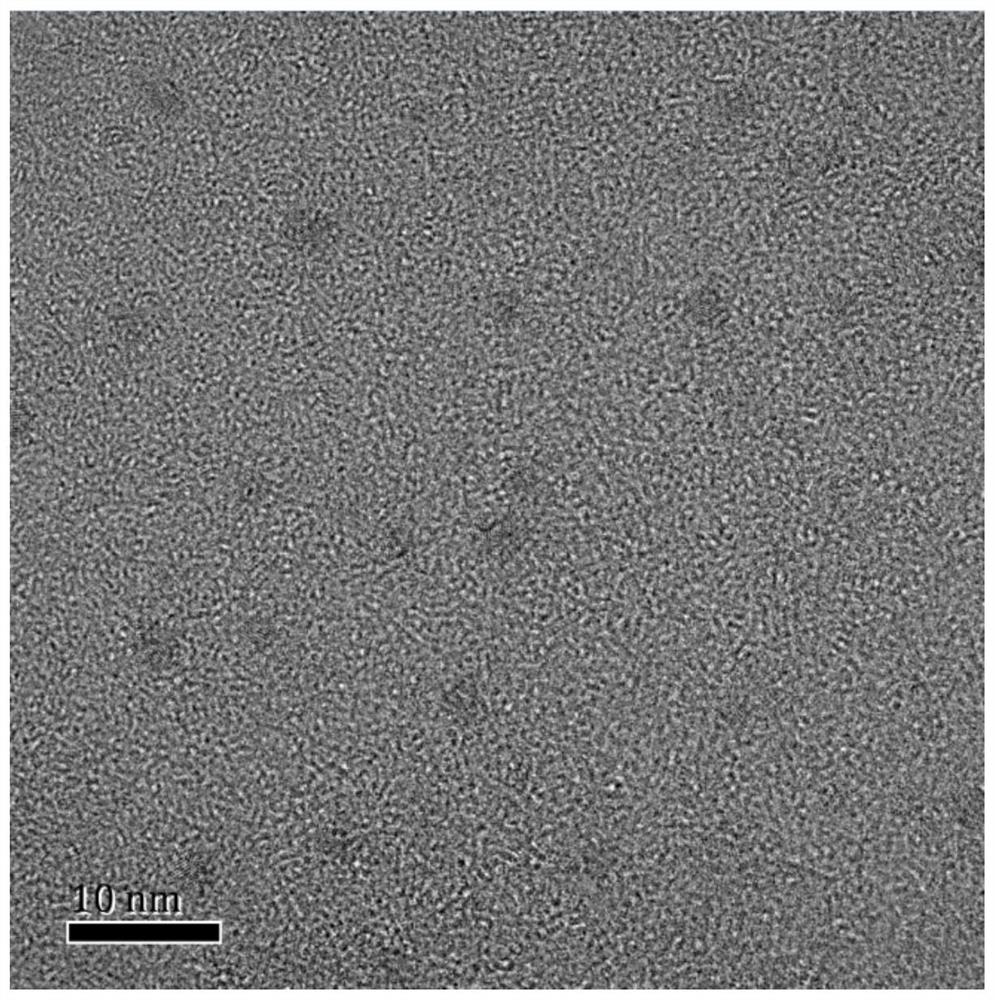

Polyimide composite material and preparation method and application thereof

ActiveCN112029098AEasy to operateLow dielectricSemiconductor/solid-state device detailsSolid-state devicesImidePolymer science

The invention relates to a polyimide composite material and a preparation method and application thereof. The polyimide composite material comprises a polyimide matrix and a carbon fluoride material distributed in the polyimide matrix; the carbon fluoride material comprises any one or a combination of at least two of graphene fluoride with the plane size smaller than or equal to 10 [mu]m, fluorinated nano carbon black with the diameter smaller than or equal to 100 nm or fluorinated graphene quantum dots with the diameter smaller than or equal to 10 nm. The three carbon fluoride materials withspecific sizes are introduced into the polyimide matrix, so that the comprehensive performance of the polyimide can be effectively improved, and the polyimide has low dielectric constant, high light transmittance, low water absorption rate, high heat resistance and excellent mechanical properties.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Energy-saving and environment-friendly light wallboard and preparation method thereof

InactiveCN111635189AHigh molding strengthImprove stress resistanceConstruction materialWallsFiberToxic industrial waste

