Coating method of neodymium-iron-boron magnets

A neodymium-iron-boron coating technology, which is applied in the direction of surface coating liquid devices, coatings, anti-corrosion coatings, etc., can solve the problem of poor coating adhesion and salt spray corrosion resistance, poor corrosion resistance, and incomplete maturity and other problems, to achieve the effects of easy control of uniformity, improved corrosion resistance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

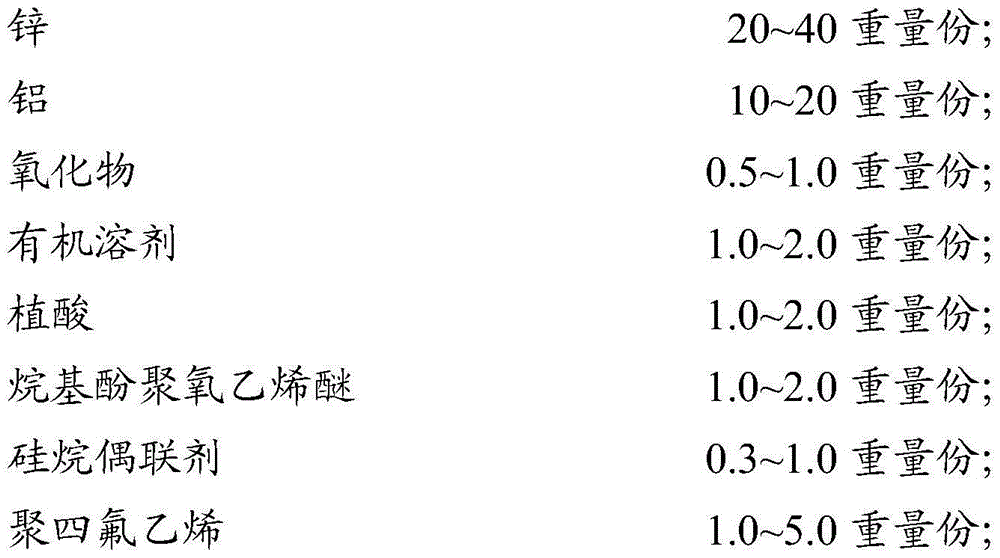

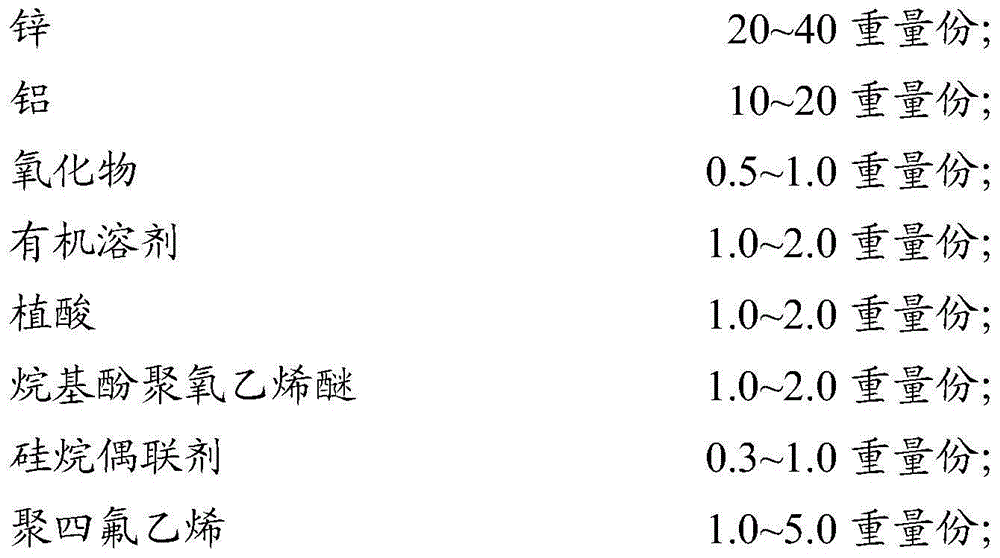

[0069] First weigh 20g of flaky zinc powder with a particle size of 3.2μm, 10g of flaky aluminum powder with a particle size of 3.2μm, 0.5g of magnesium oxide, 1.0g of organic solvent polyethylene glycol, 1.0g of phytic acid, 1.0g of Alkylphenol polyoxyethylene ether, 0.3g of silane coupling agent KH-550 and 1.0g of polytetrafluoroethylene were thoroughly mixed and stirred to obtain a zinc-aluminum coating solution.

[0070] Use 1.5kg of sintered NdFeB permanent magnet material with a size of D40*D24*4mm to vibrate, grind and polish in a vibrating chamfering machine to remove burrs and oxide scales. Then put it in the ultrasonic wave, under the condition of 50℃, pour 20g / L alkaline solution to degrease and degrease the NdFeB magnet. Under certain conditions, use secondary flowing water to clean, and observe the residual solution in the previous process until it is completely cleaned.

