Patents

Literature

41results about How to "Easy to control appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating method of neodymium-iron-boron magnets

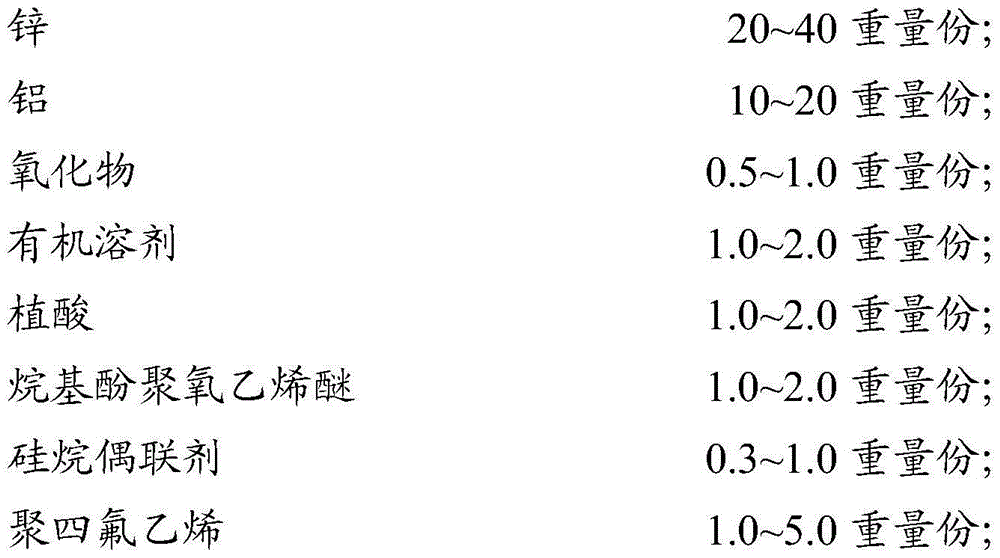

ActiveCN104148256AThickness is easy to controlEasy to control uniformityLiquid surface applicatorsAnti-corrosive paintsOrganic solventAlkylphenol

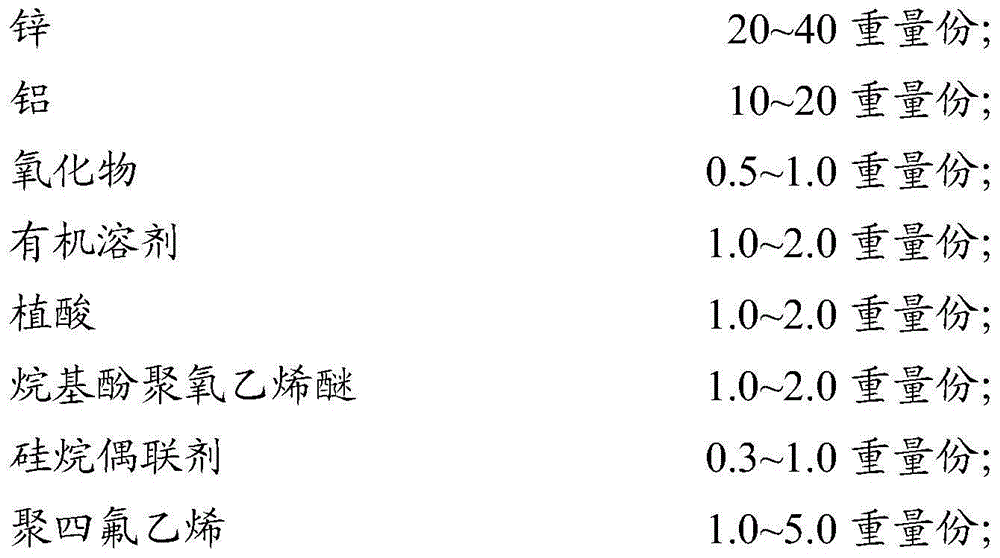

The invention provides a zinc-aluminum coating liquid of neodymium-iron-boron magnets and a coating method. The coating method includes the following steps that the surfaces of the neodymium-iron-boron magnets are coated with the zinc-aluminum coating liquid comprising 20-40 parts by weight of zinc, 10-20 parts by weight of aluminum, 0.5-1.0 part by weight of oxide, 1.0-2.0 parts by weight of organic solvents, 1.0-2.0 parts by weight of phytic acid, 1.0-2.0 parts by weight of alkylphenol ethoxylates, 0.3-1.0 part by weight of silane coupling agent and 1.0-5.0 parts by weight of polytetrafluoroethylene, and the coated neodymium-iron-boron magnets are obtained. According to the zinc-aluminum coating liquid coating method of the neodymium-iron-boron magnets, coatings are made to have high adhesive force and salt fog resistance.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

Method for preparing high fatigue property porous Ti-6Al-4V bulk material

The invention relates to porous material preparation, in particular relates to a method for preparing a high fatigue property porous Ti-6Al-4V bulk material, which is used for solving the problem of low fatigue property of the porous Ti-6Al-4V bulk material of the prior art. The method is that an 'electron beam molten metal molding technology' is utilized to prepare the large Ti-6Al-4V bulk material with the porosity of 50%-95% at first, the porous material is then subjected to two steps of thermal treatment of annealing and aging at 400 DEG C and 1000 DEG C, and the Ti-6Al-4V porous material with high fatigue strength, low elasticity modulus of (0.1-20 GPa) and 'the ratio of fatigue strength / compressive strength' of 0.7 is obtained finally. According to the method, the mechanical performance of the porous Ti-6Al-4V pore wall material is controlled through a thermal treatment technology, and thus, a large titanium alloy porous material with excellent fatigue property is obtained and can be widely applied to the fields of aerospace, medical treatment and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum-based density gradient material and preparation method and application thereof

The invention relates to an aluminum-based density gradient material and a preparation method and application thereof. A region with density in gradient change and (or) a region with density in continuous change exist in the aluminum-based density gradient material, and the materials of all the regions in the aluminum-based density gradient material are consistent. The preparation method comprises the following steps: water-soluble pole-forming agent powder and aluminum alloy powder are proportioned according to the volume ratio of the water-soluble pole-forming agent powder to the aluminum alloy powder being X to (100-X), and then are mixed uniformly to obtain mixed powder containing different amounts of pole-forming agents; die forming is carried out on laminated spread powder, and a prefabricated blank is sintered in a vacuum environment at 575-675 DEG c to obtain a sintered body; and water soaking treatment is carried out to obtain the aluminum-based density gradient material. The aluminum-based density gradient material prepared by the method has no obvious deformation, and the density from 1.1 g / cm<3>-2.7g / cm<3> in gradient distribution is achieved through adjusting porosity; and the aluminum-based density gradient material is excellent in performance and is suitable for being used as an aerospace material.

Owner:CENT SOUTH UNIV

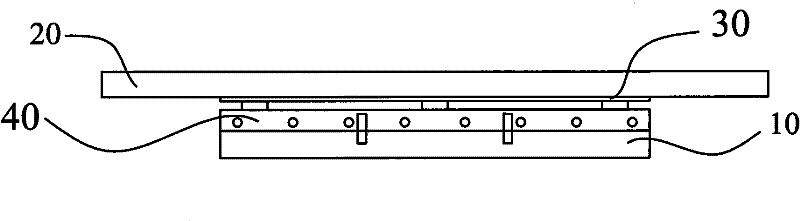

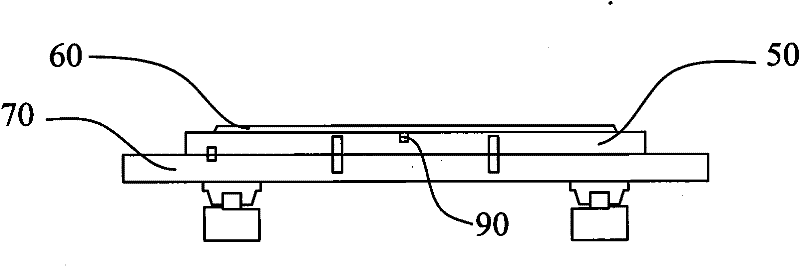

Bonding method and equipment for metal casing and plastic parts

ActiveCN102294825ASolve the problem of thermal expansion and deformationReduce distortionHeat fusionHot-melt adhesive

The invention provides a method for bonding a metal shell and a plastic component. The method comprises the following steps: pre-pressing hot melt adhesive in a part of region on the surface of the metal shell to form a hot-melting area with pre-pressed hot melt adhesive and a non-hot-melting area without pre-pressed hot melt adhesive; mounting a plastic component on the hot-melting area; performing the hot melting on the metal shell, wherein the hot melting includes hot-pressing and the cool-pressing; continuously cooling the non-hot-melting area in the hot melting process, enabling the hot-melting area and the non-hot-melting area to be stressed simultaneously with equal pressure. The invention further provides a device for bonding the metal shell and the plastic component. The device comprises an upper die, a lower die, a fixing device and a cooling device, wherein the upper die is divided into a hot-pressing upper die and a cool-pressing upper die, the lower die is used for holding the metal shell, the fixing device is used for fixing the metal shell on the lower die, and the cooling device is connected with the lower die and is used for cooling the non-hot-melting area. According to the method provided by the invention when the non-hot-melting area on the metal surface is cooled, an external force is used to maintain the pressure for stabilizing the metal plane so as to reduce the deformation.