The invention belongs to the field of buildings, and particularly discloses an energy-saving and environment-friendly light wallboard and a preparation method thereof. The light wallboard is preparedfrom the following components by weight: 10-28 parts of Portland cement, 10-25 parts of coarse aggregate, 20-40 parts of fine aggregate, 4-9 parts of silica fume, 3-5 parts of fiber, 2-7 parts of expanded perlite, 2-5 parts of water-based nano carbon black, 3-12 parts of slag powder, 4-6 parts of nano calcium carbonate, 70-120 parts of water and 2- 6 parts of an additive. The production cost is reduced, the wallboard molding strength is high, and compared with a traditional light wallboard, the light wallboard still has high strength and high waterproof performance in the long-term use process, a large amount of industrial waste residues are utilized as the raw materials, waste is turned into wealth, the purposes of saving energy and protecting the environment are achieved, and the compression resistance and the waterproof performance of the wallboard are improved.

Owner:南京紫晶藤节能科技有限公司

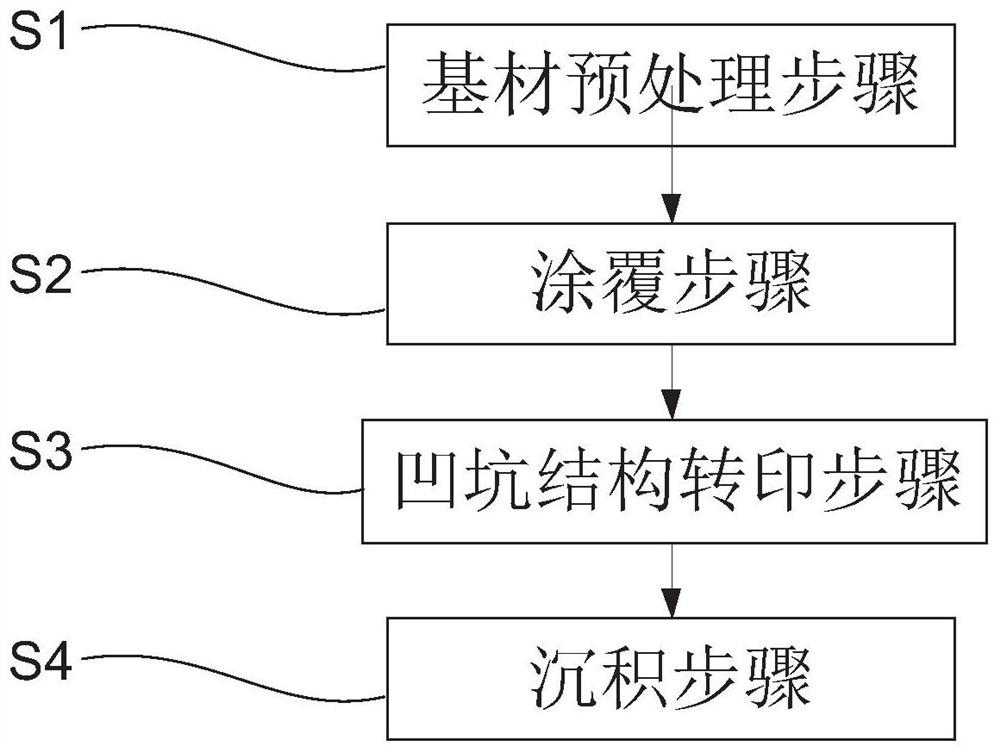

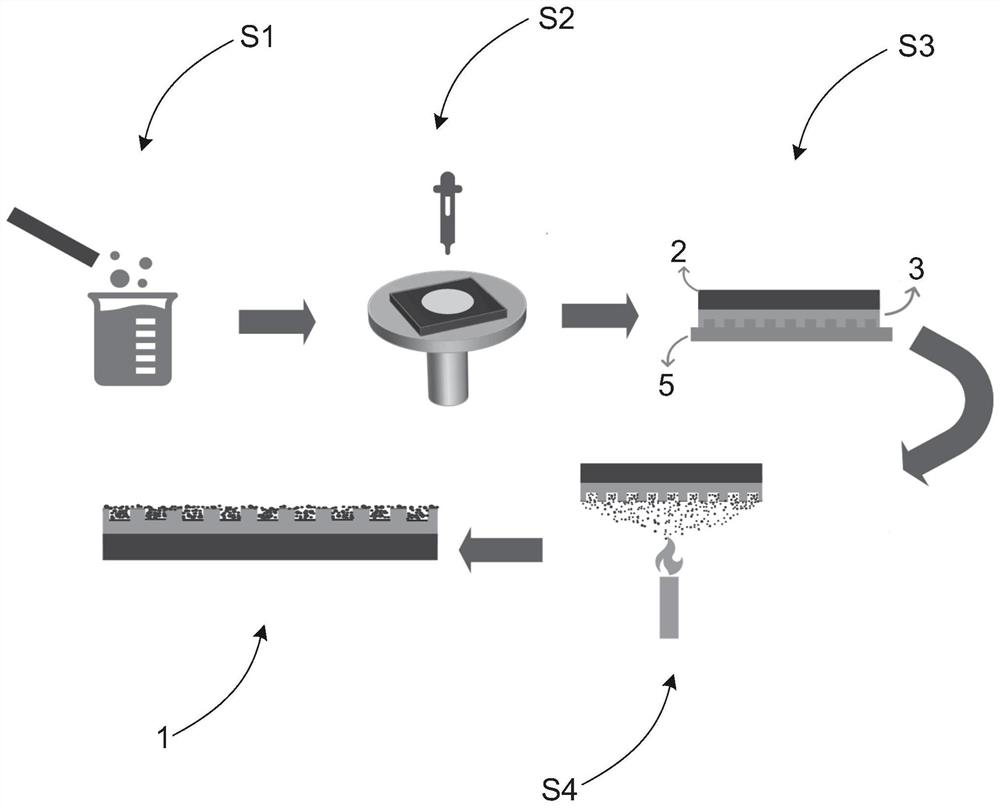

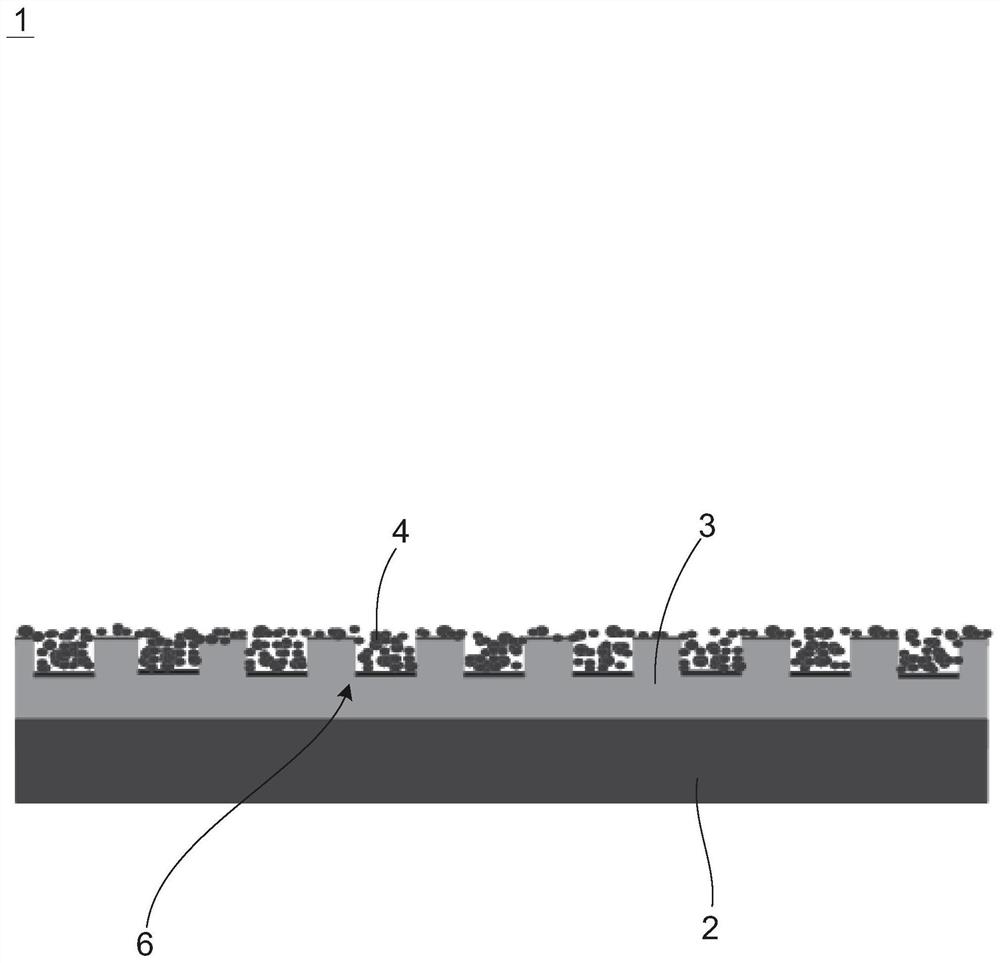

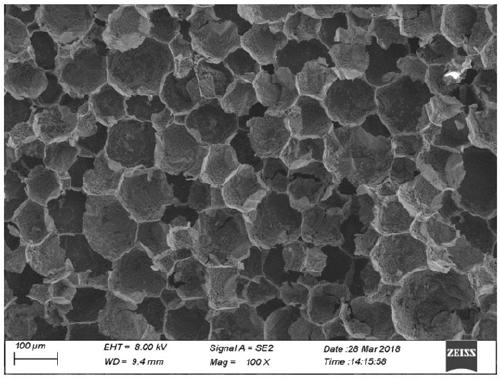

Preparation method of hydrophobic wax-proof composite coating and hydrophobic wax-proof composite coating

