Patents

Literature

131results about How to "Fast coating speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

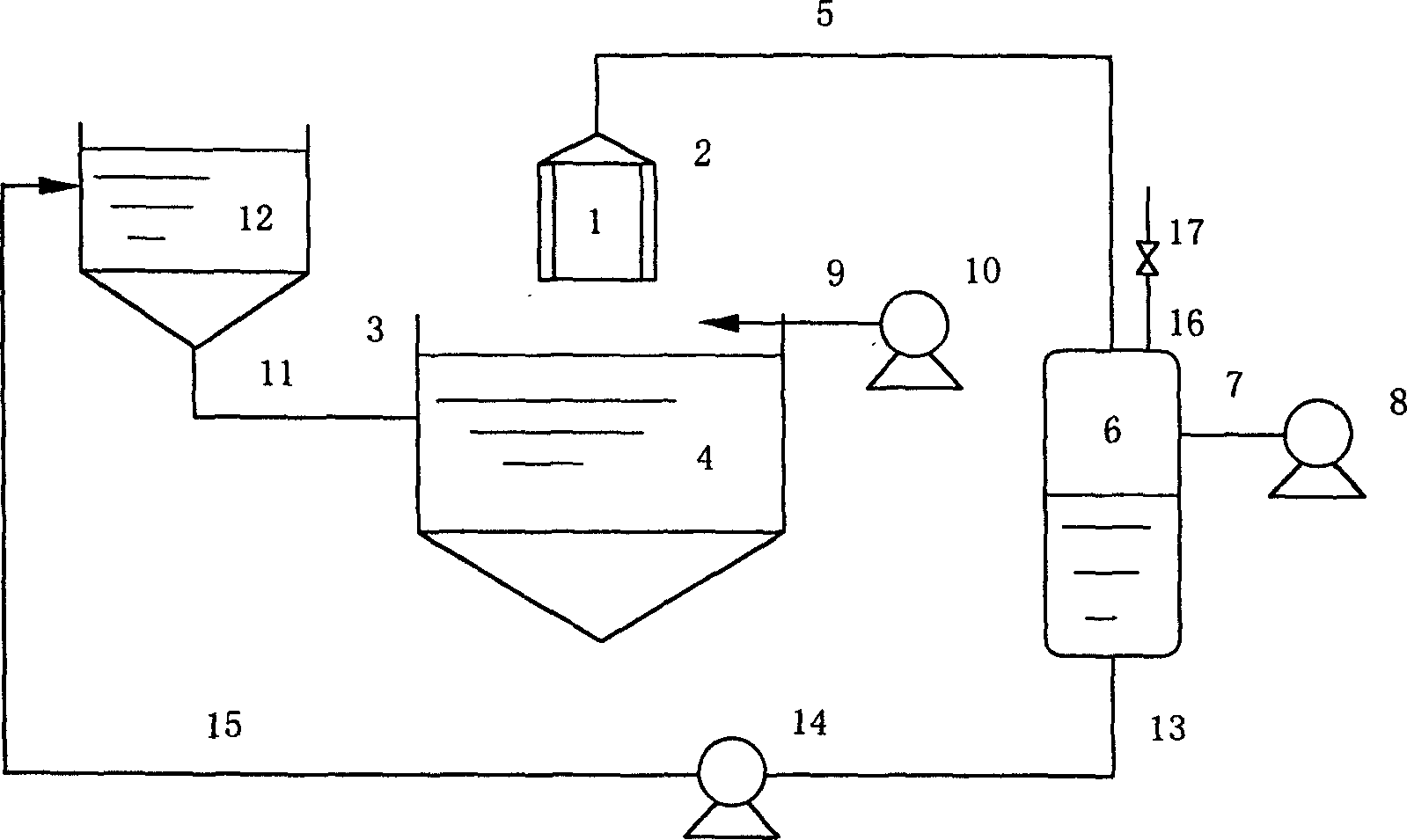

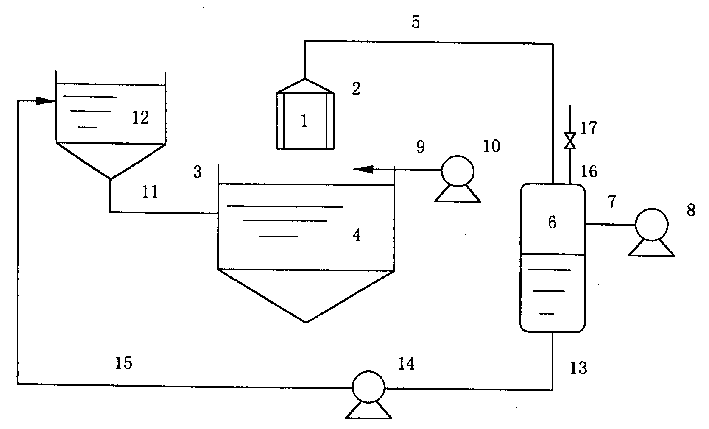

Method for coating active component on cellular carrier with two open ends

InactiveCN1199733CFast coating speedSimple methodLiquid surface applicatorsDispersed particle separationActive componentHoneycomb

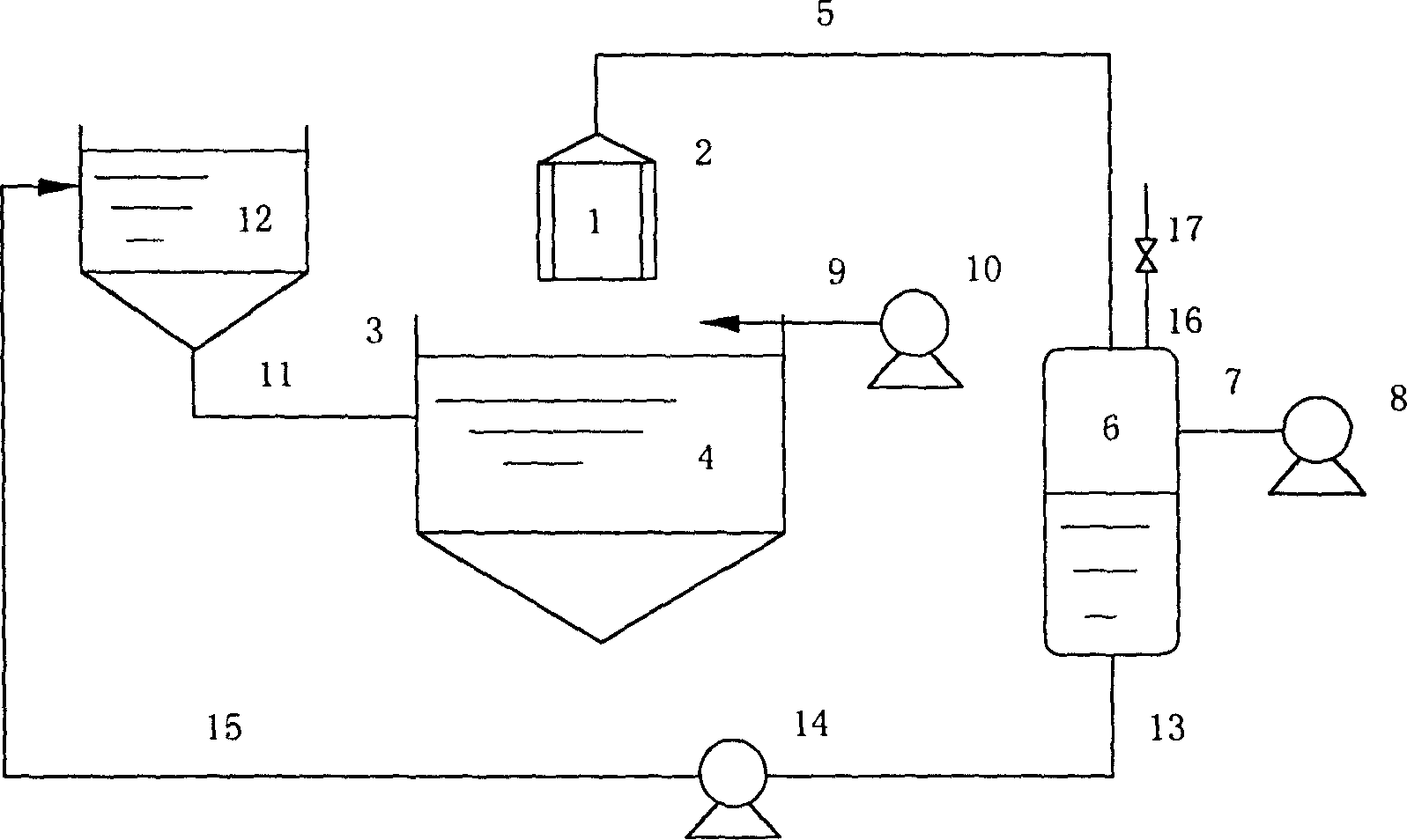

A method for coating an active component on a honeycomb carrier with both ends open includes immersing one end of the honeycomb carrier with both ends open in the slurry containing the active component, applying a vacuum at the other end, making the slurry continuously pass through the pores of the carrier, and drying A carrier coated with a slurry, wherein the volume of the slurry passing through the pores of the carrier is 1.1-50 times the volume of the carrier, the applied vacuum makes the flow rate of the slurry flow through the pores of the carrier be 90-1800 ml / g carrier / min, the slurry After continuously passing through the pores of the carrier, use a gas with a pressure of 1-3 MPa and a flow rate of 8-13 km / min to purge from one end of the carrier to remove excess slurry in the carrier pores.

Owner:CHINA PETROLEUM & CHEM CORP +1

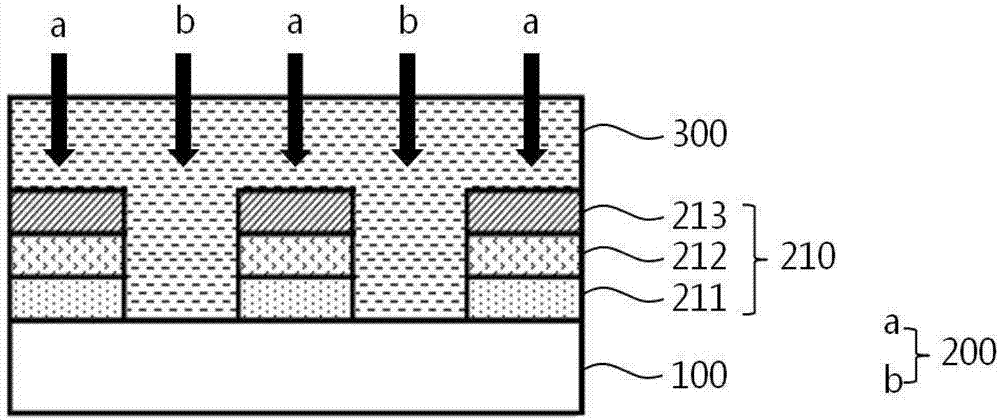

Method for boron doping of crystalline silicon solar battery

InactiveCN102437238ALow costFast coating speedFinal product manufactureSemiconductor devicesSilicon oxideOptoelectronics

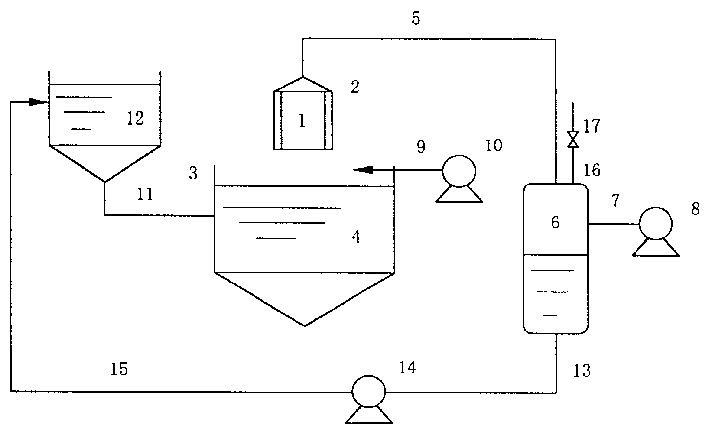

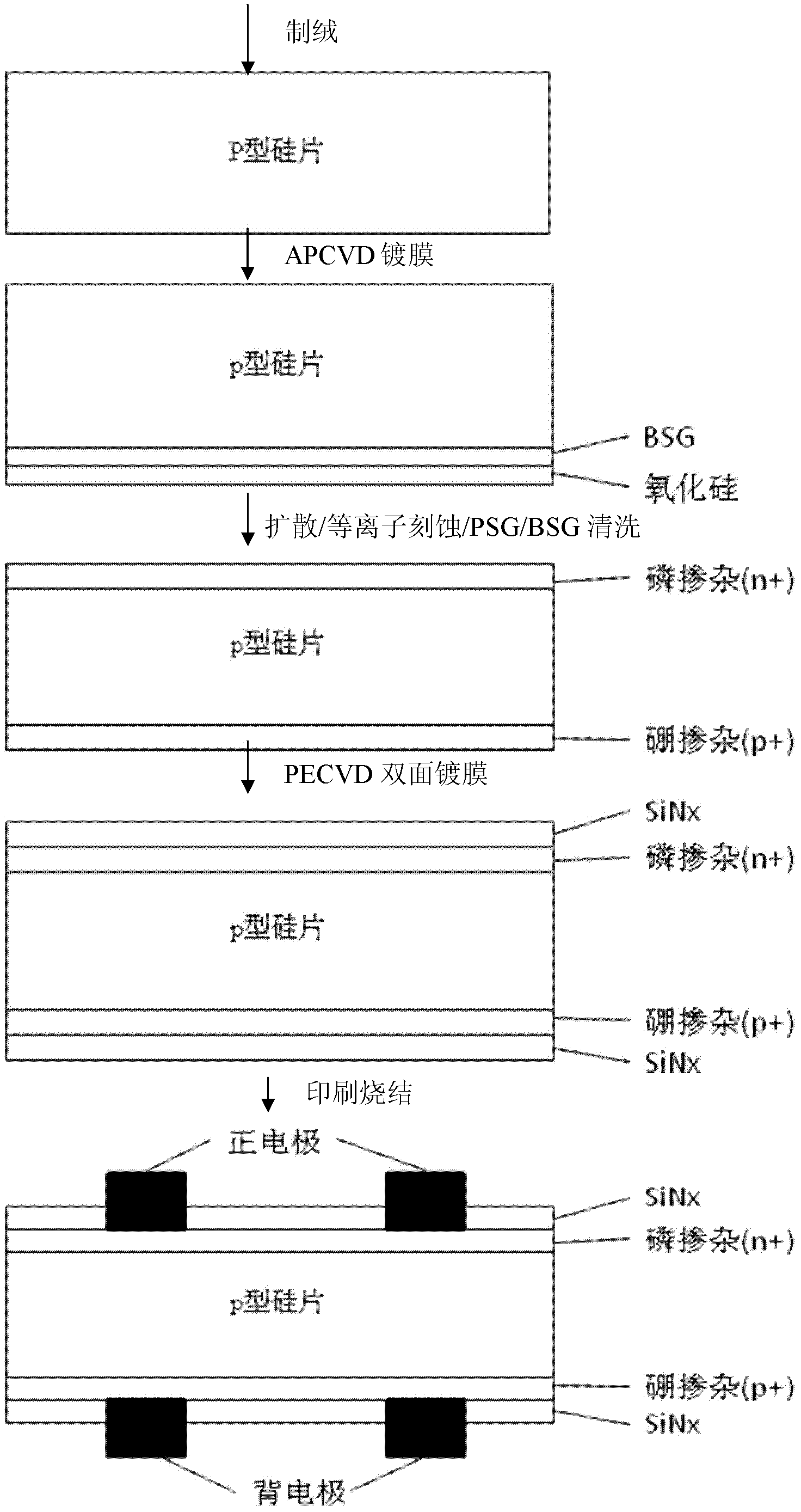

The invention discloses a method for boron doping of a crystalline silicon solar battery, which comprises the following steps that: a first layer of film-boron doped silicon oxide film is deposited on the surface of a silicon chip after the wool making, a second layer of film-silicon oxide film is deposited on the first layer of the film to be used as a barrier layer, then the silicon chip is processed at high temperature, so boron atoms can be diffused into a silicon basic body to form a boron doped layer. Due to the adoption of the method, a boron transmission electrode (p+) can be prepared on an n-type silicon chip, or a boron back surface (p+) is formed on a p-type silicon chip. Through the barrier layer, single-faced boron doping can be realized, and a boron source is free from being sucked into a diffusion furnace tube, so the corrosion of the furnace tube can be reduced, and the service life can be prolonged; and if a phosphorus source is introduced during the high-temperature annealing process, the boron doping and phosphorus doping can be respectively realized on two sides of the silicon chip.