Owner:苏州常阀阀门设备检修有限公司

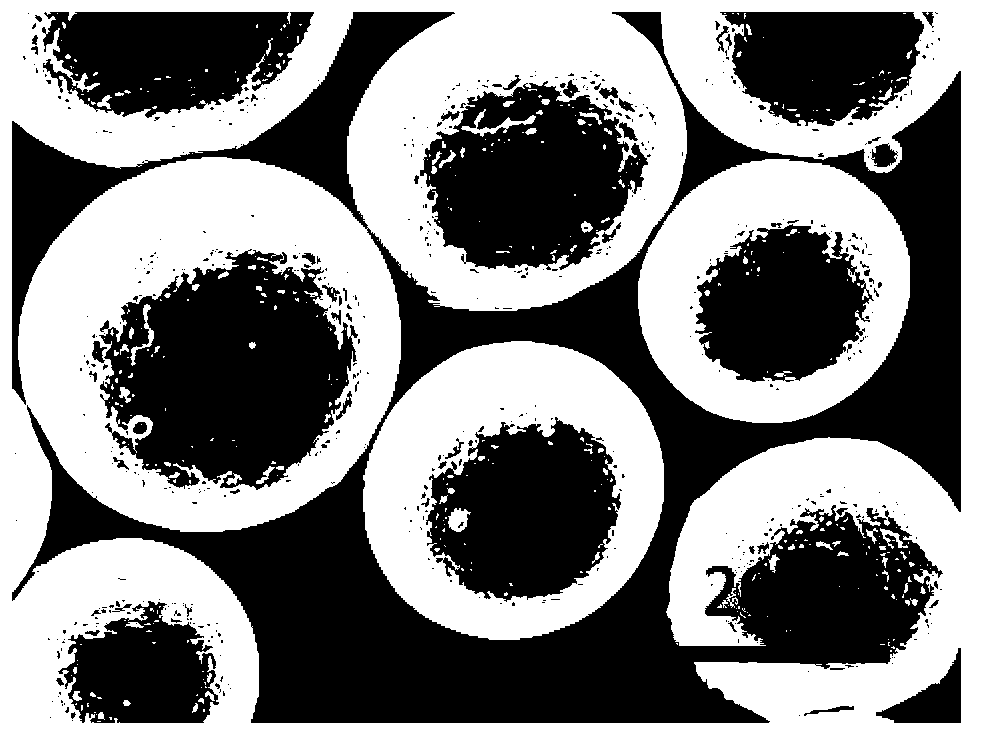

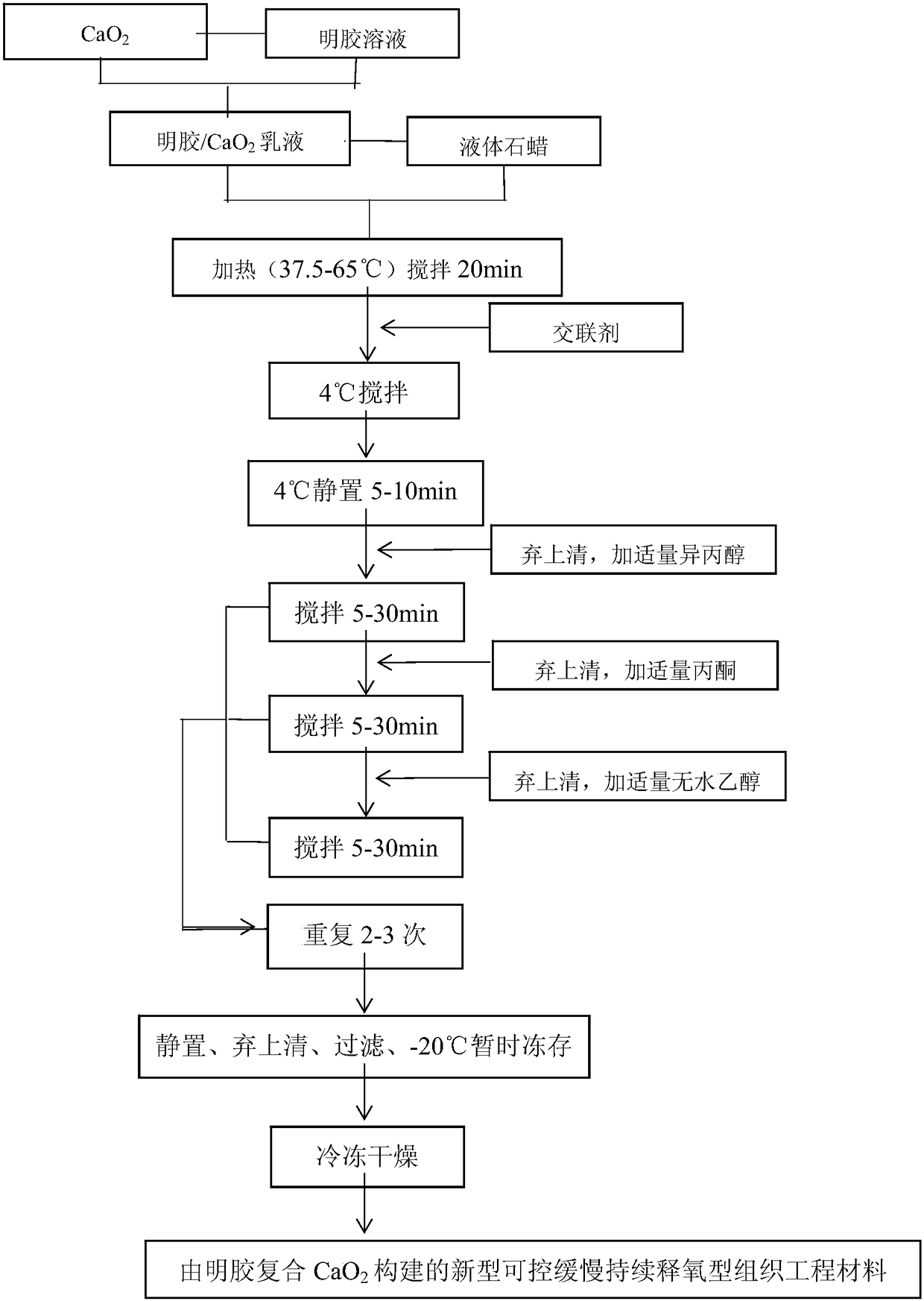

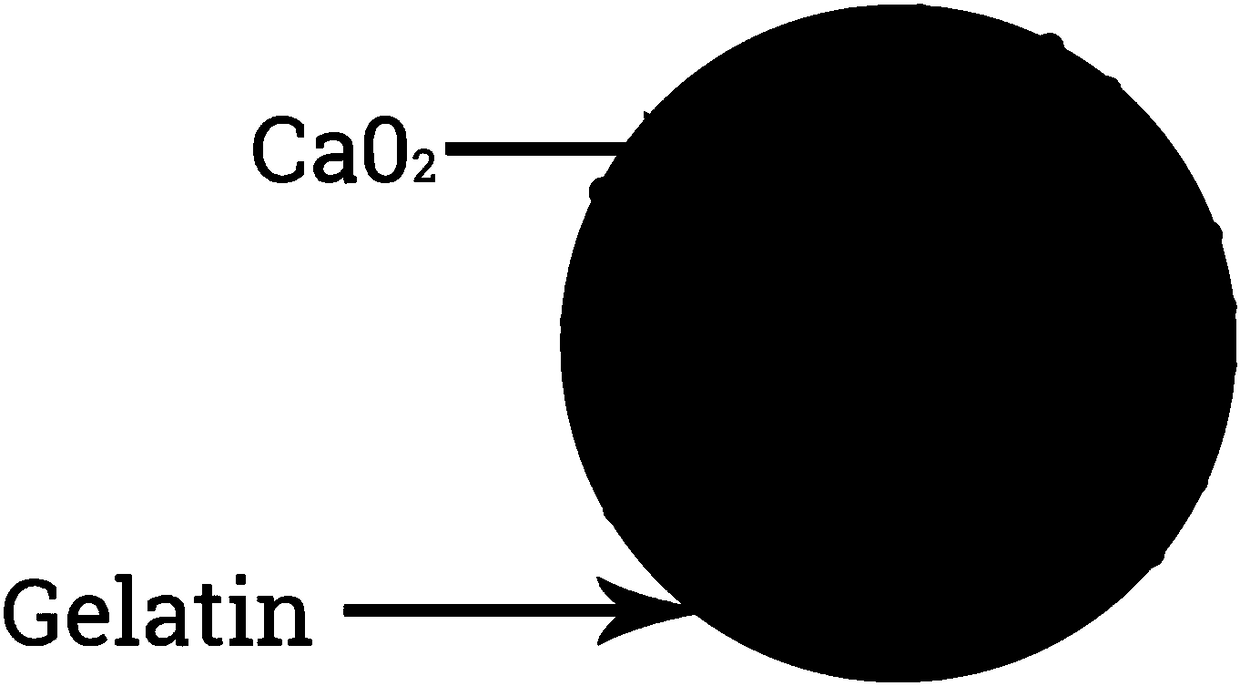

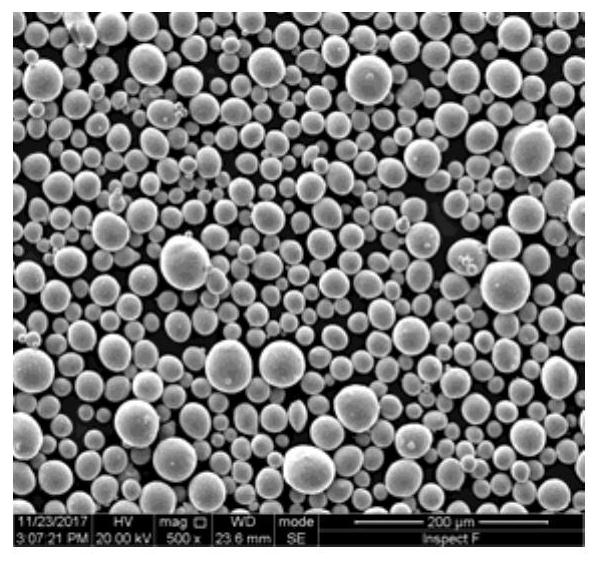

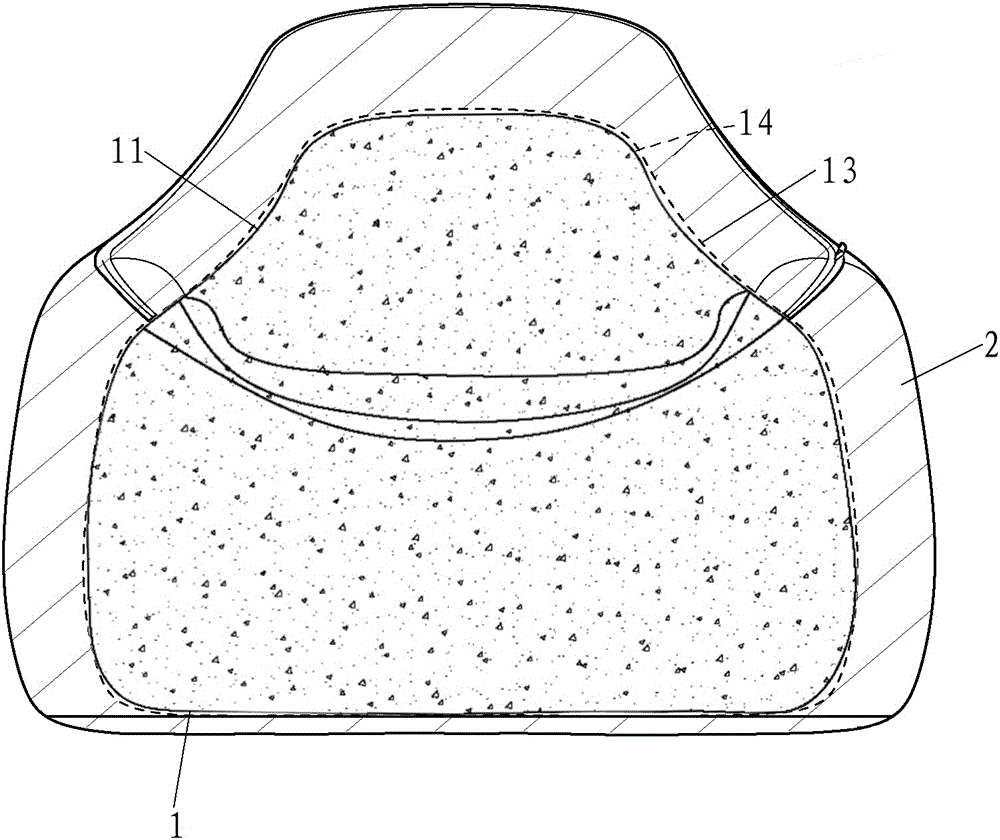

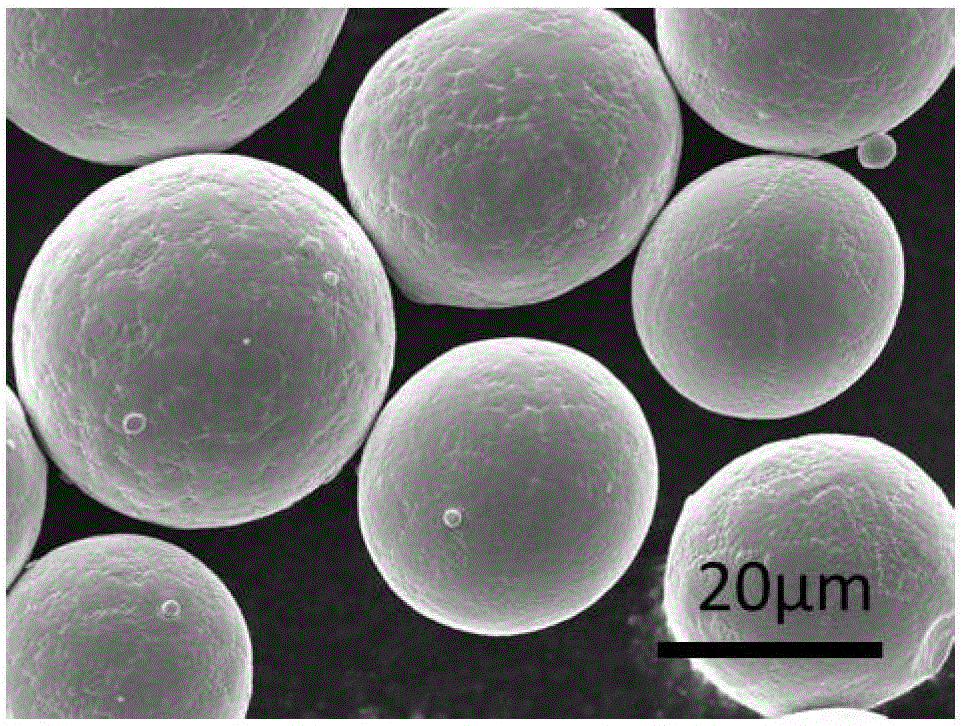

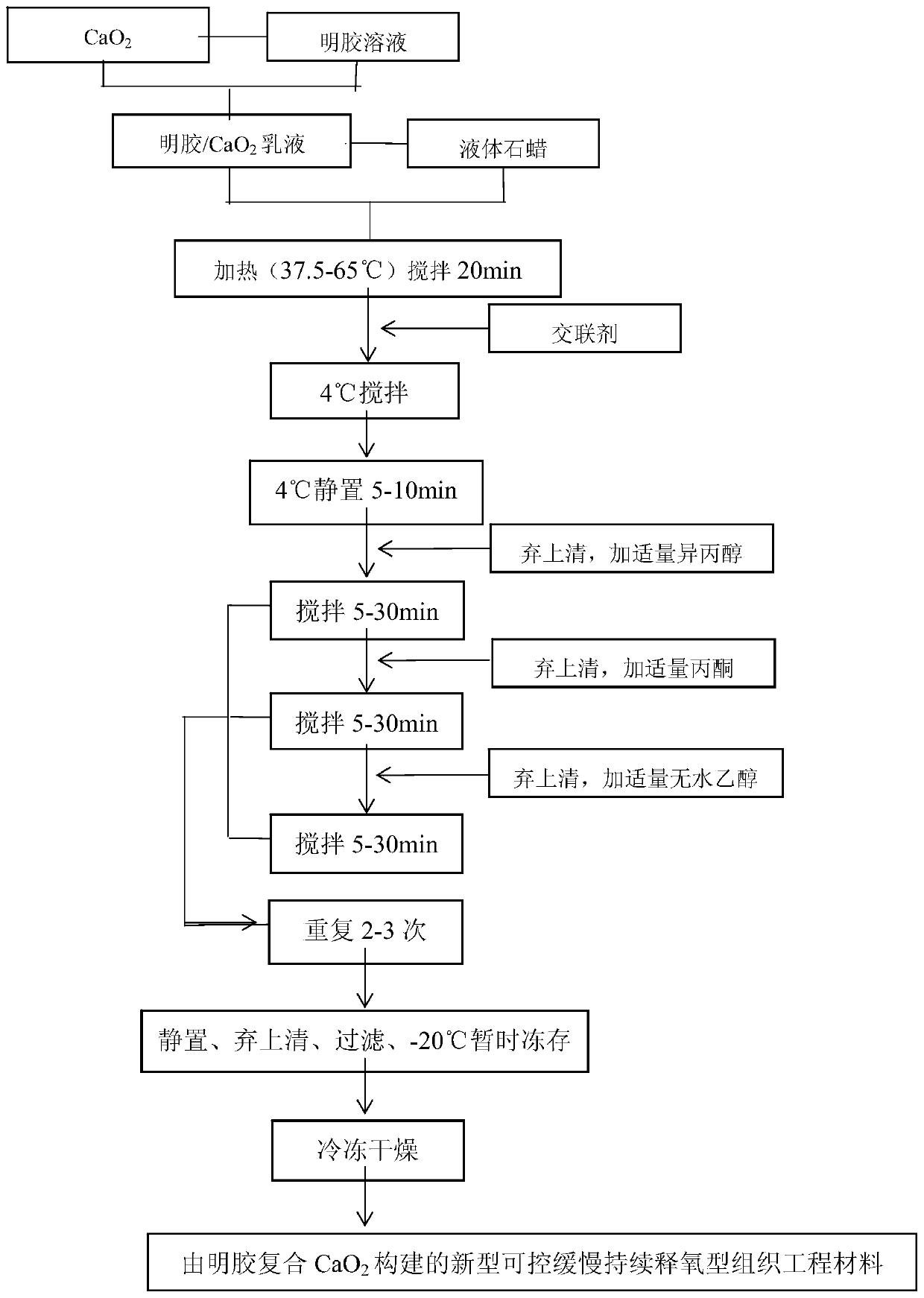

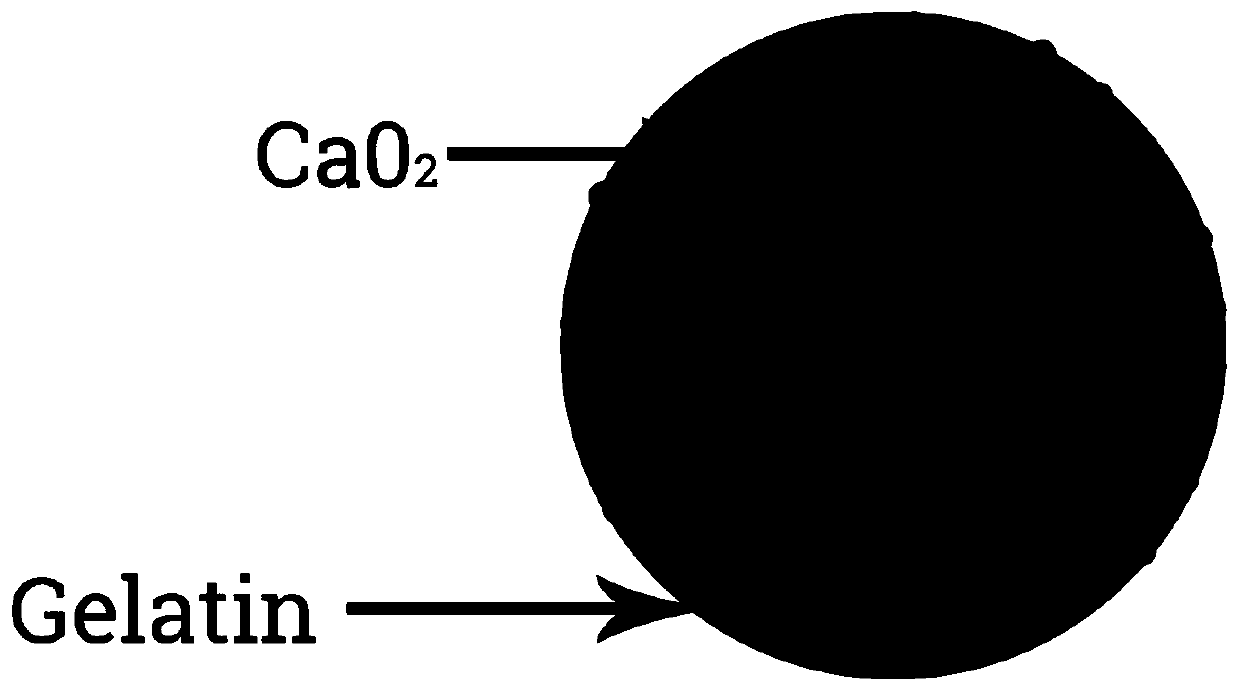

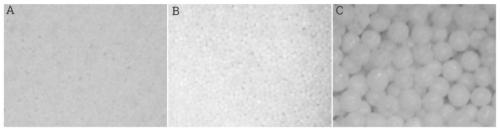

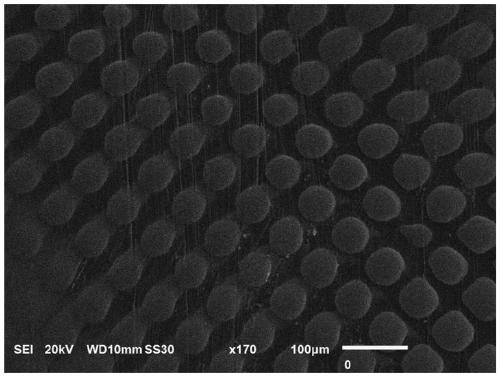

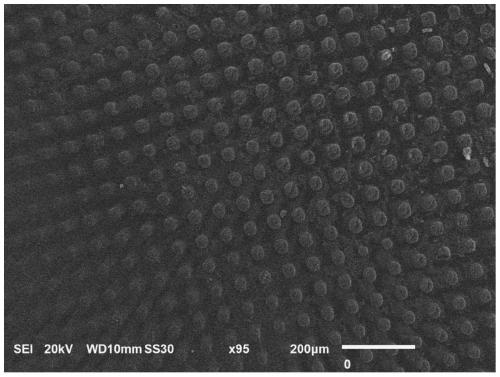

Sustained-release oxygen microsphere as well as preparation method and application thereof

ActiveCN108310470AControllable sizeExtended oxygen release timeTissue regenerationMicrocapsulesChemistryLarge applications

The invention discloses a sustained-release oxygen microsphere as well as a preparation method and application thereof. The sustained-release oxygen microsphere is a microsphere using gelatin as a matrix; the interior of the microsphere contains peroxidated inorganic particles, and preferably, the peroxidated inorganic particles are selected from one or multiple of CaO2 (calcium peroxide), MgO2 (magnesium peroxide), NaCO3 (sodium carbonate), SrO2 (strontium peroxide), BaO2 (barium peroxide), K2O2 (potassium peroxide), and Na2O2 (sodium peroxide). The sustained-release oxygen microsphere has the advantages that the size is controllable, the oxygen release time is long and controllable, the sudden release rate is low, the cell toxicity is low, the immunogenicity is low, the preparation process is relatively simple, the industrialized production is easily realized, and the like; the larger application prospect is realized in clinical application of bone defect repair.