The invention discloses a preparation method of a hydrophobic wax-proof composite coating. The preparation method comprises the following steps: a base material pretreatment step of cleaning a base material, a coating step of uniformly coating the base material with silicone rubber, a pit structure transfer printing step and a deposition step. In the pit structure transfer printing step, the gluing surface, coated with the silicon rubber, of the base material is in contact with a template with a lotus leaf surface structure, so that the gluing surface is constructed to be of a pit structure corresponding to the lotus leaf surface structure. And in the deposition step, nano carbon black particles are deposited on the gluing surface, and the nano carbon black particles enter the pits, so that the hydrophobic wax-proof composite coating is obtained. According to the preparation method of the hydrophobic wax-proof composite coating, the preparation process is simple, the cost is low, and the obtained coating has excellent super-hydrophobic and wax-proof effects, has good mechanical durability and is suitable for the oil-water two-phase flow working condition of crude oil transportation.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

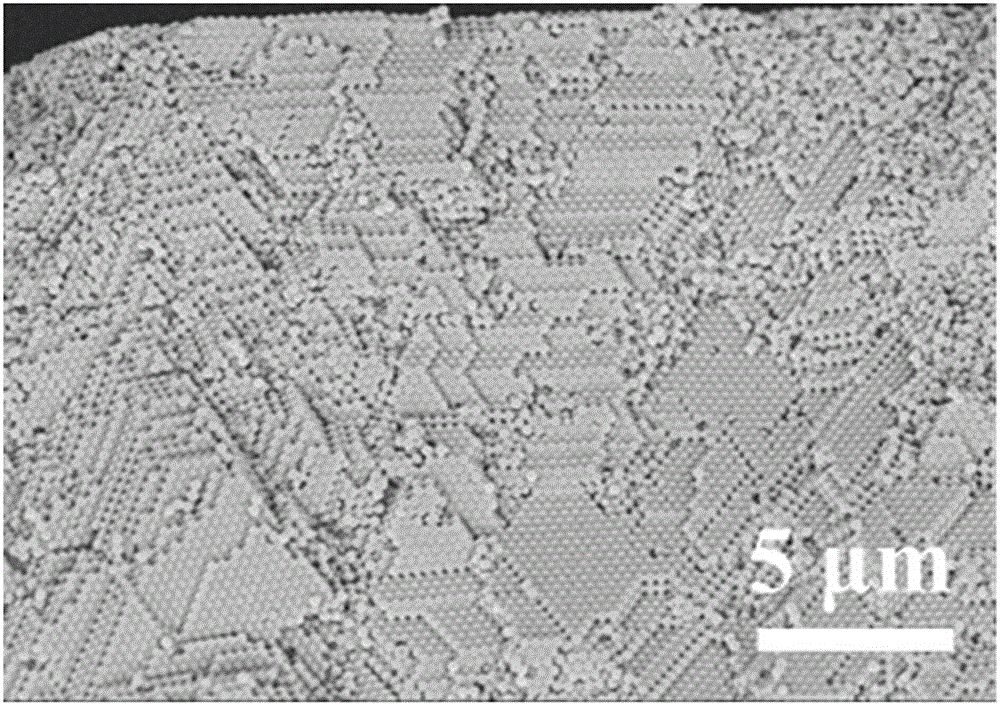

Ceramic sponge material method for preparing nanowire woven microspheres by reverse template method

The invention discloses a ceramic sponge material method for preparing Si3N4 / SiC nanowire woven microspheres by a reverse template method. The method comprises the following steps: (1) taking silica sol and water-soluble carbon black as initial raw materials, and performing ultrasonic dispersion or ball milling to prepare uniformly dispersed mixed slurry; (2) adding a surfactant into the mixed slurry obtained in the step (1), and foaming to obtain ultra-stable foam; (3) drying the foam obtained in the step (2) so as to obtain a foam body formed by silica sol nano-particles and carbon black nano-particles; and (4) carrying out a carbon thermal reduction reaction on the foam body obtained in the step (3), thereby obtaining the nanowire woven microspheres. The invention provides a low-cost preparation method of the nanowire woven microspheres, the preparation process is simple, and expensive equipment is not needed.