Owner:JA SOLAR TECH YANGZHOU +1

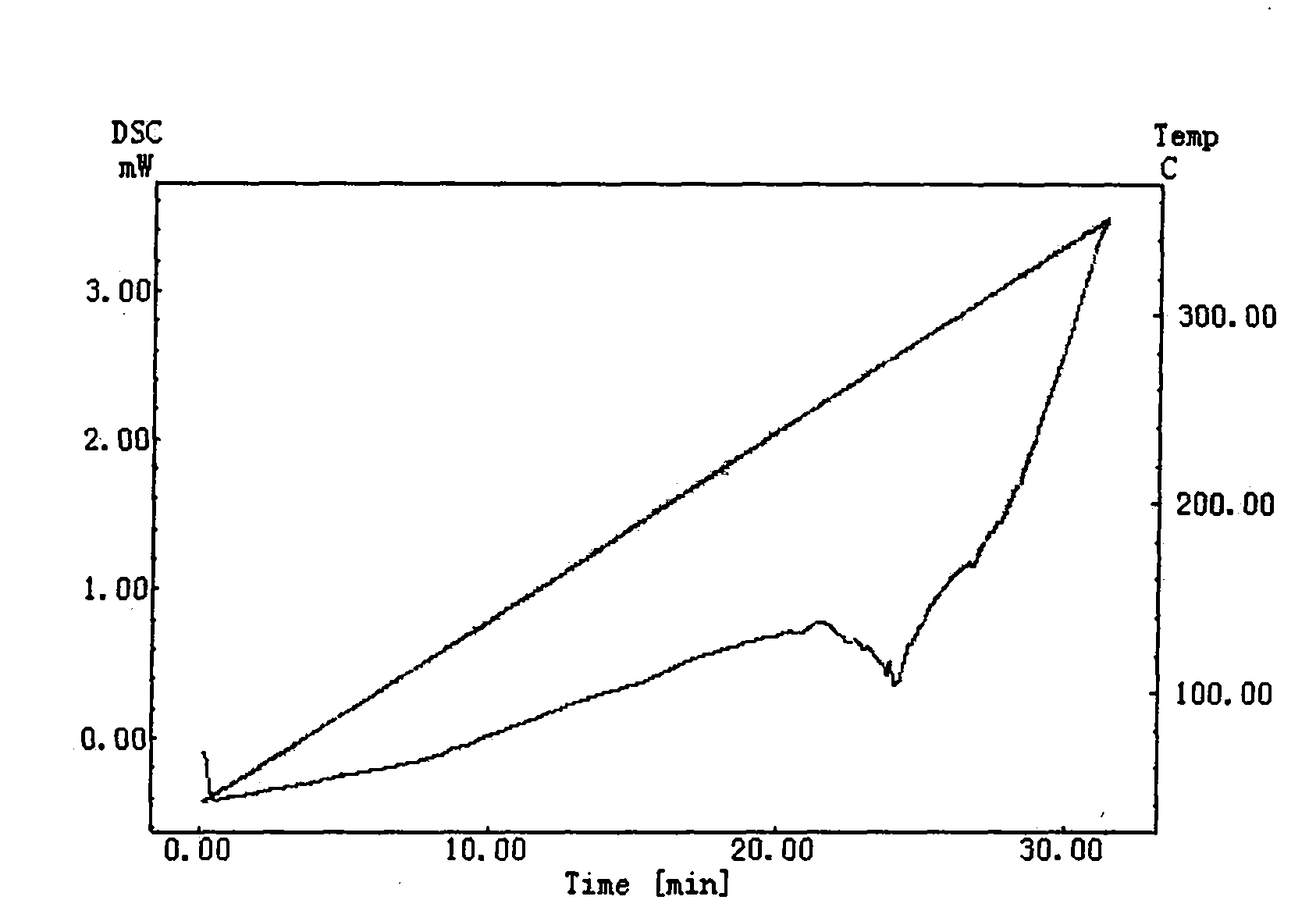

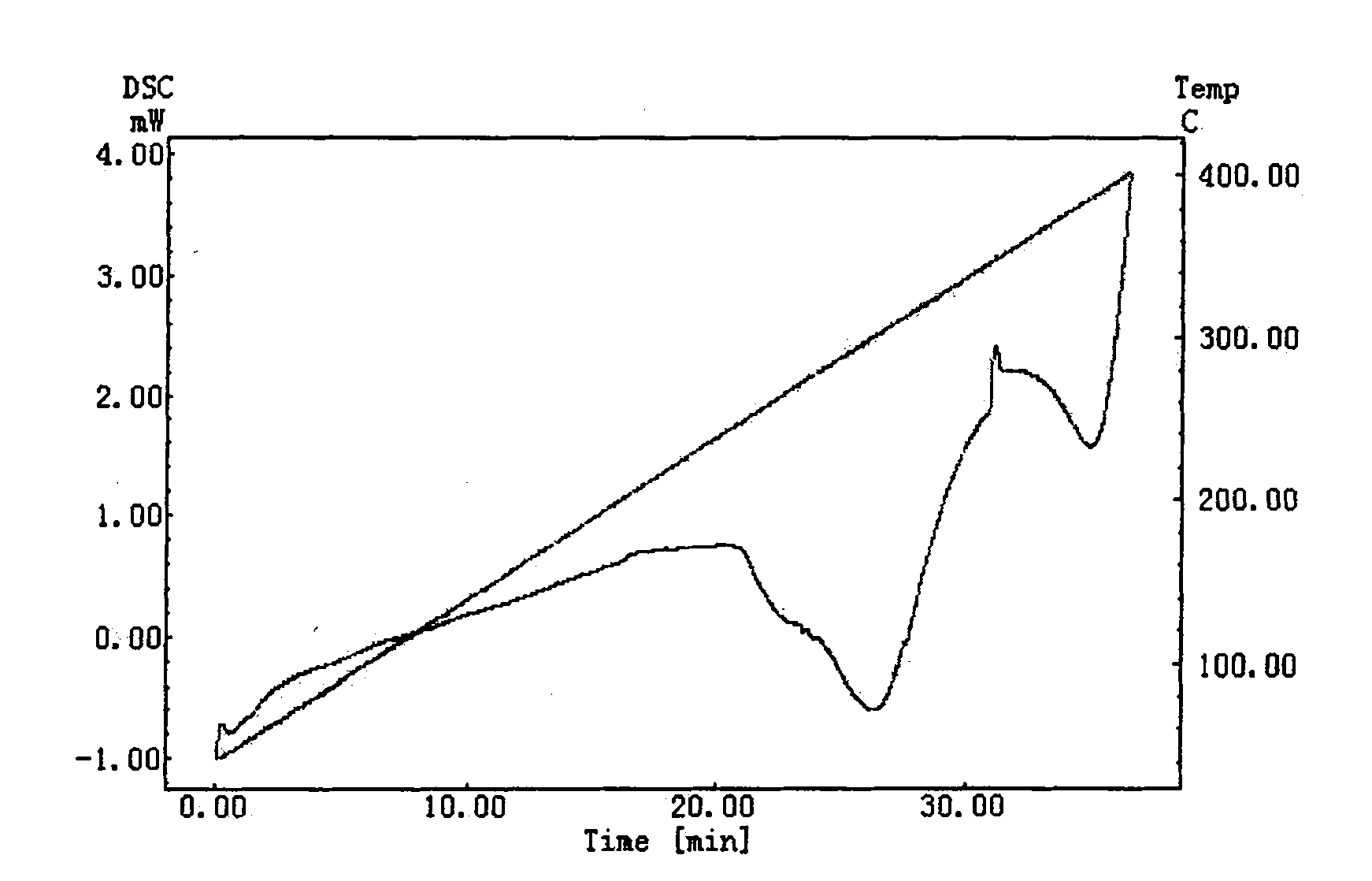

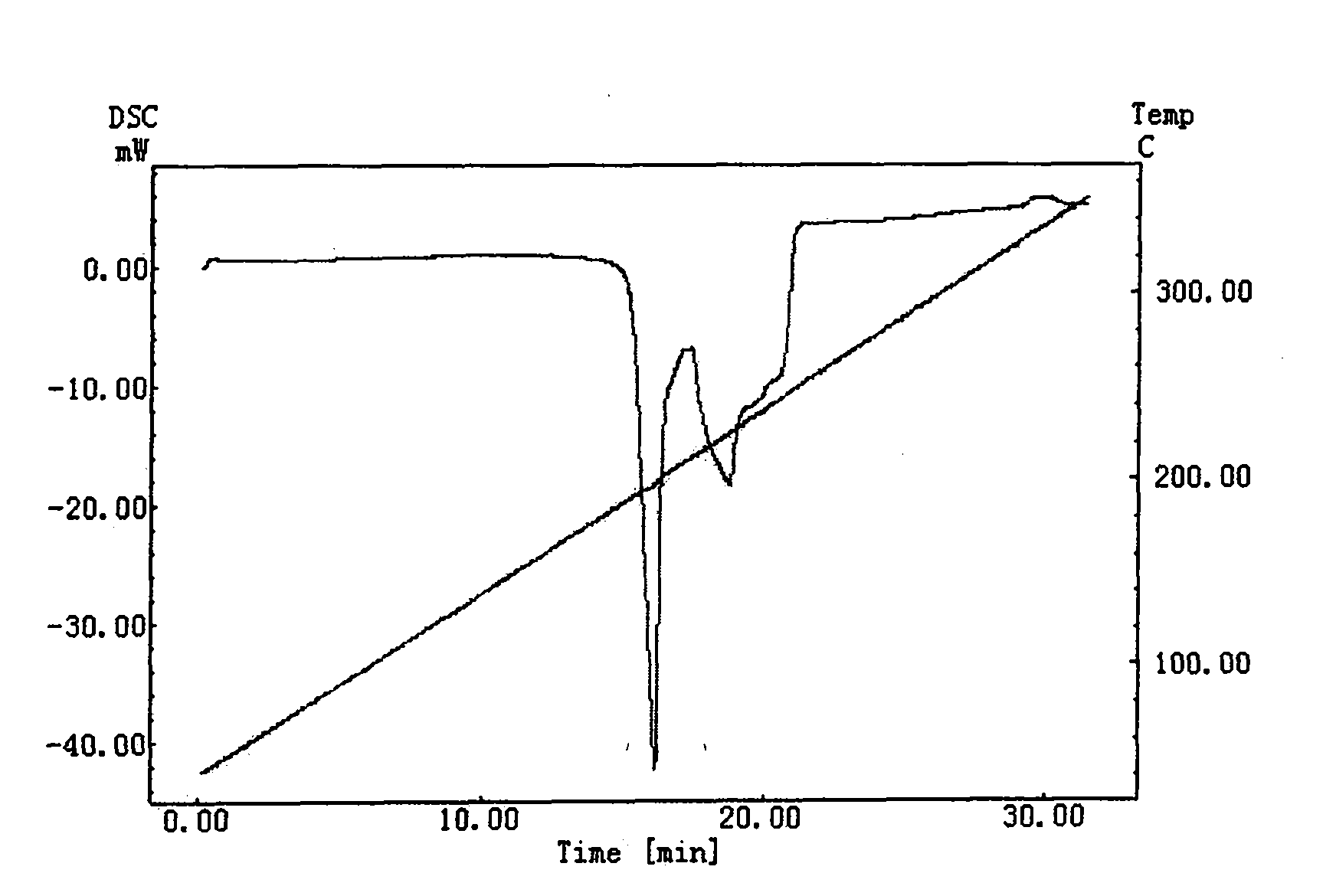

Composition of polyester hot-melt adhesive in low melting viscosity

InactiveCN1760304AReduce dosageFast and even coatingAdhesivesHyperbranched polyesterDicarboxylic acid

A thermofusible polyester adhesive with low viscosity in fused state contains proportionally the polyester diol prepared by polycondensation reaction between binary carboxylic acid and C2-6 diol, and the superbranced polyester prepared by copolymerization reaction between 3,5-dihydroxytoluene and 3,5-dihydroxybenzoic acid.

Owner:SHANGHAI LIGHT IND RES INST +1

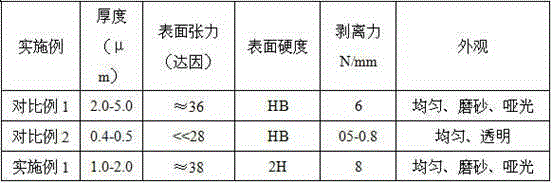

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

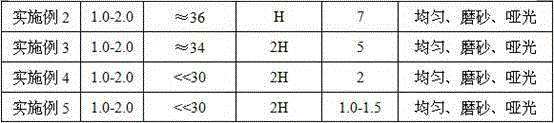

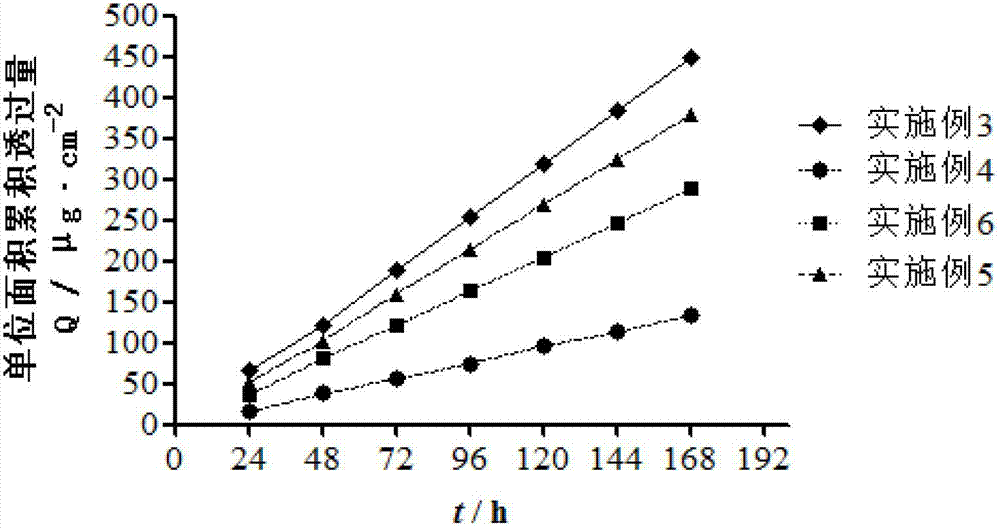

Tulobuterol containing pressure-sensitive adhesive, transdermal paster, and its preparing method and use

ActiveCN1640388ALow costImprove productivityOrganic active ingredientsRespiratory disorderTransdermal patchPolymer science

The present invention discloses a transcutaneous plaster containing tulobuterol, its preparation method and application. The pressure-sensitive adhesive used by said invention is a hot-melt pressure-sensitive adhesive whose melting point is 50-250 deg.C. the described hot-melt pressure-sensitive adhesive is an adhesive made up by using thermoplastic polymer as main raw material, and hs the hot-melting and pressure-sensitive double characteristics. Said product contains no organic solvent, and its coating speed is quick, and its cost is low.

Owner:YABAO PHARMA GRP CO LTD

Porous coated member and manufacturing method thereof using cold spray

InactiveCN1918316APrevent oxidationNo damageMolten spray coatingLighting elementsPorous coatingChemical composition

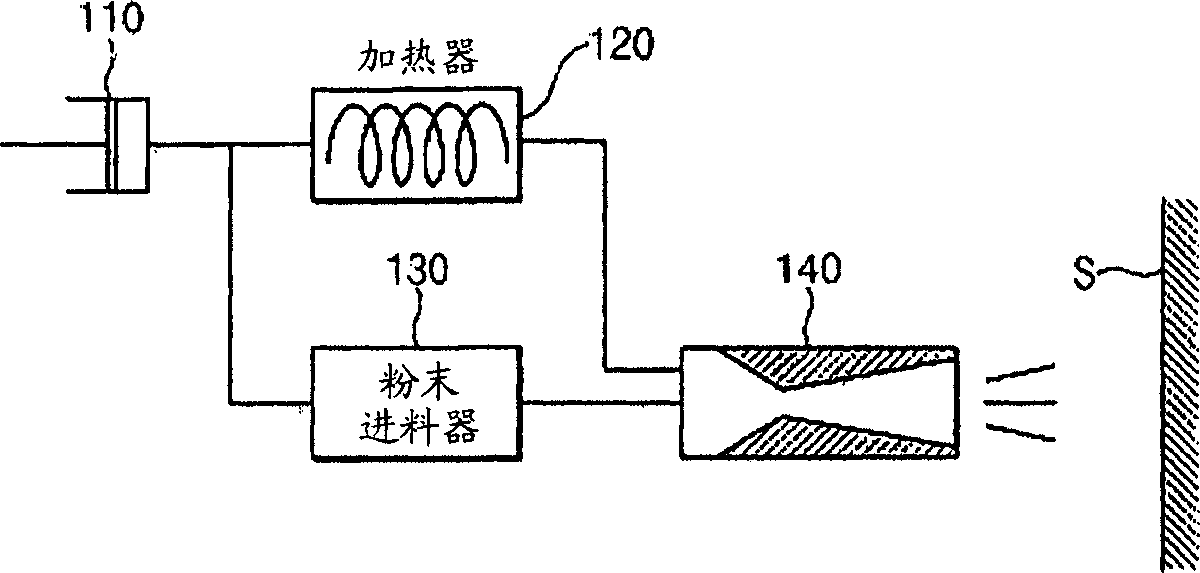

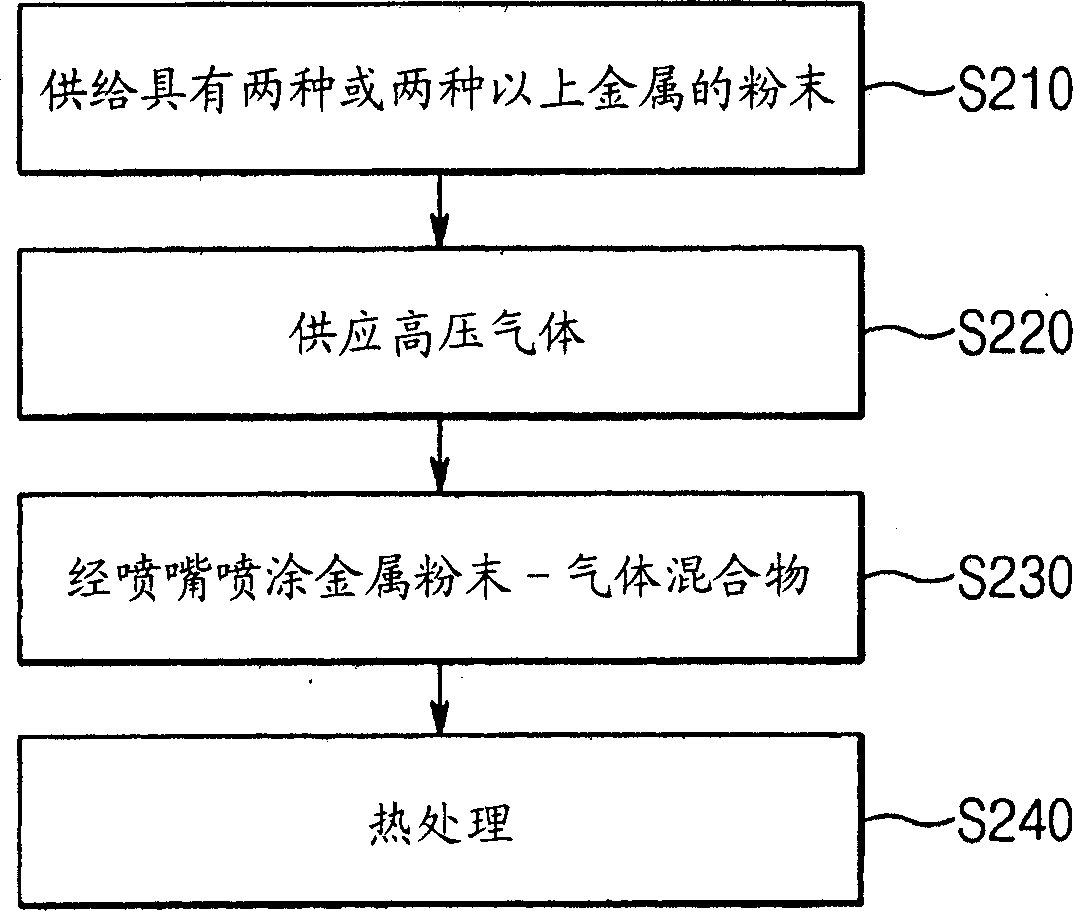

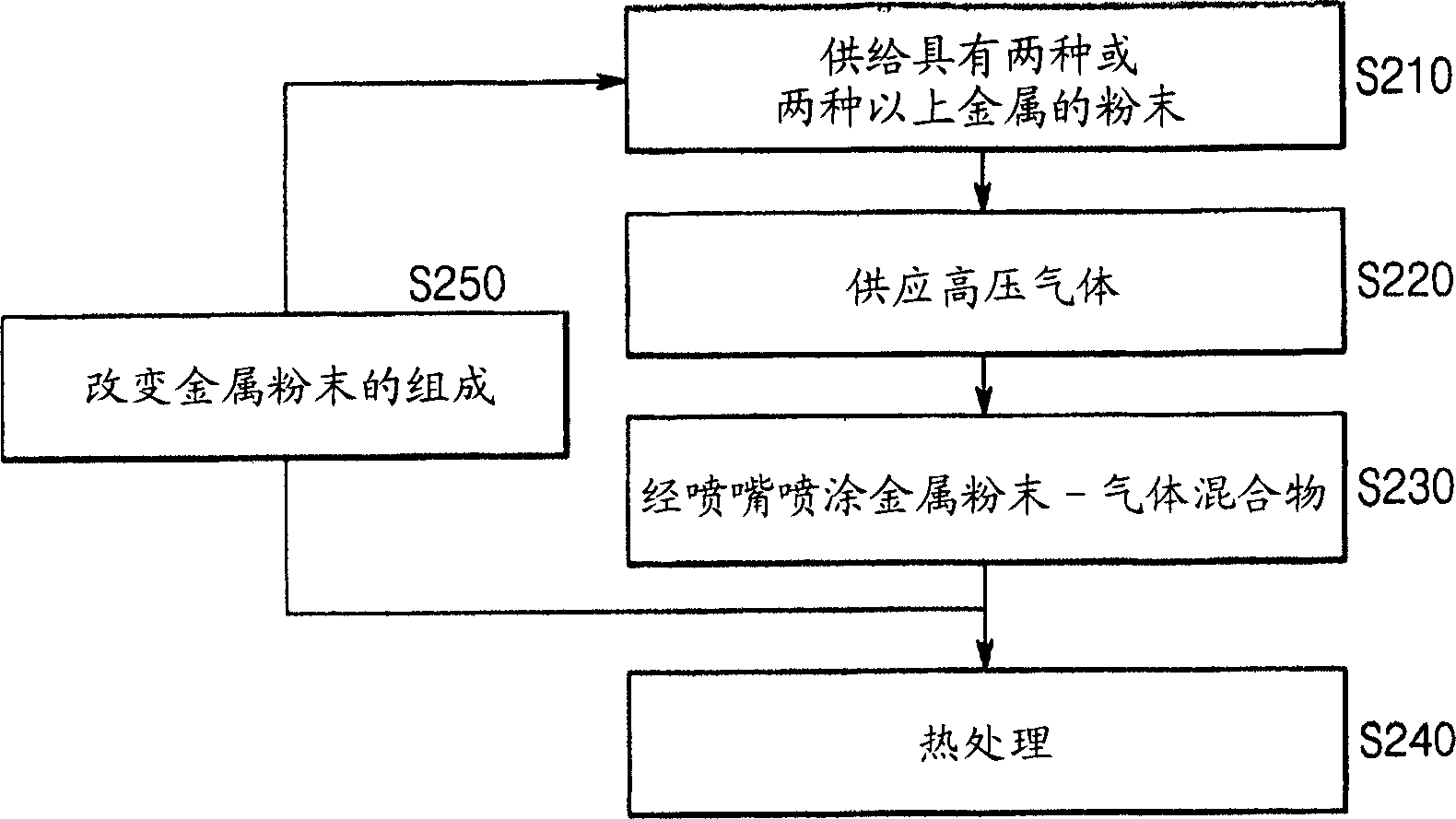

Disclosed is a coated member on which a porous metal coating layer is formed and a method of producing the same. The method comprises providing the mother material, feeding powder having a metal composition, which includes at least two different metals selected from the group consisting of Al, Mg, Zn, and Sn and which is expressed by xA-(1-x)B (0<x<1, where x is a weight ratio of A and B), onto the mother material, supplying high pressure gas to the powder, applying the metal powder using on the mother material by spraying the metal powder using the high pressure gas through an supersonic nozzle, and heat-treating the coated mother material to form the porous coating layer. In the method, it is possible to freely control the pore size and porosity of the coated member. Accordingly, it is available to various members for thermal and mechanical applications.

