Epoxy zinc-aluminum pseudo-alloy cold-coating primer and preparation method thereof

A pseudo-alloy and zinc epoxy technology, applied in the field of coatings, can solve problems such as low construction efficiency, environmental pollution, and high energy consumption, and achieve the effects of fast coating speed, low energy consumption, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

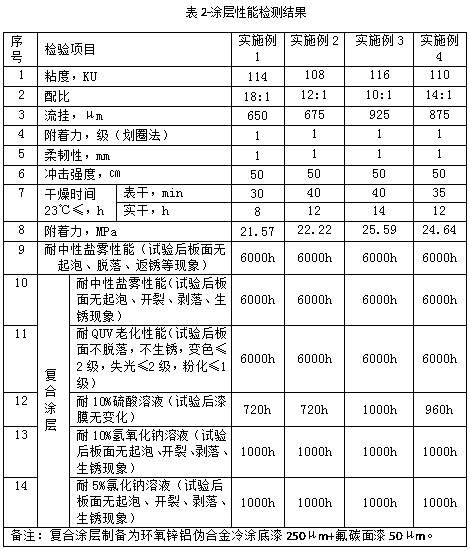

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of epoxy zinc-aluminum pseudo-alloy cold coating primer

[0035] Component 1 paint prepares raw materials according to the following mass percentages: epoxy resin A 23%, dispersant 0.2%, polyamide wax paste 3%, zinc powder 33%, XY-110 non-leafing aluminum powder 27%, silicon Micropowder 5%, defoamer 0.3%, silane coupling agent 0.5%, xylene 6%, butanol 2%;

[0036] Component two curing agent prepares raw materials according to the following mass percentages: D3014 addition amine curing agent 100%,

[0037] The preparation method comprises the following steps:

[0038] Component one preparation method:

[0039] A. At 200 rpm, add epoxy resin A to a clean stirring tank, stir evenly, add dispersant, polyamide wax slurry, and stir until uniform;

[0040] B. Add silicon micropowder and zinc powder in sequence under stirring at 300 rpm, and stir until uniform without obvious lumps;

[0041] C. Increase the rotating speed to 1500 rpm, disperse ...

Embodiment 2

[0049] Embodiment 2: the preparation of epoxy zinc aluminum pseudo-alloy cold coating primer

[0050] Component 1 paint prepares raw materials according to the following mass percentages: epoxy resin A 15%, epoxy resin B 8%, dispersant 1.5%, polyamide wax paste 3%, zinc powder 10%, XY-110 non-floating 8% aluminum powder, 40% silicon powder, 1% defoamer, 0.5% silane coupling agent, 6% xylene, 7% butanol;

[0051] Component two curing agent prepares raw materials according to the following mass percentages: D3014 addition amine curing agent 80%, K54 curing agent 20%;

[0052] The preparation method comprises the following steps:

[0053] Component one preparation method:

[0054] A. At a speed of 400 rpm, add epoxy resin A and epoxy resin B to a clean stirring tank, stir evenly, then add dispersant and polyamide wax slurry in turn, and stir until uniform;

[0055] B. Add silicon micropowder and zinc powder in sequence under stirring at 600 rpm, and stir until uniform without ...

Embodiment 3

[0064] Embodiment 3: the preparation of epoxy zinc-aluminum pseudo-alloy cold coating primer

[0065] Component 1 paint prepares raw materials according to the following mass percentages: epoxy resin A 23%, epoxy resin B 8%, dispersant 0.4%, polyamide wax paste 5%, zinc powder 22%, XY-110 non-floating 12% aluminum powder, 13% silicon powder, 0.6% defoamer, 1% silane coupling agent, 12% xylene, 3% butanol;

[0066] Component two curing agent prepares raw materials according to the following mass percentages: D3014 addition amine curing agent 88%, K54 curing agent 12%;

[0067] The preparation method comprises the following steps:

[0068] Component one preparation method:

[0069] A. At a speed of 300 rpm, add epoxy resin A and epoxy resin B to a clean stirring tank, stir evenly, then add dispersant and polyamide wax slurry in turn, and stir until uniform;

[0070] B. Add silicon micropowder and zinc powder in sequence under stirring at 500 rpm, and stir until uniform withou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com