Owner:北京华圻生态科技有限公司

Primer glue for polyurethane structural adhesive, preparation method and applications thereof

ActiveCN110643324AHigh bonding strengthImprove adhesionNon-macromolecular adhesive additivesAircraft accessoriesEpoxyPolymer science

The invention relates to a primer glue for a polyurethane structural adhesive, a preparation method and applications thereof, wherein the raw materials comprise, by mass, 10-20% of N-(beta-aminoethyl-gamma-aminopropyl)trimethoxysilane, 10-30% of epoxy group 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 10-30% of acryloyloxy gamma-(methacryloyloxy) propyltrimethoxysilane, 19.5-69.5% of isopropanol and 0.1-1% of nanometer carbon black. The invention further provides a sliding rail for bonding a window body by using the polyurethane structural adhesive and the primer glue. According to the invention, by matching the polyurethane structural adhesive and the primer glue, the problems of easy shedding, glue breaking and the like of the polyurethane structural adhesive during the use are solved soas to prolong the service life.

Owner:BEIJING HANGBO NEW MATERIAL TECH +1

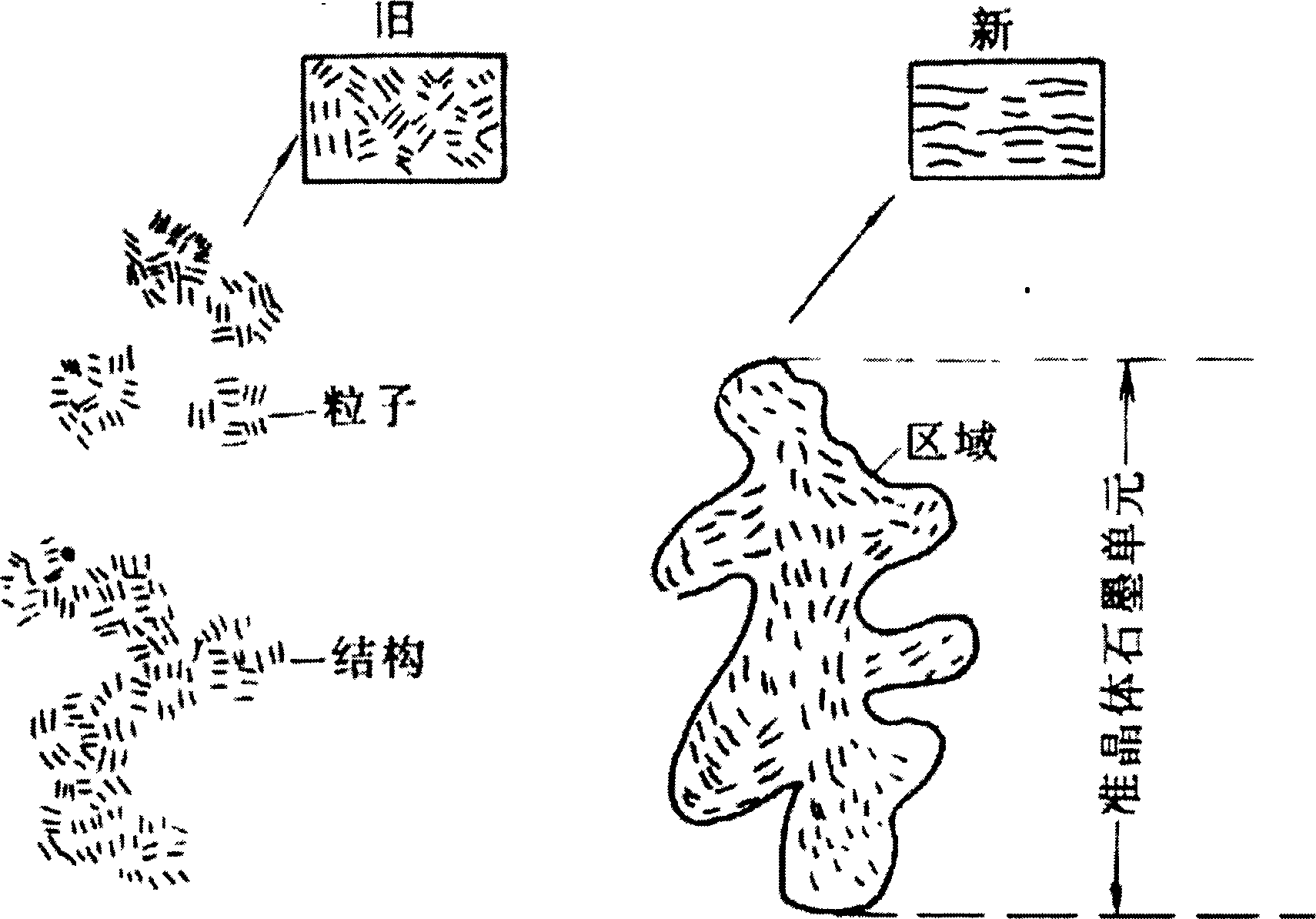

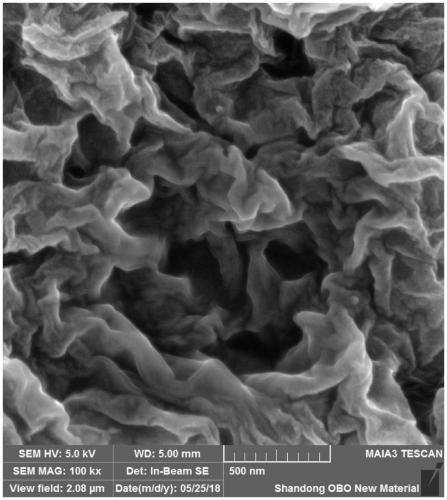

Nano lamellar carbon black emulsion as well as preparation method and application thereof

ActiveCN113122024AEliminate the problem of environmental pollution caused by loose packagesAvoid reunionFibre typesPigment treatment with macromolecular organic compoundsEmulsionAbrasive agent

The invention discloses a nano lamellar carbon black emulsion as well as a preparation method and application thereof. The preparation method comprises the steps that powdery carbon black is ground in the presence of a grinding agent and water and then dried, blocky carbon black is obtained, the blocky carbon black is mixed with a dispersing agent and water and then ground, and then the nano carbon black emulsion with the carbon black particle size not larger than 100 nm is prepared. The nano carbon black is converted into a lamellar structure from a spherical structure and has more excellent application performance than one-time grinding or cleavage, and dust pollution is avoided in the preparation process; and the processing equipment is conventional equipment, and a green manufacturing technology is provided.