Owner:SKC SOLMICS

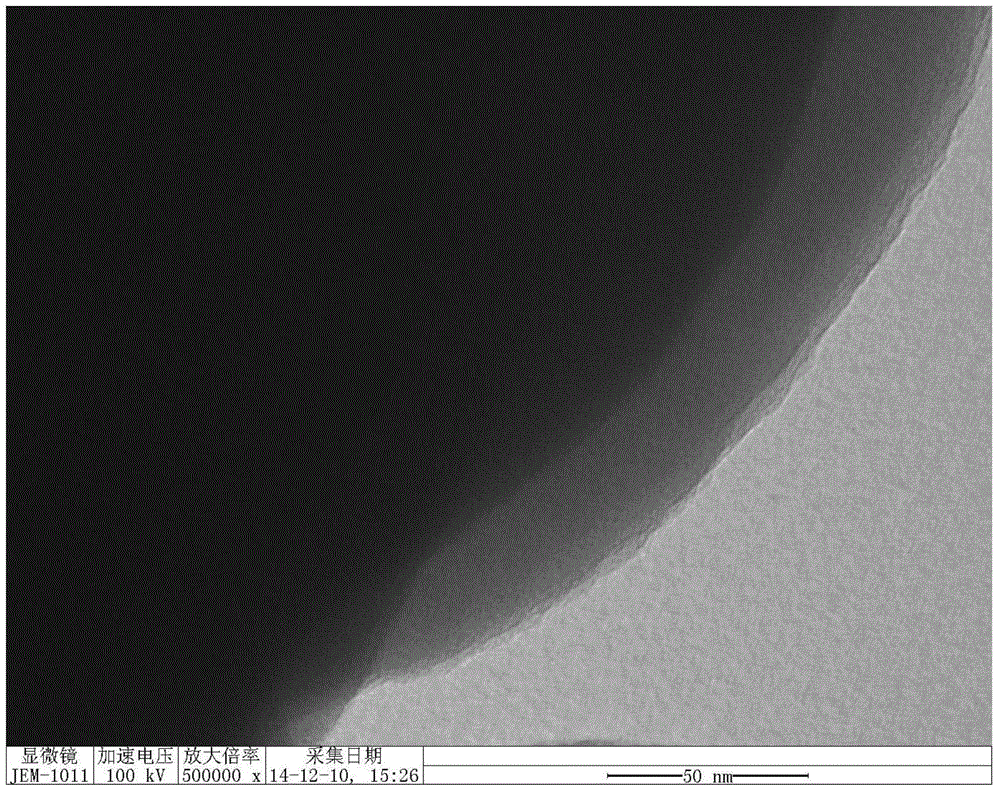

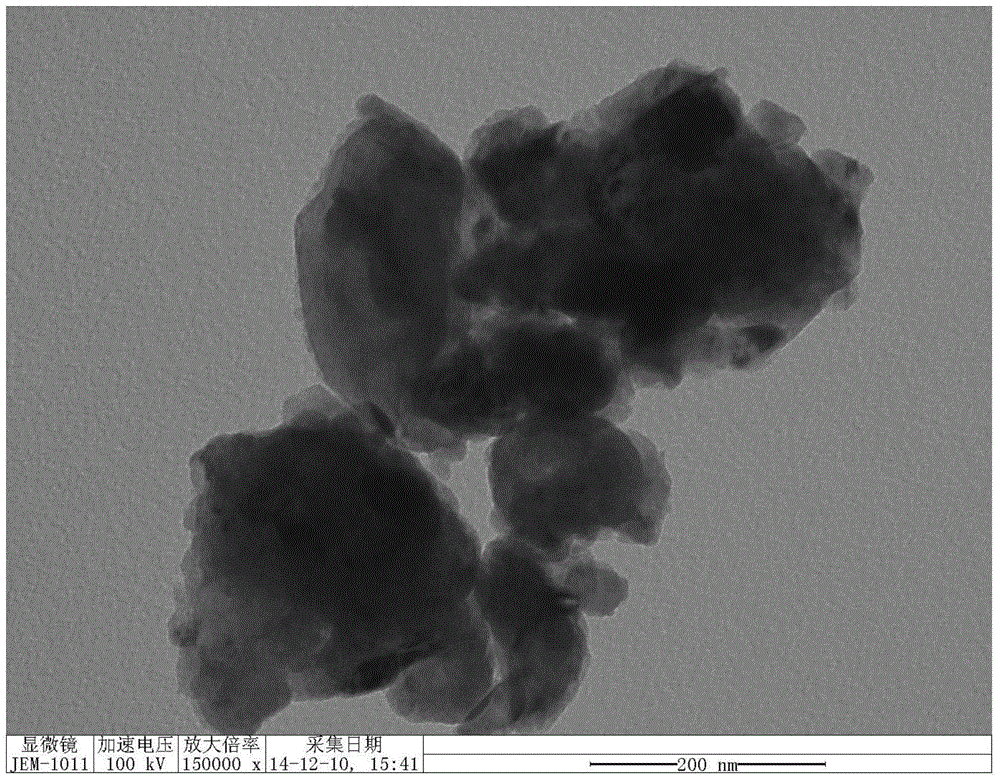

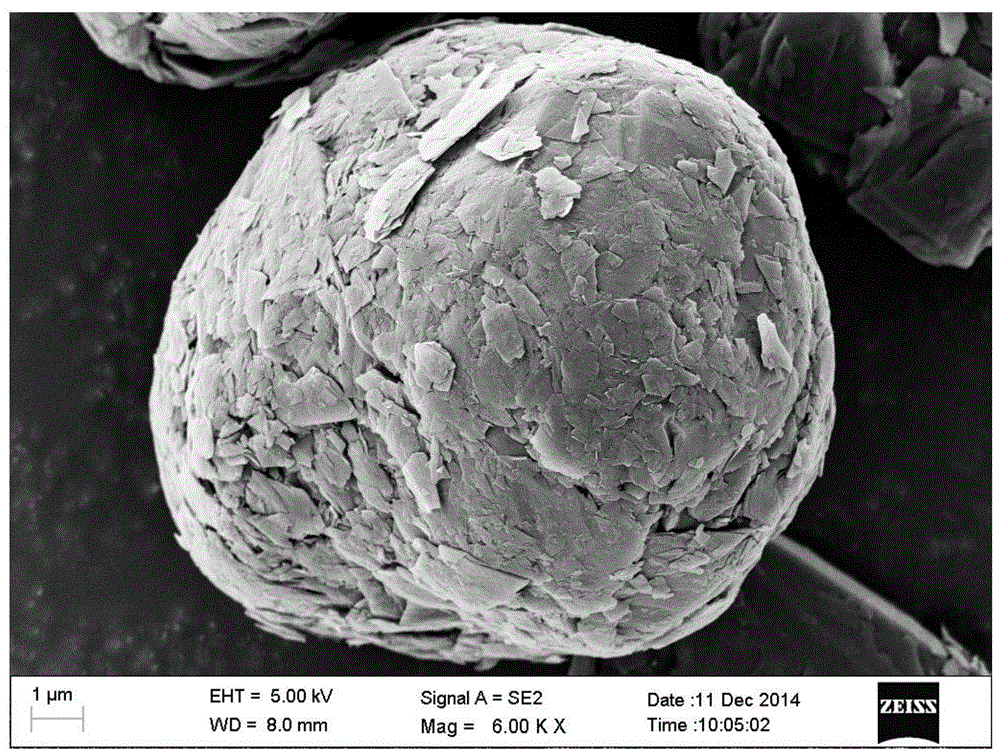

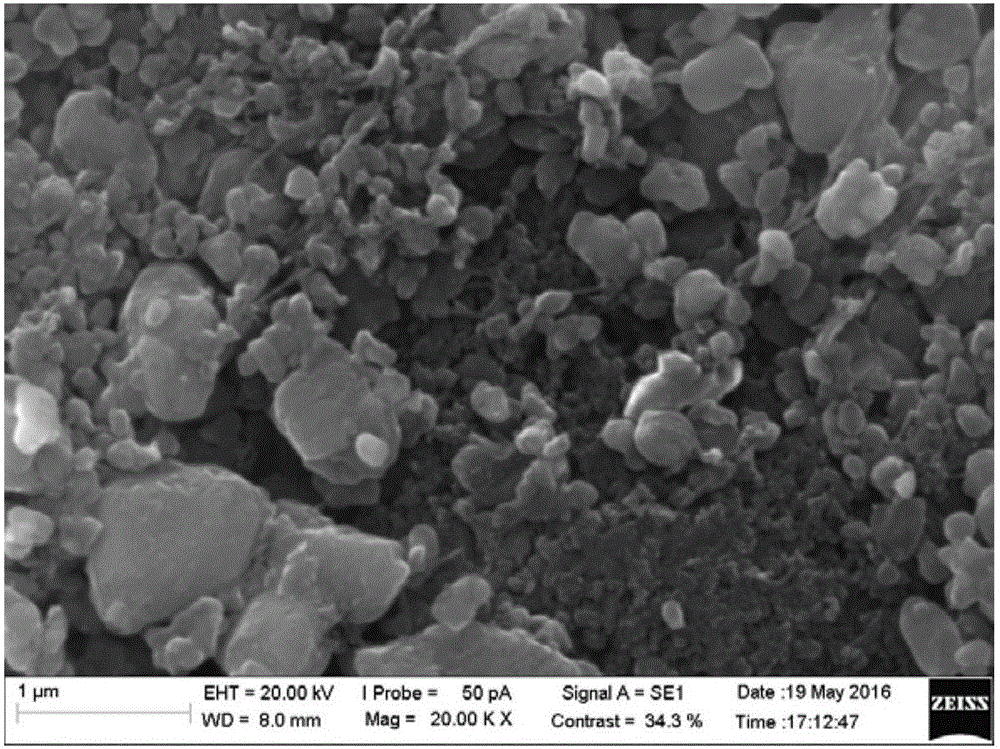

Simple preparation method of graphite and/or silicon negative electrode material with surface coated with carbon

InactiveCN104538598APrecise thickness controlIncreasing the thicknessCell electrodesGraphiteBuffer solution

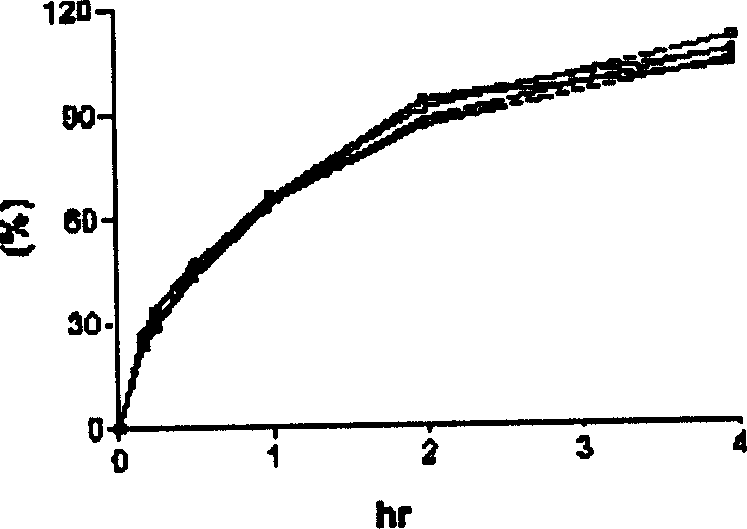

The invention relates to a simple preparation method of a graphite and / or silicon negative electrode material with the surface coated with carbon. The method comprises the steps that dopamine hydrochloride, water and alkaline matter are used for preparing a dopamine buffer solution, natural spherical graphite and / or silicon and the dopamine buffer solution are mixed, stirred for 0.1-96 hours at the temperature ranging from 10 DEG C to 100 DEG C, filtered and dried to obtain graphite and / or silicon coated with a dopamine precursor, the graphite and / or the silicon coated with the dopamine precursor is carbonized for 0.1-96 hours at the temperature ranging from 200 DEG C to 3500 DEG C under the protection of inert gases, and finally modified graphite and / or modified silicon evenly coated with amorphous carbon is obtained. The coating method is easy, convenient and low in operating cost and has great industrial prospect. Compared with an existing coating method, the method has the advantages that a coating layer is uniform, and the coating rate is high; moreover, the thickness of the coating layer can be accurately controlled by adjusting the concentration of the dopamine solution and the stirring time so that the optimum thickness of the graphite coated with the amorphous carbon can be obtained after optimization.

Owner:SHANDONG UNIV

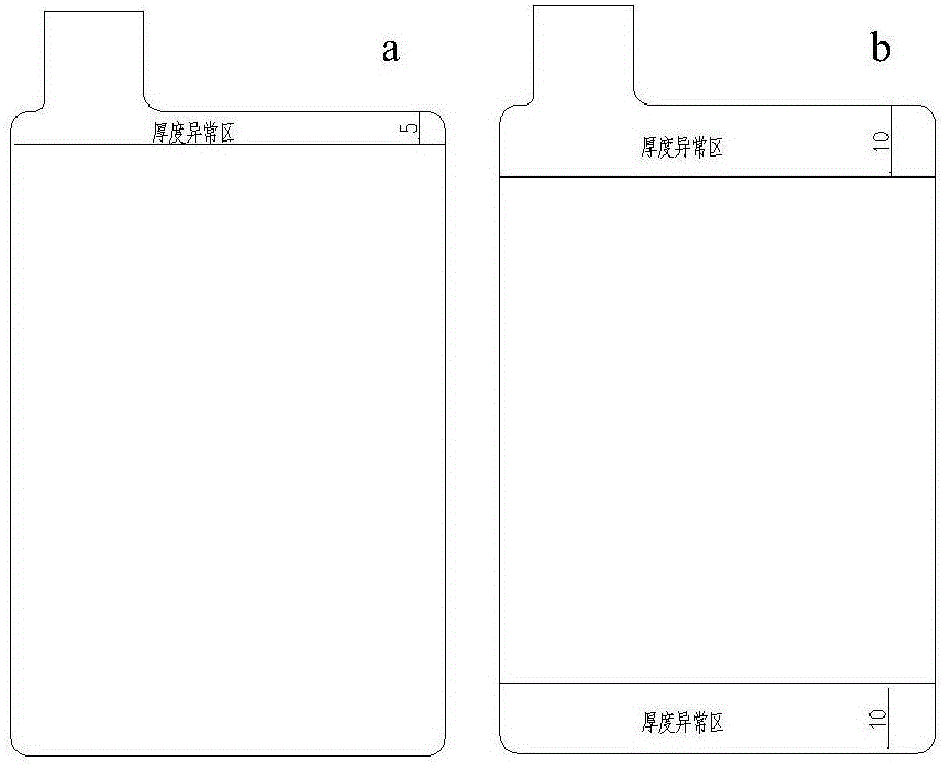

Preparation method of water system laminated type lithium-ion battery pole piece

ActiveCN106129326AQuality assuranceConsistent densityElectrode rolling/calenderingElectrode collector coatingMeasuring instrumentEngineering

The invention discloses a preparation method of a water system laminated type lithium-ion battery pole piece and belongs to the technical field of production of lithium-ion batteries. The method has the following advantages that (1) continuous coating is realized, the coating efficiency is improved, the range of a coating thickness abnormal region is reduced and the coating thickness is monitored online; (2) continuous roll pressing is realized, the roll pressing efficiency is improved, a roll pressing thickness is monitored online and frequent vibration loss of a roll pressing machine is alleviated; (3) the thicknesses of cut regions are the same in a cutting process, the cutting defects are small and the stability is good; (4) the slicing efficiency can be improved by utilizing high-speed slicing equipment, surface defects of the pole piece can be monitored online by utilizing a CCD (Charge Coupled Device) image measuring instrument and NG pole pieces are eliminated; and (5) the waste of raw material left overs is reduced and the utilization rate of positive and negative electrode foils and positive and negative electrode materials is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

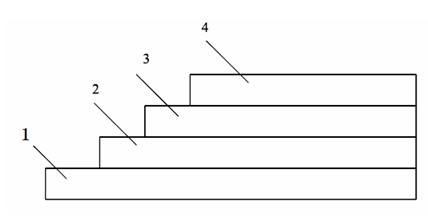

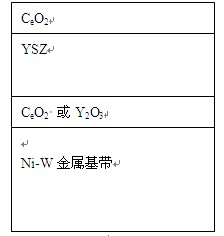

Multichannel pulsed laser deposition method for preparing YSZ buffer layer

ActiveCN102251219AOvercome the disadvantage of small coating areaPurely unidirectionalVacuum evaporation coatingSputtering coatingDeposition temperatureLaser coating

The invention discloses a multichannel pulsed laser deposition method for preparing a YSZ buffer layer, which comprises the following steps of: arranging a nickel-tungsten metal base band, a Hastelloy band, a stainless steel band or other metal base bands in a deposition cavity, winding on a band roller of a metal band transmission device of multichannel pulsed laser deposition equipment for multiple times, and raising the temperature of a heater to deposition temperature; opening an oxygen channel; starting a YSZ target manipulator and beginning the x-direction and y-direction scanning and rotation of a YSZ laser evaporation target platform; opening an optical path window of a laser, and beginning pre-evaporating the YSZ target platform; beginning depositing; and making the metal base band pass through the heater for multiple times due to multiple winding of a roll shaft of the transmission device, and finally stopping corresponding equipment. The YSZ buffer layer is prepared by the multichannel pulsed laser deposition method, so that a defect of a small deposition area of a unichannel pulsed laser deposition method is overcome, the deposition speed is greatly improved, various advantages of the pulsed laser deposition method are exerted fully, and the prepared YSZ buffer layer has single orientation, high surface quality and high crystallinity.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