Owner:SOUTHERN MEDICAL UNIVERSITY

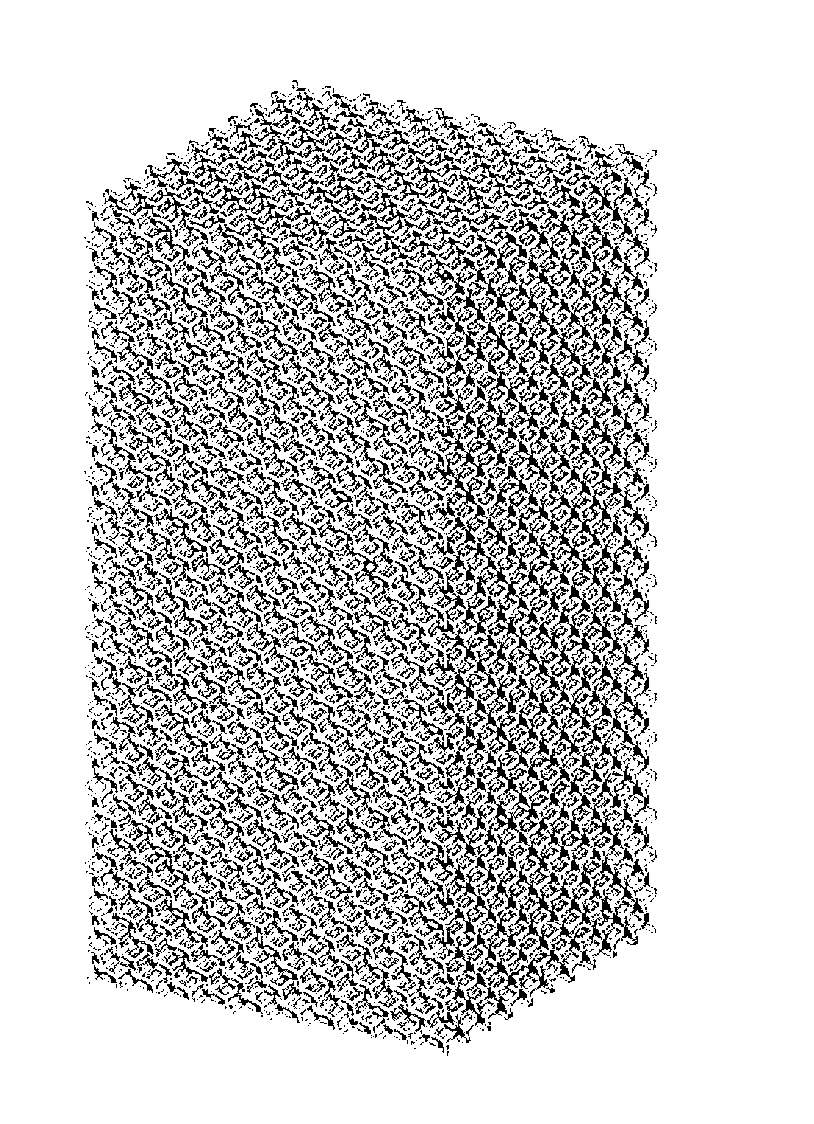

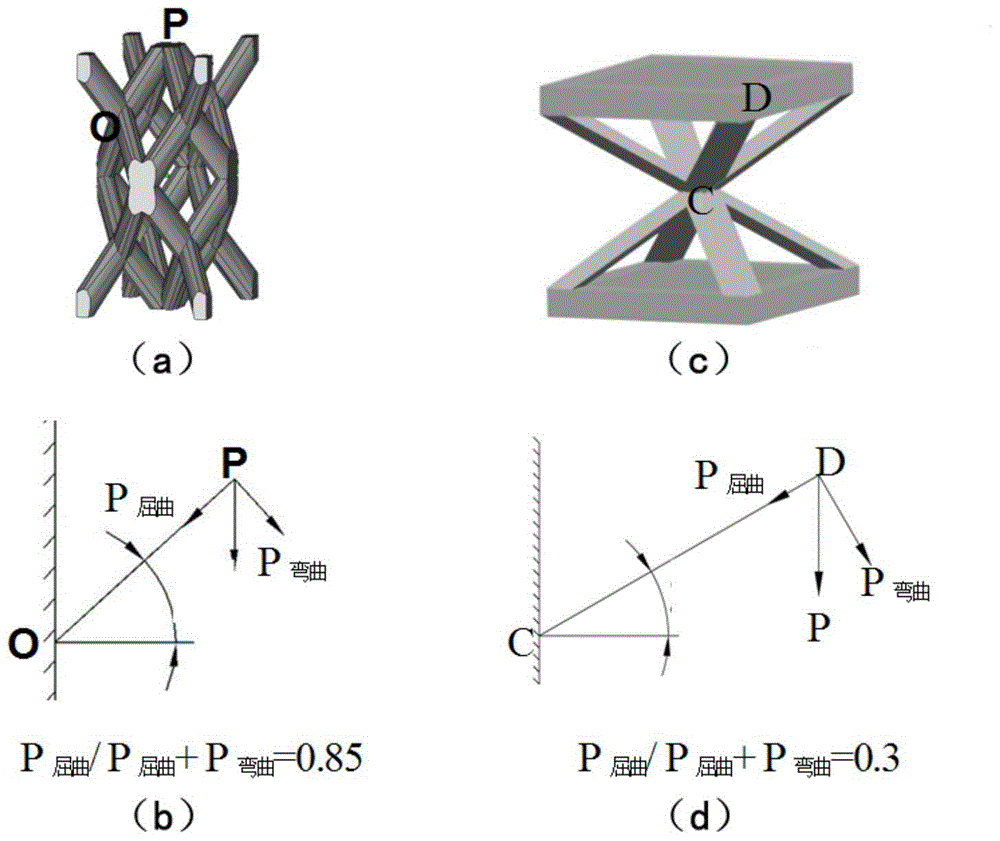

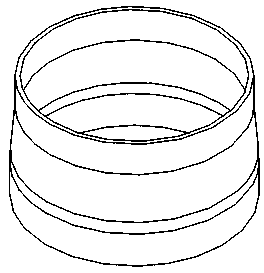

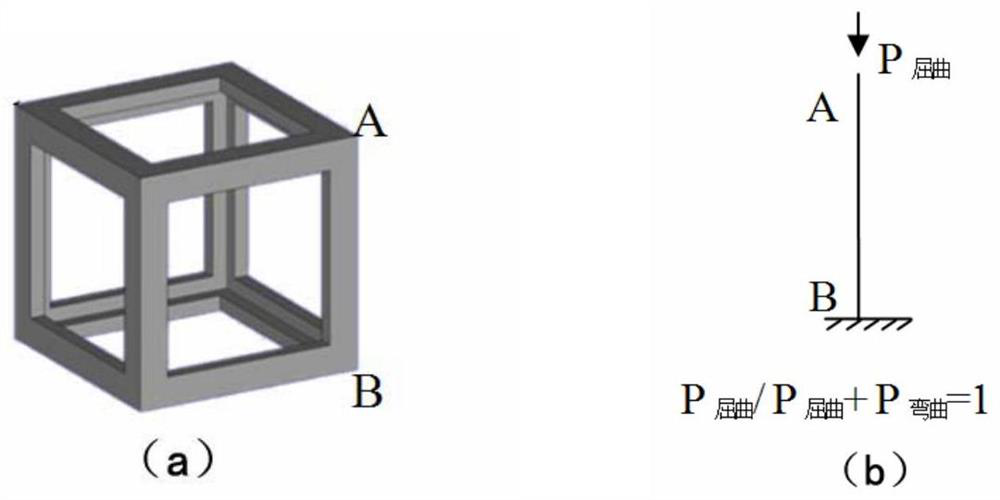

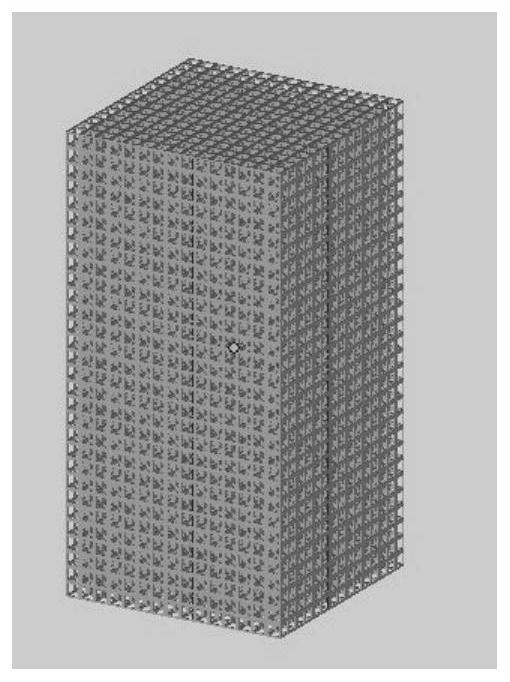

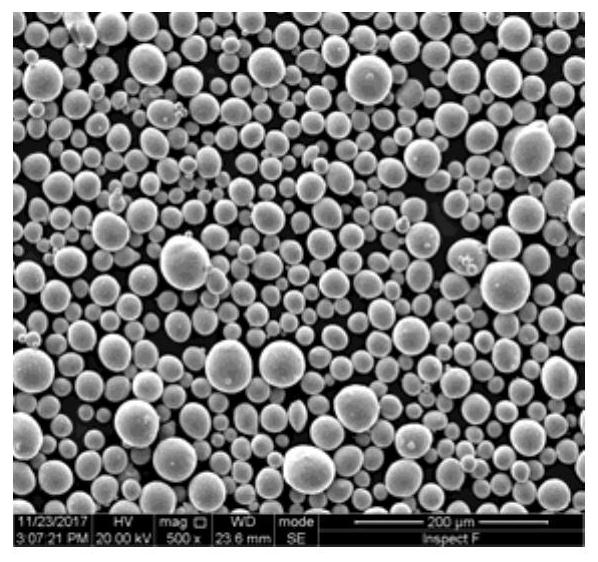

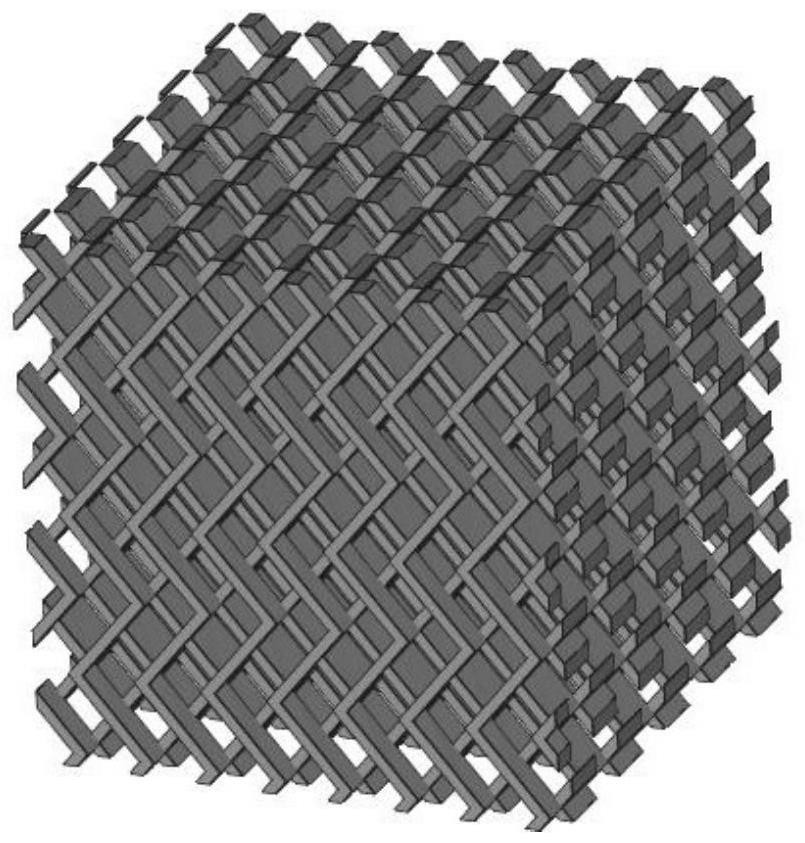

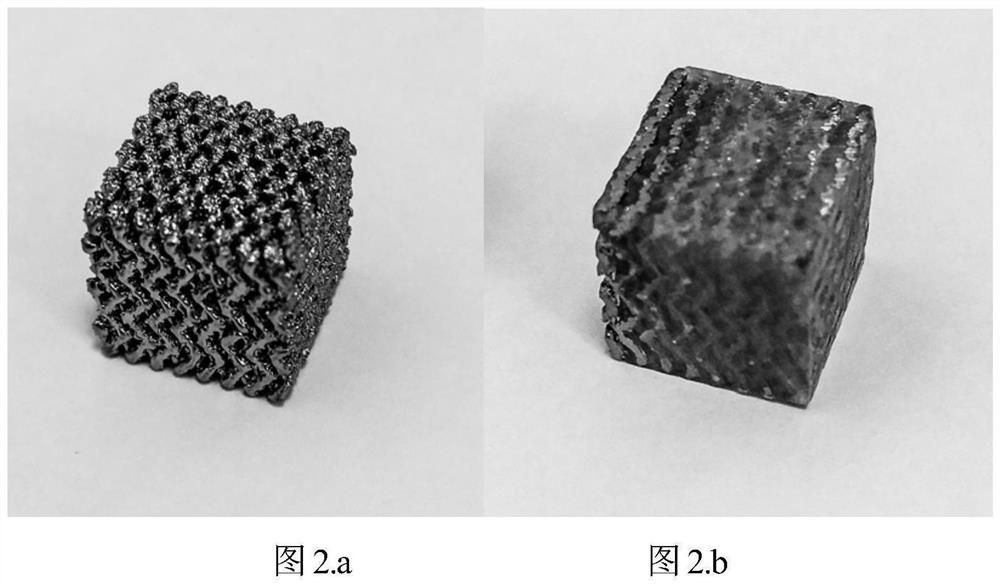

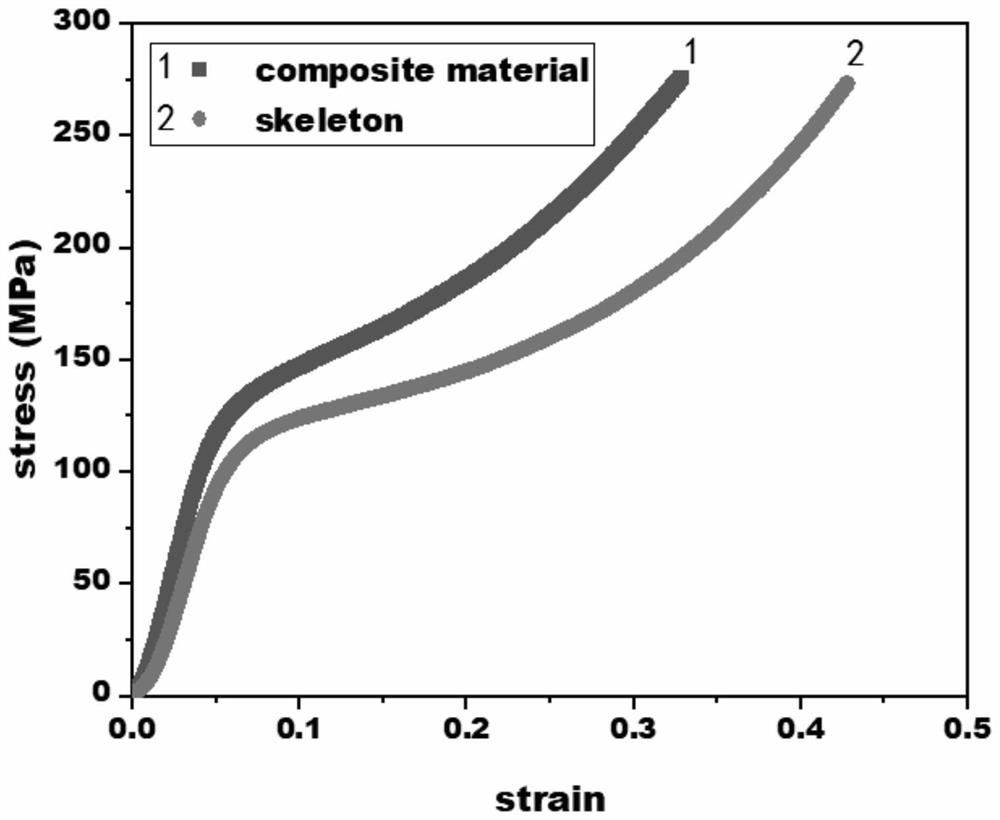

Gradient porous Ti-6Al-4V block material concurrently having high strength and high absorption energy, and preparation method thereof

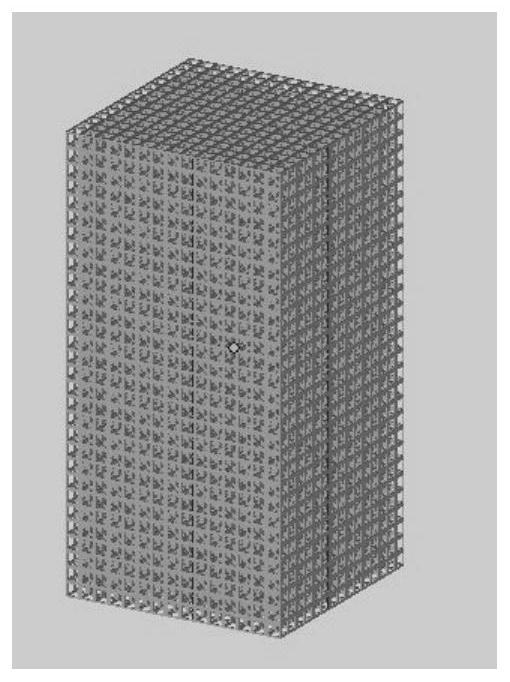

ActiveCN106148749APorosity is easy to controlEasy to control appearanceAdditive manufacturing apparatusPorosityHigh absorption

The invention discloses a gradient porous Ti-6Al-4V block material concurrently having high strength and high absorption energy, and a preparation method thereof, and belongs to the technical field of porous materials. According to the present invention, the large size Ti-6Al-4V gradient porous material with an effectively density of 0.2-2.0 g / cm<3> is prepared through an electron beam melting metal forming technology, and by adjusting the porosity distribution and the unit structure and optimizing the process parameters, the lightweight Ti-6Al-4V porous material concurrently having high strength (~200 MPa) and high absorption energy (~90 MJ / m<3>) and having low elastic modulus (0.1-20 GPa) is obtained; and the preparation method has characteristics of simple process and low cost, and is suitable for industrial scale production, and the porous Ti-6Al-4V block material can be widely used in the fields of aerospace, medical treatment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

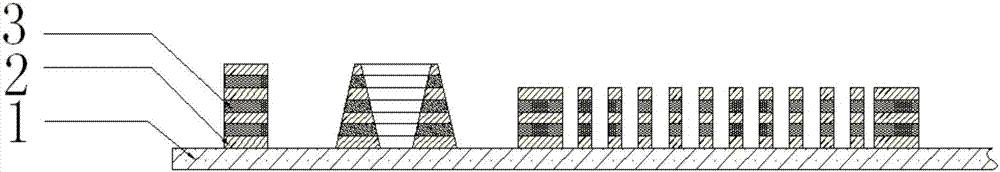

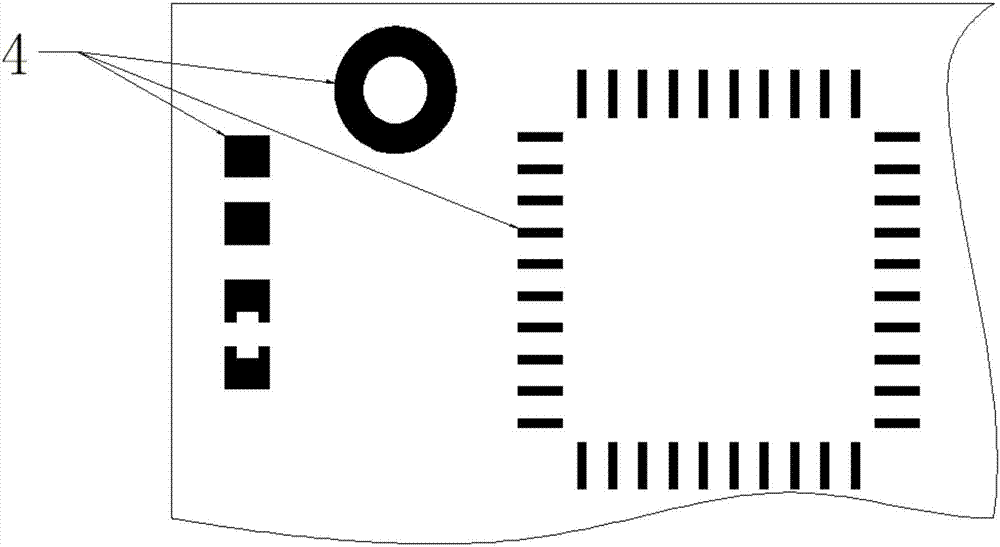

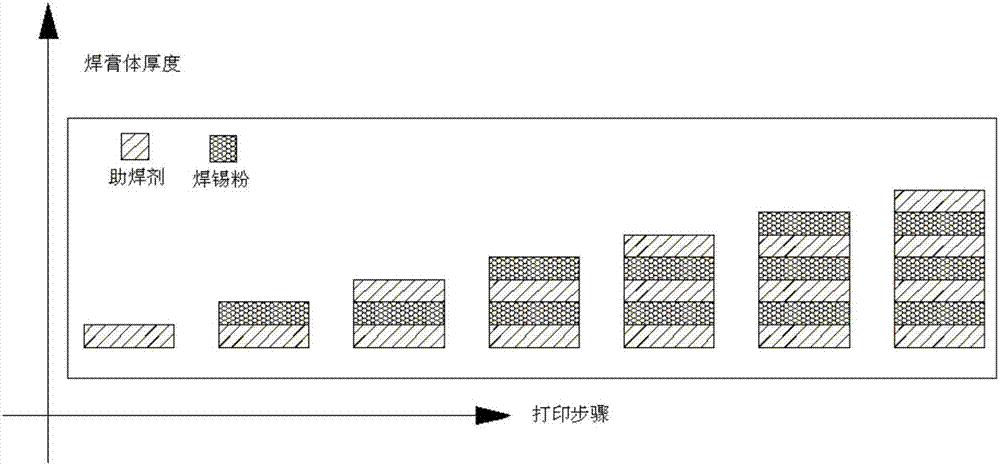

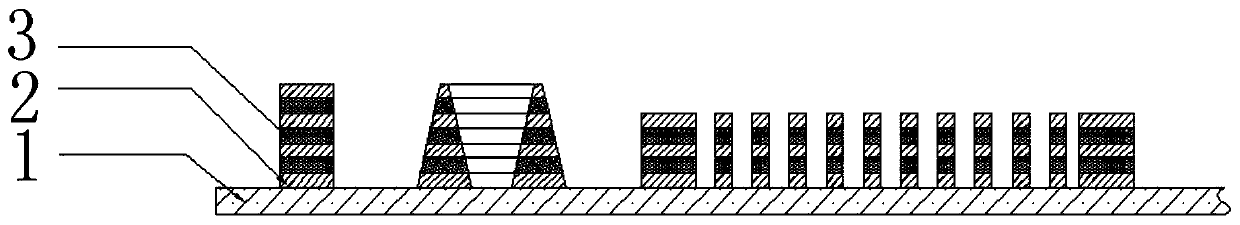

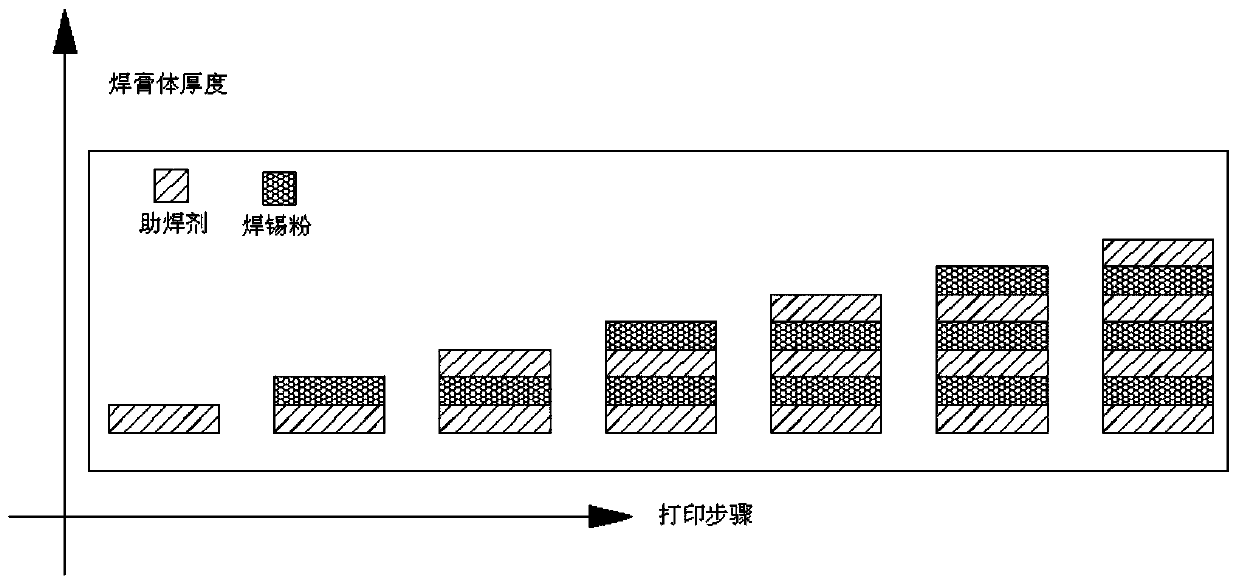

Process method for printing soldering paste bodies on circuit board in three-dimensional (3D) manner

ActiveCN107182172AEasy to control appearanceSolve the problem of easy short circuit in weldingPrinted circuit assemblingEngineeringSolder paste

The invention provides a process method for printing soldering paste bodies on a circuit board in a three-dimensional (3D) manner. The process method is a process method capable of accurately printing soldering paste bodies in a three-dimensional (3D) manner. With the process method adopted, the shapes of the soldering paste bodies are controllable, the coating efficiency of soldering paste is high, and different thickness and different shapes can be realized. According to the technical schemes of the invention, the process method is implemented through following manners: a layer of flux of which the shape conforms to the shape of a pad is printed so as to be adopted as a solder powder fixing medium; a layer of solder powder is printed on the flux at a position where the pad is located; after one independent soldering paste body is obtained through layer-by-layer printing, a next soldering paste body is printed; flux layers and solder powder layers which are printed layer by layer are mixed, so that the soldering paste bodies can be formed in real time in a printing process; the flux layers and solder powder layers are printed alternately so as to form required soldering paste bodies; flux is printed at the last layer, so that the 3D printing of the soldering paste is terminated; and flux and solder powder multi-layer liquid naturally compounded soldering paste body layout distribution of different thicknesses and different shapes can be formed on the same printed circuit board.

Owner:成都联创鸿发科技有限公司

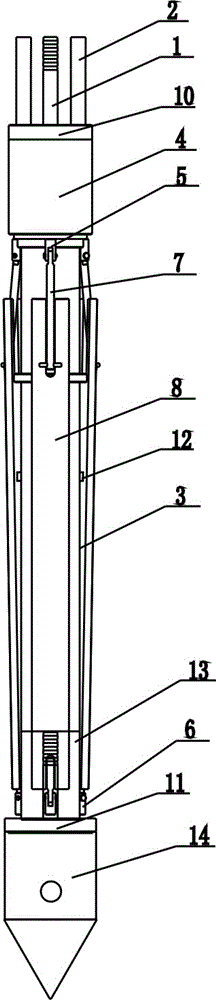

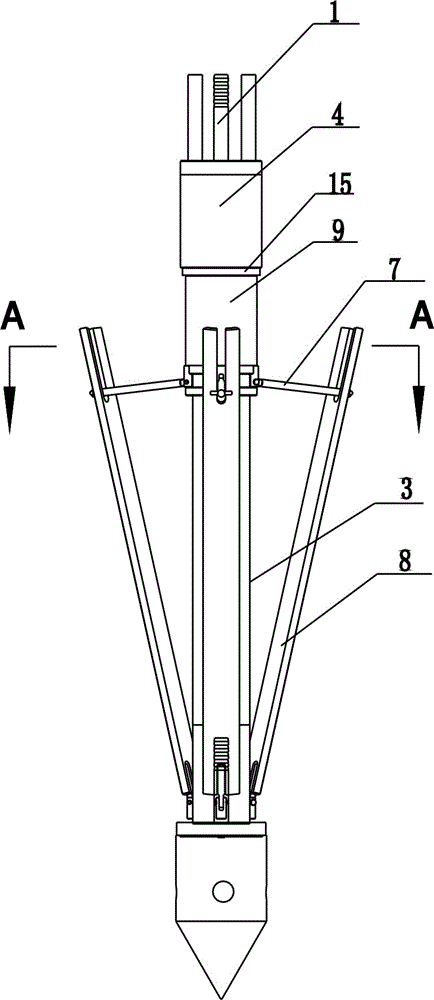

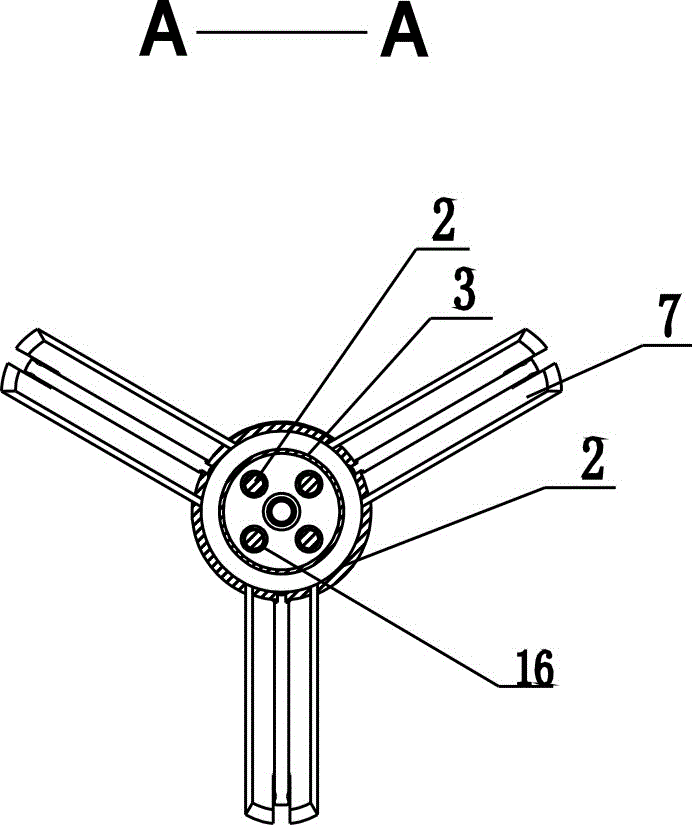

Tile leaf type expansion anchor rope/rod

The invention discloses a tile leaf type expansion anchor rope / rod. The tile leaf type expansion anchor rope / rod comprises a grouting pipe, an anchor rope, an anchor rope guide steel pipe, a guide cap and a main steel pipe; the anchor rope guide steel pipe is positioned in the main steel pipe; the anchor rope is positioned in the anchor rope guide steel pipe; the guide cap is positioned at the lower end of the main steel pipe; the upper end of the main steel pipe is sleeved with a cylindrical piston; the cylindrical piston is sleeved with a piston outer steel pipe; the piston outer steel pipe and the main steel pipe are both bonded with the upper end of the cylindrical piston; the upper ends of the piston outer steel pipe and the main steel pipe are connected through an upper bearing body; the guide cap and the lower end of the main steel pipe are connected through a lower bearing body; the outer cylindrical surface of the lower end of the cylindrical piston is provided with a step, whose outer diameter is larger than the inner diameter of the piston outer steel pipe; the outer cylindrical surface of the main steel pipe is provided with a limiting ring, whose outer diameter is larger than the inner diameter of the cylindrical piston; slurry starts to enter an expansion cavity in sequence through the main steel pipe until the expansion cavity is fully injected; and the slurry is solidified to become a standard conical anchor expansion body. The conical anchor expansion body is suitable for clay stratum, higher in firmness, convenient to operate and low in cost.

