Preparation method of ceramic printing ink containing carbon black

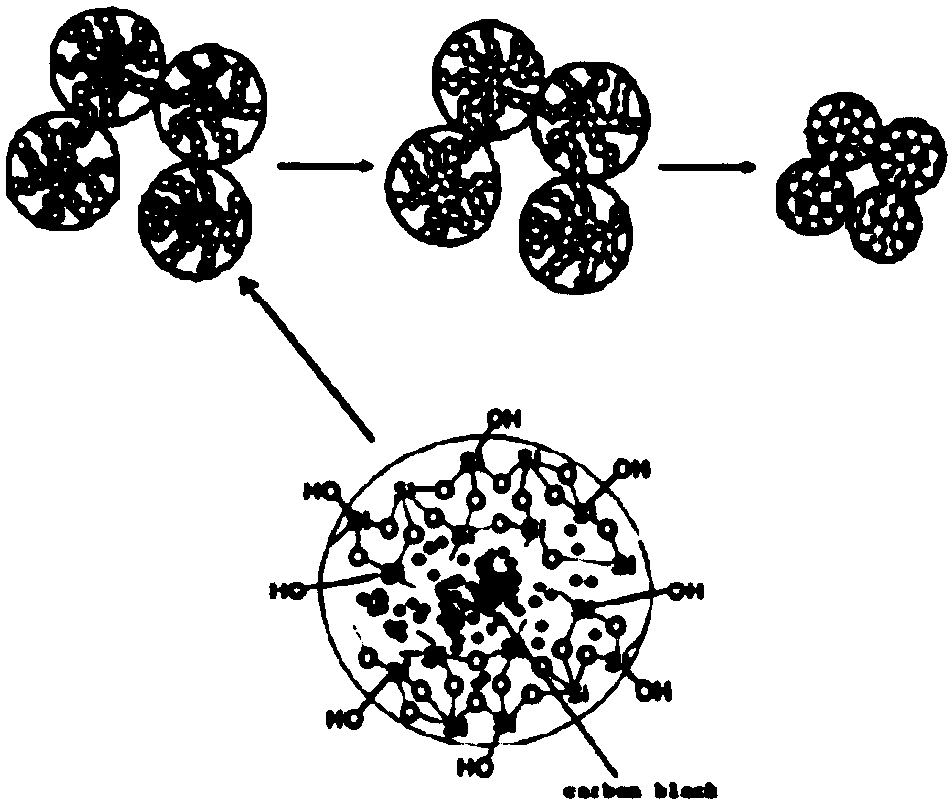

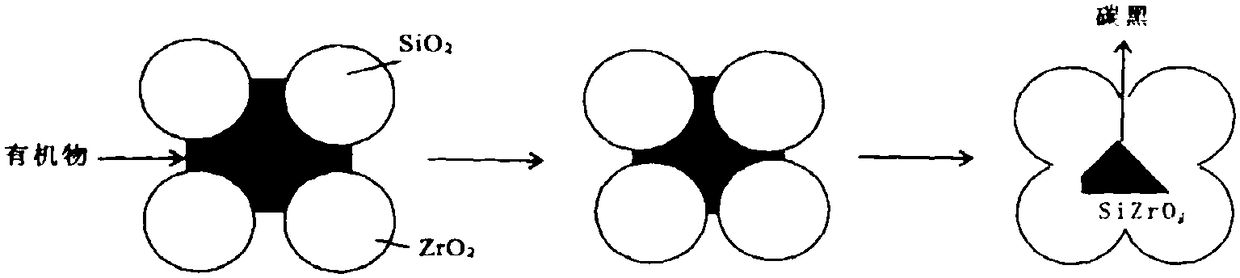

A technology of printing ink and wrapping carbon black, which is applied in ink, household utensils, applications, etc., to achieve the effect of good high temperature stability, pure color tone and deep hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

