Lithium battery plastic coating device

A lithium battery and equipment technology, applied in the field of lithium battery plastic wrapping equipment, can solve the problems of cell difficulty, film shrinkage failure, inconsistent length of cell wrapping, etc., and achieve improved shrinkage quality, good wrapping quality, and wrapping speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

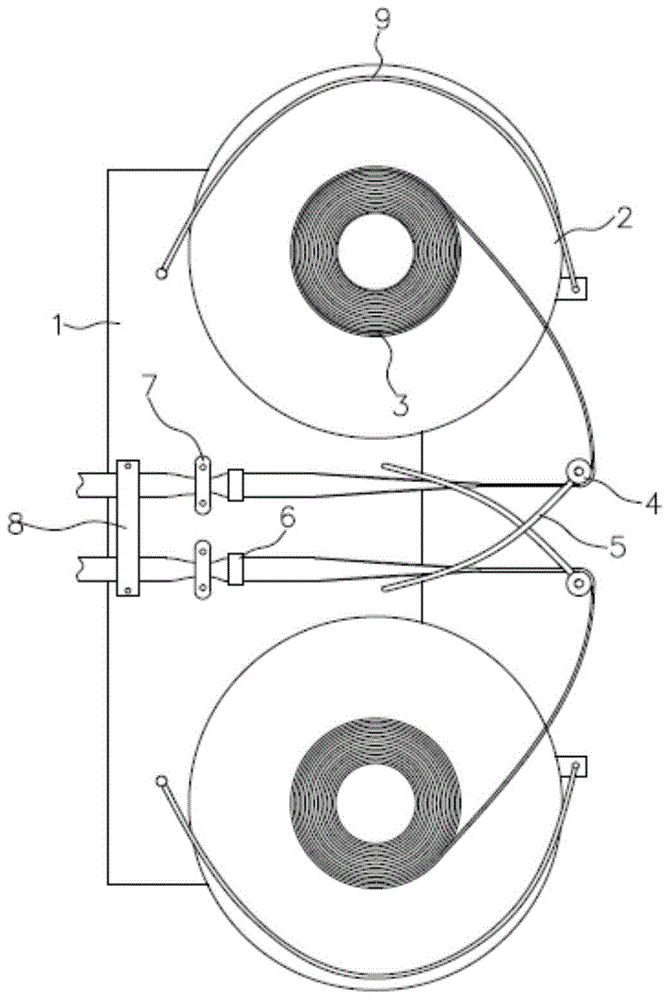

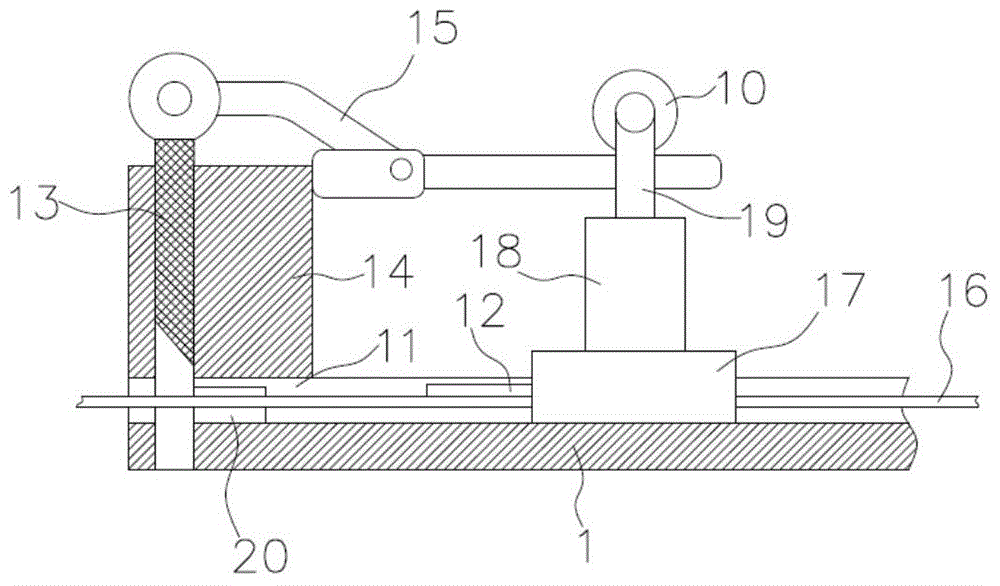

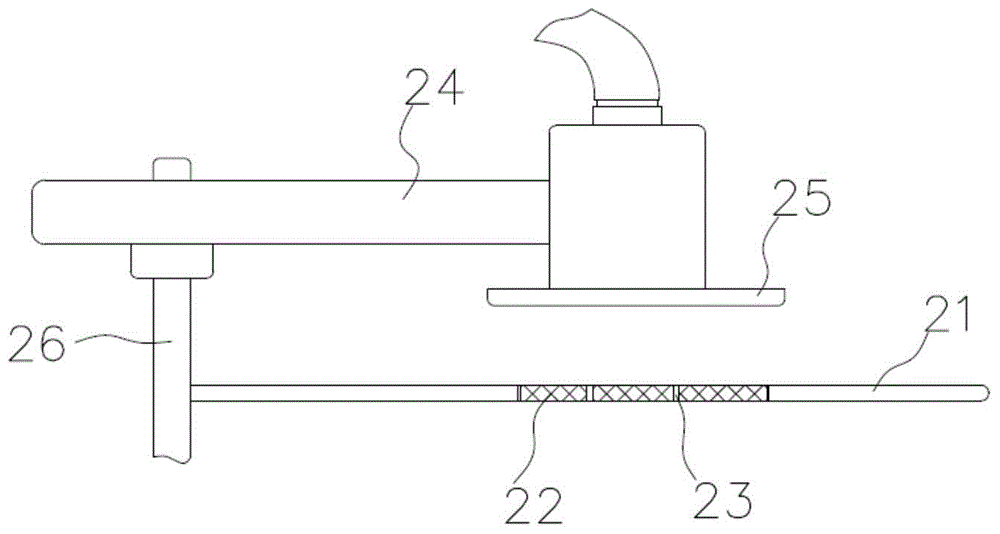

[0031] Such as Figure 1 to Figure 6 As shown, a lithium battery plastic packaging equipment includes a base 1, and the base 1 is provided with: a film feeding mechanism, a film cutting mechanism, a coating workbench, a feeding mechanism and a discharging mechanism.

[0032] Such as figure 1 As shown, the film feeding mechanism includes two turntables 2 for placing the roll film, and each turntable 2 is provided with a tension wheel 4 and a pressing part for pre-expanding the flat roll film on the corresponding film release path. The roll film for plastic wrapping is placed on the turntable, and the film is released by rotating the turntable. The tension wheel is used to guide the walking path of the film release, and the extrusion part is used to pre-expand the flat roll film to avoid adhesion on the inner wall of the film, which is convenient for follow-up Push the cell into the membrane.

[0033] The motor that drives the turntable 2 is housed on the base 1 to drive the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com