Owner:孙贵超 +1

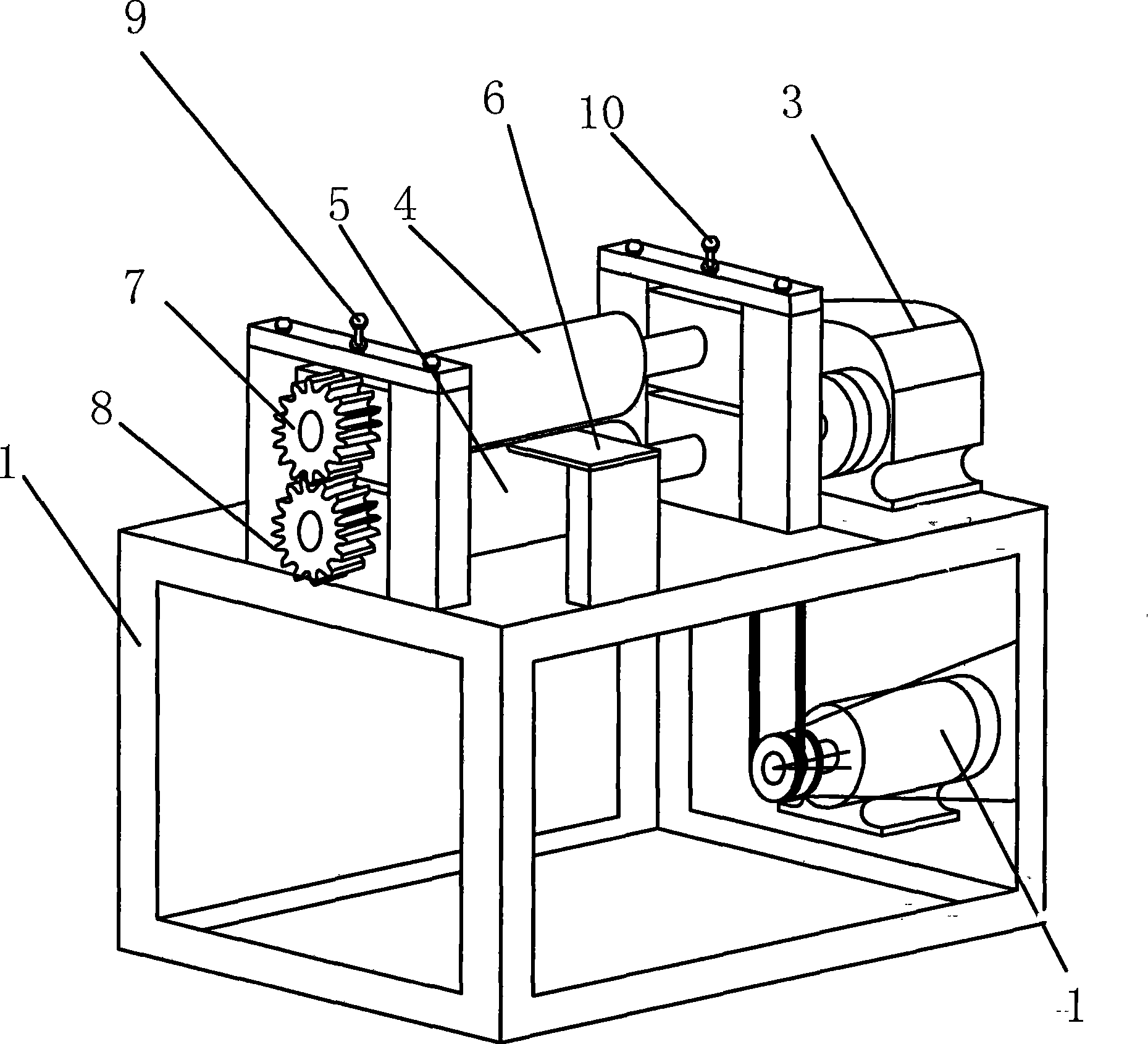

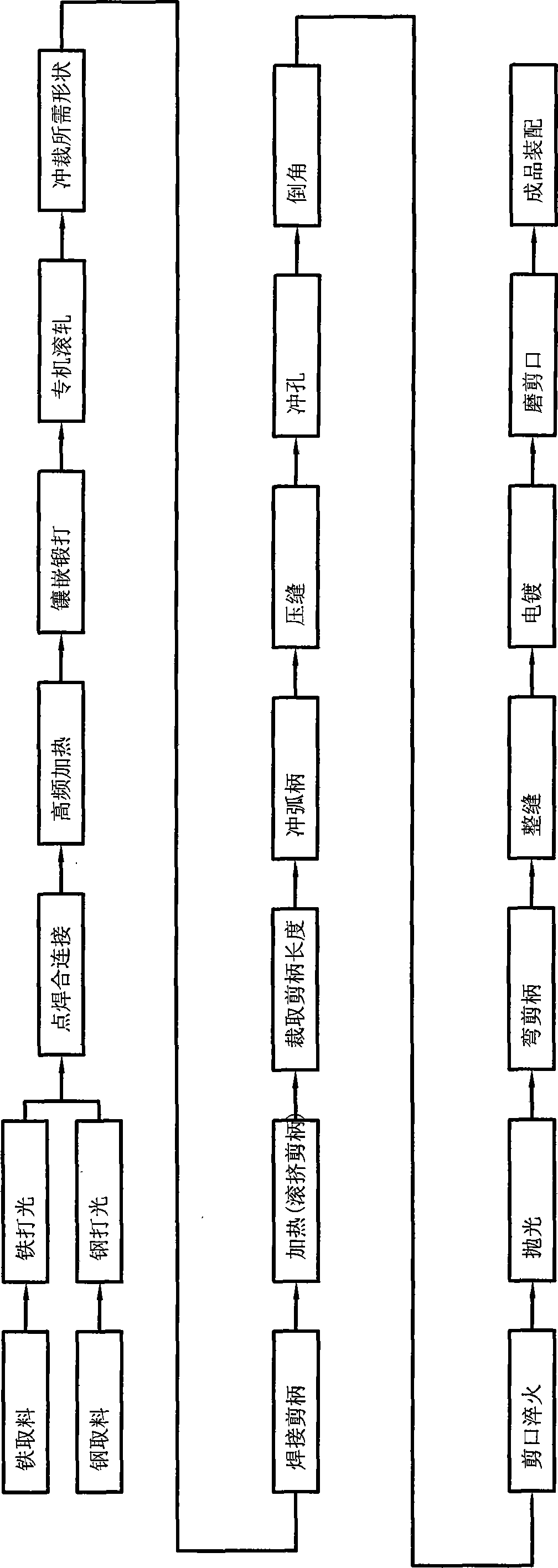

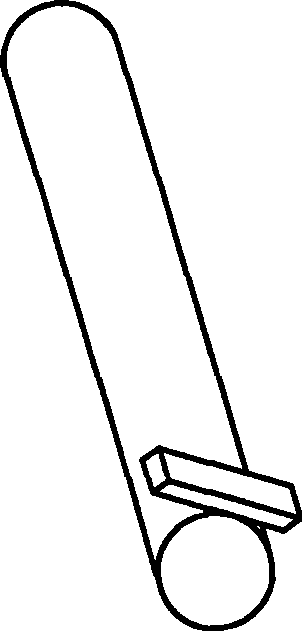

Method for rolling and processing tool bits, and rolling equipment thereof

The invention provides a method for rolling and processing tool bits. The method comprises the following steps: (1) selecting hot-rolled iron plate or hot-rolled wire blank as tool body material and high-carbon steel blank as tool edge material, polishing the hot-rolled iron plate or hot-rolled wire blank and the high-carbon steel blank and welding the high-carbon steel blank and the hot-rolled iron plate or hot-rolled wire blank into a raw material blank; (2) heating the raw material blank to a set temperature; (3) obtaining a rough processed blank by taking out and forging the raw material blank heated to the set temperature and inlaying the high-carbon steel blank into the hot-rolled iron plate or hot-rolled wire blank; (4) obtaining a fine processed blank by rolling and shaping the rough processed blank; and (5) obtaining a tool bit by cutting the fine processed blank according to the shape of a to-be-processed tool bit. The invention also provides rolling equipment for realizing the rolling-processing method. The invention provides the method for rolling and processing tool bits, and the rolling equipment thereof, which have the advantages of adopting machining, greatly improving product qualification ratio, reducing processing cost, improving working efficiency, protecting environment and saving energy.

Owner:陈敦松

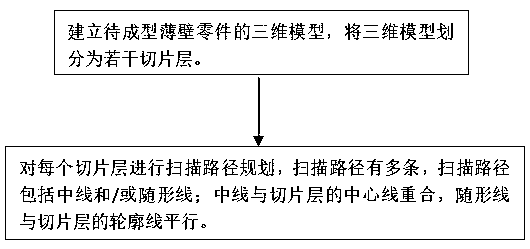

Method for planning laser scanning path of thin-walled part and 3D printing method

InactiveCN110744055AKeep original featuresKeep featuresAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningEngineering

The invention relates to the technical field of additive manufacturing, and particularly discloses a method for planning a laser scanning path of a thin-walled part. The method for planning the laserscanning path of the thin-walled part comprises the following steps that a three-dimensional model of the to-be-formed thin-walled part is established and is divided into a plurality of slice layers;and scanning paths of the slice layers are planned, wherein the number of the scanning paths is more than one, and each scanning path comprises a center line coinciding with the center of the corresponding slice and / or a following line parallel to the contour line of the corresponding slice layer. The invention further provides a 3D printing method adopting the method for planning the laser scanning path of the thin-walled part. By the adoption of technical solution, the thickness of a blank of the thin-walled part can be decreased, and the forming quality of the part is improved.

Owner:TSC LASER TECH DEV BEIJING CO LTD

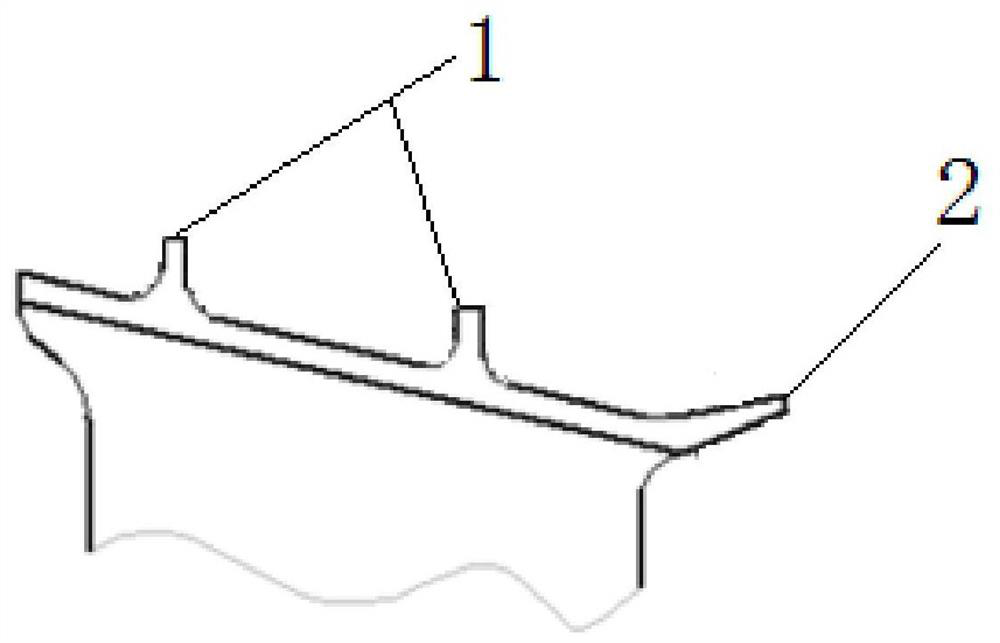

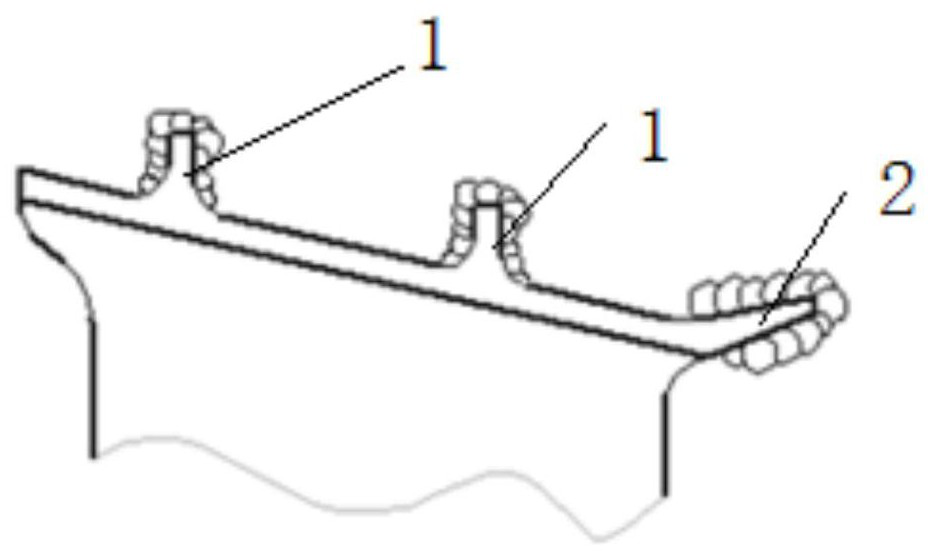

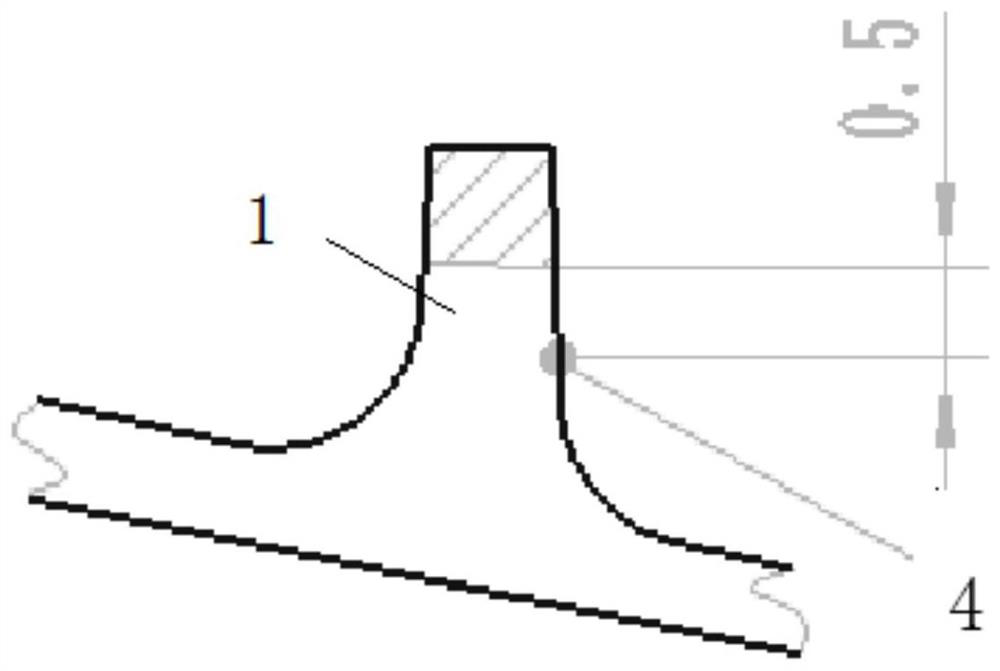

Forging method for Y-shaped blanks made of plastic materials

InactiveCN106607533AControl shapeSmall sizeMetal-working apparatusHigh volume manufacturingPlastic materials

The invention relates to a forging method, in particular to production of various Y-shaped blanks made of plastic forming materials. Through the forging method for manufacturing the Y-shaped blanks, the problems that the Y-shaped blanks are difficult to manufacture, boundary dimensions are inaccurate, the utilization rate of materials is low, macroscopic streamlines do not follow outlines, and energy is wasted are solved. In all links of forging operation, plate blank manufacturing, the lengths of kerfs and the positions of punched holes can be accurately controlled, and thus the outlines and dimensions of the Y-shaped blanks are easily controlled, and mass production is facilitated. The working procedures are simple, the forging heating number is small, and waste of energy for forging heating and consumption caused by self-heating of the materials are reduced. The dimensions of the blanks are easily controlled, and the maximum utilization rate of the materials can be achieved. The obtained Y-shaped blanks can maintain the original forging streamlines, and finally produced forgings can have good anti-fatigue ability.

