Shrink wrapping machine

A packaging machine and thermal expansion technology, applied in the directions of packaging, wrapping paper, packaging paper shrinkage, etc., can solve the problems of uneven heating temperature distribution of heat shrinkable film, complex structure of heat shrinkable packaging machine, poor shrinkage effect of heat shrinkable film, etc. Achieve the effect of good operation control, simple structure and improved shrinkage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

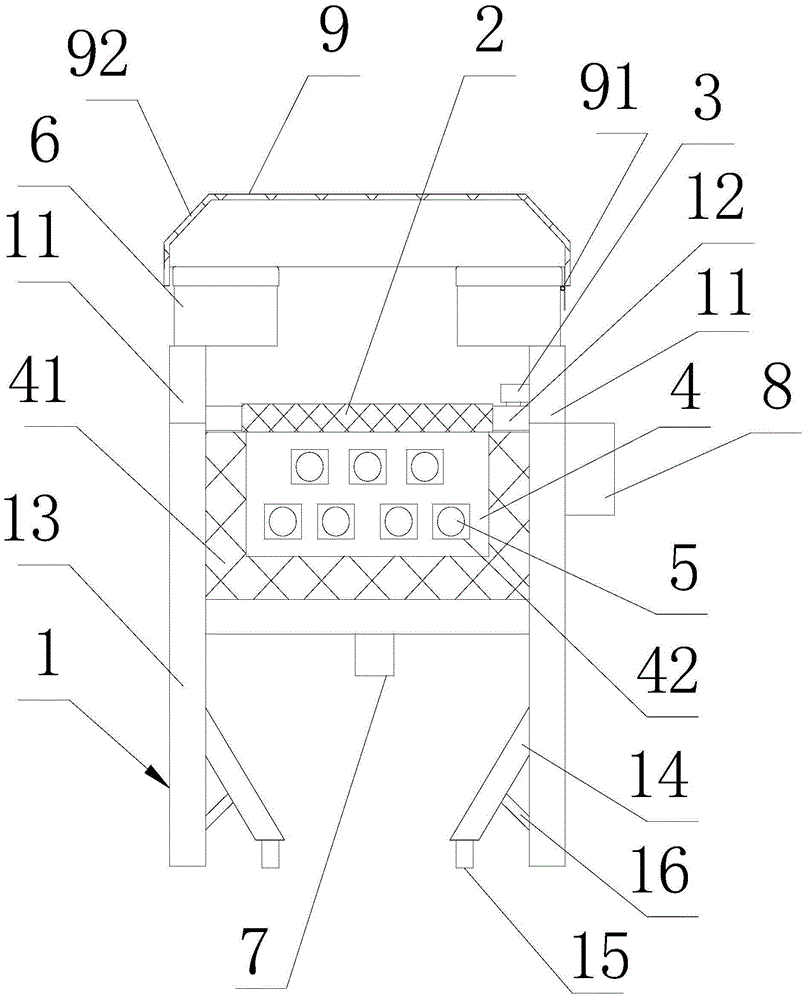

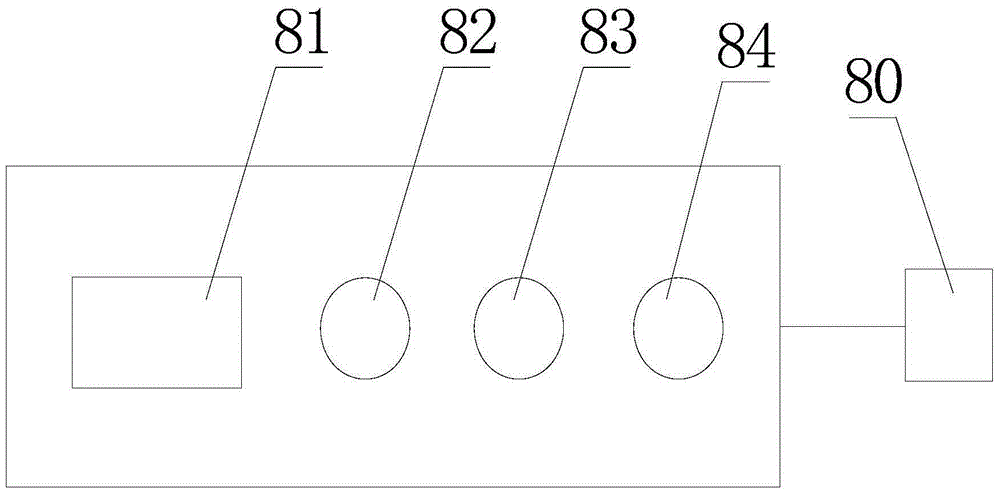

[0011] Such as figure 1 , figure 2 As shown, the heat-shrinkable packaging machine includes a frame 1, a network chain 2, and a drive motor 3. The top of the frame 1 is provided with two connecting plates 11, and at least two connecting plates 11 are rotatably connected to the two connecting plates 11. The driving shaft 12 of the net chain 2 is sleeved, the driving motor 3 is connected to the driving shaft 12, the top of the connecting plate 11 is higher than the top of the net chain 2, and is fixedly connected to the connecting plate 11 below the net chain 2 There is a placement box 4, the cavity length of the placement box 4 is less than the length of the net chain 2, a number of heating devices 5 are arranged in the placement box 4, and sponge bodies are arranged on the side walls of the placement box 4 41, the placement box 4 is provided with at least one control damper 7 for controlling the heat dissipation of the heating device 5, the top of the connection plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com