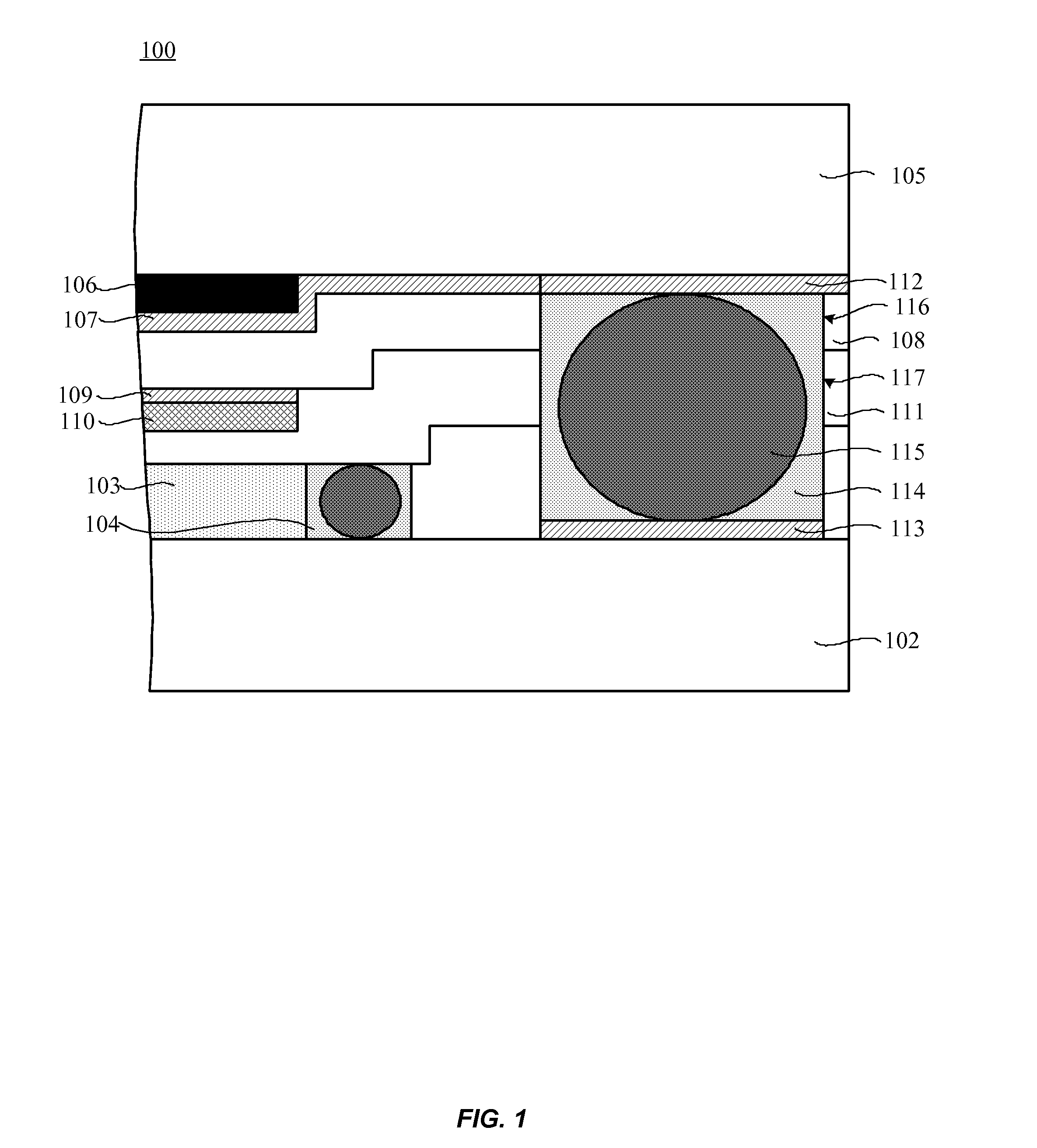

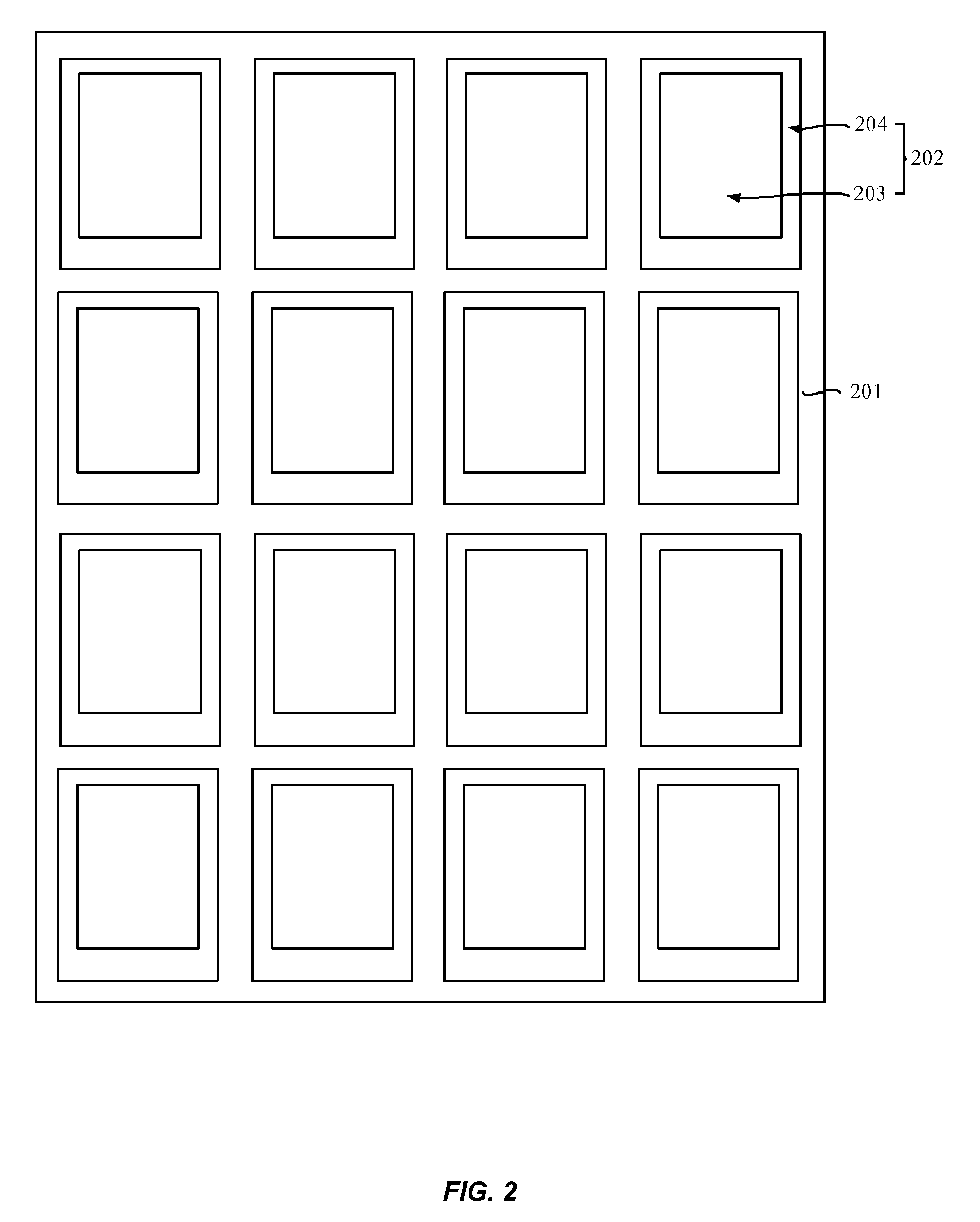

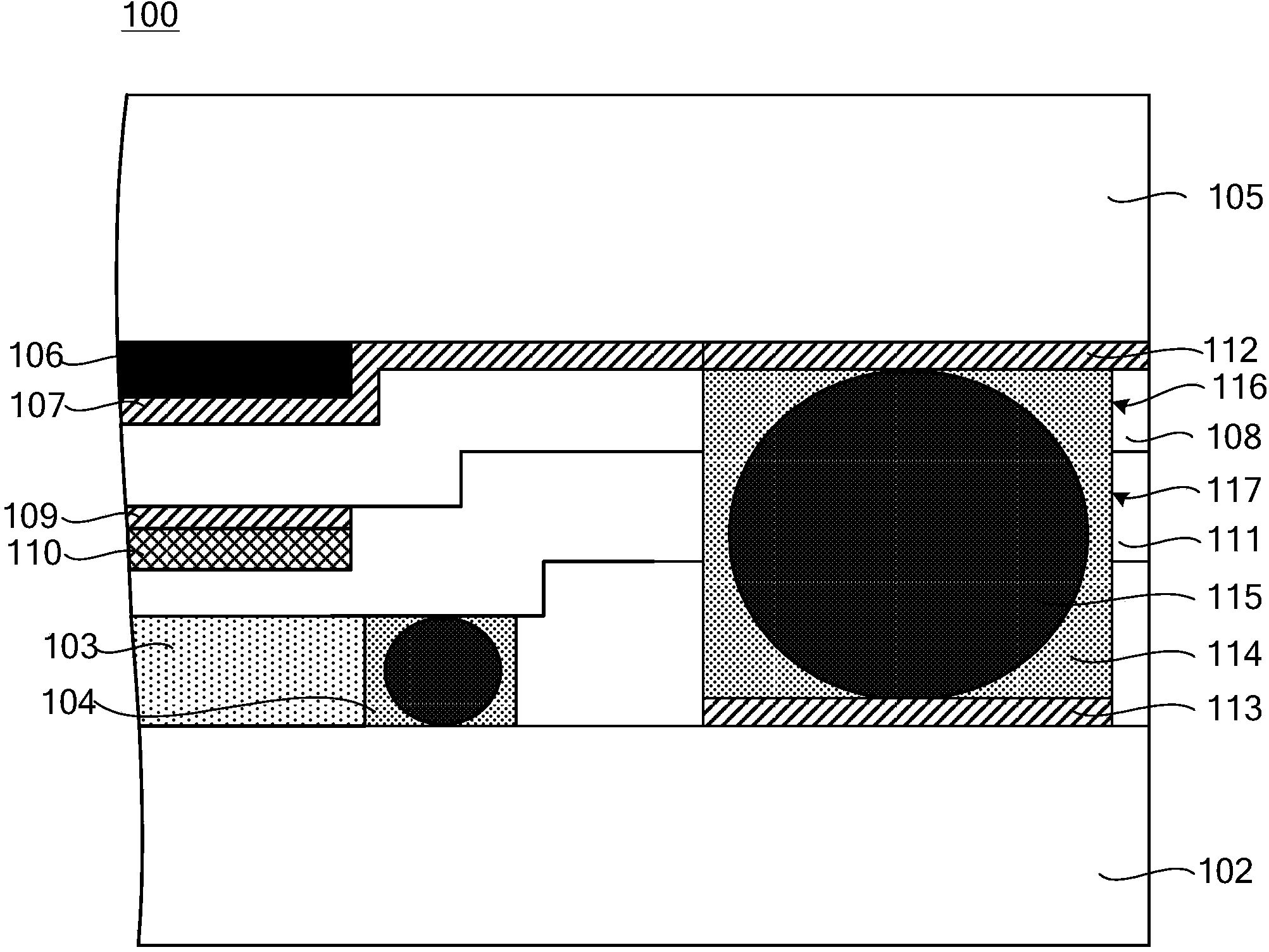

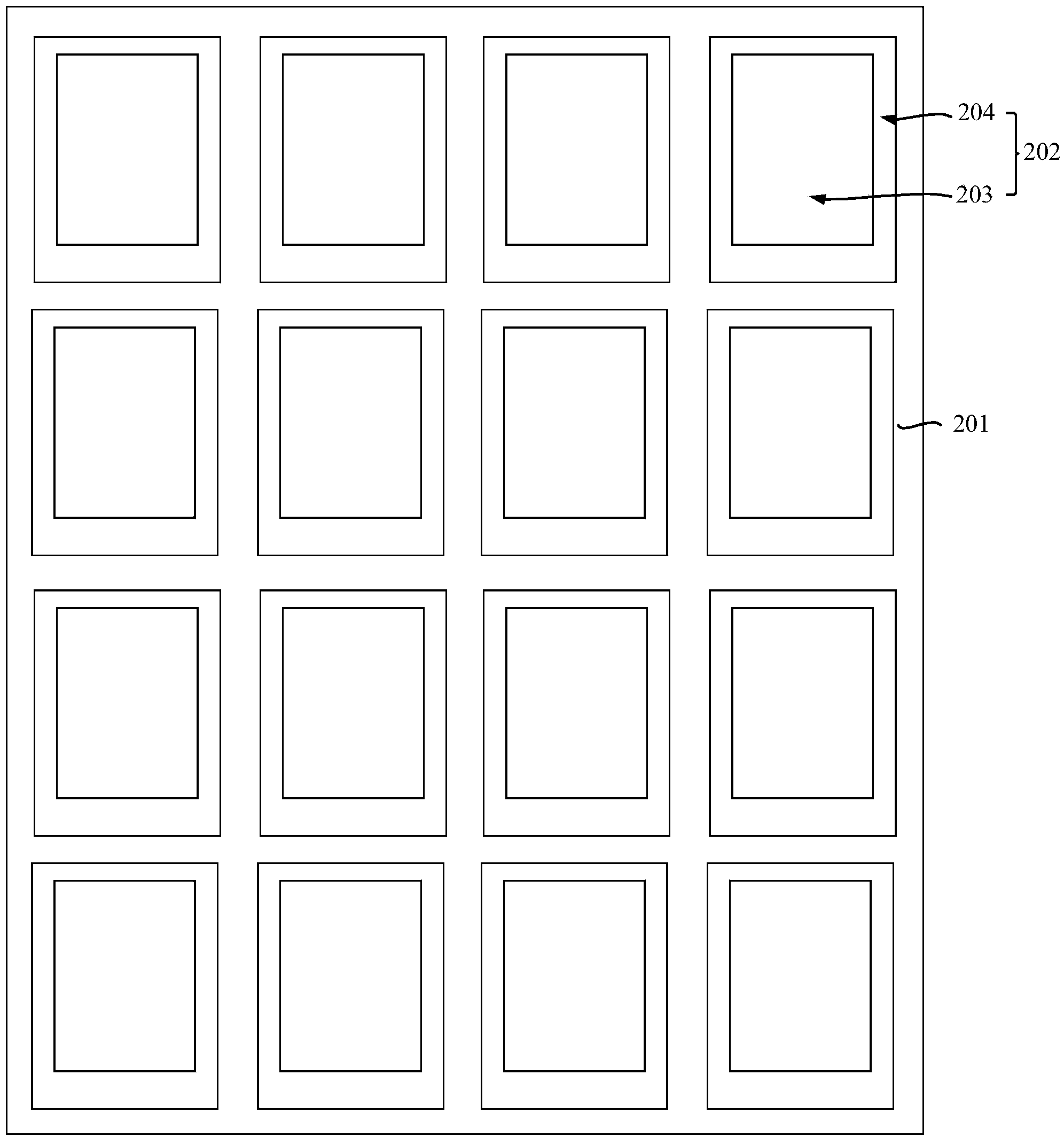

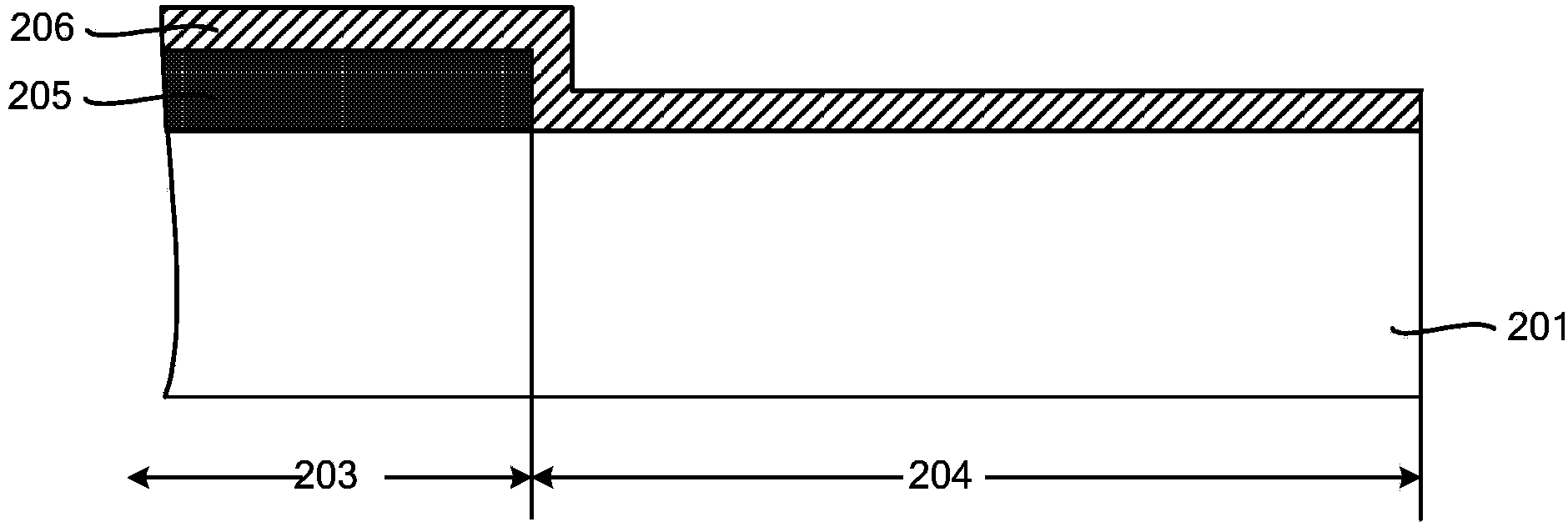

Color filter substrate for in-cell touch panel and manufacturing method thereof

ActiveUS20140168541A1Precise cuttingFast coating speedDecorative surface effectsNon-linear opticsOrganic filmOptoelectronics

An in-cell touch color filter substrate is disclosed. The color filter substrate includes a substrate including a plurality of display areas and a plurality of non-display areas, where each non-display area surrounds one of the display areas. The color filter substrate also includes a first metal layer, a first organic film layer, a second metal layer including a plurality of conductive pads provided in the non-display areas, and a second organic film layer, successively formed on the substrate. In addition, a plurality of through holes or through slots are formed on the first organic film layer in the non-display areas, where the conductive pads electrically connect with the first metal layer via the through holes or through slots, and where the conductive pads are exposed through the second organic film layer.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Water-based coating and preparation method thereof

ActiveCN101942256AReduce pollutionPollution meetsAnti-corrosive paintsPotassium persulfateSodium acetate

The invention relates to a water-based coating. The water-based coating is prepared form the following raw materials in percentage by weight: 52 to 55 percent of water, 0.5 to 0.7 percent of sodium dodecyl sulfate, 20 to 25 percent of methyl methacrylate, 3 to 4.5 percent of butyl acrylate, 0 to 2 percent of ethyl hexyl acrylate, 1 to 1.5 percent of acrylic acid, 10 to 15 percent of butyl methacrylate, 1 to 2 percent of butyl maleate, 0.6 to 1 percent of ethyl acrylate, 0.4 to 1 percent of itaconic acid, 0.8 to 1 percent of ammonia water, 0.1 to 0.2 percent of antifoaming agent, 0.05 to 0.1 percent of sodium acetate, 0.1 to 0.2 percent of preservative and 0.1 to 0.2 percent of potassium persulfate. The invention also provides a method for preparing the water-based coating. The water-based coating of the invention is innoxious and has a small amount of environmental pollution; and a coating layer formed by coating has the advantages of high brightness, toughness, excellent anti-explosion performance, excellent subsequent processing performance, capability of stamping gold rapidly and efficiently and good gold stamping effect.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

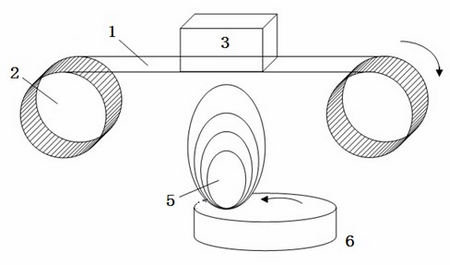

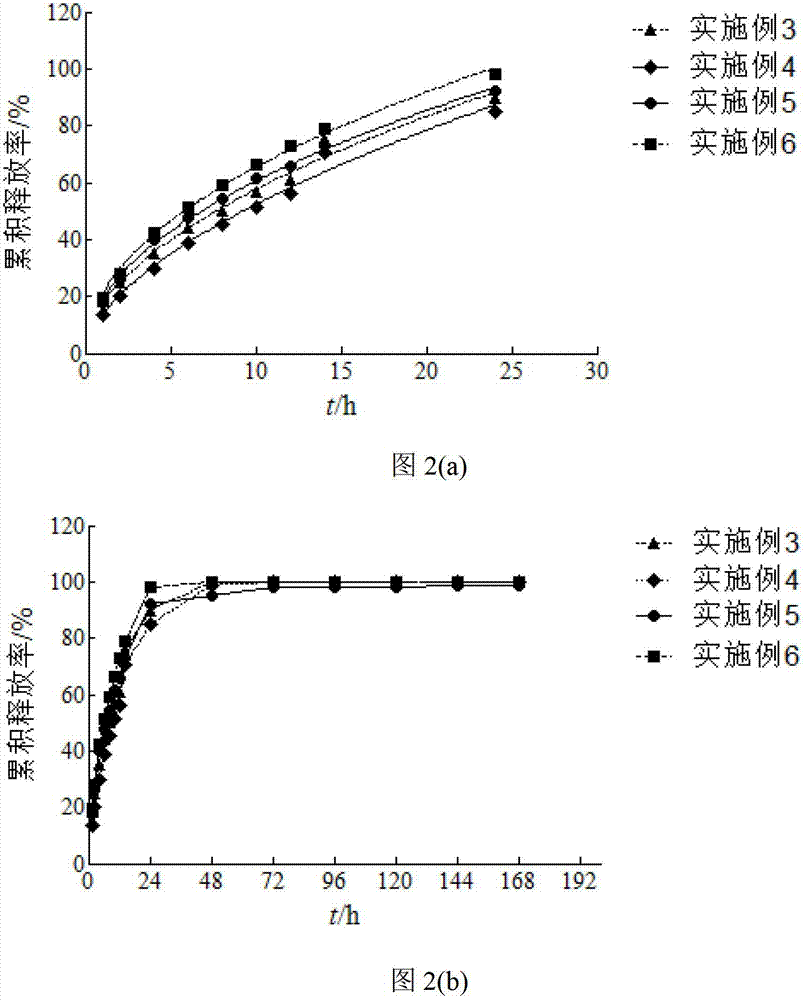

Organic polymer coating material as well as method of coating fertilizer by using coating material

The invention relates to an organic polymer coating material as well as a method of coating a fertilizer by using the coating material. The organic polymer coating material is characterized by comprising the following components in percent by weight: 10%-32% of a polyamide curing agent, 8%-20% of paraffin and the balance being cycloaliphatic epoxy resin. The invention provides an organic polymer coating material which is cheap, free from white pollution and capable of precisely controlling degradation rate and time, and has dewatering and water-blocking functions. The invention further provides a method of uniformly spraying an organic polymer, the curing agent and a sealing material on various granulated fertilizer surfaces to form an organic-polymer-coated granulated fertilizer which has a controlled release function. The coated fertilizer prepared by using the method disclosed by the invention has a nutrient release period of 2-3 months, can promote the degradation of putamina in soil and does not damage a soil structure and a plant root. Besides, the coating speed is high, the yield is high and the cost is low.