Owner:SHAANXI HONGYUAN AVIATION FORGING

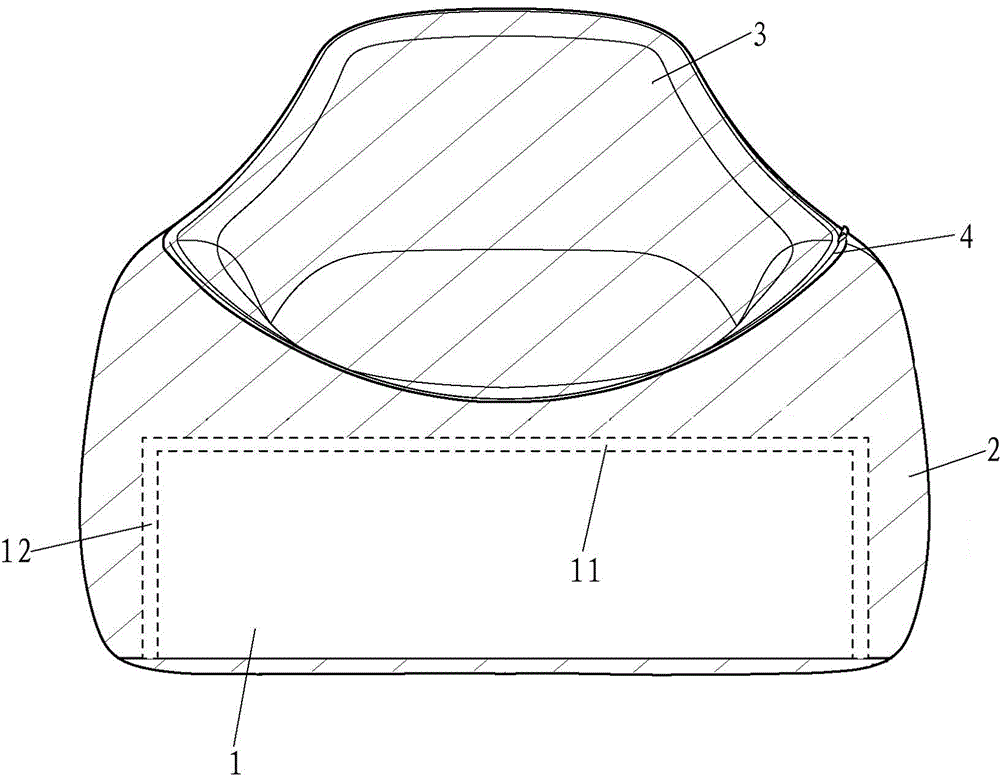

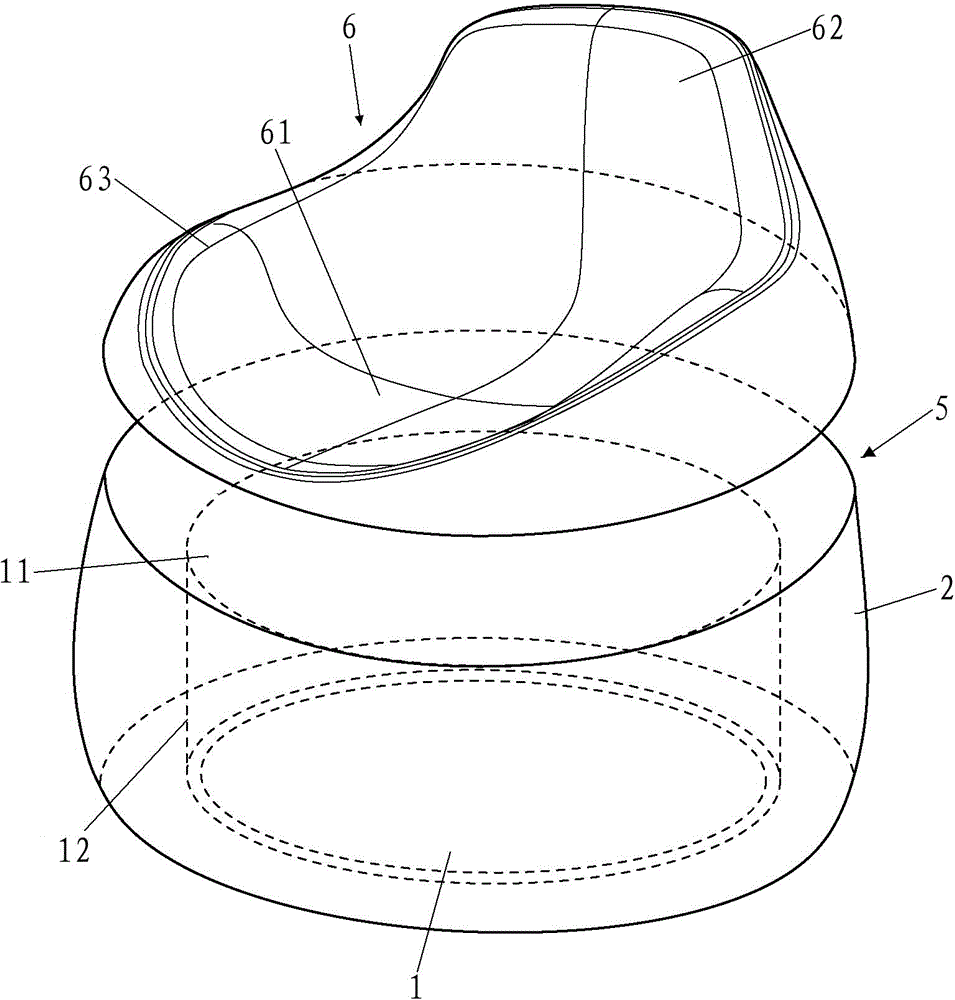

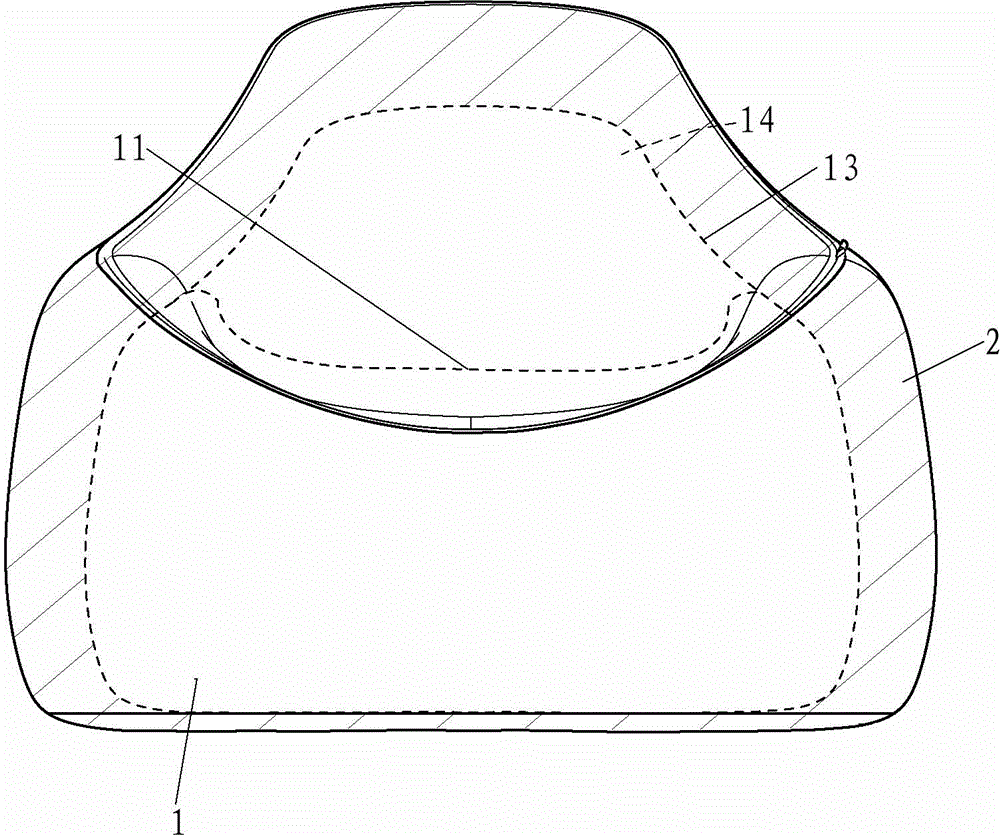

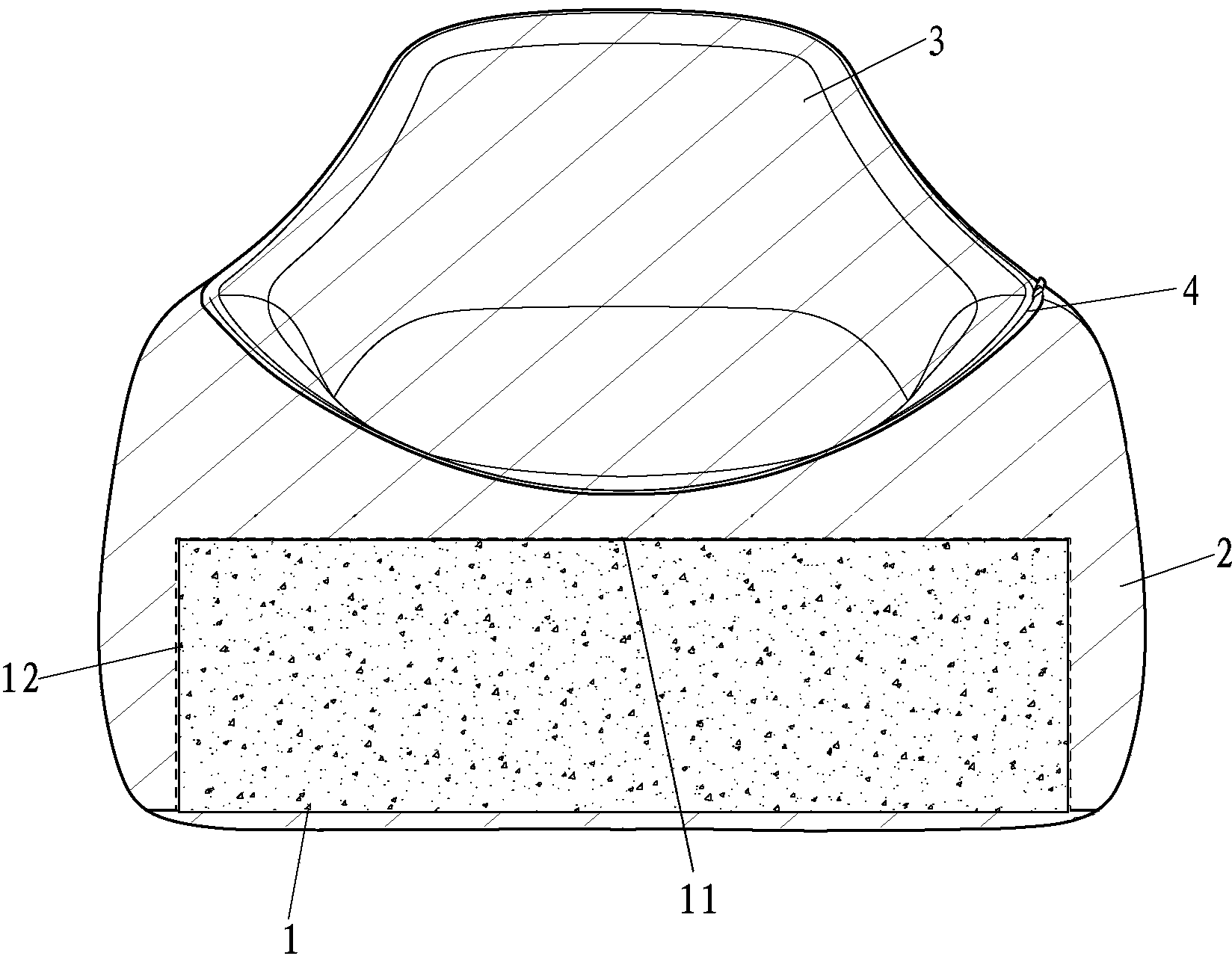

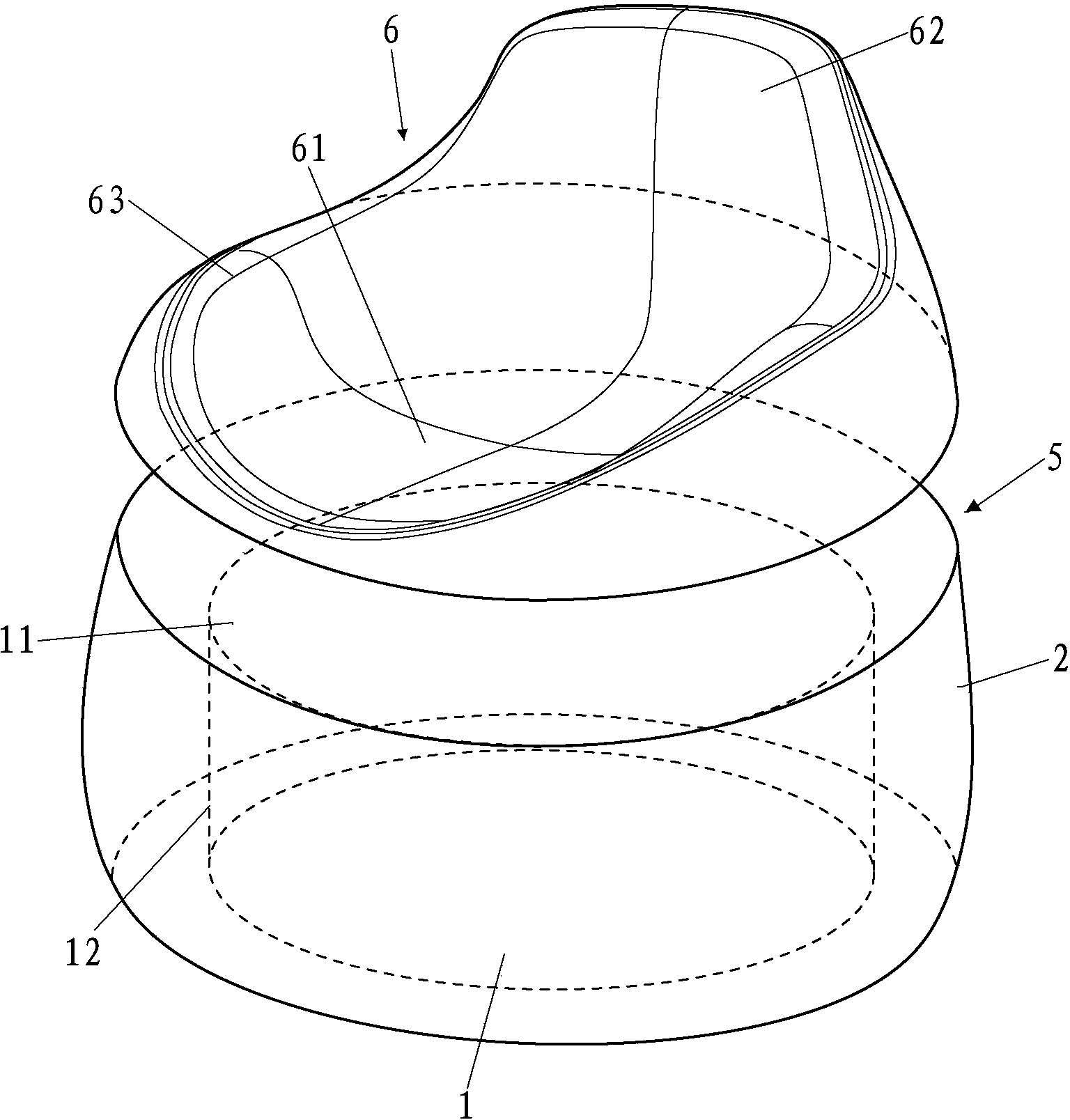

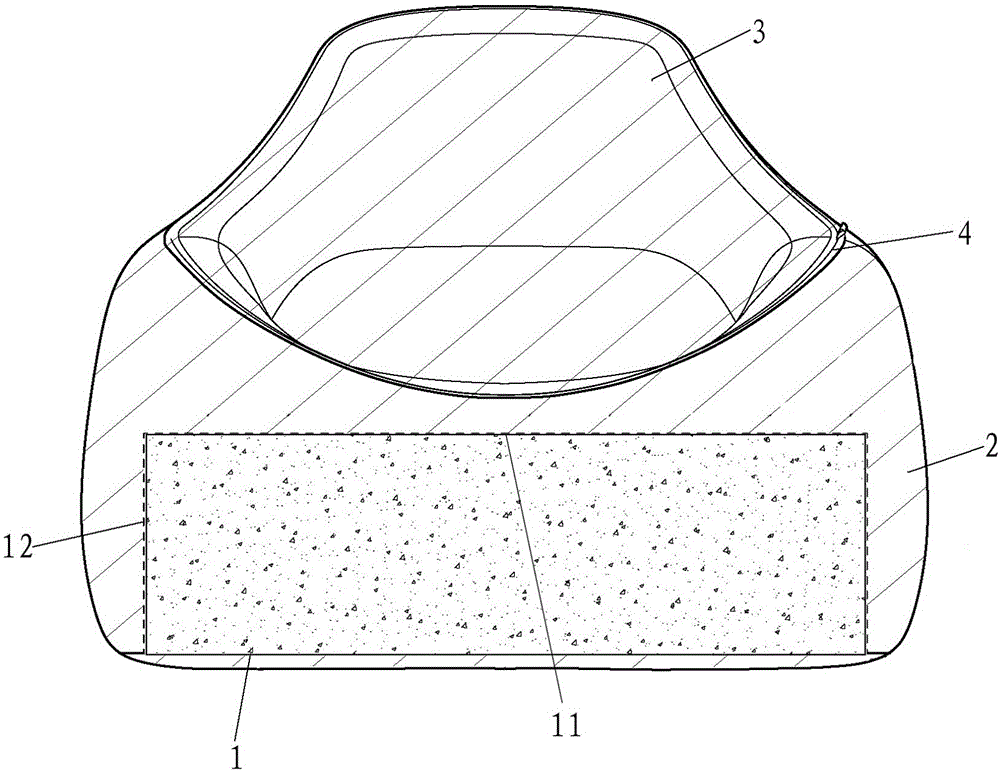

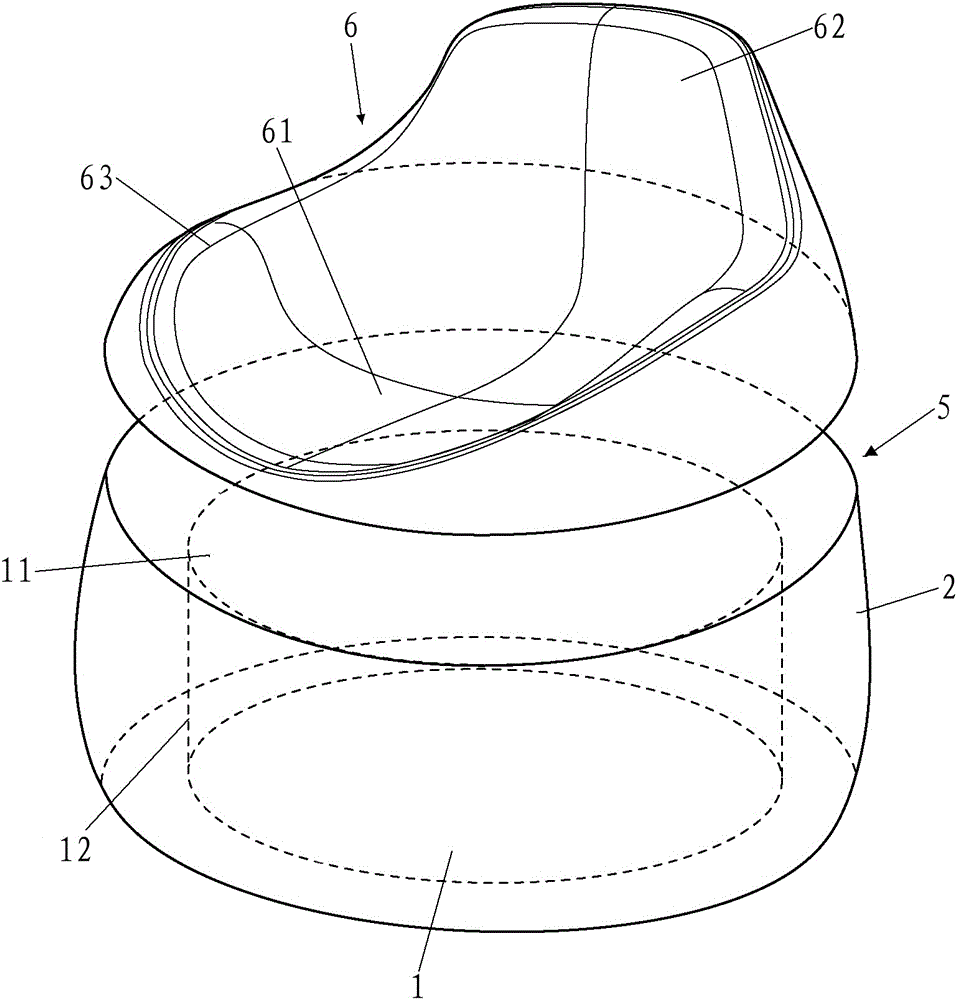

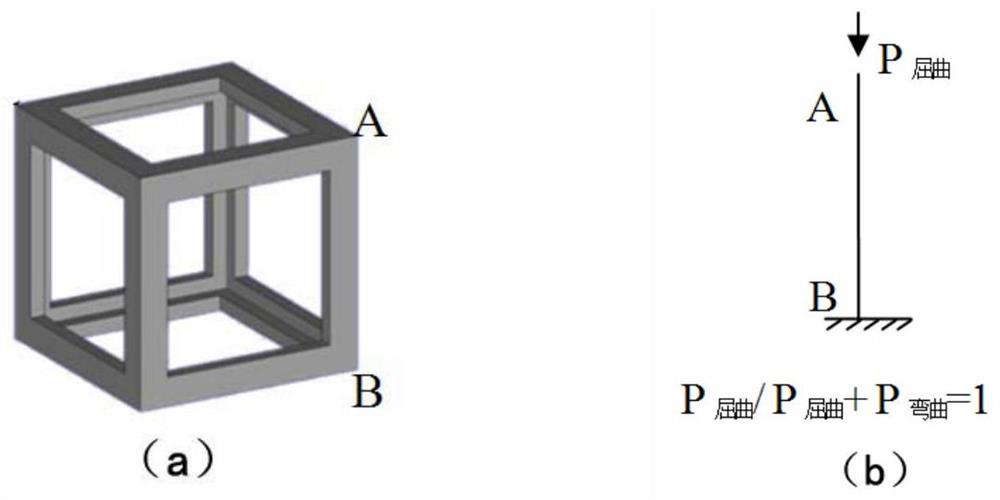

Sponge sofa and making method thereof

InactiveCN104095431ASimple preparation processEasy to control appearanceSofasCouchesMaterials scienceManufacturing technology

The invention discloses a sponge sofa and a making method thereof, the sponge sofa comprises a sofa frame, and a sponge layer with sofa backrests and sofa armrests are integrally foamed on the outer surface of the sofa frame. The sponge sofa is prepared as follows: first, making the sofa frame, then placing the sofa frame into a die, and integrally foaming the sponge layer on the outer surface of the sofa frame. The sponge sofa prepared by the method has the advantages of simple manufacture technology, easy controlled appearance, mechanized production and excellent life and the like.

Owner:ZINUS

Iron-based alloy reactive armor shell with low collateral damage and preparation method thereof

InactiveCN104406462ASatisfy service processingAvoid damageArmoured vehiclesDamage effectsPowder metallurgy

The invention discloses an iron-based alloy reactive armor shell with low collateral damage. The shell comprises a reactive armor housing and a reactive armor chamber shell positioned in the reactive armor housing, and is prepared by iron powder of 70-97 parts by weight, copper powder of 2-30 parts by weight and graphite powder of 0.3-1 part by weight through a powder metallurgy method and a subsequent processing technology. A preparation method adopts the powder metallurgy method, and comprises such processes as powder mixing, compression molding, sintering, shaping, oil containing, cleaning, surface treatment and welding. The reactive armor shell prepared by the method is lower in fragment collateral damage effect after the reactive armor effect, and has such advantages as high strength, low cost, controllable shape and batch production.