Owner:SUZHOU UNIV

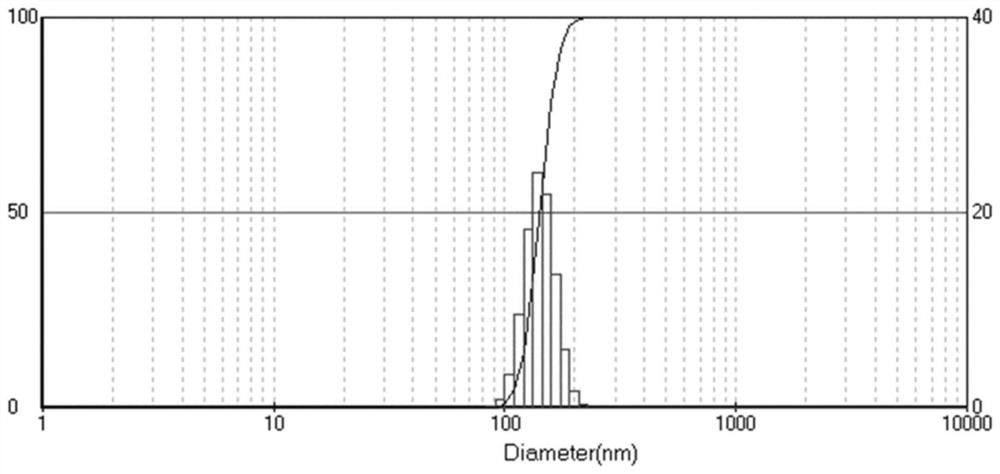

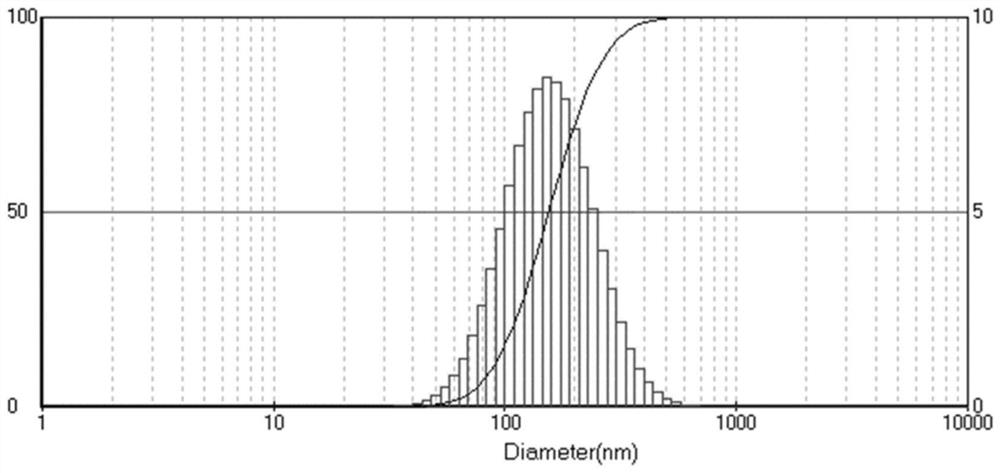

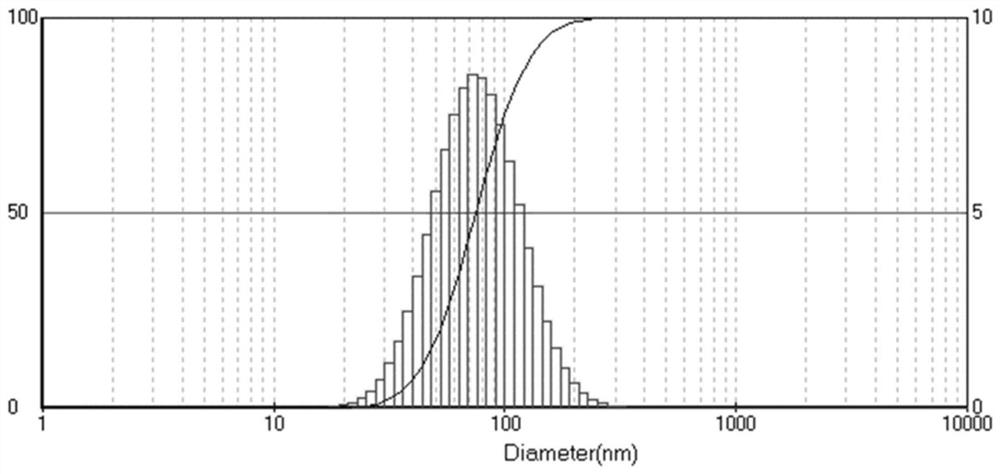

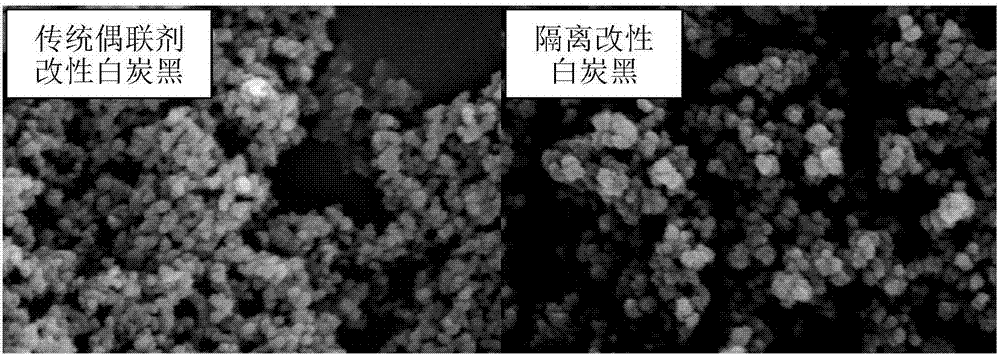

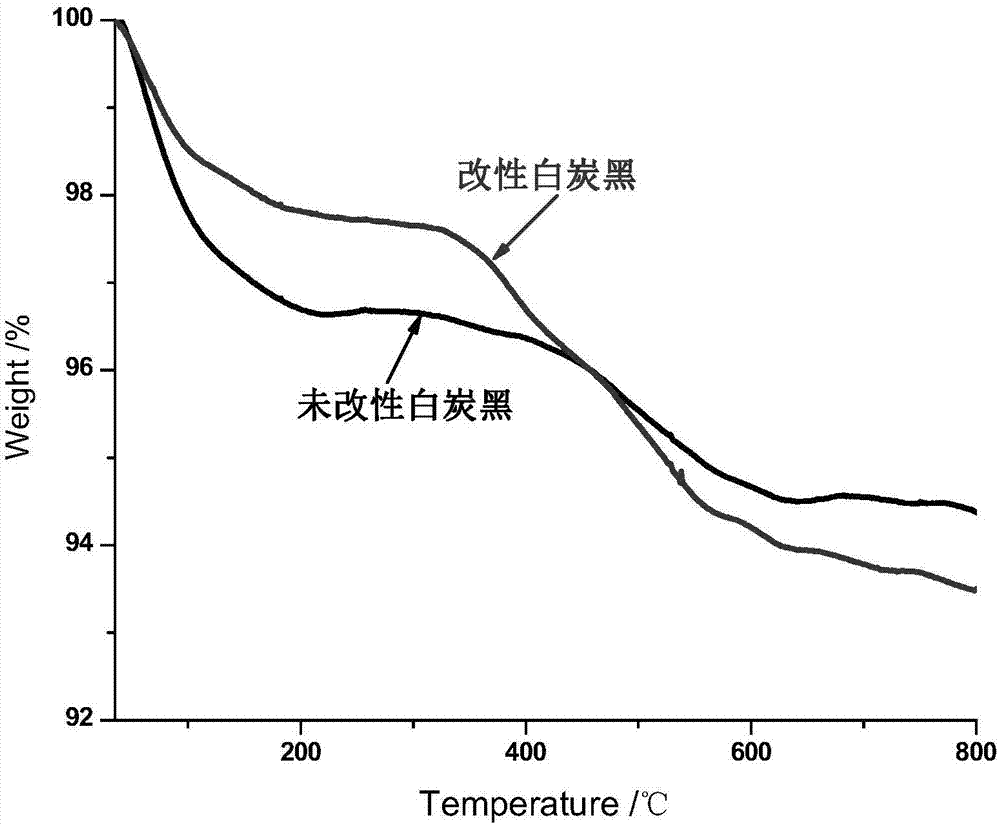

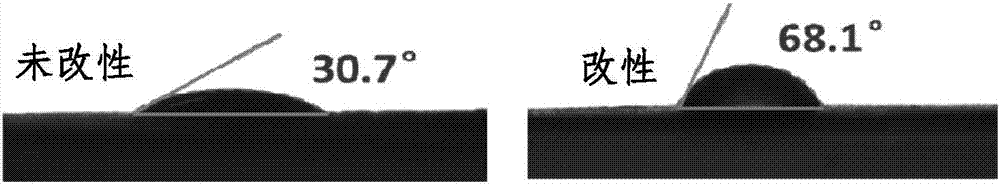

Preparation method of modified white carbon black with chemical isolating structures

The invention discloses a preparation method of modified white carbon black with chemical isolating structures and relates to application of a chemical isolating method to modifying white carbon black. By means of the characteristic that a saline coupling agent can be grafted to white carbon black and organic functional groups in the saline coupling agent can be reacted with special functional groups, modified white carbon black, the nanoparticles of the white carbon black of which are isolated by organic chain sections is prepared. The modified white carbon black can be uniformly dispersed stably in form of nanoparticles in a polymer substrate if being used as filler. The modification method is