Owner:NINGXIA VIKO GREEN TECH CO LTD

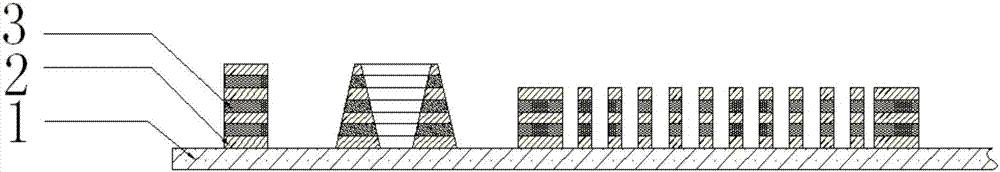

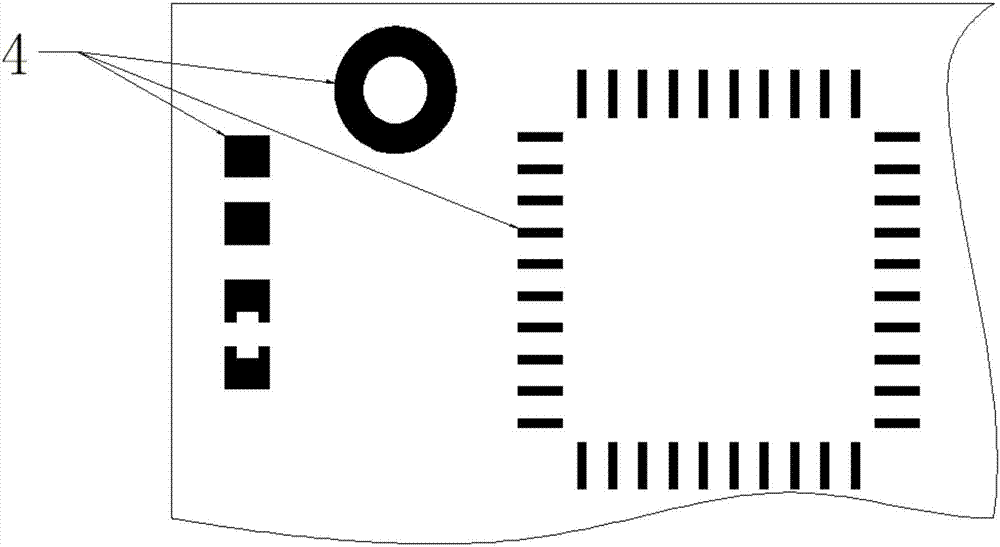

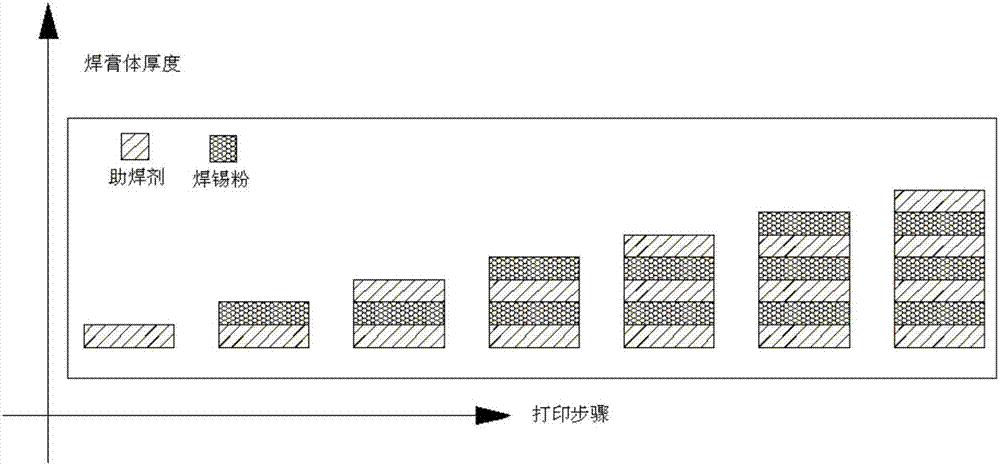

Process method for printing soldering paste bodies on circuit board in three-dimensional (3D) manner

ActiveCN107182172AEasy to control appearanceSolve the problem of easy short circuit in weldingPrinted circuit assemblingEngineeringSolder paste

The invention provides a process method for printing soldering paste bodies on a circuit board in a three-dimensional (3D) manner. The process method is a process method capable of accurately printing soldering paste bodies in a three-dimensional (3D) manner. With the process method adopted, the shapes of the soldering paste bodies are controllable, the coating efficiency of soldering paste is high, and different thickness and different shapes can be realized. According to the technical schemes of the invention, the process method is implemented through following manners: a layer of flux of which the shape conforms to the shape of a pad is printed so as to be adopted as a solder powder fixing medium; a layer of solder powder is printed on the flux at a position where the pad is located; after one independent soldering paste body is obtained through layer-by-layer printing, a next soldering paste body is printed; flux layers and solder powder layers which are printed layer by layer are mixed, so that the soldering paste bodies can be formed in real time in a printing process; the flux layers and solder powder layers are printed alternately so as to form required soldering paste bodies; flux is printed at the last layer, so that the 3D printing of the soldering paste is terminated; and flux and solder powder multi-layer liquid naturally compounded soldering paste body layout distribution of different thicknesses and different shapes can be formed on the same printed circuit board.

Owner:成都联创鸿发科技有限公司

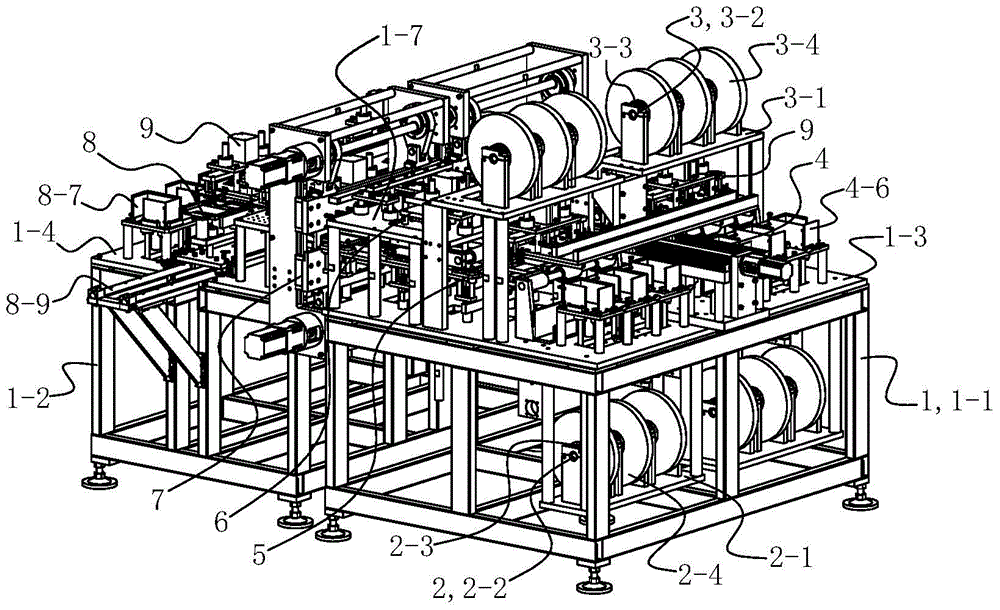

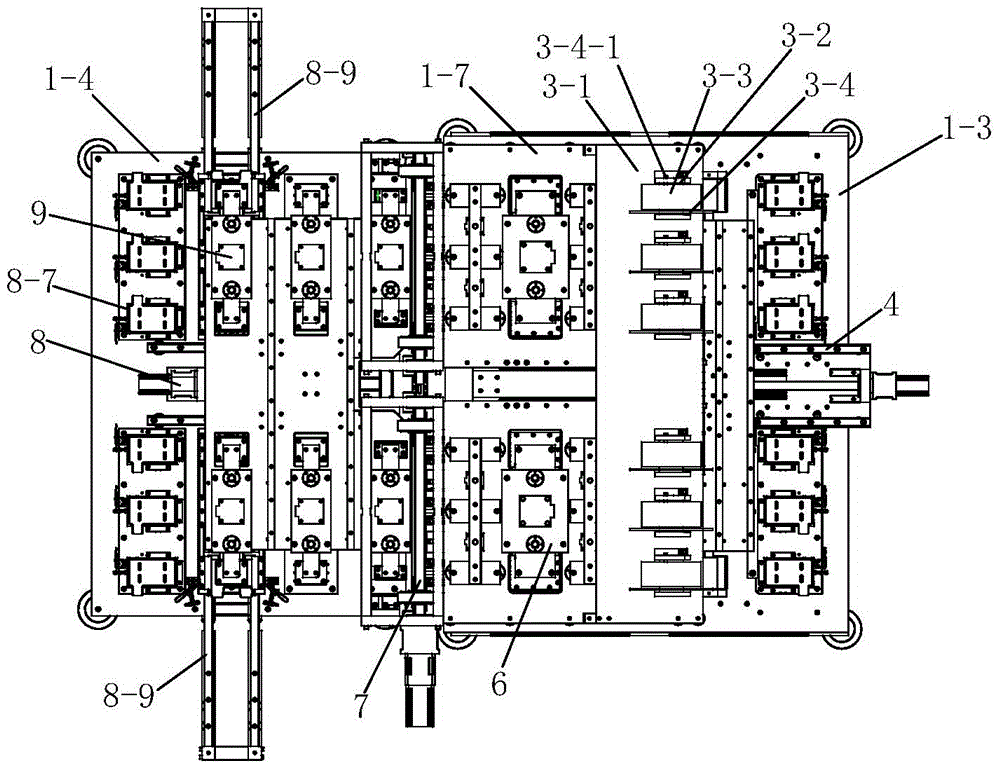

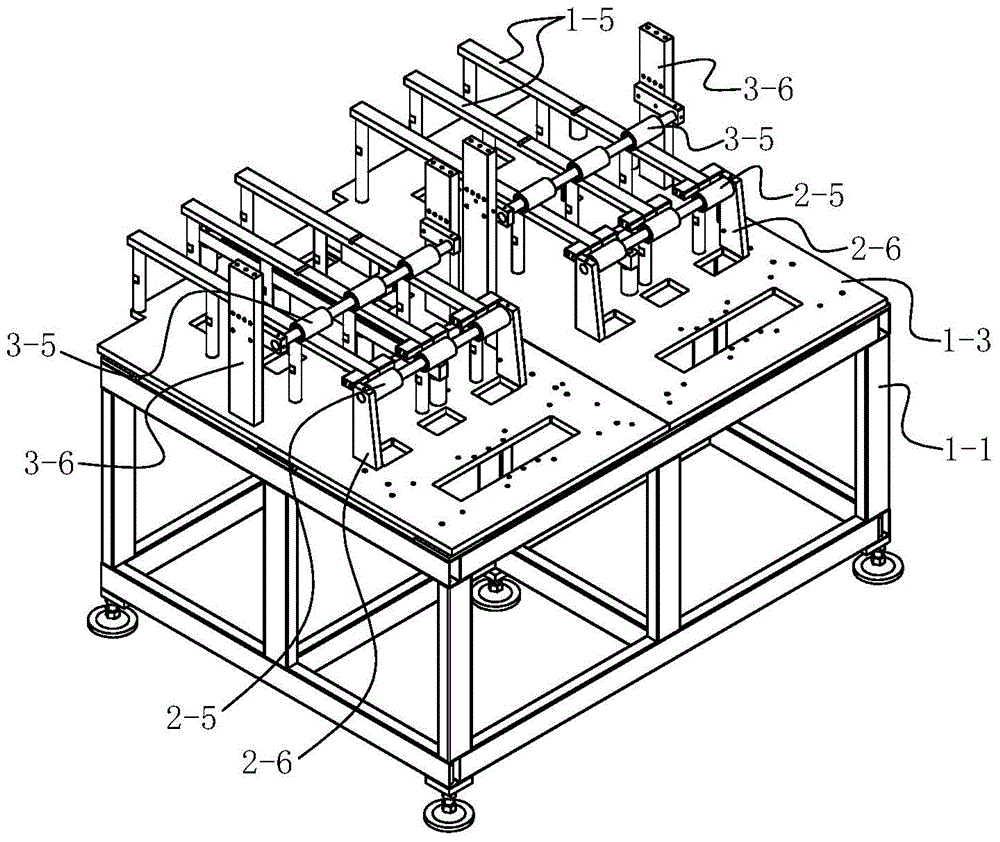

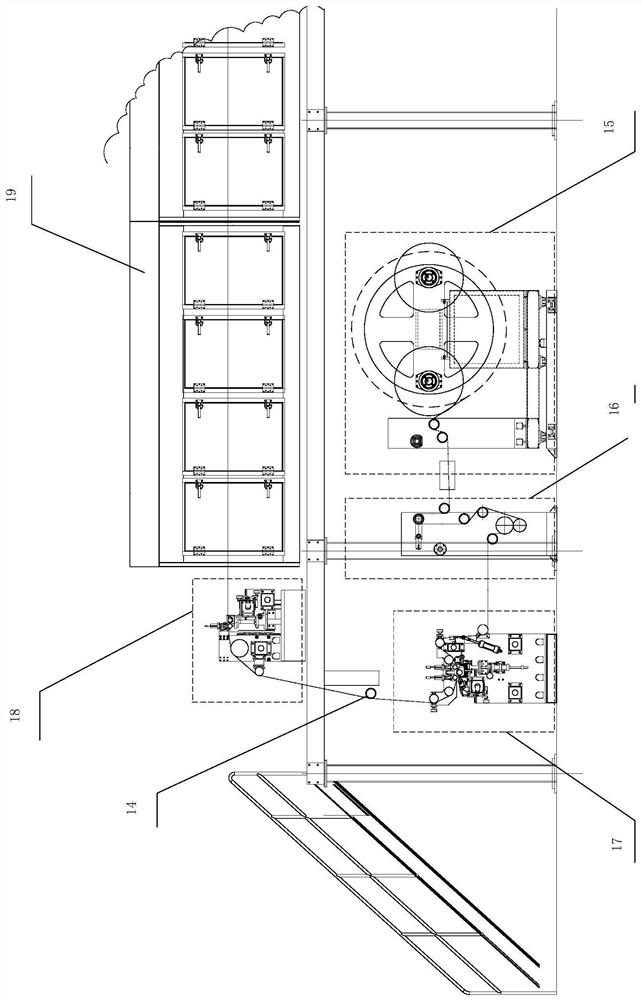

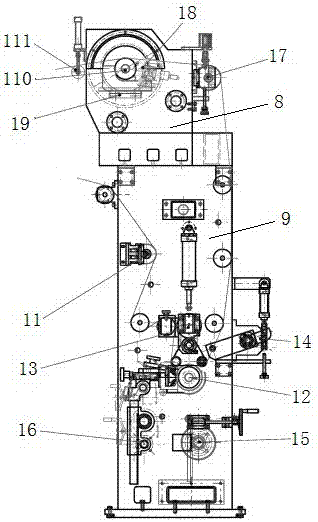

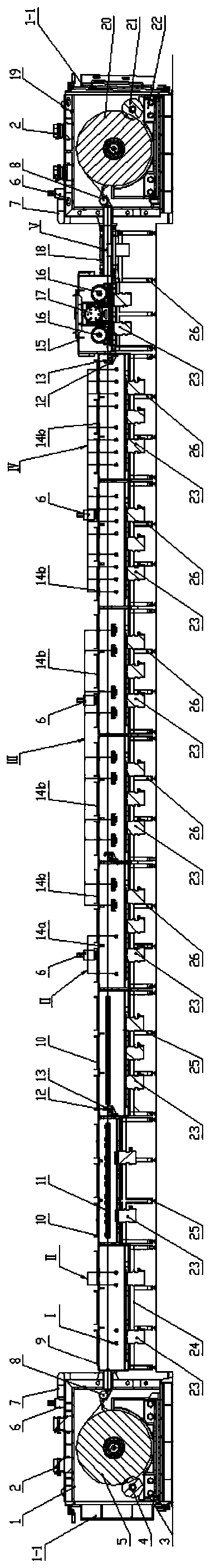

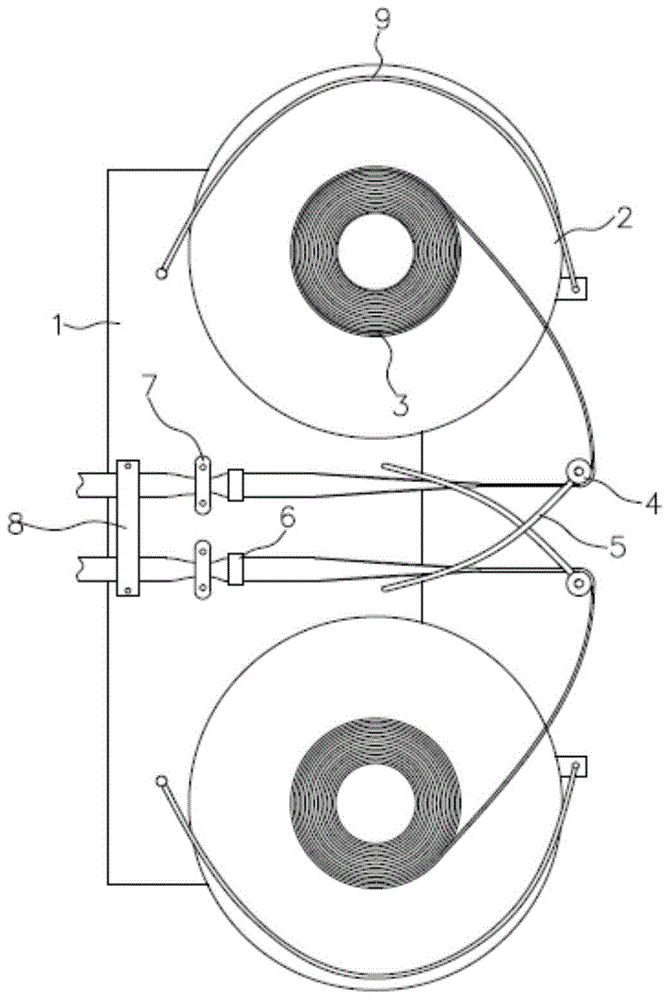

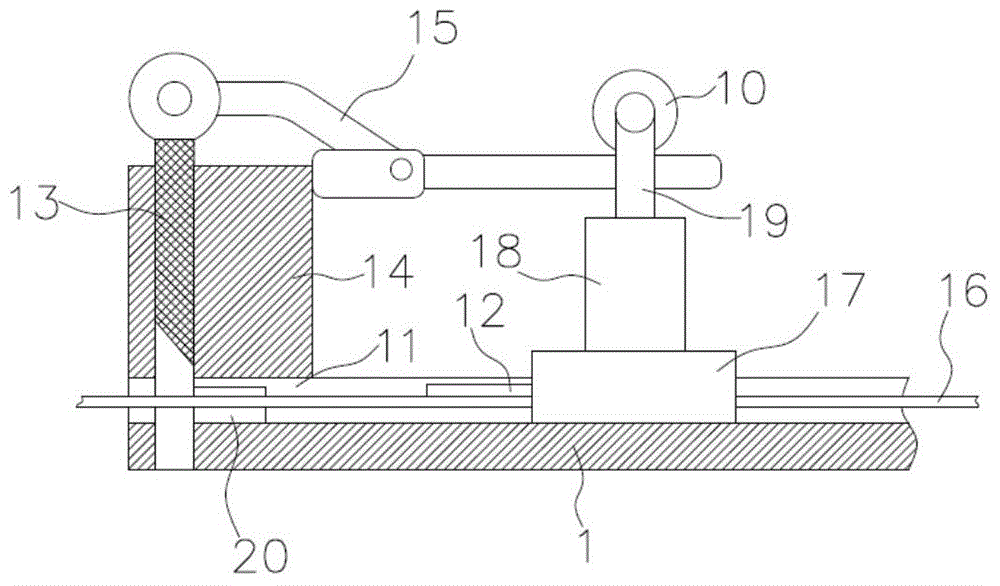

Automatic film-enveloping and piece-laminating machine

ActiveCN104064813ANo relative displacementHigh coating precisionAssembling battery machinesFinal product manufactureEngineeringAutomation

The invention relates to an automatic film-enveloping and piece-laminating machine. The machine comprises a stander, a lower diaphragm unreeling device, an upper diaphragm unreeling device, a piece-feeding device, a piece-moving device, a sealing-pressing device, a shearing device and a piece-laminating device, wherein long-strip-shaped piece-moving platforms are arranged on the stander; the piece-feeding device comprises sucking disc piece-fetching mechanisms and a piece-feeding translation mechanism; the piece-moving device comprises a clamp plate translation mechanism, piece-moving substrates, clamp plate air cylinders, base plates and clamp plates; the sealing-pressing device comprises a heat-seal assembly and a heat-seal lifting mechanism, the heat-seal assembly is located above the piece-moving platforms, and the heat-seal lifting mechanism is used for driving the rising and the falling of the heat-seal assembly; the piece-laminating device comprises sucking disc piece-fetching mechanisms, a piece-laminating translation mechanism and piece-collecting mechanisms, and the piece-laminating translation mechanism is used for driving the sucking disc piece-fetching mechanisms to carry out translational motion. According to the automatic film-enveloping and piece-laminating machine, the full automation is realized during film-enveloping, heat-seal, shearing and piece-laminating processes, the film-enveloping precision is high, the film-enveloping speed is high, and the film-enveloping effect is good.