Owner:ZHONGBEI UNIV

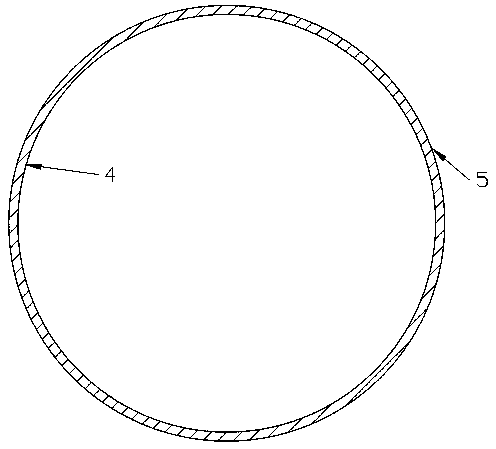

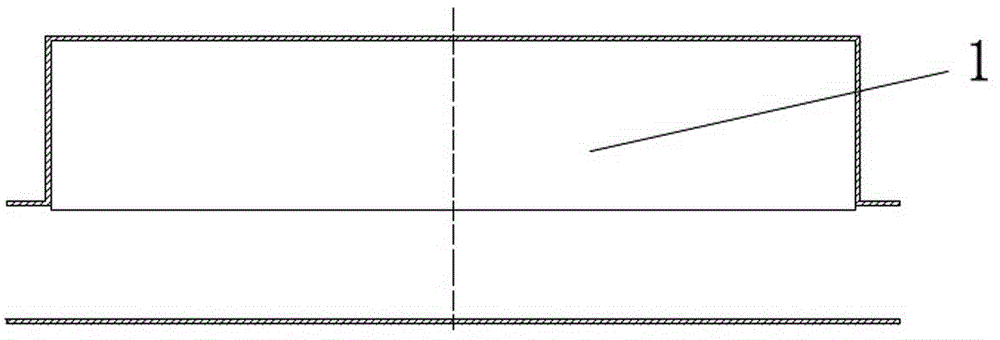

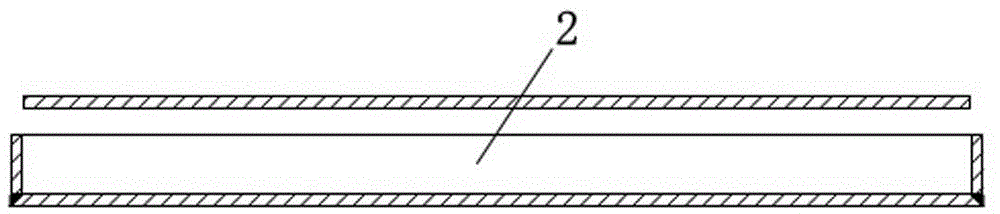

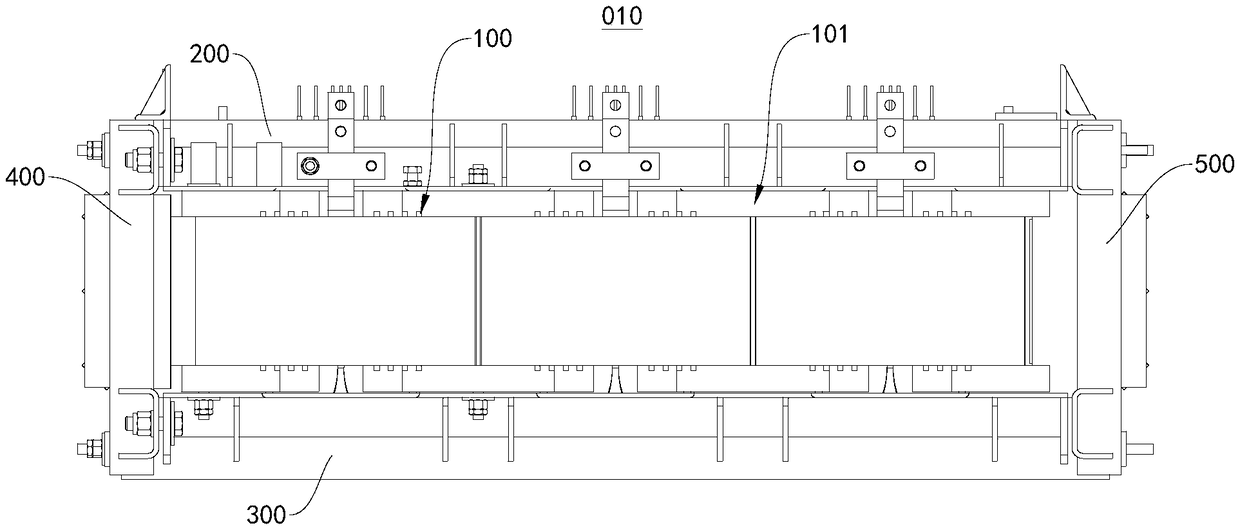

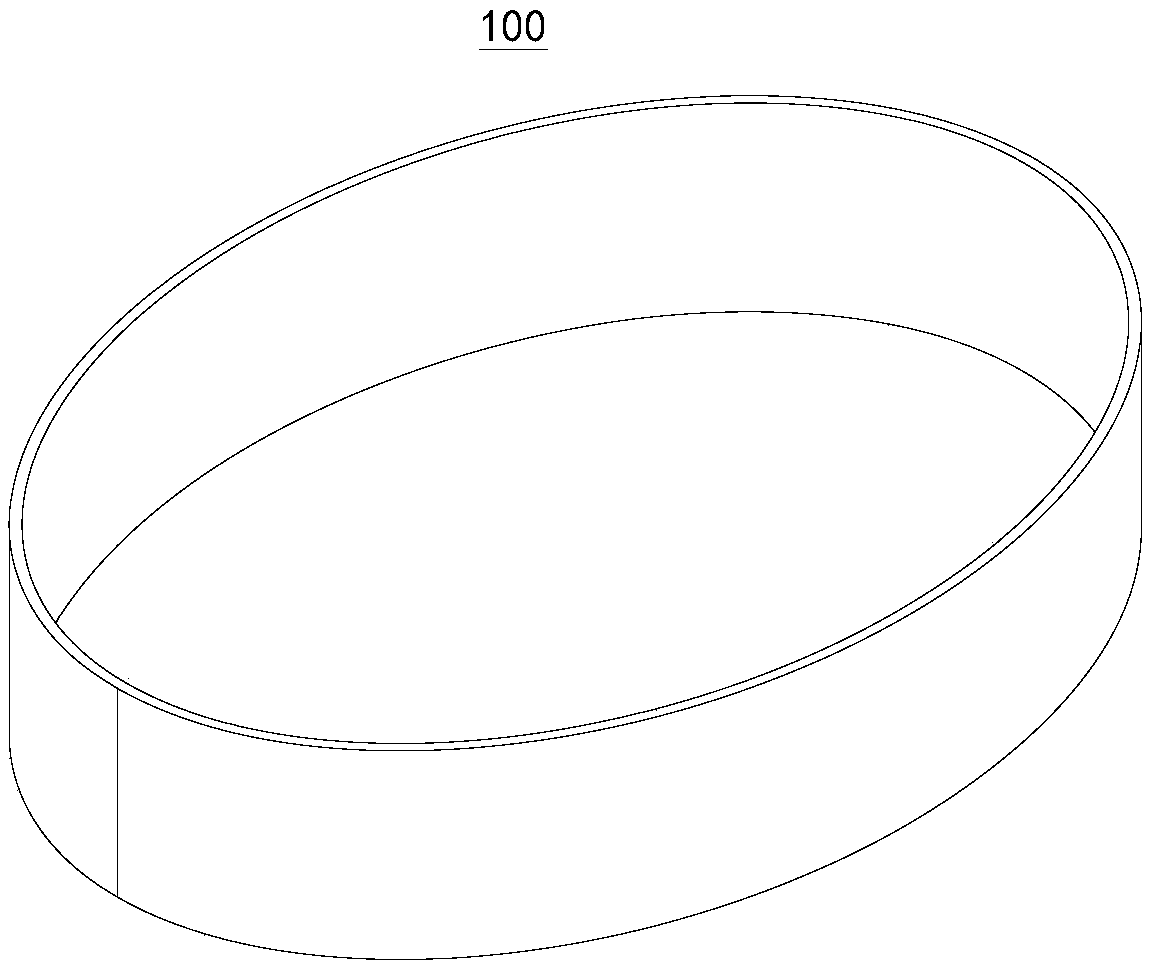

Transformer

PendingCN109285674ASmooth rotationEasy to operateTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringDistribution transformer

The invention relates to the technical field of distribution transformers, in particular to a transformer. The transformer includes an elliptical coil, an upper clamp and a lower clamp. The ellipticalcoil is clamped between the upper clamp and the lower clamp, and the upper clamp and the lower clamp clamp the elliptical coil in the axial direction of the elliptical coil, and the elliptical coil is used for wire winding. The transformer rotates smoothly at the time of wire winding, a coil better fits the surface of the elliptical coil in the winding process, and the wound coil turns are not loose and not easy to deform, and have better short-circuit resistance and excellent safety.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL +2

Fe-based alloy reactive armor shell with low collateral damage and preparation method thereof

The invention discloses an iron-based alloy reactive armor shell with low collateral damage. The shell comprises a reactive armor housing and a reactive armor chamber shell positioned in the reactive armor housing, and is prepared by iron powder of 70-97 parts by weight, copper powder of 2-30 parts by weight and graphite powder of 0.3-1 part by weight through a powder metallurgy method and a subsequent processing technology. A preparation method adopts the powder metallurgy method, and comprises such processes as powder mixing, compression molding, sintering, shaping, oil containing, cleaning, surface treatment and welding. The reactive armor shell prepared by the method is lower in fragment collateral damage effect after the reactive armor effect, and has such advantages as high strength, low cost, controllable shape and batch production.

Owner:ZHONGBEI UNIV

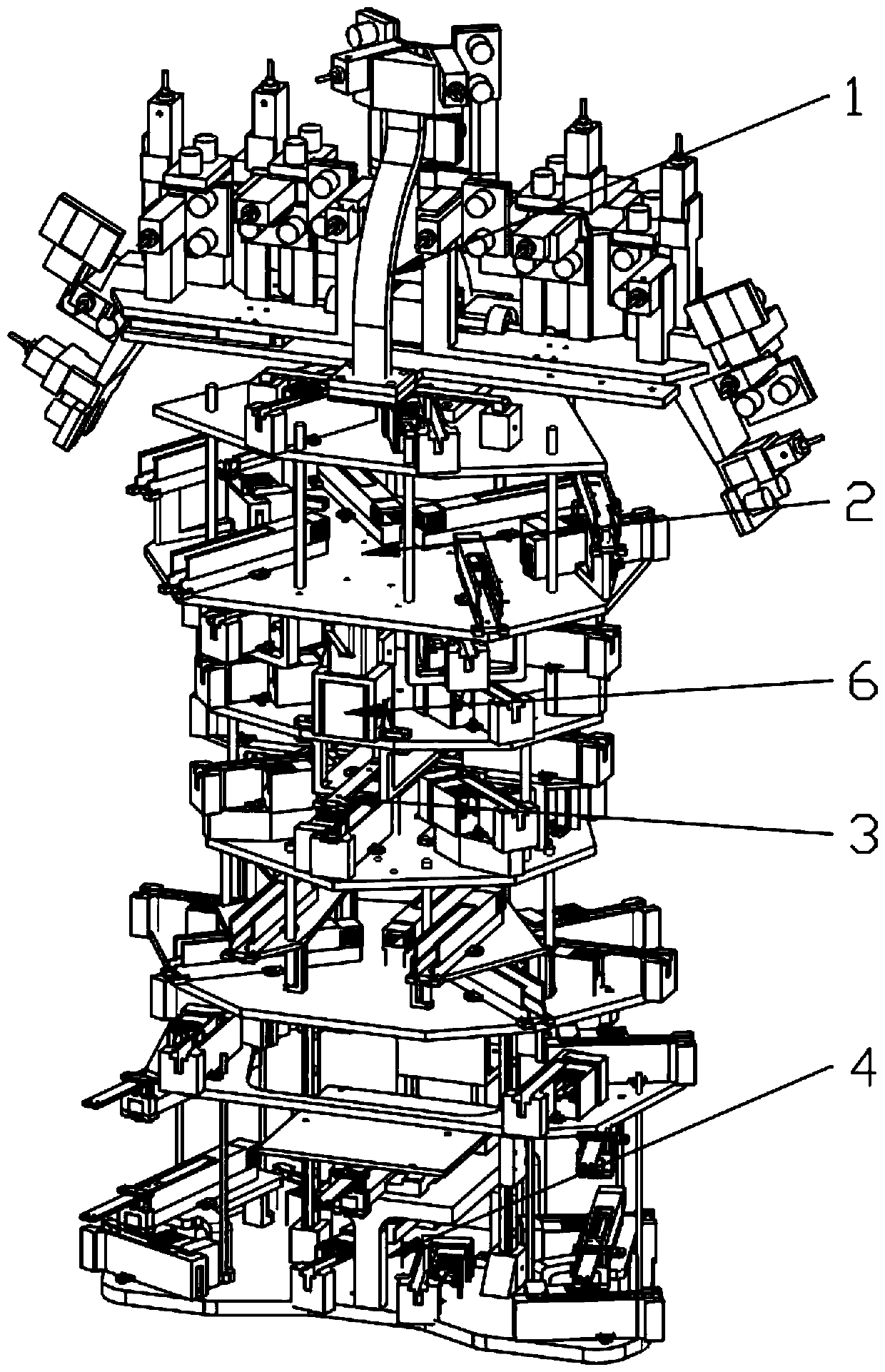

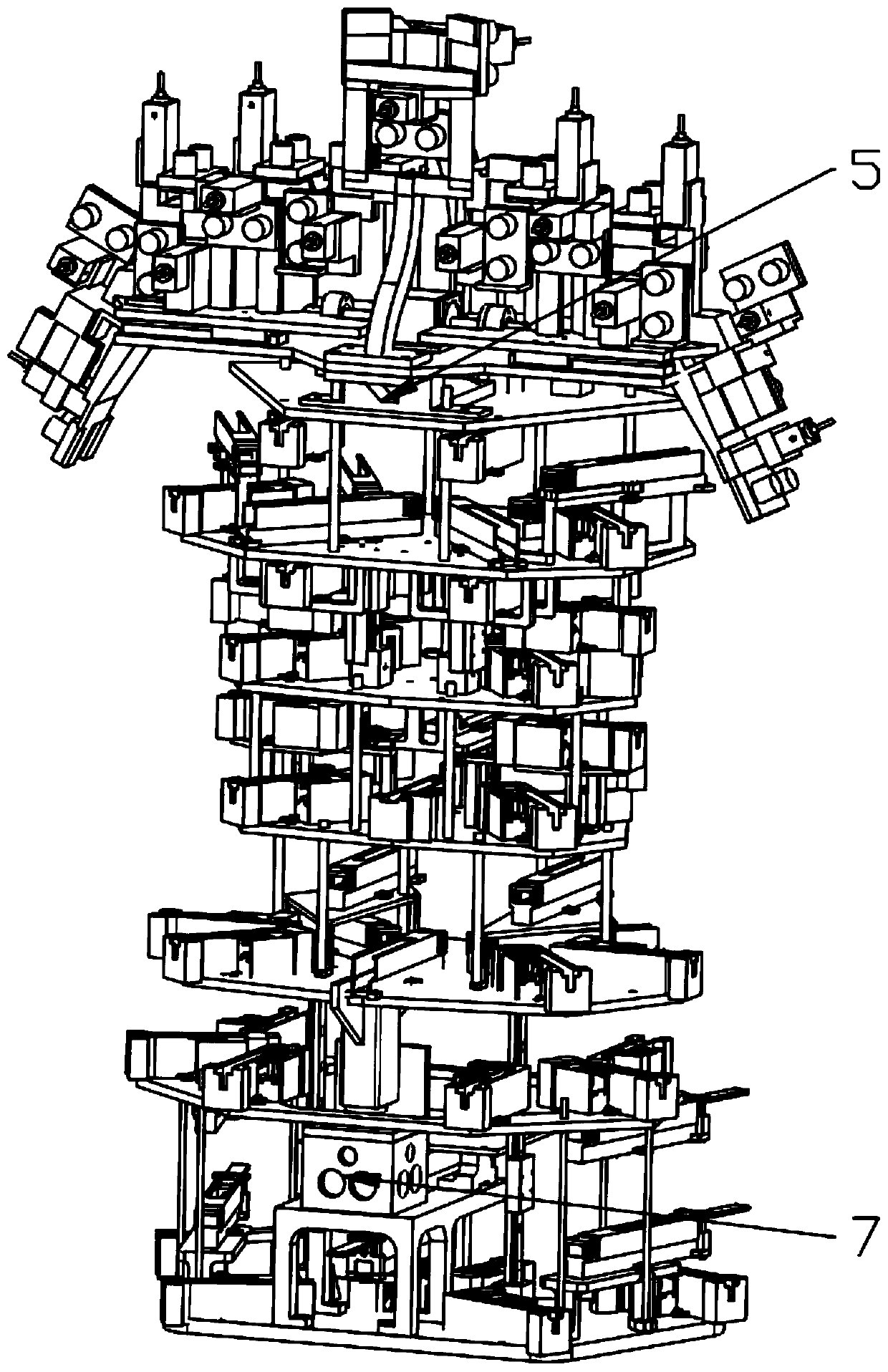

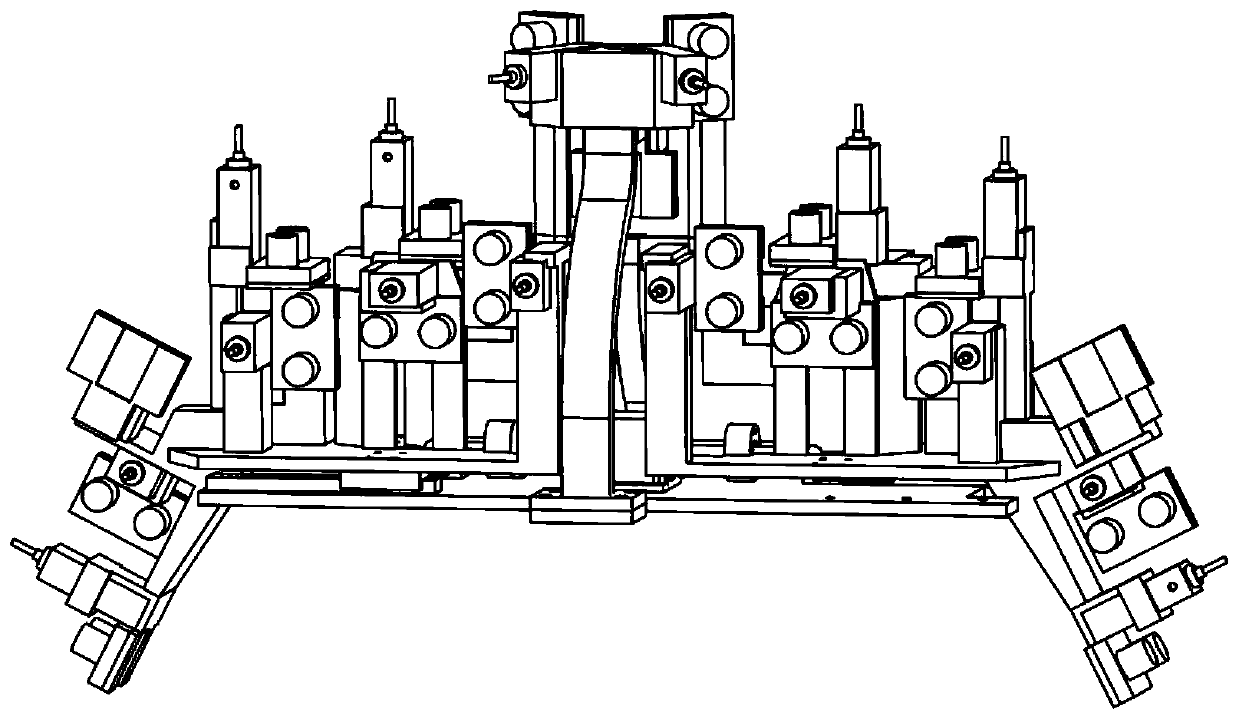

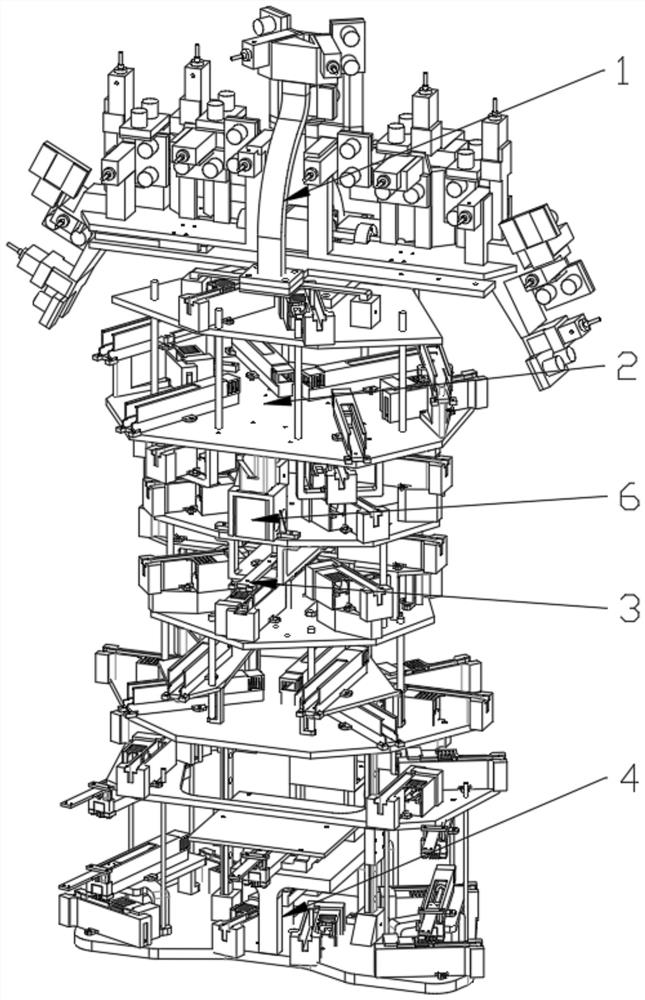

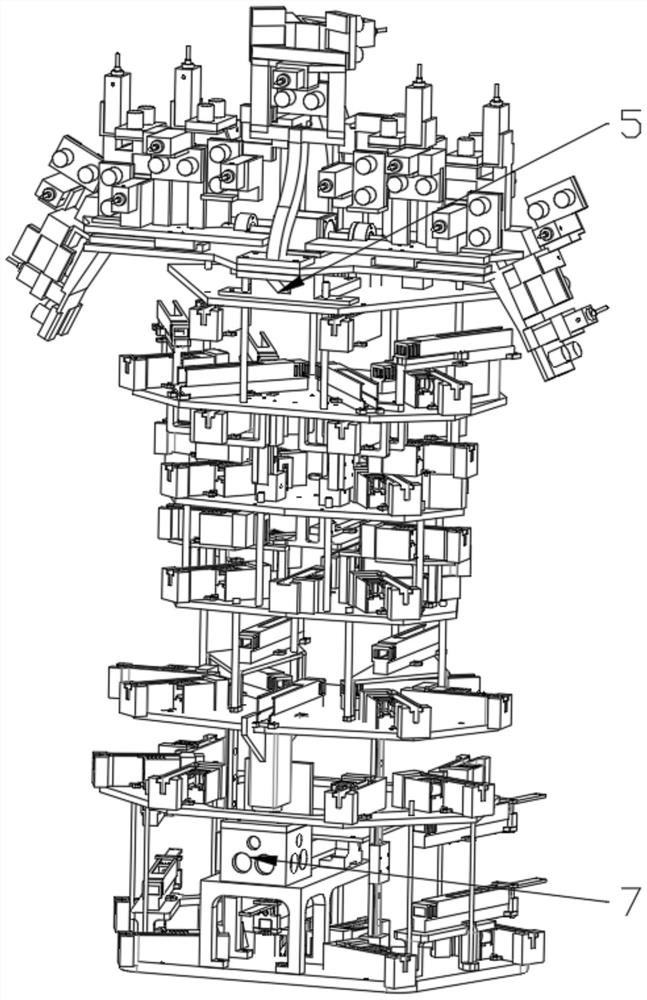

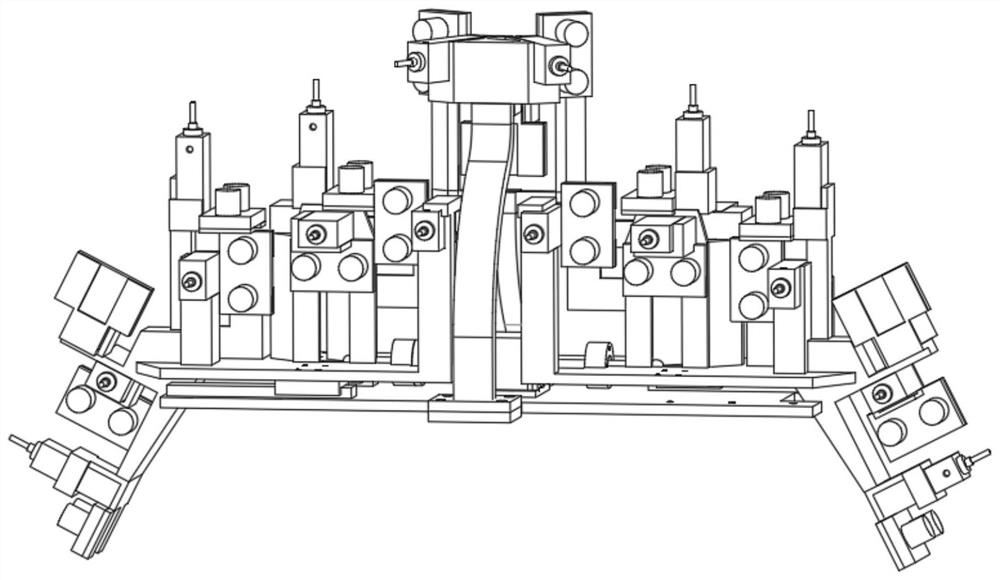

Shape-controllable dress form robot based on segmented skins

ActiveCN110561447AEasy modular installationEasy to debugProgramme-controlled manipulatorButtocksOnline and offline

The invention discloses a shape-controllable dress form robot based on segmented skins. The dress form robot comprises a plurality of parts which respectively simulate the shapes of buttocks, the chest, the waist and shoulders, wherein each part is composed of an inner shape driving module of a multilayer structure and an outer skin characterized by a segmented curved surface. Each inner shape driving module is composed of a plurality of spatially distributed linear propelling mechanisms, and the linear propelling mechanisms control the deformation of the segmented curved surfaces. By adjusting the propelling amount of the linear propelling mechanisms, the shape of the segmented curved surface pieces is controlled, and the simulation of the transverse shape of a human body is realized. Therelative distance between adjacent parts is controlled by a displacement adjusting supporting mechanism, so that the simulation of the longitudinal height of the human body is realized. The fitting result of the human body is represented by the tights worn on the robot, and the robot can be used for simulating the shape of the human body of a customer in garment customization and simulating the dressing effect of a real person on a garment by the robot in the online and offline garment sale.

