Method for boron doping of crystalline silicon solar battery

A technology of solar cells and boron doping, applied in the field of solar cells, can solve the problems of shortened service life of quartz furnace tubes, corrosion of quartz furnace tubes, etc., and achieves the effects of fast coating speed, low equipment cost, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

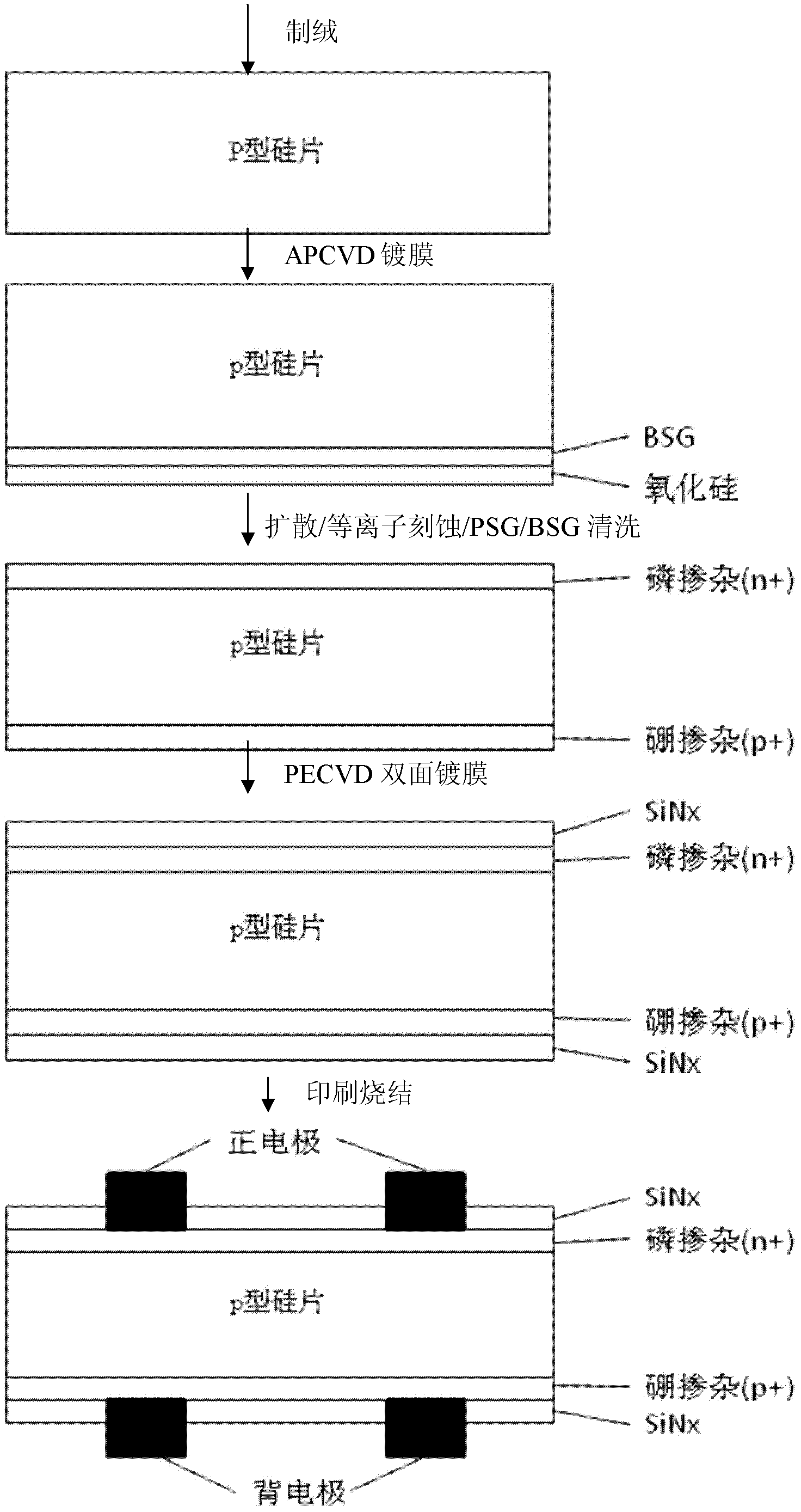

[0027] Utilize the boron doping method of the present invention to form a boron back field to prepare a p-type solar cell, such as figure 1 As shown in , this embodiment includes the following steps:

[0028] (1) Wafer selection, texturing and cleaning

[0029] Select a p-type monocrystalline silicon wafer, use 0.5-3% by weight of sodium hydroxide aqueous solution to make texture to obtain a pyramid-shaped texture, and then wash off the lye;

[0030] (2) Atmospheric pressure chemical vapor deposition method APCVD coating

[0031] Deposit BSG (boron-doped silicon oxide) on one side of the silicon wafer, and then deposit a second layer of silicon oxide on the BSG. The reaction atmosphere used in the atmospheric pressure chemical vapor deposition method is SiH 4 , O 2 , B 2 h 6 ; Wherein the film thickness of the first layer of film-boron-doped silicon oxide film is 100nm, and the concentration of boron in the boron-doped silicon oxide film is 10 22 / cm 3 ; The film thickn...