Owner:上海恒动新能源有限公司

Polyurethane wire enamel and preparation method thereof

The invention discloses polyurethane wire enamel which is characterized by being prepared from raw materials in parts by weight (kilogram) as follows: 12-15 parts of polyurethane resin, 10-15 parts of E-12 epoxy resin, 1-2 parts of monobutyltin oxide, 2-3 parts of montmorillonite powder, 6-9 parts of pentaerythritol hexaacrylate, 3-4 parts of 1,6-hexamethylene diisocyanate, 12-15 parts of nylon 12, 2-3 parts of tree ash, 1-2 parts of 2-ethyl-4-methylimidazole, 3-4 parts of jade powder, 7-9 parts of an assistant, 100-120 parts of xylene and 100-120 parts of m, p-cresol. According to a preparation method, defects of poor flexibility, small adhesive force and smaller DV (diameter and velocity) values of a polyurethane enamelled wire produced with a conventional method are overcome, and the adherence and the heat resistance are improved. According to the polyurethane wire enamel prepared with the method, the margin of a wire coating process is large, and the wire coating velocity is high. The method can be used for preparing novel 180-grade polyurethane wire enamel with high DV values.

Owner:铜陵天河特种电磁线有限公司

Double-sided coating equipment and processing technology applying double-sided coating equipment

PendingCN112604911ACorrection high efficiencyBroaden applicationPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to double-sided coating equipment. The double-sided coating equipment comprises front-side coating equipment and back-side coating equipment, wherein the back-side coating equipment comprises a second rack, and a first guide roller, a traction roller, a second guide roller and a second coating roller which are sequentially distributed below a base material in the back-side coating direction of the base material are erected on the second rack; and a glue tank used for infiltrating part of the second coating roller is arranged under the second coating roller, the second guide roller is arranged on one side of the second coating roller, a second scraper is fixed to the other side of the second coating roller, the blade point of the second scraper is connected with the outer surface of the second coating roller in an abutting mode, the front-side coating equipment is located below the back-side coating equipment, and a middle roller is positioned between the front-side coating equipment and the back-side coating equipment. According to the high-efficiency double-sided coating equipment and a processing technology applying the double-sided coating equipment, double-sided coating can be achieved on one coating line.

Owner:SUZHOU ACME MACHINERY

Porous nickel and carbon compound and preparation method of porous nickel and carbon compound

ActiveCN106622248ALow densityEasy to suspendCarbon preparation/purificationMetal/metal-oxides/metal-hydroxide catalystsCarbon layerGas phase

The invention discloses a porous nickel and carbon compound and a preparation method of the porous nickel and carbon compound. A continuous carbon layer coats the surface of porous nickel and micro-pores are formed in the carbon layer; the carbon comprises one or more of functional groups including hydrogen, oxygen, nitrogen and the like; the preparation method of the porous nickel and carbon compound comprises the following steps: putting the porous nickel into a chemical vapor deposition device and introducing a carbon source or a mixture of the carbon source and a nitrogen source and the like at a high temperature; generating the continuous carbon layer on the surface of the porous nickel within certain time. According to the porous nickel and carbon compound, the porous nickel can have a plurality of forms including small grains, blocks or membrane-shaped objects and the like; the nickel and carbon compound can be used as a hydrogenation catalyst in different reactors; compared with pure porous nickel, the porous nickel and carbon compound has the advantages of small density, high mechanical strength, small abrasion in the reactors and controllable hydrogenation degree; the porous nickel and carbon compound can also be used as a multifunctional current collector for 1V to 4V electrochemical energy storage, and has the advantages of electrochemical capacitance higher than that of pure foam nickel and great mechanical strength and is suitable for being continuously coated.

Owner:江苏中天碳基材料有限公司

Method for performing surface treatment on golf head by aluminium -titanium nitride composite coating

ActiveCN101979703ASimple processGood repeatabilityVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium alloy

The invention discloses a method for performing surface treatment on a golf head by an aluminium-titanium nitride composite coating. The method comprises the following steps of: gasifying aluminium-titanium alloy under a vacuum condition, forming plasma, and forming a composite coating of aluminium-titanium alloy and aluminium-titanium nitride on the surface of the golf head by a physical vapour deposition method. The treated golf head has good wear resistance, solvent resistance, salt and fog corrosion resistance and a vivid rosy appearance colour. The coating has good comprehensive mechanical performance, certain hardness and certain toughness. Therefore, the golf head has good impact resistance and good adhesion firmness with a golf head base material and completely meets the requirements on the surface quality of the golf head.

Owner:范文波

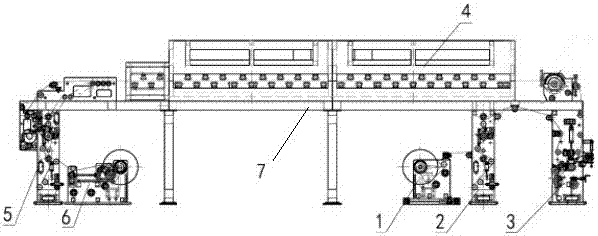

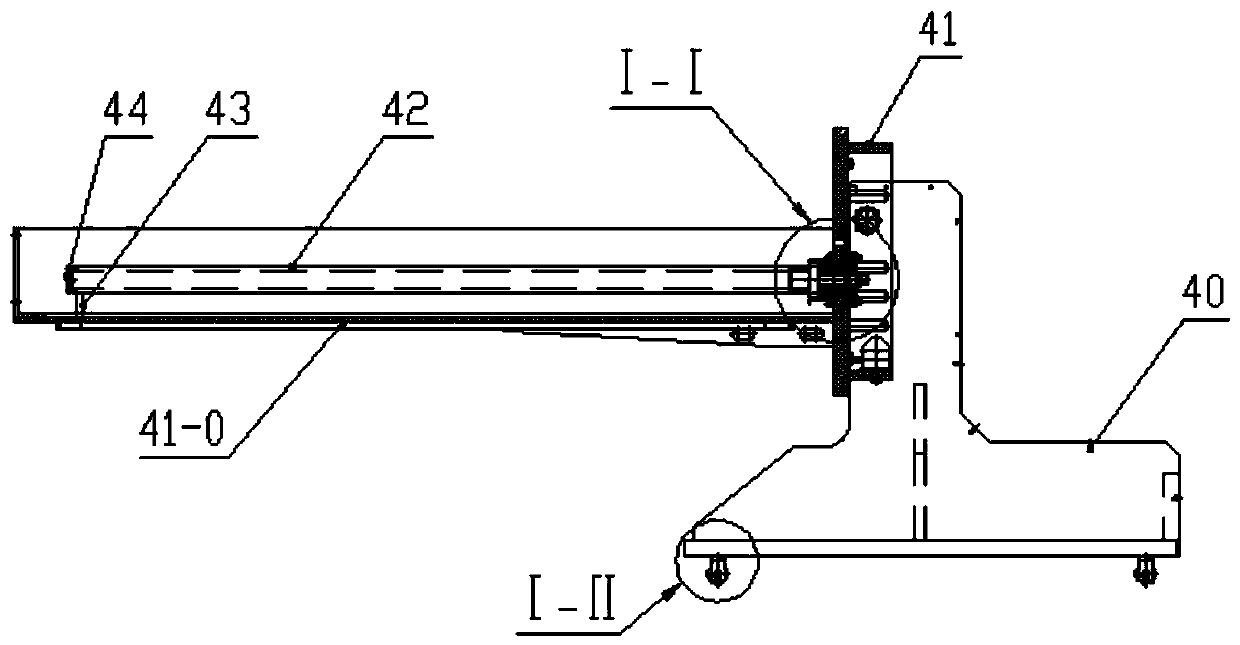

Aluminum foil double-face fast coating device and method

InactiveCN107159524ASave spaceFast coatingPretreated surfacesCoatingsEngineeringStructural engineering

The invention provides an aluminum foil double-face fast coating device. The aluminum foil double-face fast coating device comprises a first frame, an unwinding mechanism, a feeding drawing mechanism, a coating mechanism, a drying oven, a discharging drawing mechanism and a winding mechanism, wherein the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism are arranged on the first frame. The coating mechanism is a double-face ladder type coating mechanism which comprises a front side coating mechanism body and a back side coating mechanism body. The drying oven is a suspension drying oven. Aluminum foil sequentially passes through the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism, and then double-face coating is completed. An aluminum foil double-face fast coating method sequentially comprises the steps of unwinding, front side coating, back side coating, double-face drying and winding. According to the aluminum foil double-face fast coating device and method, through the ladder type one-time front side and back side coating and one-time double-face drying technologies, the material conveying path is greatly shortened, fast coating is achieved, the coating speed can reach 150m / min, in addition, the double faces are dried at a time after being coated, the space of the drying oven is saved, the manufacturing cost is reduced, meanwhile, energy is saved by about 160KW / h, and the aluminum foil double-face fast coating device and method are suitable for gravure coating and reverse kiss coating.

Owner:XIAN XINDA MACHINERY

Method for coating active component on cellular carrier with two open ends

InactiveCN1461673ACoating speed is fastSimple methodLiquid surface applicatorsDispersed particle separationActive componentBiochemical engineering

A process for coating active component on the cellular carrier with two open ends includes such steps as immersing one end of said carrier in the active component slurry while applying vacuum to its another end for forcing the slurry to flow through the channels of carrier, scavenging by high-pressure gas for removing excess slurry from channels, and drying.

Owner:CHINA PETROLEUM & CHEM CORP +1

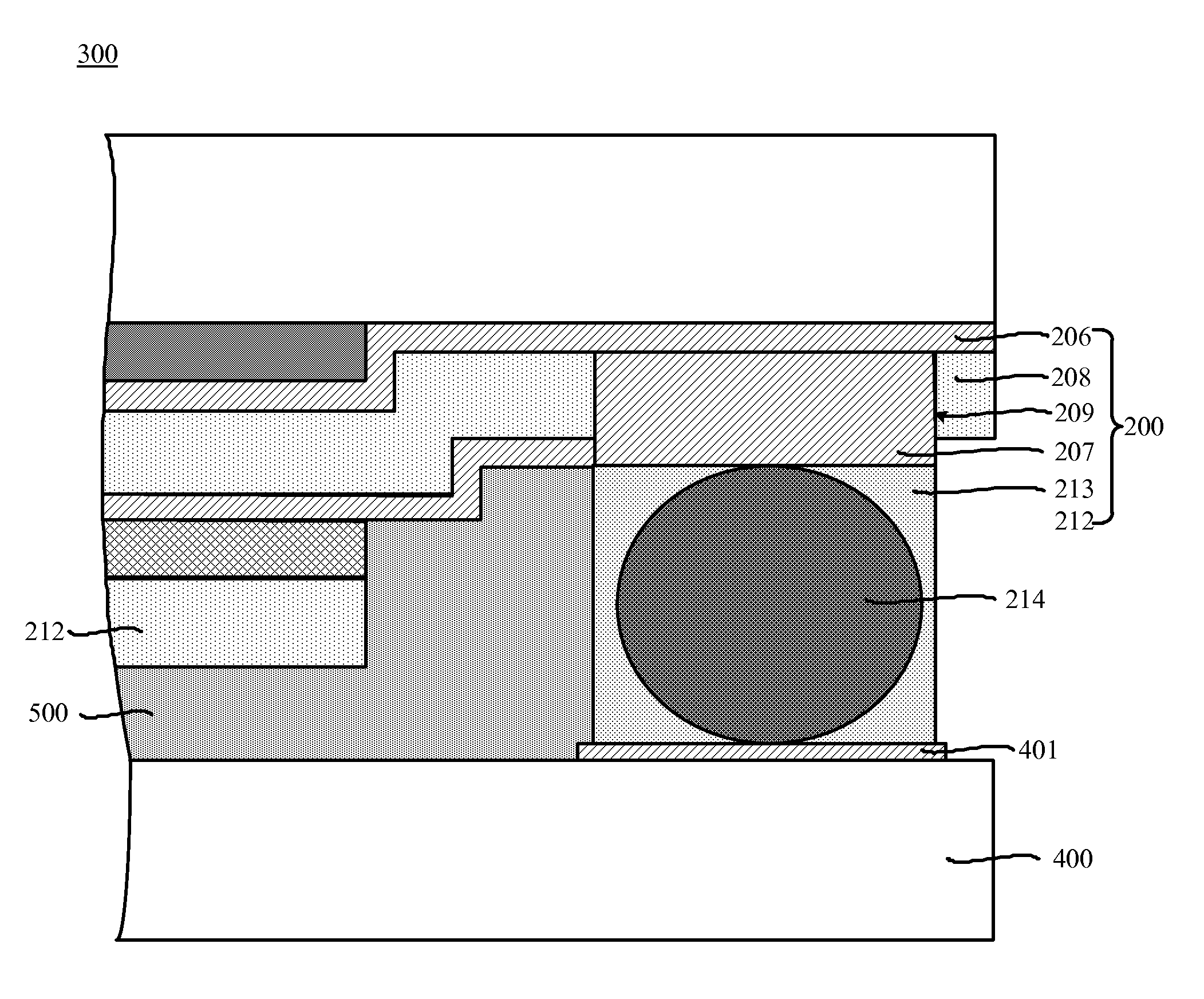

Embedded touch colour-film substrate and manufacturing method thereof

ActiveCN103984145AReduce the number of coatsShorten coating timeNon-linear opticsInput/output processes for data processingCushionOptoelectronics

The invention discloses an embedded touch colour-film substrate and a manufacturing method thereof. The embedded touch colour-film substrate comprises a substrate, first metal layers, first organic film layers, second metal layers and second organic film layers, wherein the substrate comprises multiple display areas and multiple nondisplay areas surrounding the display areas; the first metal layers, the first organic film layers, the second metal layers and the second organic film layers are formed on the substrate in sequence; each of the second metal layers comprises multiple electric conduction cushions arranged in the nondisplay areas; multiple through holes or through grooves are formed in each of the first organic film layers in the nondisplay areas; the electric conduction cushions are respectively and electrically connected with the first metal layers through the through holes or the through grooves; moreover, the electric conduction cushions are respectively exposed outside the second organic film layers. By applying the embedded touch colour-film substrate provided by the invention, the time on coating a frame sealing glue can be effectively shortened, so that the production efficiency can be improved greatly.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Roll sticking prevention lithium battery cathode material and preparation method thereof

The invention provides a roll sticking prevention lithium battery cathode material and a preparation method thereof. The cathode material is prepared by the following raw materials of, by weight, 50-96 parts of carbon powder, 0.5 part of a conductive agent, 0.6-2.0 parts of a thickening agent, 2.0-3.0 parts of an adhesive, 5-10 parts of an oiliness agent and a proper amount of deionized water. The preparation method comprises the following steps of a. weighing the carbon powder, the conductive agent, the thickening agent, the an adhesive, the oiliness agent and the deionized water according to the above weight parts; b. adding the thickening agent into the proper amount of the deionized water, stirring for 3-5 hours with a high speed, standing for 3-5 hours to prepare a thickening agent aqueous solution with a solid content being 1.0791%-2.5% by mass; c. adding the conductive agent, stirring for 0.8-1.2 hours with a high speed; d. adding the oiliness agent, stirring for 0.8-1.2 hours with a high speed; e. adding the adhesive, stirring for 0.8-1.2 hours with a high speed; f. adding the carbon powder in four times, adding half the amount for the first time, and adding a half of the left amount for the subsequent time, stirring for 8-12 minutes with a low speed after the addition of each time to make the carbon powder moist enough; and g. stirring for 3-5 hours with a high speed, vacuum-pumping and stirring uniformly at a low speed to obtain the roll sticking prevention lithium battery cathode material.