Owner:ZHEJIANG UNIV

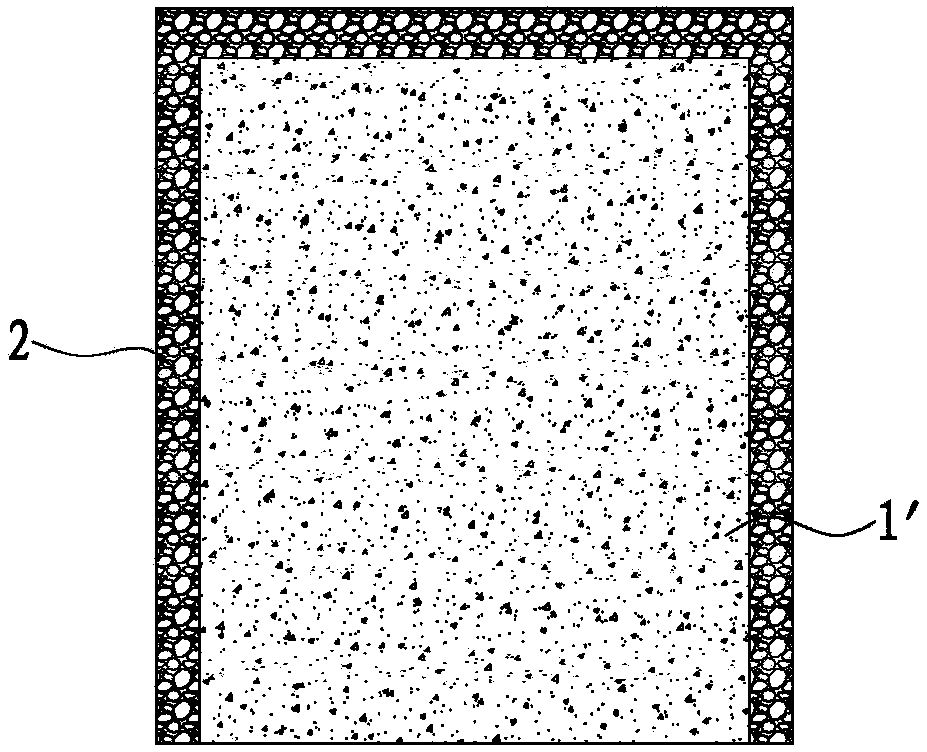

Sponge sofa or sponge stool structure

The invention discloses a sponge sofa or sponge stool structure which comprises a low-density sponge foaming forming sofa base or low-density sponge foaming forming stool base with the foaming density of 10-35 kg / m<3>, wherein a high-density sponge cladding layer with the foaming density of 35-60 kg / m<3> is integrally foamed on the outer surface of the base; the hardness of the sponge sofa base or the sponge stool base is Share A 20+; the hardness of the sponge cladding layer is 30-80 Kgf. The sponge sofa structure has the characteristics of simple manufacturing process, shape controllability, high production efficiency and low manufacturing cost. In addition, a low-density sponge of the sponge sofa base or the sponge stool base is relatively low in price and light in weight and has certain supporting strength and supporting toughness. Therefore, the consumption of a high-density sponge can be reduced, and the material cost and weight of a whole sponge sofa or stool can be further reduced. Moreover, the sponge cladding layer is integrally foamed on the outer surface of the sponge sofa base or the sponge stool base, is firmly attached to the surface of the base and is unlikely to loosen, and thus the service life of the sponge sofa or stool is guaranteed.

Owner:ZINUS (XIAMEN) INC

Preparation method of reactive sealant resin

The invention discloses a preparation method of reactive sealant resin, which comprises the following steps: (1) polymerizing a hydroxyl-containing initiator with an epoxy compound under the action ofan alkali catalyst to obtain polyether polyol; (2) adding an alkoxide reagent and a halogenated end-capping reagent containing double bonds into the polyether polyol obtained in the step (1) to reactso as to obtain a double-bond end-capped polyether crude product, and refining the obtained crude product so as to obtain a modified polyether product; and (3) carrying out silane end-capping reaction on the modified polyether and hydrogen-containing silane under the action of a hydrosilylation catalyst to obtain the target product reactive sealant resin. The resin is excellent in property, and has good adhesion and finishing property.

Owner:WANHUA CHEM GRP CO LTD +1

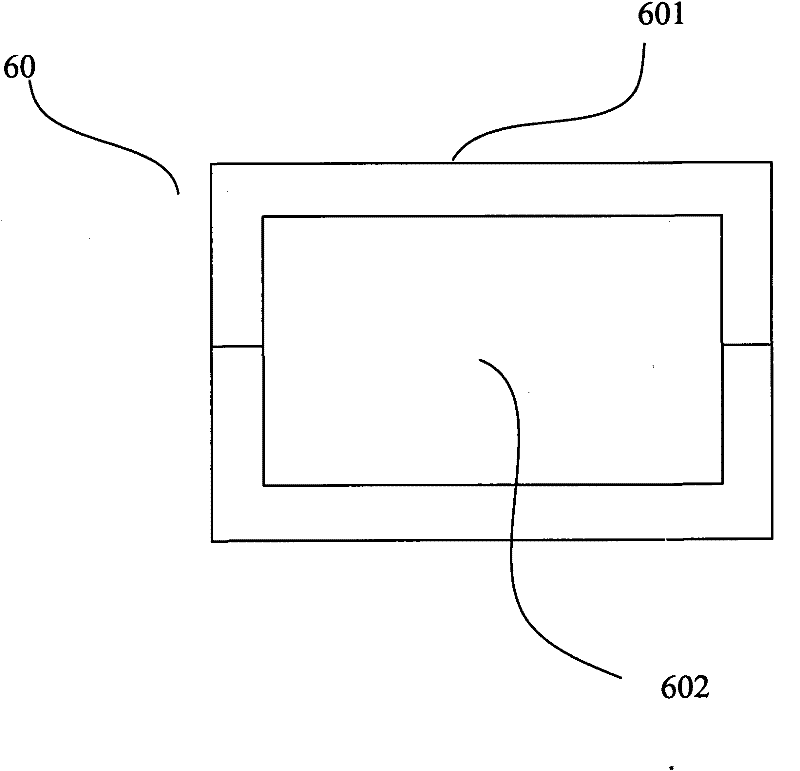

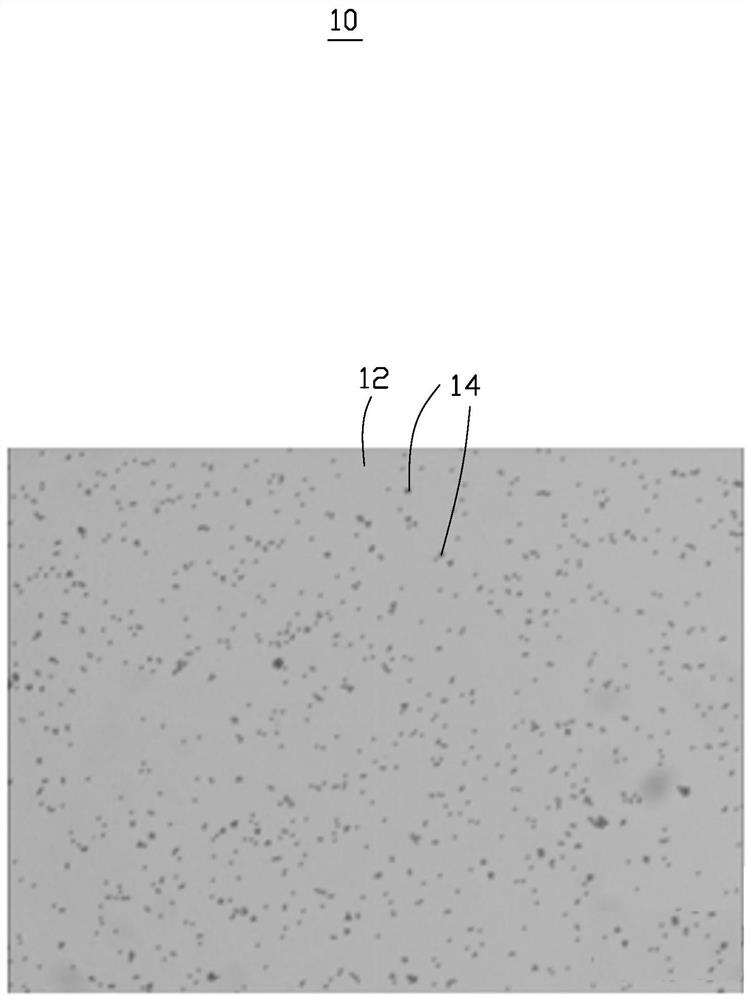

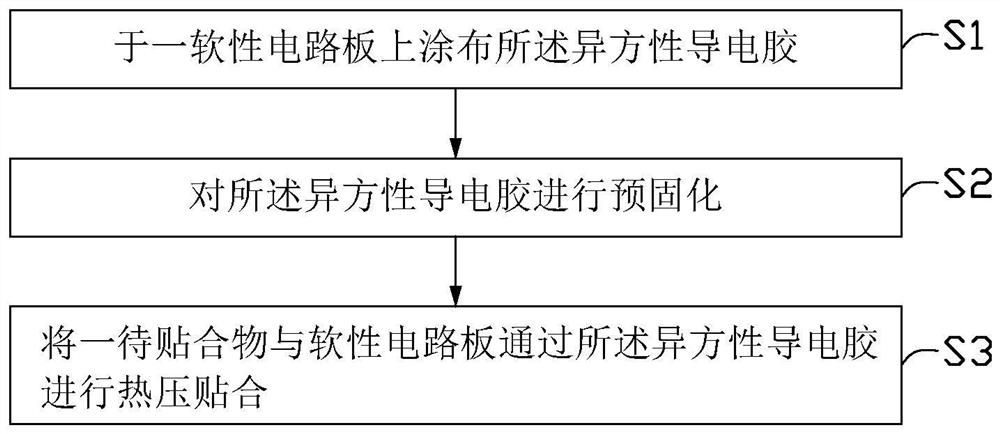

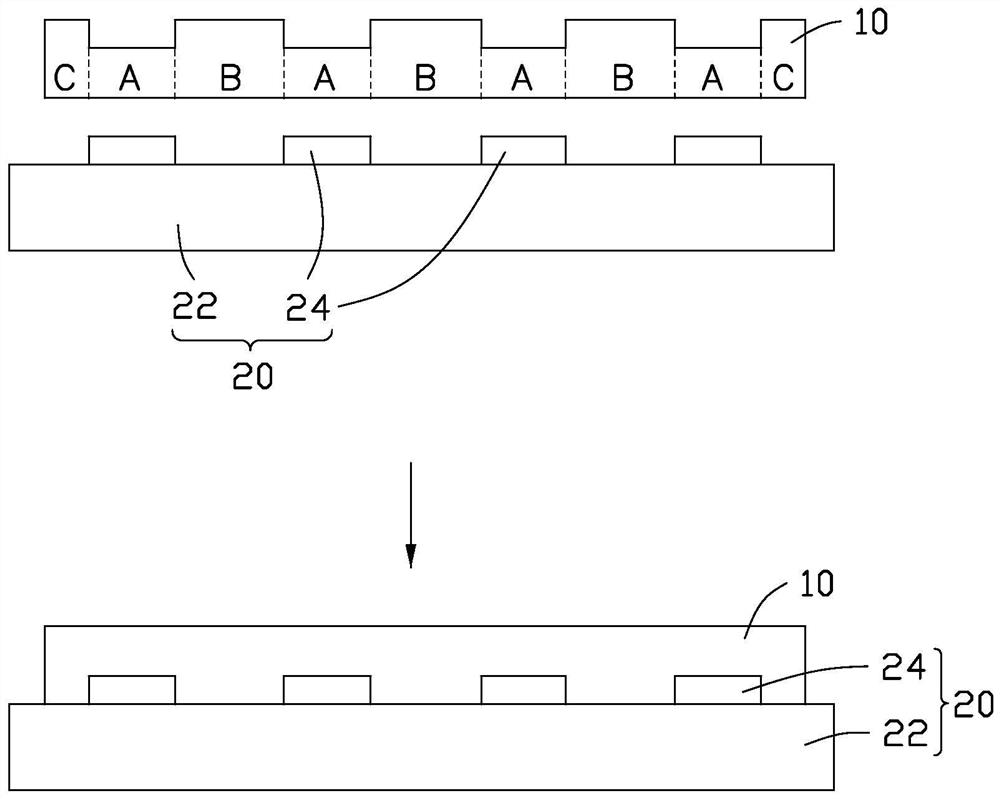

Anisotropic conductive adhesive and pasting method

InactiveCN113046004AEasy to control appearanceReduced risk of deformationAdhesive processes with adhesive heatingElectrically-conducting adhesivesPolymer scienceAnisotropic conductive adhesive

The embodiment of the invention provides an anisotropic conductive adhesive and a pasting method. The anisotropic conductive adhesive comprises a liquid optical transparent adhesive and a plurality of conductive particles mixed in the liquid optical transparent adhesive, wherein each conductive particle comprises a conductive ball and an insulating layer wrapping the conductive ball.

Owner:INTERFACE TECH CHENGDU CO LTD +3

A kind of polyurethane foam sponge sofa, sponge stool

InactiveCN103908103BSimple preparation processEasy to control appearanceSofasCouchesToluene diisocyanateSilicone oil

The invention provides a polyurethane foamed sponge sofa or sponge stool which comprises a liner and an outer pack wrapped outside the liner. The liner is prepared by foaming the following components in parts by weight: 100 parts of at least one polyether glycol, 15-85 parts of toluene diisocyanate, 0.1-0.3 part of tin catalyst, 0.1-0.3 part of amine catalyst, 0.8-6 parts of water and 0.5-2 parts of silicon oil surfactant. The outer pack is prepared by foaming the following components in parts by weight: 100 parts of at least one polyether glycol, 25-80 parts of diphenylmethane diisocyanate, 0.1-0.5 part of tin catalyst, 0.1-0.6 part of amine catalyst, 0.2-3.5 parts of water and 0.3-3 parts of silicon oil surfactant. The polyurethane foamed sponge sofa or sponge stool has the characteristics of simple manufacturing technique, controllable appearance, high production efficiency, low cost, long service life and light weight, and is very convenient to use.

Owner:ZINUS

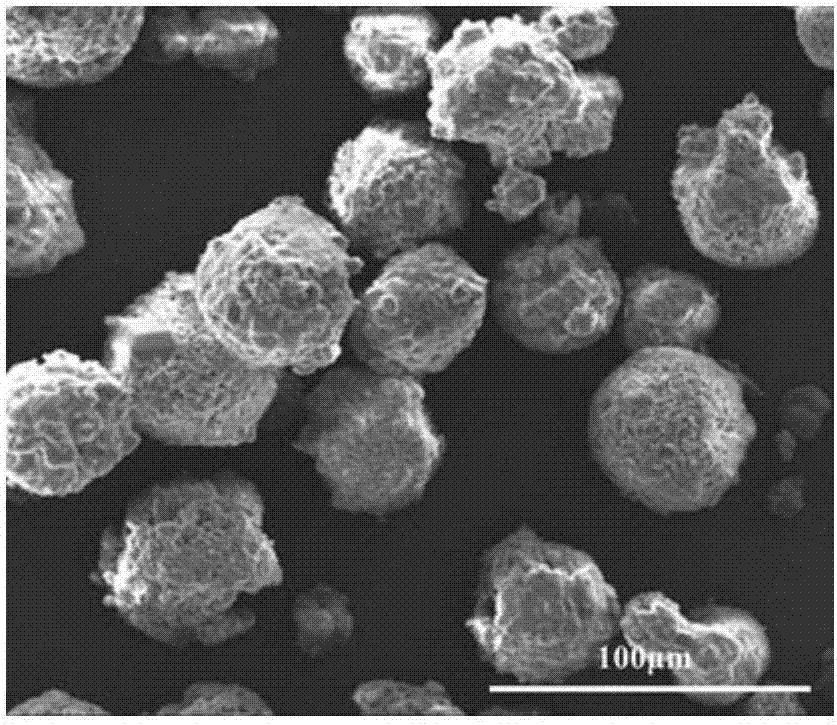

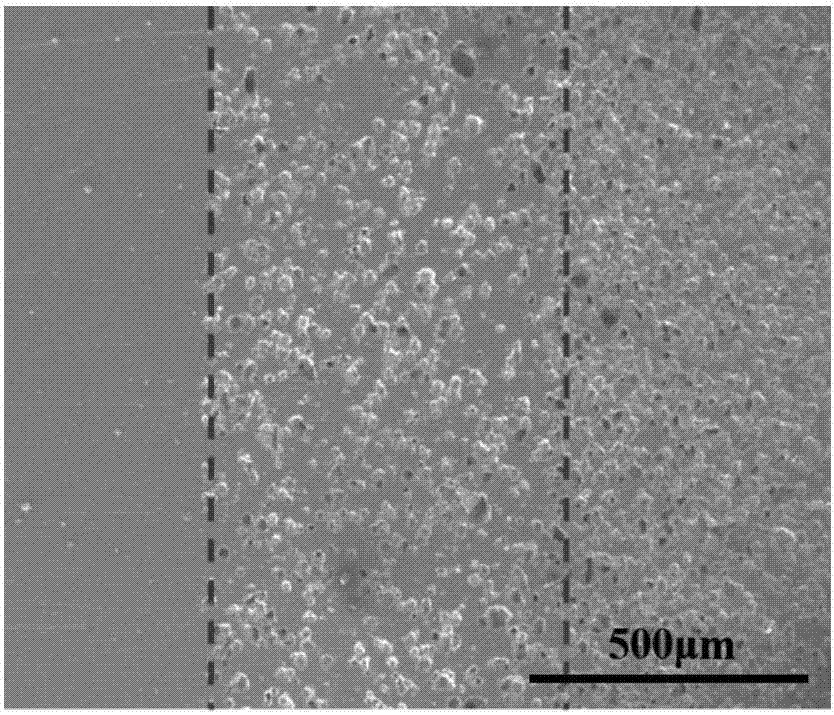

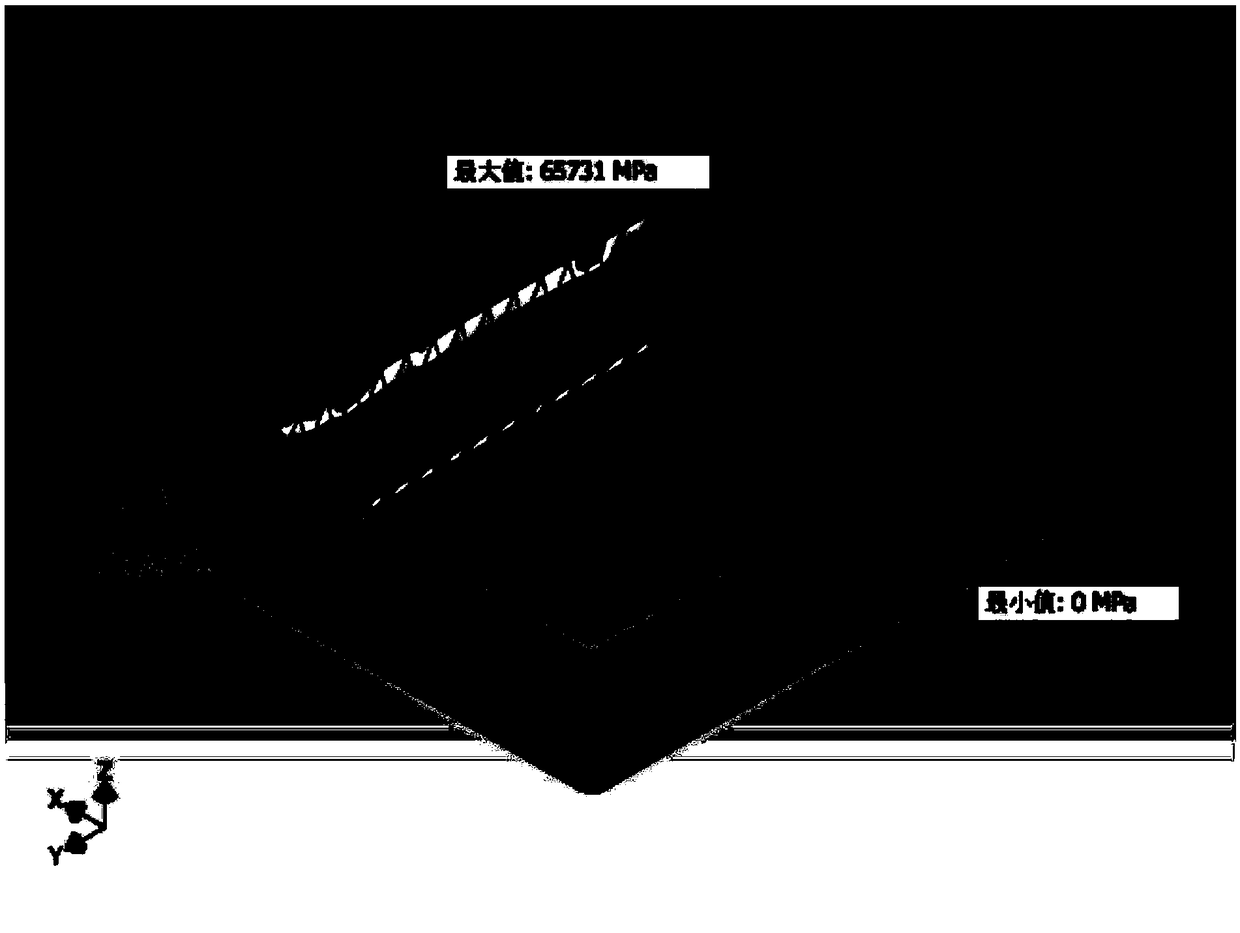

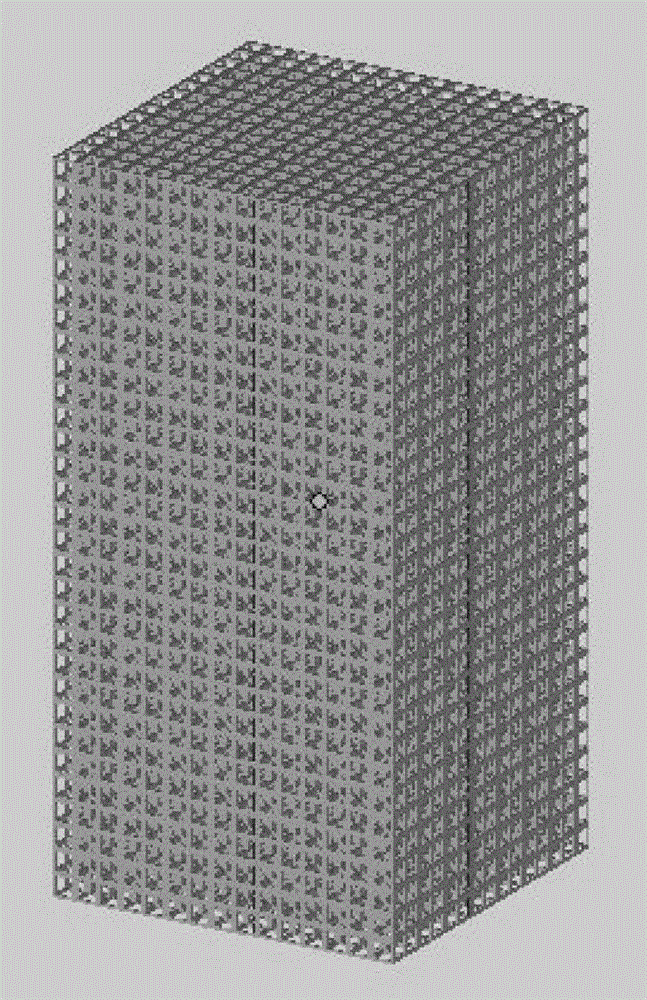

Method for preparing ultrahigh-strength titanium alloy porous material based on additive manufacturing technology