[0071] Then put the NdFeB magnet obtained in the above steps into a nitric acid solution wi...

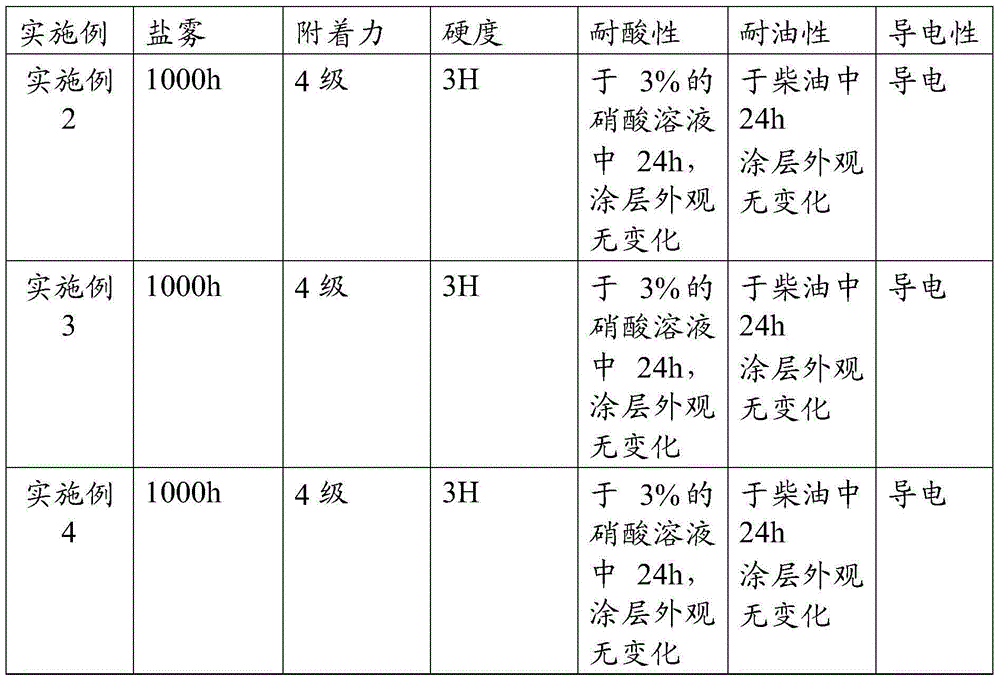

Embodiment 2

[0078] First weigh 20g of flaky zinc powder with a particle size of 3.2μm, 10g of flaky aluminum powder with a particle size of 3.2μm, 0.5g of magnesium oxide, 1.0g of organic solvent polyethylene glycol, 1.0g of phytic acid, 1.0g of Alkylphenol polyoxyethylene ether, 0.3g of silane coupling agent KH-550 and 1.0g of polytetrafluoroethylene are fully mixed and stirred to obtain a zinc-aluminum coating solution; aluminum powder, epoxy resin, polyamide resin , methyl etherified amino resin and organic solvent ethylene glycol, after fully mixing and stirring, obtain epoxy resin containing 150g / L aluminum powder, 450ml / L organosilicon modification, 300ml / L polyamide resin, 300ml / L formazan Organic coating solution for etherified amino resin.

[0079] Use 1.5kg of sintered NdFeB permanent magnet material with a size of D40*D24*4mm to vibrate, grind and polish in a vibrating chamfering machine to remove burrs and oxide scales. Then put it in the ultrasonic wave, under the condition ...

Embodiment 3

[0086] First weigh 20g of flaky zinc powder with a particle size of 3.2μm, 10g of flaky aluminum powder with a particle size of 3.2μm, 0.5g of magnesium oxide, 1.0g of organic solvent polyethylene glycol, 1.0g of phytic acid, 1.0g of Alkylphenol polyoxyethylene ether, 0.3g of silane coupling agent KH-550 and 1.0g of polytetrafluoroethylene are fully mixed and stirred to obtain a zinc-aluminum coating solution; aluminum powder, epoxy resin, polyamide resin , methyl etherified amino resin and organic solvent ethylene glycol, after fully mixing and stirring, obtain epoxy resin containing 150g / L aluminum powder, 450ml / L organosilicon modification, 300ml / L polyamide resin, 300ml / L formazan Organic coating solution for etherified amino resin.

[0087] Use 1.5kg of sintered NdFeB permanent magnet material with a size of D40*D24*4mm to vibrate, grind and polish in a vibrating chamfering machine to remove burrs and oxide scales. Then put it in the ultrasonic wave, under the condition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com