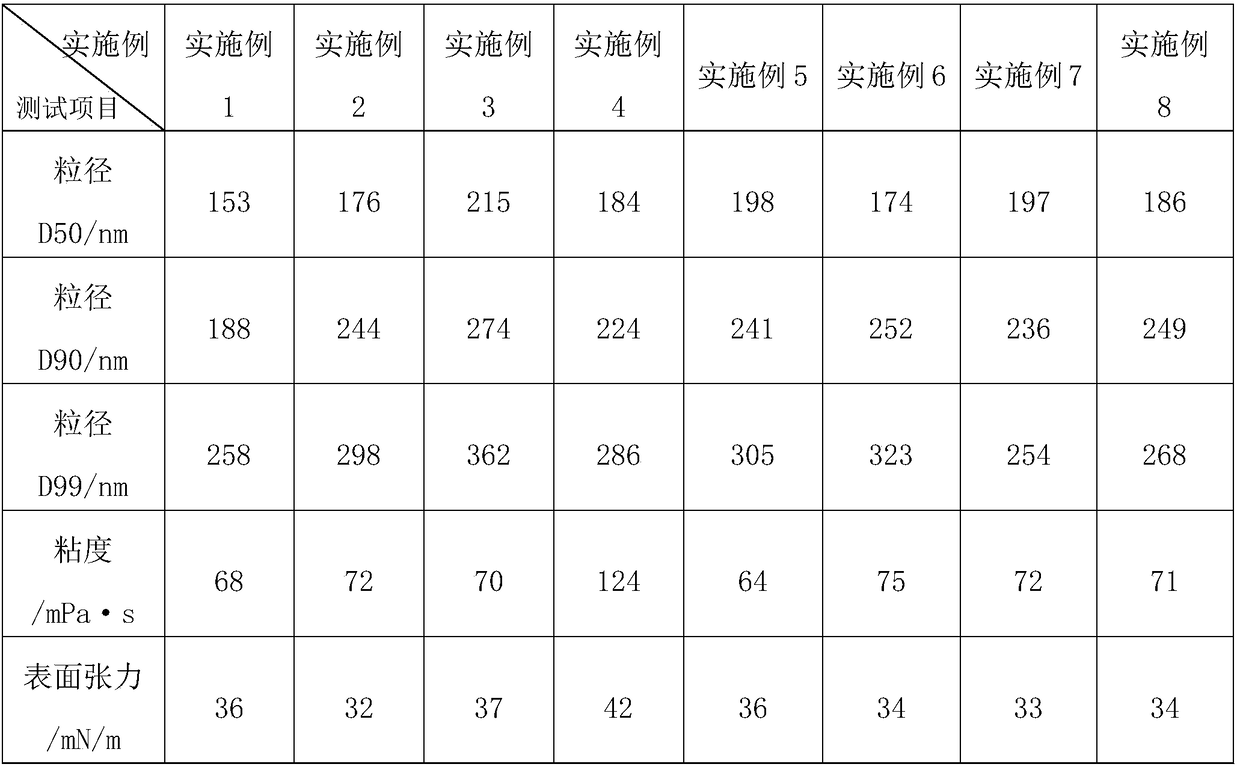

Examples

Embodiment 1

[0031] The preparation method of the novel package carbon black ceramic printing ink:

[0032] Specifically:

[0033] 1. Preparation of modified carbon black: Mix and stir high blackness carbon black (particle size <25nm) with concentrated sulfuric acid and potassium permanganate, reflux at 60°C for 3h, then filter, wash, and dry at 110°C to obtain oxidation modification nano carbon black.

[0034] 2. Preparation of modified carbon black sol: 6.6kg modified carbon black and 1.2kg PVP were dissolved in 184L absolute ethanol, ultrasonically dispersed for 30min and stirred for 4h to obtain uniformly dispersed modified carbon black sol.

[0035] 3. Preparation of silica sol: Mix and stir 30L tetraethyl silicate and 132L absolute ethanol thoroughly, adjust the pH of the solution to 3 with 0.1mol / L dilute hydrochloric acid, and hydrolyze at a constant temperature of 60°C for 45min to obtain uniformly dispersed silica sol.

[0036] 4. Preparation of zirconium sol: 24.5 kg of zircon...

Embodiment 2

[0041] The preparation method of the novel package carbon black ceramic printing ink:

[0042] Specifically:

[0043] 1. Preparation of modified carbon black: Mix and stir high blackness carbon black (particle size<25nm) and hydrogen peroxide, reflux at 60°C for 3h, then filter, wash, and dry at 100°C to obtain oxidatively modified nano-carbon black.

[0044] 2. Preparation of modified carbon black sol: 6.6kg modified carbon black and 1.2kg PVP were dissolved in 184L absolute ethanol, ultrasonically dispersed for 30min and stirred for 4h to obtain uniformly dispersed modified carbon black sol.

[0045] 3. Preparation of silica sol: Mix and stir 30L tetraethyl silicate and 132L absolute ethanol thoroughly, adjust the pH of the solution to 3 with 0.1mol / L dilute hydrochloric acid, and hydrolyze at a constant temperature of 60°C for 45min to obtain uniformly dispersed silica sol.

[0046] 4. Preparation of zirconium sol: 24.5 kg of zirconium oxychloride was fully dissolved in 15...

Embodiment 3

[0051] The preparation method of the novel package carbon black ceramic printing ink:

[0052] Specifically:

[0053] 1. Preparation of modified carbon black: Mix and stir high blackness carbon black (particle size<25nm) with concentrated sulfuric acid and potassium permanganate, reflux at 60°C for 3h, then filter, wash, and dry at 100°C to obtain oxidation modification nano carbon black.

[0054] 2. Preparation of modified carbon black sol: 6.6kg modified carbon black and 1.2kg PVP were dissolved in 184L absolute ethanol, ultrasonically dispersed for 30min and stirred for 4h to obtain uniformly dispersed modified carbon black sol.

[0055] 3. Preparation of silica sol: Mix and stir 30L tetraethyl silicate and 132L absolute ethanol thoroughly, adjust the pH of the solution to 3 with 0.1mol / L dilute hydrochloric acid, and hydrolyze at a constant temperature of 60°C for 45min to obtain uniformly dispersed silica sol.

[0056] 4. Preparation of zirconium sol: 24.5 kg of zirconi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com