characterized in that by means of various methods, (I) or (II) structures are established among the nanoparticles of the white carbon black; and the nanoparticles of the white carbon black are isolated by means of the structure. The method can be directly realized by modifying the white carbon black by means of the coupling agent of the (I) or (II) structures; or can be indirectly realized by modifying the white carbon black by means of the coupling agent of the (III) structure and is then further reacted with the white carbon black modified by the saline coupling agent of an (IV) structure or a compound of an (V) structure. The formulae are as shown in the specification.

Owner:BEIJING UNIV OF CHEM TECH

Multifunctional graphene modified non-woven fabric and preparation method thereof

ActiveCN110284265AWith anti-static effectIncrease intrinsic conductivityElectroconductive/antistatic filament manufactureNon-woven fabricsUltravioletNano carbon

The invention discloses a multifunctional graphene modified non-woven fabric and a preparation method thereof. The multifunctional graphene modified non-woven fabric is obtained by blending nano-carbon blacks having specific DBP values with reduced graphene oxide at a specific ratio, blending the mixture with polypropylene, and conducting melt-spraying. The nano-carbon blacks with different DBP values are distributed in different regions of the surface of the reduced graphene oxide to form a unique nano-composite structure, so that the non-woven fabric exhibits excellent electrical conductivity., and after the addition of the polypropylene, the antistatic property of the non-woven fabric can be effectively improved. At the same time, through the addition of graphene, the far-infrared emission, anti-ultraviolet, antibacterial and anti-mite effects of the polypropylene non-woven fabric can also be significantly improved, and thus the polypropylene non-woven fabric can be applied in the fields of home textiles, carpets, garments, masks, medical protective gears and the like.

Owner:HANGZHOU GAOXI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com