ActiveCN113564416APorosity is easy to controlEasy to control appearanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention relates to the field of porous material preparation, in particular to a method for preparing an ultrahigh-strength titanium alloy porous material based on an additive manufacturing technology. According to the method, the uniform porous titanium alloy material with the unit cell size and hole pattern being adjustable is prepared through a selective laser melting forming technology, and a uniform porous titanium alloy block material with the effective density being 0.5-2.0 g / cm < 3 >, the strength capable of reaching 600 MPa, the absorbed energy reaching 90 MJ / m < 3 > and the elastic modulus being 0.1-20 GPa can be obtained by optimizing additive manufacturing process parameters and selecting proper heat treatment. The method is simple in preparation process, low in cost and suitable for industrial production, and has a good application prospect in the fields of aerospace lightweight design, medical treatment, energy absorption and shock absorption, filtration and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A sponge sofa structure

InactiveCN104095433BIncrease productivityReduce manufacturing costStuffed mattressesSpring mattressesManufacturing technologyEngineering

The invention discloses a sponge sofa structure, which comprises a styrofoam sofa base formed by styrofoam foaming, and a sponge layer is integrally foamed on the top surface or the outer surface of the styrofoam sofa base. The sponge sofa structure has the characteristics of simple manufacture technology, easy controlled appearance, high production efficiency and low production cost; in addition, because the styrofoam material is low in price, and has certain support strength and support toughness, the styrofoam material can effectively replace a part of characteristics of hard sponge, the use amount of sponge can be reduced, the material cost of the whole product can be reduced; furthermore, the sponge layer is integrally foamed on the surface of the styrofoam sofa base, is firmly combined with the surface of the styrofoam sofa base, and is not easy to get loose, and the service life of the product can be ensured.

Owner:ZINUS

Method for preparing ultra-high-strength titanium alloy porous material based on additive manufacturing technology

ActiveCN113564416BPorosity is easy to controlEasy to control appearanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention relates to the field of porous material preparation, in particular to a method for preparing ultra-high-strength titanium alloy porous material based on additive manufacturing technology. This method prepares a uniform porous titanium alloy material with adjustable unit cell size and pore shape through "selective laser melting forming technology". By optimizing the process parameters of additive manufacturing and selecting appropriate heat treatment, it can be obtained: the effective density is 0.5-2.0g / cm 3 , the strength can reach 600MPa, and the absorption energy can reach 90MJ / m 3 , A uniform porous titanium alloy bulk material with an elastic modulus of 0.1-20GPa. The method of the invention has simple preparation process and low cost, is suitable for industrialized production, and has good application prospects in the fields of aerospace lightweight design, medical treatment, energy absorption and shock absorption, filtration and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for preparing porous ti-6al-4v bulk material with high fatigue performance

The invention relates to porous material preparation, in particular relates to a method for preparing a high fatigue property porous Ti-6Al-4V bulk material, which is used for solving the problem of low fatigue property of the porous Ti-6Al-4V bulk material of the prior art. The method is that an 'electron beam molten metal molding technology' is utilized to prepare the large Ti-6Al-4V bulk material with the porosity of 50%-95% at first, the porous material is then subjected to two steps of thermal treatment of annealing and aging at 400 DEG C and 1000 DEG C, and the Ti-6Al-4V porous material with high fatigue strength, low elasticity modulus of (0.1-20 GPa) and 'the ratio of fatigue strength / compressive strength' of 0.7 is obtained finally. According to the method, the mechanical performance of the porous Ti-6Al-4V pore wall material is controlled through a thermal treatment technology, and thus, a large titanium alloy porous material with excellent fatigue property is obtained and can be widely applied to the fields of aerospace, medical treatment and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of slow and controlled oxygen release microsphere and its preparation method and application

ActiveCN108310470BEasy to control appearanceChange particle sizeTissue regenerationMicrocapsulesInorganic particleMicrosphere

The invention discloses a sustained-release oxygen microsphere as well as a preparation method and application thereof. The sustained-release oxygen microsphere is a microsphere using gelatin as a matrix; the interior of the microsphere contains peroxidated inorganic particles, and preferably, the peroxidated inorganic particles are selected from one or multiple of CaO2 (calcium peroxide), MgO2 (magnesium peroxide), NaCO3 (sodium carbonate), SrO2 (strontium peroxide), BaO2 (barium peroxide), K2O2 (potassium peroxide), and Na2O2 (sodium peroxide). The sustained-release oxygen microsphere has the advantages that the size is controllable, the oxygen release time is long and controllable, the sudden release rate is low, the cell toxicity is low, the immunogenicity is low, the preparation process is relatively simple, the industrialized production is easily realized, and the like; the larger application prospect is realized in clinical application of bone defect repair.

Owner:SOUTHERN MEDICAL UNIVERSITY

Process method of 3D printing solder paste body on printed circuit board

ActiveCN107182172BEasy to control appearanceSolve the problem of easy short circuit in weldingPrinted circuit assemblingEngineeringSolder paste

The invention provides a process method for printing soldering paste bodies on a circuit board in a three-dimensional (3D) manner. The process method is a process method capable of accurately printing soldering paste bodies in a three-dimensional (3D) manner. With the process method adopted, the shapes of the soldering paste bodies are controllable, the coating efficiency of soldering paste is high, and different thickness and different shapes can be realized. According to the technical schemes of the invention, the process method is implemented through following manners: a layer of flux of which the shape conforms to the shape of a pad is printed so as to be adopted as a solder powder fixing medium; a layer of solder powder is printed on the flux at a position where the pad is located; after one independent soldering paste body is obtained through layer-by-layer printing, a next soldering paste body is printed; flux layers and solder powder layers which are printed layer by layer are mixed, so that the soldering paste bodies can be formed in real time in a printing process; the flux layers and solder powder layers are printed alternately so as to form required soldering paste bodies; flux is printed at the last layer, so that the 3D printing of the soldering paste is terminated; and flux and solder powder multi-layer liquid naturally compounded soldering paste body layout distribution of different thicknesses and different shapes can be formed on the same printed circuit board.

Owner:成都联创鸿发科技有限公司

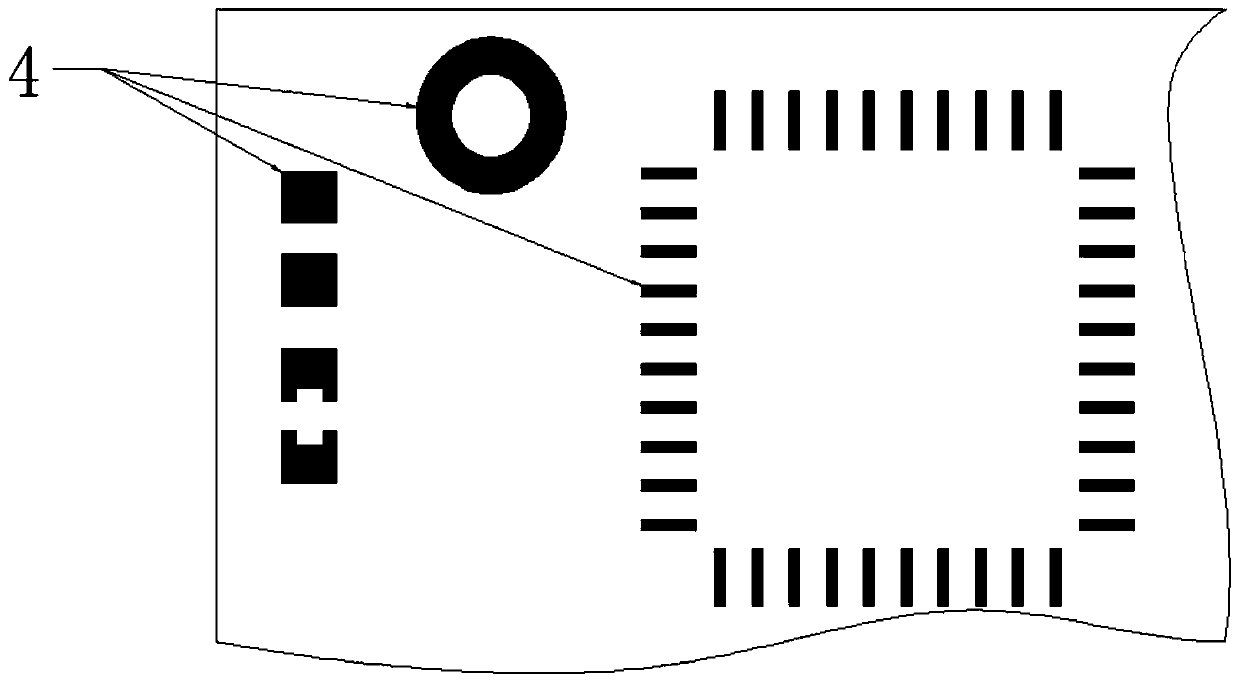

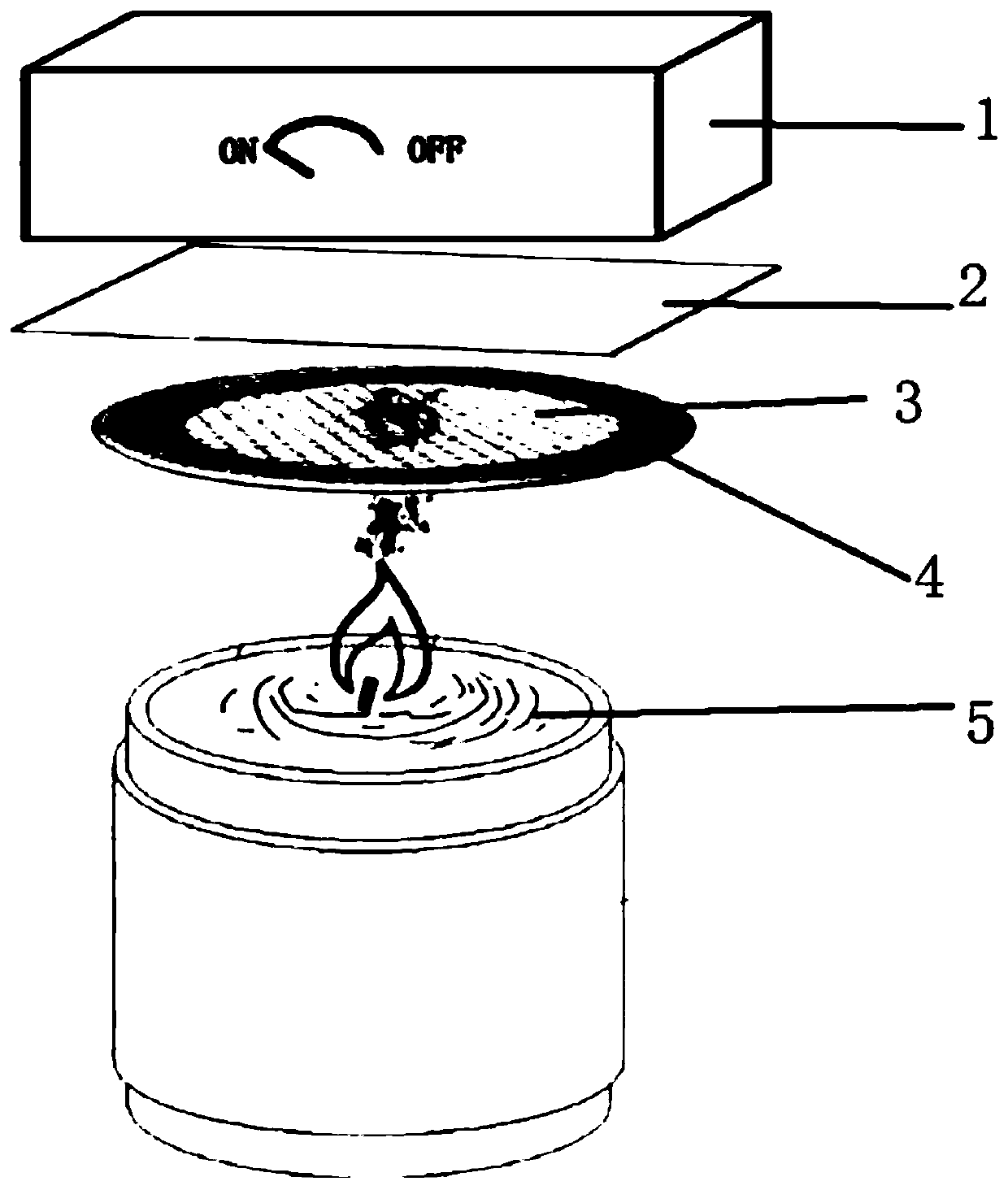

Preparation method for size-controllable amorphous carbon array

InactiveCN110255529ASimple manufacturing methodWide range of materialsNanotechnologyNano-carbonNanotechnologyMagnet

The invention relates to a preparation method for carbon black, specifically to a preparation method for a size-controllable amorphous carbon array. According to the invention, the characteristic that carbon black is simple and easy to prepare is utilized, and carbon black is very uniform and fine (40 nm) and is allowed to enter a template material to prepare a carbon black array; and the characteristics of a magnet switch are skillfully utilized, so the prepared array is not destroyed. The size-controllable amorphous carbon array prepared in the invention can be applied to the fields of gas-solid reactions, computer-simulated calculation and verification, etc.; and the array is simple and easy to operate.

Owner:JIANGSU UNIV

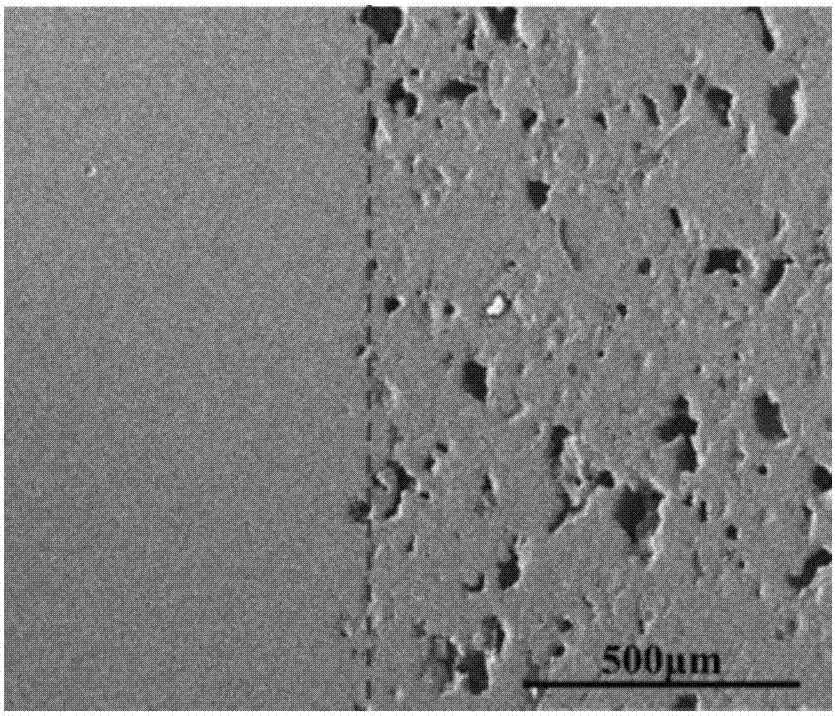

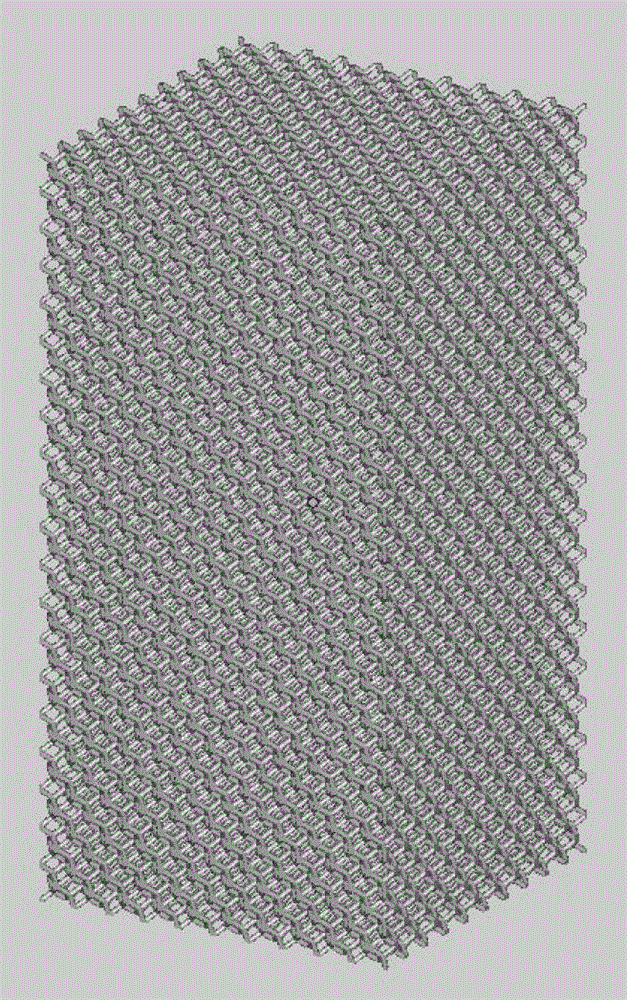

Preparation method of light, high-strength and high-energy-absorption composite material

PendingCN114806133AHigh tensile strengthHigh compressive strengthAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyCompressive strength

The invention relates to the field of composite material preparation, in particular to a preparation method of a light, high-strength and high-energy-absorption composite material, which is suitable for preparing a titanium alloy-polyurea composite material with a three-dimensional interpenetrating characteristic. The method comprises the following steps: preparing an alloy porous material; modifying the surface of the alloy porous material; infiltrating polyurea into the alloy porous material, and carrying out heat treatment; the composite material is formed by compounding a titanium alloy porous material and a polyurea reinforced phase, wherein the porosity of the titanium alloy porous material is 60-80%, and the titanium alloy porous material and the polyurea reinforced phase are printed through an additive manufacturing technology; the two groups of phases are communicated with each other and interspersed in a three-dimensional space; when the density is 2.0-3.5 g / cm < 3 >, the tensile strength of the composite material reaches 200MPa, the compressive strength reaches 600MPa, the recoverable strain reaches 25%, and the absorption energy reaches 50KJ / cm < 3 >. The method is simple in process step and low in production cost, and has good application prospects in the fields of national defense, aerospace, automobiles, energy and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for repairing wear and cracks of blade crown and sealing teeth

ActiveCN110819982BReduce labor intensitySimple processing technologyMetallic material coating processesTurbine bladeMechanical engineering

The invention discloses a method for repairing wear and cracks of blade crowns and sealing teeth. Laser cladding technology is used to repair the worn parts of turbine blade crowns and sealing teeth and the cracks of blade crowns and sealing teeth. It can be cut and processed to restore its external dimensions to the original design geometric dimensions and technical indicators, and can be used again. Laser cladding has the characteristics of rapid melting. Compared with the conventional as-cast structure, the substructure of the laser cladding solidified structure is significantly refined, and a fine and uniform alloy structure can be obtained. The mechanical properties of the turbine blade after laser cladding repair are close to the forging standard.

Owner:AECC AVIATION POWER CO LTD

A shape-controllable humanoid robot based on segmented skin

ActiveCN110561447BEasy modular installationEasy to debugProgramme-controlled manipulatorHuman bodyStructural engineering

The invention discloses a shape-controllable dress form robot based on segmented skins. The dress form robot comprises a plurality of parts which respectively simulate the shapes of buttocks, the chest, the waist and shoulders, wherein each part is composed of an inner shape driving module of a multilayer structure and an outer skin characterized by a segmented curved surface. Each inner shape driving module is composed of a plurality of spatially distributed linear propelling mechanisms, and the linear propelling mechanisms control the deformation of the segmented curved surfaces. By adjusting the propelling amount of the linear propelling mechanisms, the shape of the segmented curved surface pieces is controlled, and the simulation of the transverse shape of a human body is realized. Therelative distance between adjacent parts is controlled by a displacement adjusting supporting mechanism, so that the simulation of the longitudinal height of the human body is realized. The fitting result of the human body is represented by the tights worn on the robot, and the robot can be used for simulating the shape of the human body of a customer in garment customization and simulating the dressing effect of a real person on a garment by the robot in the online and offline garment sale.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com