Embodiment 2

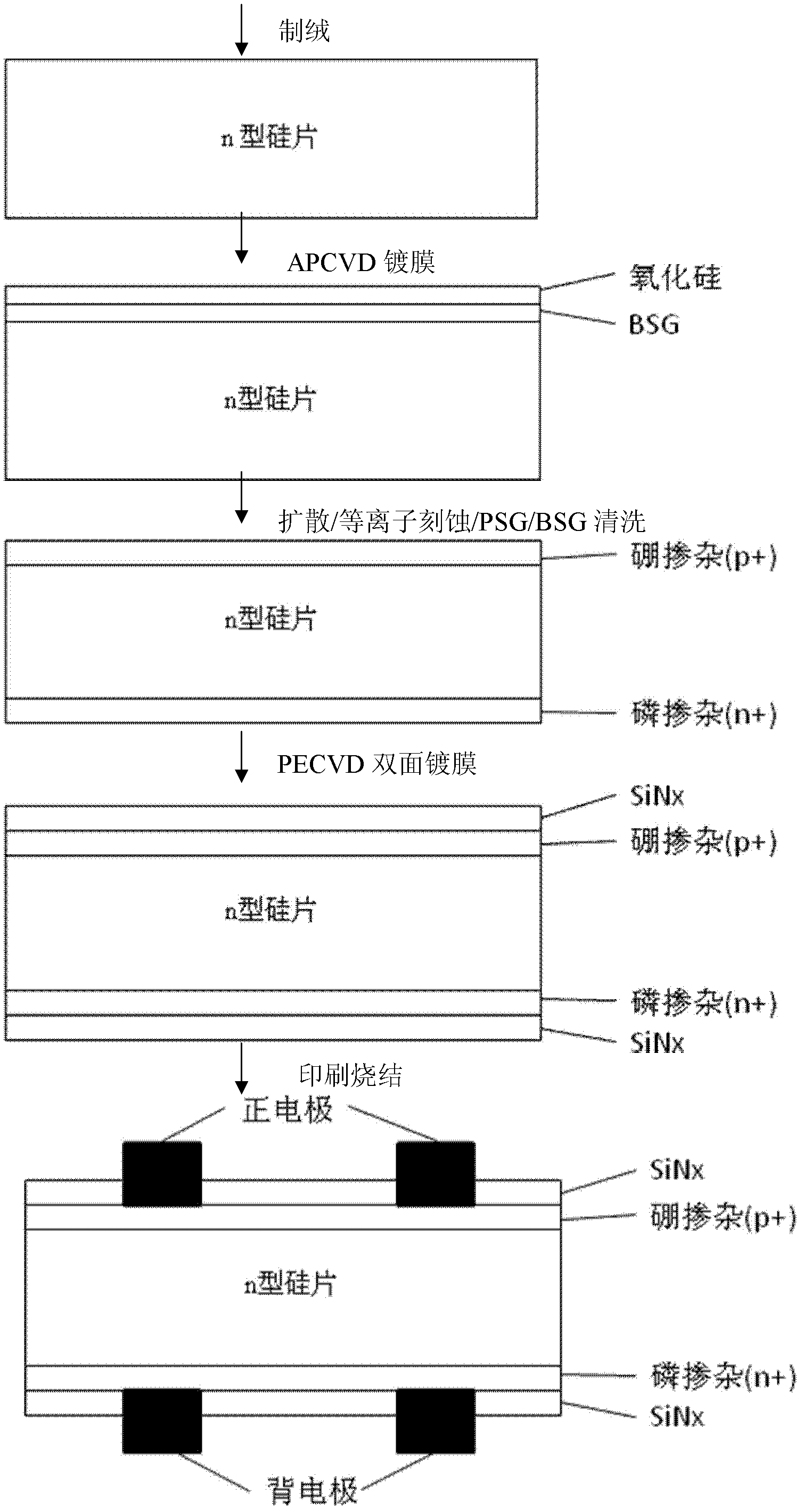

[0042] Utilize the boron doping method of the present invention to form a boron emitter to prepare an n-type solar cell, such as figure 2 As shown, this embodiment includes the following steps:

[0043] (1) Wafer selection, texturing and cleaning

[0044] Select n-type monocrystalline silicon wafers, use 0.5-3% by weight aqueous sodium hydroxide solution to make texture to obtain pyramid-shaped texture, and then wash off the lye;

[0045] (2) APCVD coating

[0046] Deposit BSG (boron-doped silicon oxide) on one side of the silicon wafer, and then deposit a second layer of silicon oxide on the BSG. The reaction atmosphere used in the atmospheric pressure chemical vapor deposition method is SiH 4 , O 2 , B 2 h 6 ; Wherein the film thickness of the first layer of film-boron-doped silicon oxide film is 100nm, and the concentration of boron in the boron-doped silicon oxide film is 10 22 / cm 3 The film thickness of the second film-silicon oxide film is 100nm;

[0047] (3) H...

Embodiment 3

[0057] (1) Wafer selection, texturing and cleaning

[0058] Select p-type polysilicon wafer, use HF and HNO 3 Mixing solutions to make suede;

[0059] (2) Atmospheric pressure chemical vapor deposition method APCVD coating

[0060] Deposit BSG (boron-doped silicon oxide) on one side of the silicon wafer, and then deposit a second layer of silicon oxide on the BSG. The reaction atmosphere used in the atmospheric pressure chemical vapor deposition method is SiH 4 , O 2 , B(CH 3 ) 3 ; The film thickness of the first layer of film-boron-doped silicon oxide film is 5nm, and the concentration of boron in the boron-doped silicon oxide film is 10 17 / cm 3 ; The film thickness of the second film-silicon oxide film is 5nm;

[0061] (3) High temperature diffusion

[0062] The boron-doped silicon oxide film and the silicon oxide film double-layer film deposited by the normal pressure chemical vapor deposition method APCVD are used as the barrier layer, the silicon wafer is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com