Owner:焦作市亿锂达能源科技有限公司

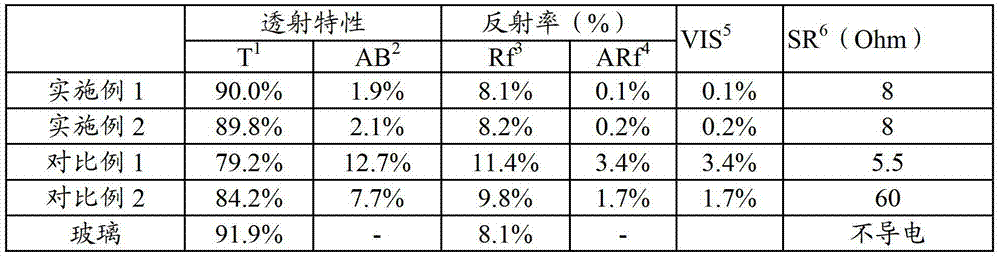

Transparent conductive substrate and touch panel having the same

InactiveCN103713765AEasy to manufactureImprove productivityConductive layers on insulating-supportsNon-linear opticsPolymer resinRefractive index

A transparent conductive substrate used for the detection of a touched position in a touch screen panel and a touch panel having the same. The transparent conductive substrate includes a base substrate, a transparent conductive layer formed on the base substrate, the transparent conductive layer including a pattern part which includes a transparent conductive film coating the base substrate and a non-pattern part through which the base substrate is exposed, and a polymer resin layer containing a resin that has a refractive index from 1.4 to 1.6, the polymer resin layer being formed on the transparent conductive layer while filling the non-pattern part, the thickness of the polymer resin layer from the pattern part ranging from 1 to 1000 [mu]m. The transparent conductive film includes a first thin film on the base substrate, a metal thin film on the first thin film, and a second thin film on the metal thin film.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

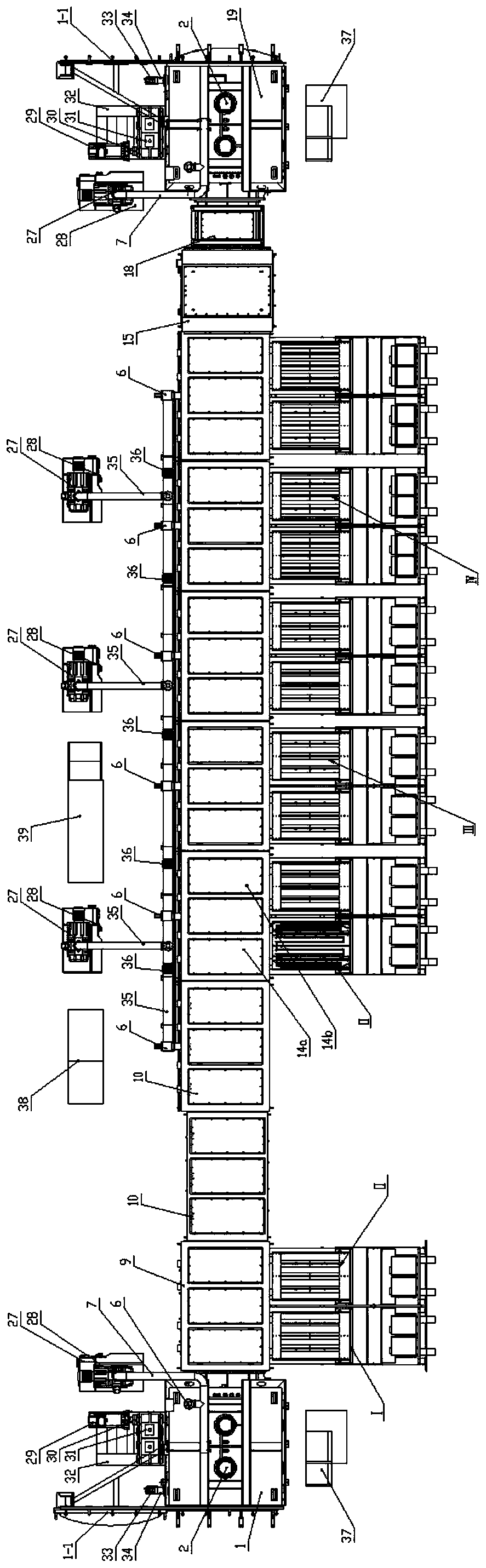

Metal foil winding type vacuum coating continuous production line

PendingCN111058009ATimely correction of process parametersGuaranteed color uniformityVacuum evaporation coatingSputtering coatingProduction lineMetal foil

The invention relates to a metal foil winding type vacuum coating continuous production line. The continuous production line comprises a coating chamber, the coating chamber is divided into a front section and a rear section, windows are correspondingly disposed on one sides of cavities at the front section and the rear section, and rails perpendicular to racks are arranged on one sides of the racks corresponding to the windows; a planar rectangular cathode arc source device is disposed in the front section, and comprises a target material and a moving trolley, and the target material is fixedon a vertical panel of the moving trolley and is positioned in a supporting drawer box; the moving trolley walks on the vertical rail, a sealing door bracket composed of a frame and a vertical panelis arranged on the moving trolley, a side of the vertical panel facing the window is a seal surface and is in seal design correspondingly with a window frame of the window, and a groove-shaped supporting drawer extending to the window is fixed on the vertical panel. A rotary columnar medium-frequency magnetron sputtering target device is disposed in the rear section, and comprises a sputtering target and a moving trolley assembly, the sputtering target is fixed on the vertical panel and is located in the supporting drawer box; and the target material and the sputtering target are respectivelypushed into or pulled out of each chamber by the moving trolley. The coating layer is uniform and stable in color, and the technological process is reliable.

Owner:DONGGUAN HUICHENG VACUUM TECH

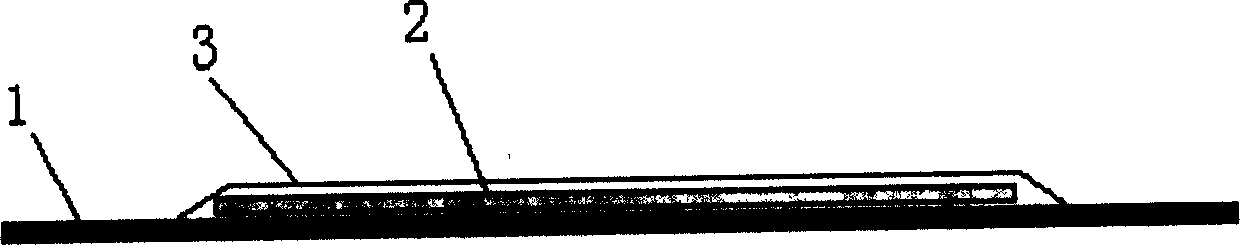

Controlled release transdermal patch for preventing and treating cardiovascular and cerebrovascular system diseases and preparation method thereof

InactiveCN101810596AGood film formingExcellent water vapor permeabilityOrganic active ingredientsOil/fats/waxes non-active ingredientsTransdermal patchComposite film

The invention relates to a controlled release transdermal patch for preventing and treating cardiovascular and cerebrovascular system diseases, which consists of a protectively layer, a medicine release layer, a medicine storage layer and a back lining layer through being sequentially overlapped, wherein the protectively layer is siliconized anti-sticking paper or a polyethylene film or a siliconized polyester film, the back lining layer is an aluminum foil, an aluminum foil and polyethylene composite film or a polyester composite film, the medicine releasing layer is prepared from 3 to 8 percent of cyclovimbuxine D, 60 to 70 percent of pressure sensitive adhesive substrates, 5 to 10 percent of composite transdermal penetrating agents, 20 to 30 percent of plasticizing agents and 1 to 3 percent of cross-linking agents, the medicine storage layer consists of 8 to 15 percent of the cyclovimbuxine D, 50 to 60 percent of the pressure sensitive adhesive substrates, 1 to 5 percent of composite transdermal penetrating agents, 20 to 30 percent of plasticizing agents and 1 to 3 percent of cross-linking agents. The patch of the invention is prepared by an organic solvent dispersing method, the preparation process is simple, the prepared patch has the exact curative effect, stable quality, high safety and convenient use, and is applicable to the long-time prevention and treatment of the cardiovascular and cerebrovascular diseases.

Owner:GUANGZHOU UNIVERSITY OF CHINESE MEDICINE

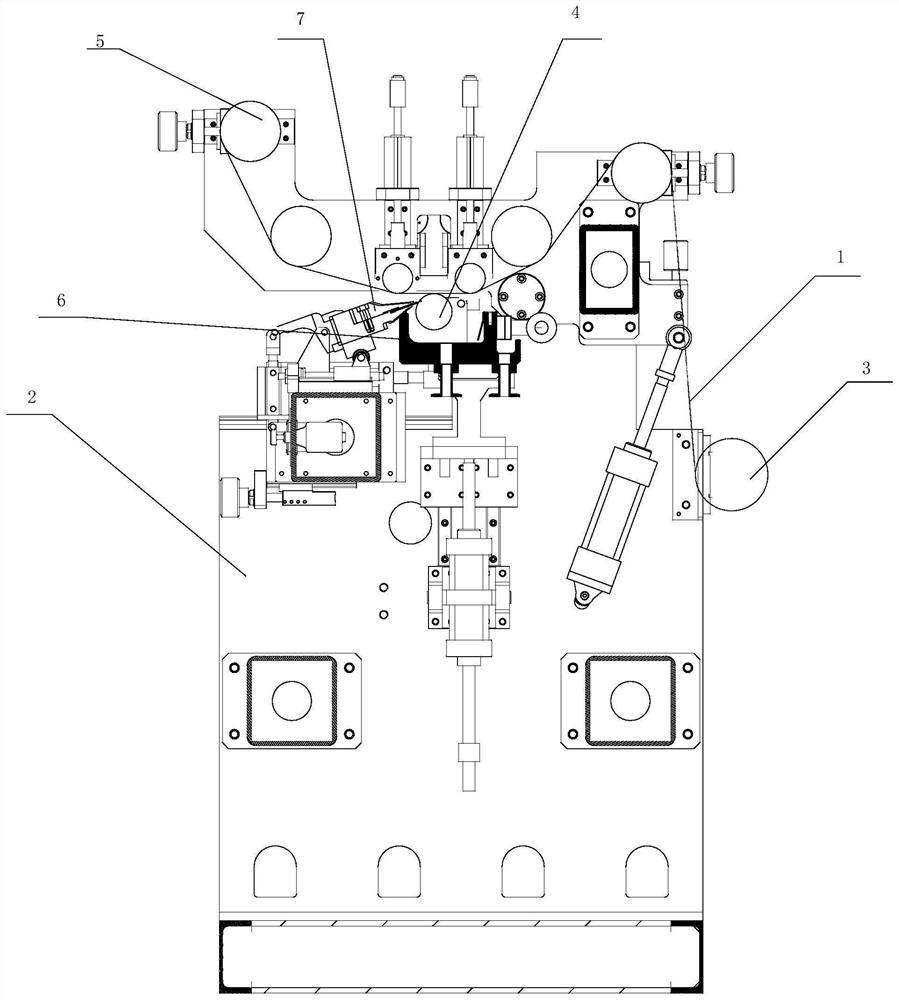

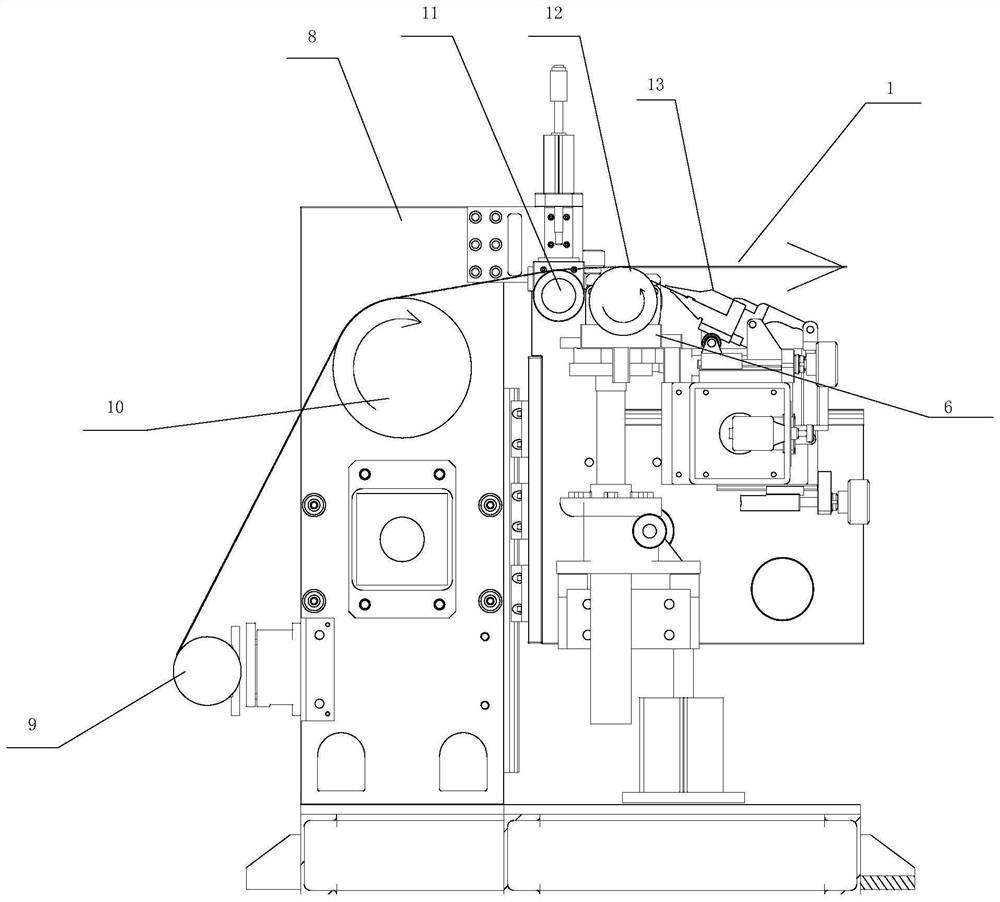

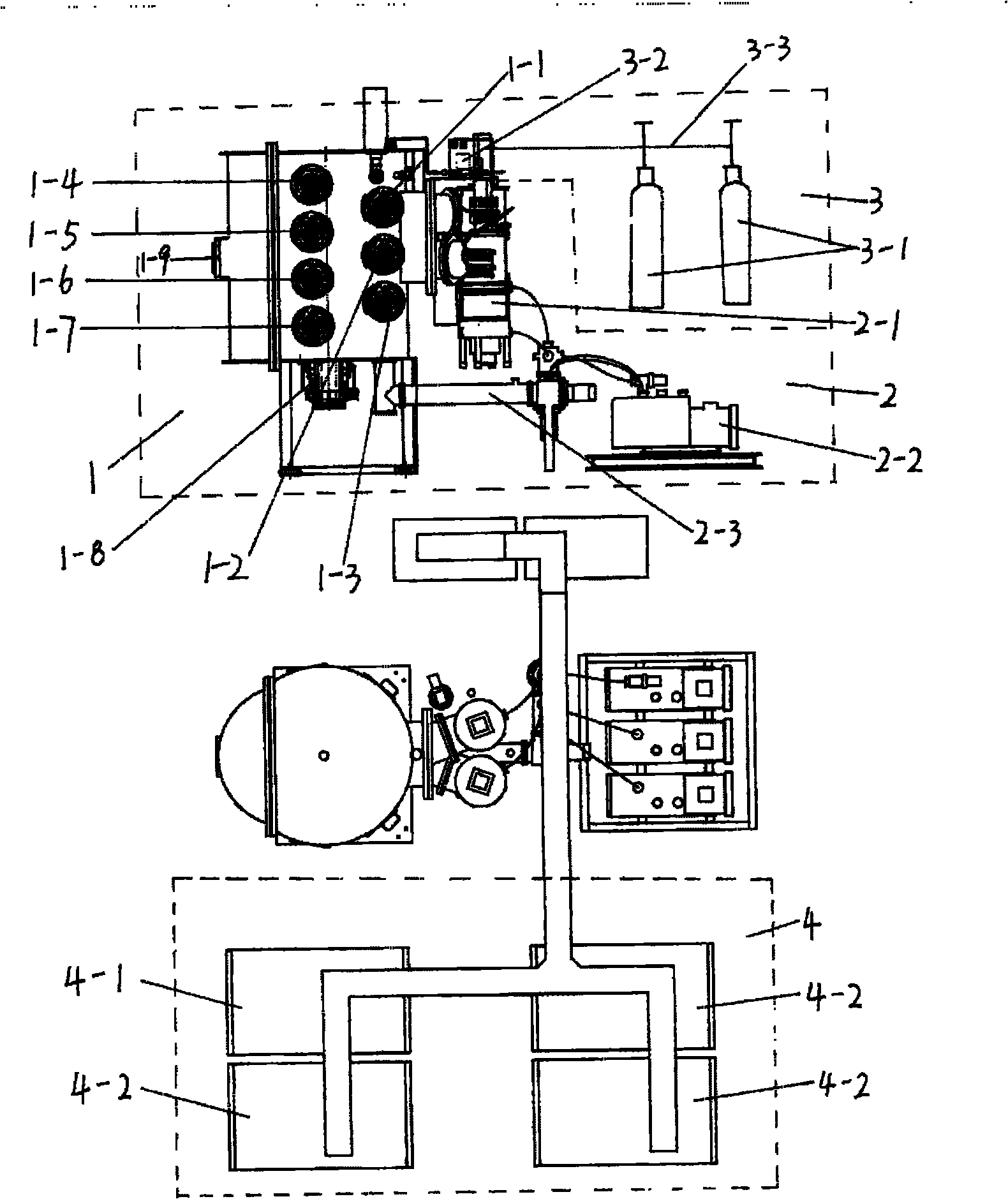

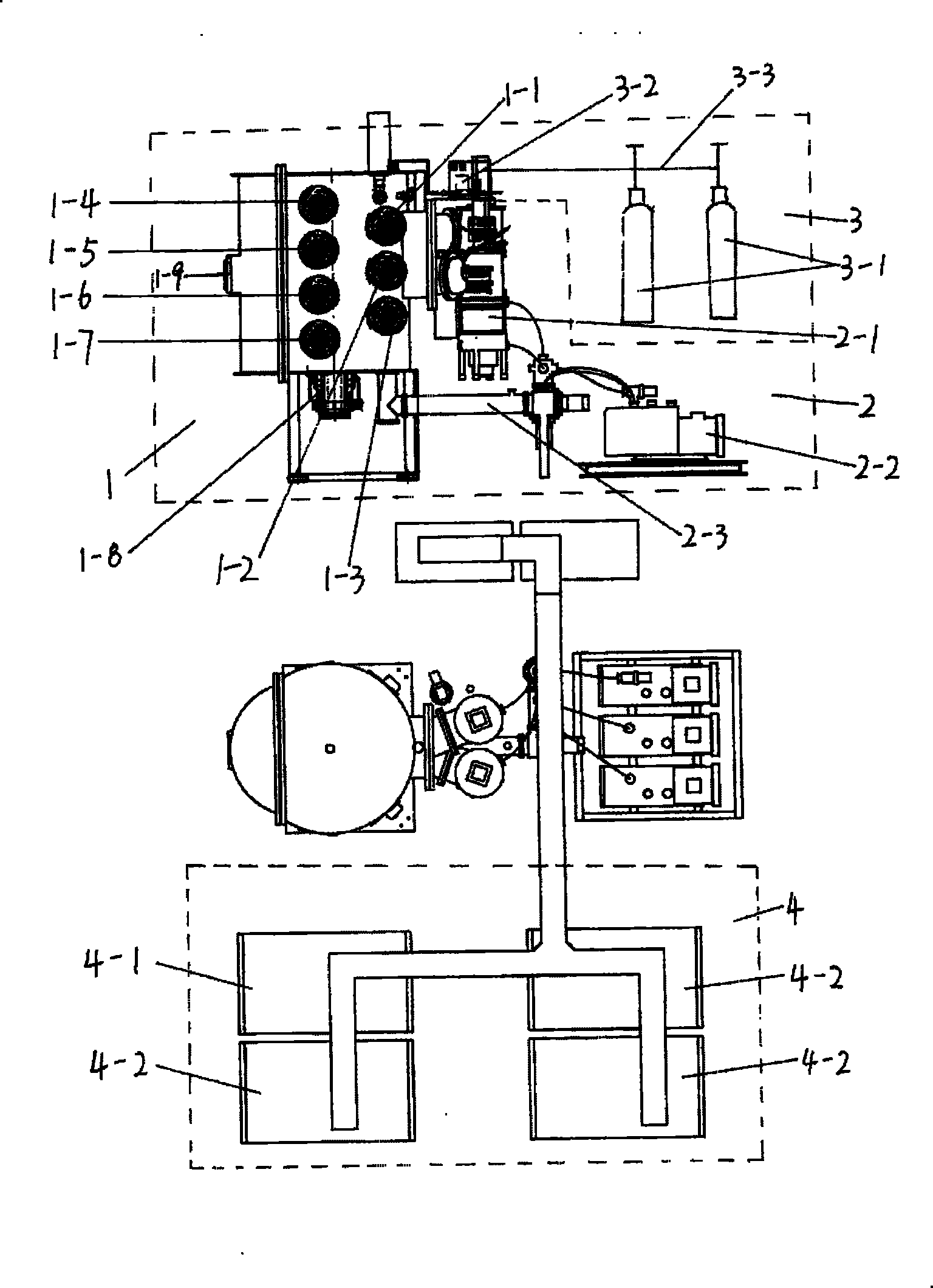

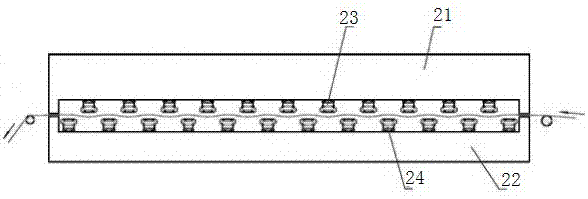

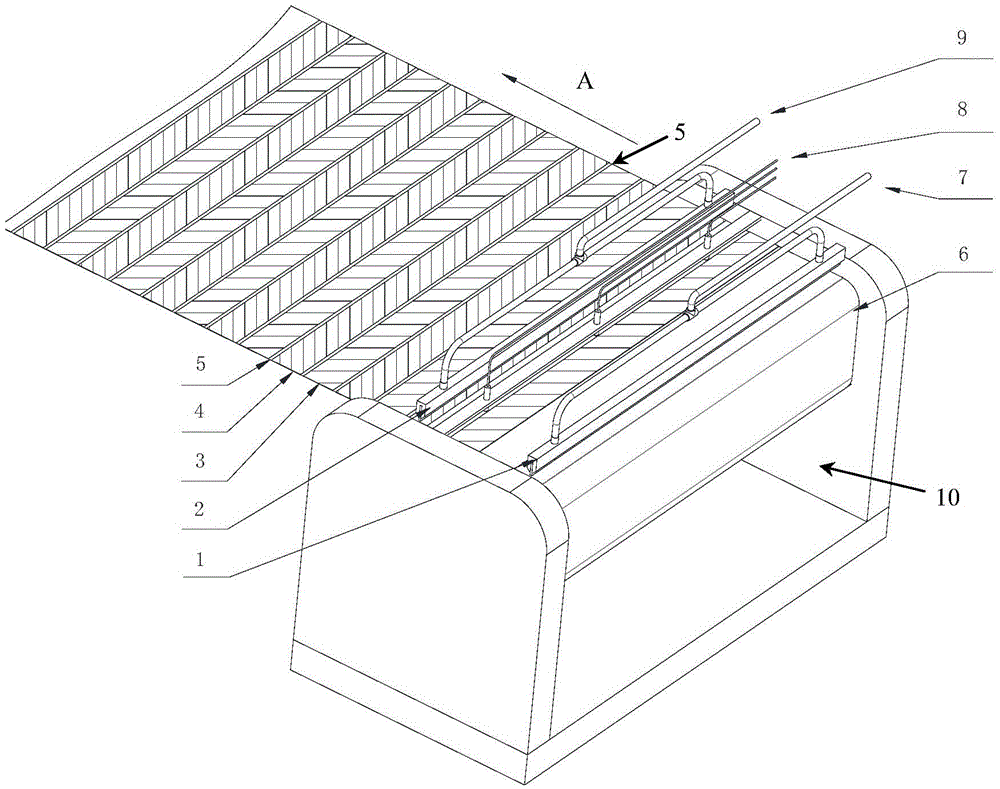

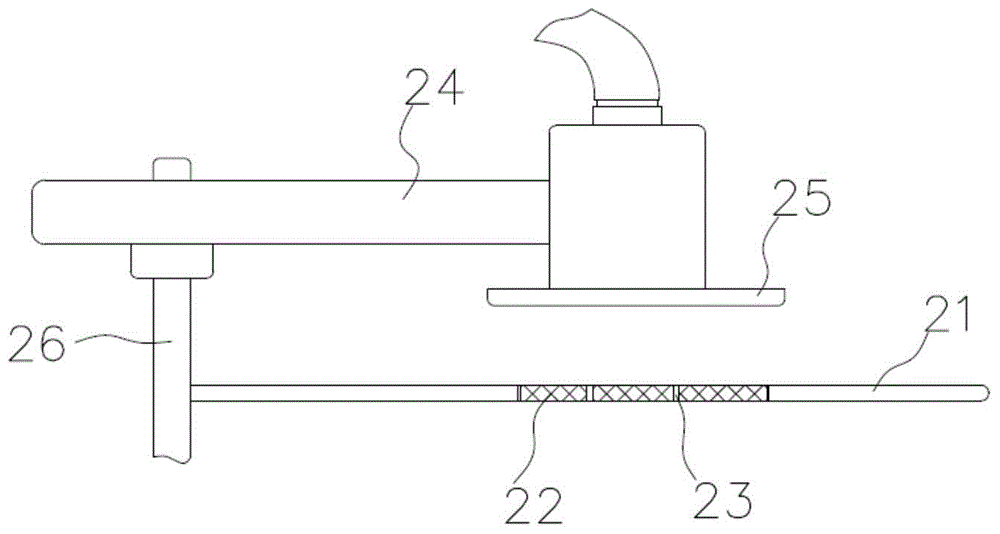

Spraying device for film surface of secondary battery

InactiveCN105583125ALarge capacityFast coating speedLiquid surface applicatorsElectrode collector coatingFilm baseEngineering

The invention discloses a spraying device for the film surface of a secondary battery. The spraying device comprises a coating frame (10) arranged horizontally. A film base material (6) is transversely placed at the top of the coating frame (10). A first coating set and a second coating set are installed on the top face of the film base material (6) in a spaced manner. The first coating set and the second coating set are used for carrying out interval coating on the top face of the film base material (6) in an alternating manner. The spraying device for the film surface of the secondary battery enables coating speed to be free of restriction of an interval coating process while increasing the coating speed of a coating machine substantially, and the effect of effectively reducing coating intervals is ensured, so that larger capacity of the battery is ensured. Product use experience of users is improved easily, wide application and popularization of the high-capacity secondary battery are promoted, and the spraying device has great production practice significance.

Owner:TIANJIN LISHEN BATTERY

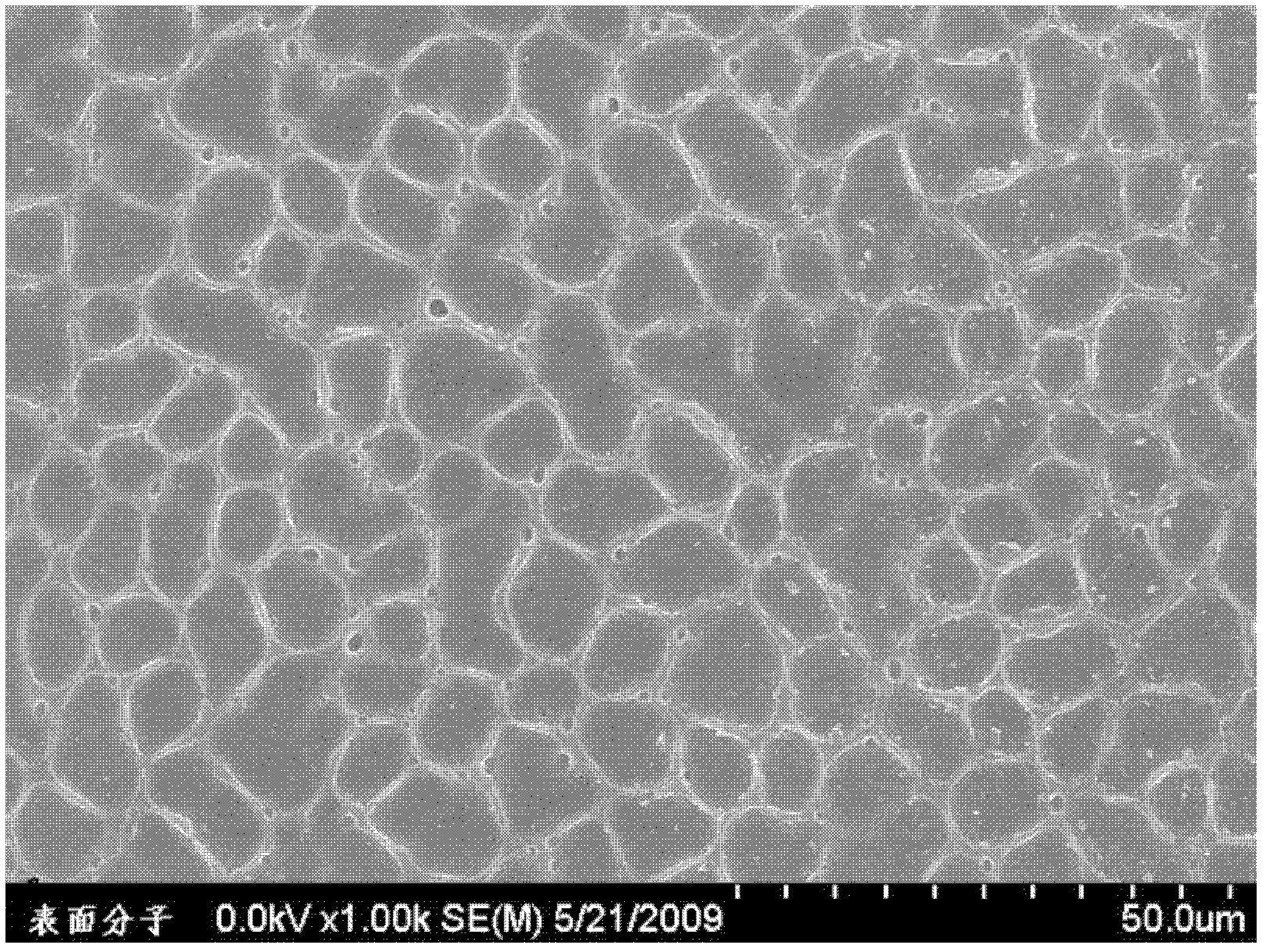

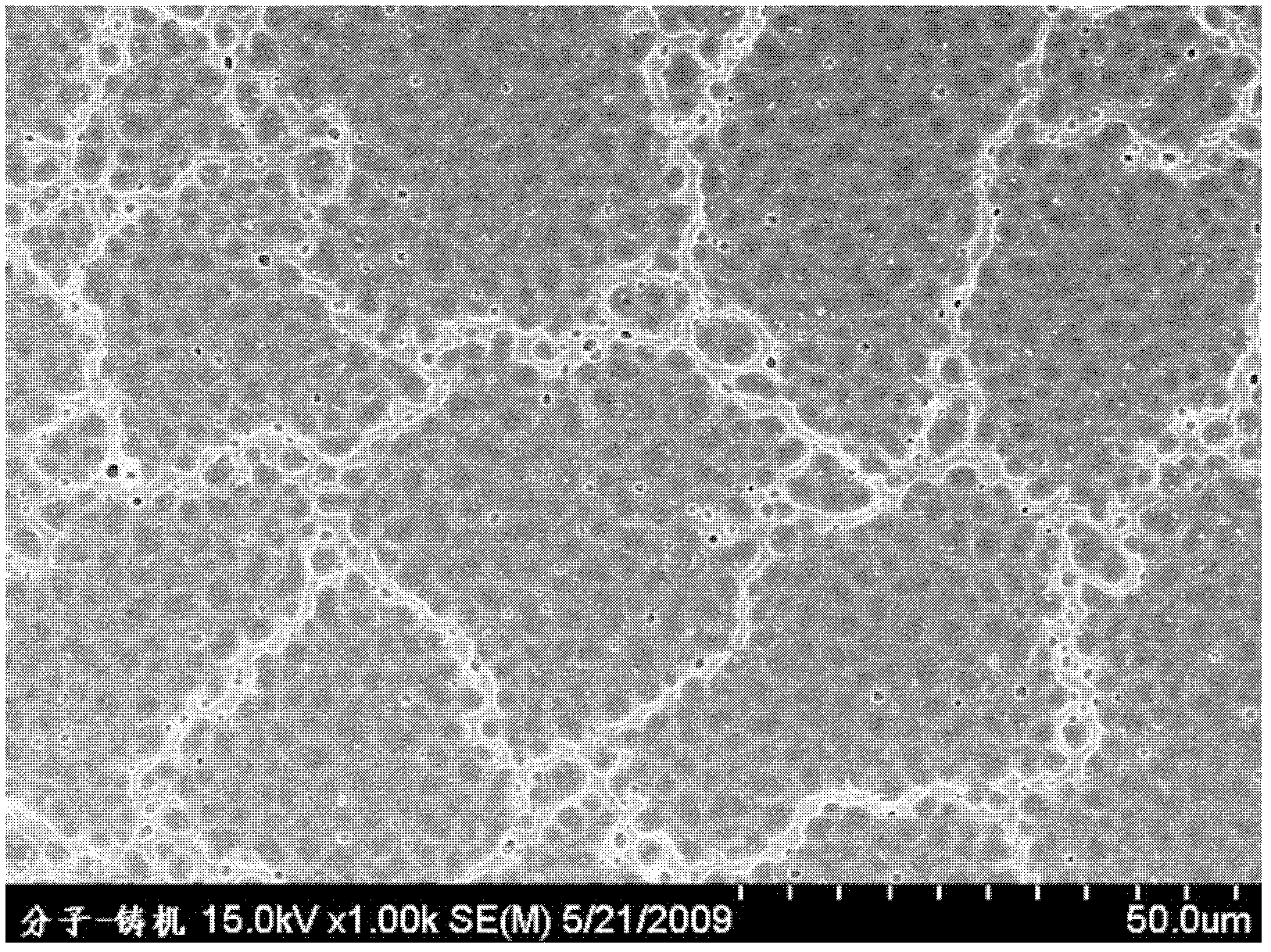

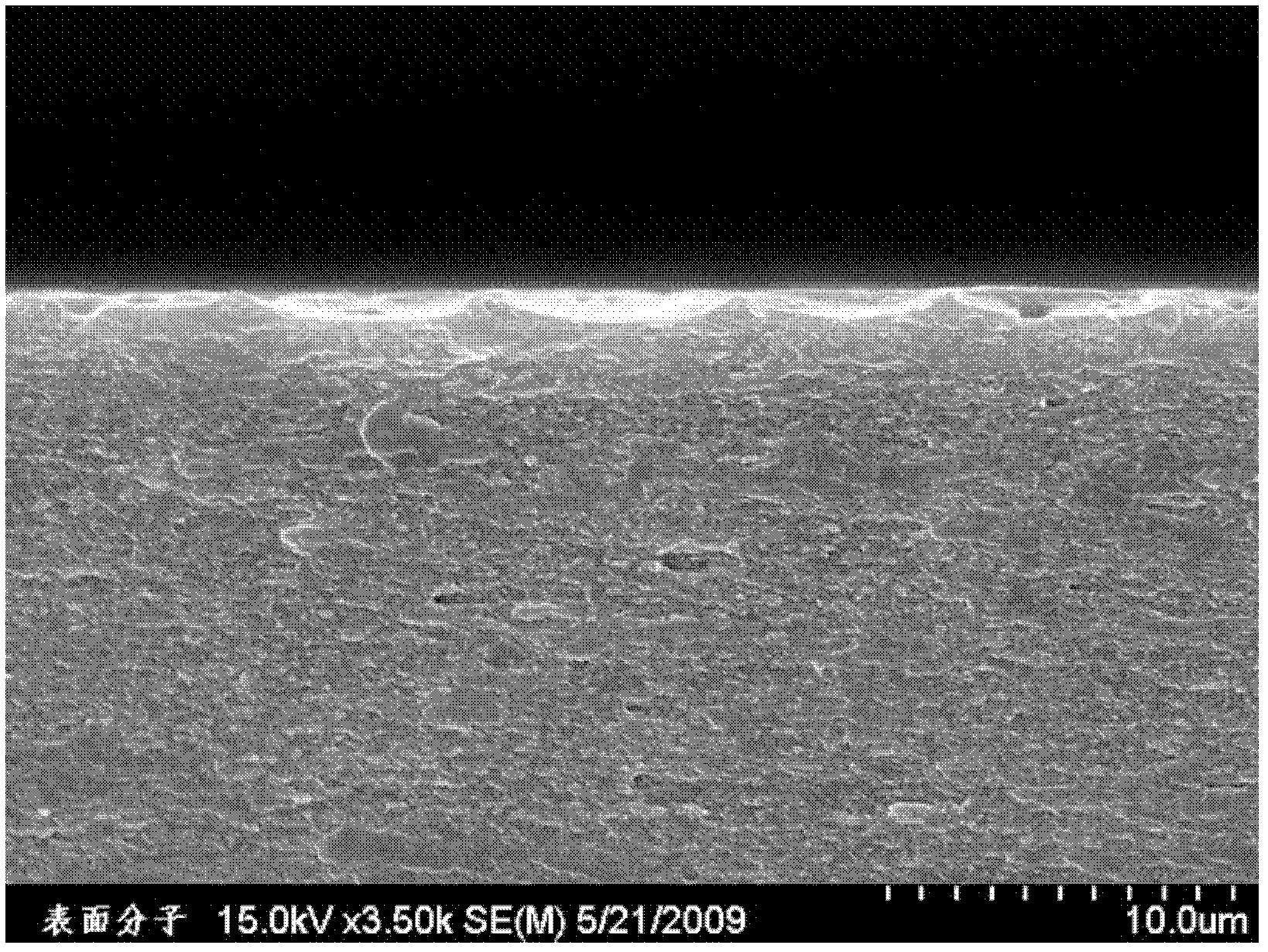

Optical films with controlled surface morphology and the method of manufacturing the same

InactiveCN102574342AGood removal effectImprove productivityOptical articlesThin material handlingSurface roughnessEngineering

Provided are an optical film for use in flat panel display (FPD) devices, and a method for manufacturing the same. Particularly, there is provided a method for imparting surface roughness to an optical film, which includes forming dented craters having a radius of curvature of 10 nm-100 [mu]m on the surface of an optical film obtained by a solution casting process and forming a plateau between one crater and another crater. There is also provided an optical film obtained by the same method.

Owner:SK INNOVATION CO LTD

High-performance waterborne pressure-sensitive adhesive and preparation method thereof and PE protective film

InactiveCN105969265AHigh solid contentMatching scienceFilm/foil adhesivesEster polymer adhesivesPressure sensitiveChemistry

The invention discloses a high-performance waterborne pressure-sensitive adhesive for a polyethylene protective film. A mode of seed emulsion polymerization is adopted, a seed emulsion is prepared, a pre-emulsion is dropwise added to the seed emulsion, reaction is conducted completely in a mode of replenishing an initiator, cooling, pH value adjusting and filtering are conducted, and the high-performance waterborne pressure-sensitive adhesive is obtained. The invention further provides the polyethylene protective film of the waterborne pressure-sensitive adhesive. The prepared emulsion pressure-sensitive adhesive can obtain the protective film with proper peel strength by adjusting the dosage of a cross-linking agent and coated adhesive quantity and is widely used for door window framework profiles, window frame profiles, solar frame profiles, decorative panels such as aluminum-plastic panels and plastic gusset plates, curtain wall profiles and decoration strip profiles.

Owner:JIANGYIN JIANGTAI HIGH POLYMER NEW MATERIAL CO LTD

Lithium battery plastic coating device

ActiveCN104577214AImprove shrinkage qualityFast coating speedFinal product manufactureElectrolyte accumulators manufactureFilm-coated tabletFilm coating

The invention discloses a lithium battery plastic coating device which comprises a base, wherein a film supply mechanism, a film cutting mechanism, a film coating working table, a feeding mechanism and a discharging mechanism are arranged on the base; the film supply mechanism is provided with two rotary tables for placing winding film; a tensioning wheel and a squeezing part for pre-expanding the flat winding film are sequentially arranged on a film releasing path corresponding to each rotary table; the film cutting mechanism is arranged on the film releasing path and is provided with a film pulling component for pulling the winding film and a cutter for cutting the film off; a film absorbing component pulled out by the winding film and a pushing cylinder for pushing a lithium battery subjected to film coating out are arranged on the film coating working table; the feeding mechanism is provided with a feeding channel for conveying lithium batteries in a single row, and an air cylinder capable of pushing the lithium battery into the pull-out winding film is arranged at the end part of the feeding channel; the discharging mechanism is provided with a discharging channel for receiving the lithium batteries pushed out by the pushing cylinder; leveling clamp plates for adjusting positions of the lithium batteries in the film are arranged on the two sides of the discharging channel; an elastic pressing plate for acting on the lithium batteries is arranged at the end part of the discharging channel. The lithium battery plastic coating device is high in film coating speed and quality.

Owner:TIANNENG SAFT ENERGY JOINT CO

Period effect percutaneous patch of self viscosity elastic body substrate containing testosterone and preparation method thereof

ActiveCN102772417AShort heating timeAvoid pollutionOrganic active ingredientsOil/fats/waxes non-active ingredientsElastomerTransdermal patch

The invention discloses a period effect percutaneous patch of a self viscosity elastic body substrate covering and bearing testosterone and a preparation method thereof. The period effect percutaneous patch comprises a support layer, a medicine taking self viscosity elastic body substrate layer and a separation layer. The support layer is covered on one side of the medicine taking self viscosity elastic body substrate layer, and the separation layer is covered on the other side of the medicine taking self viscosity elastic body substrate layer. The period effect percutaneous patch adopts the lipotropy elastic body substrate with the low melting point to contain the testosterone, and a stable and effective testosterone blood concentration is maintained in 7 days. The patch is excellent in medicine skin penetrating performance, good in adhering performance, high in medicine loading rate, good in air permeability and free of residue when being stripped from the skin. A preparation process of the period effect percutaneous patch of the testosterone uses no machine solvent and is environment-friendly, coating is carried out in a melting state, and the preparation process has the advantages of being high in coating speed, high in production efficiency and low in cost.

Owner:SHANGHAI MODERN PHARMA ENG INVESTIGATION CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com