A method for preparing porous ti-6al-4v bulk material with high fatigue performance

A technology of ti-6al-4v and bulk materials, which is applied in the field of preparing porous Ti-6Al-4V bulk materials with high fatigue performance, can solve the problems of low fatigue performance and achieve high fatigue strength, high biocompatibility, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

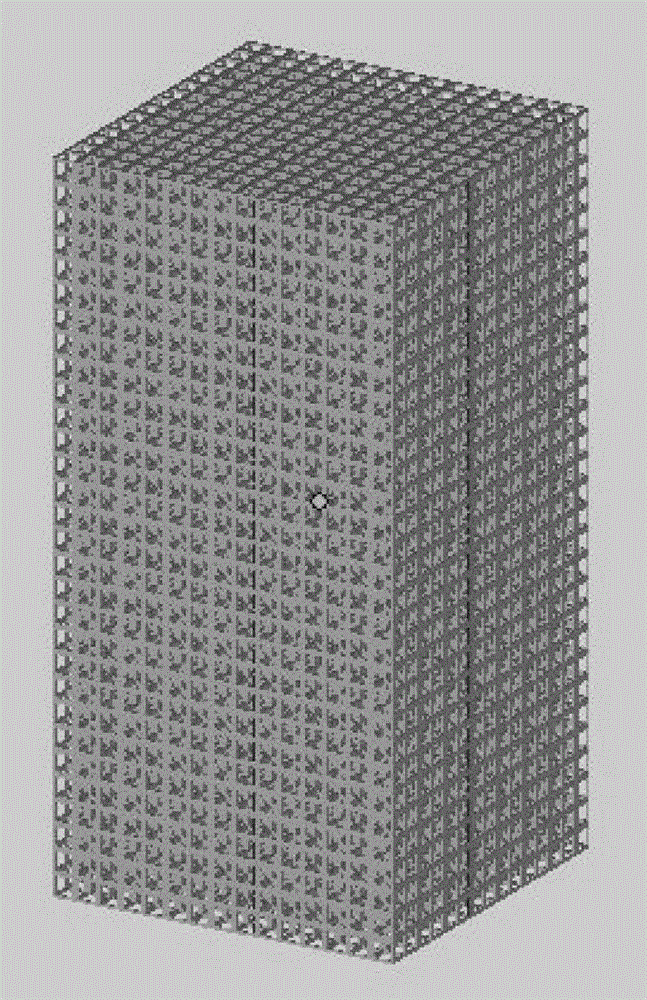

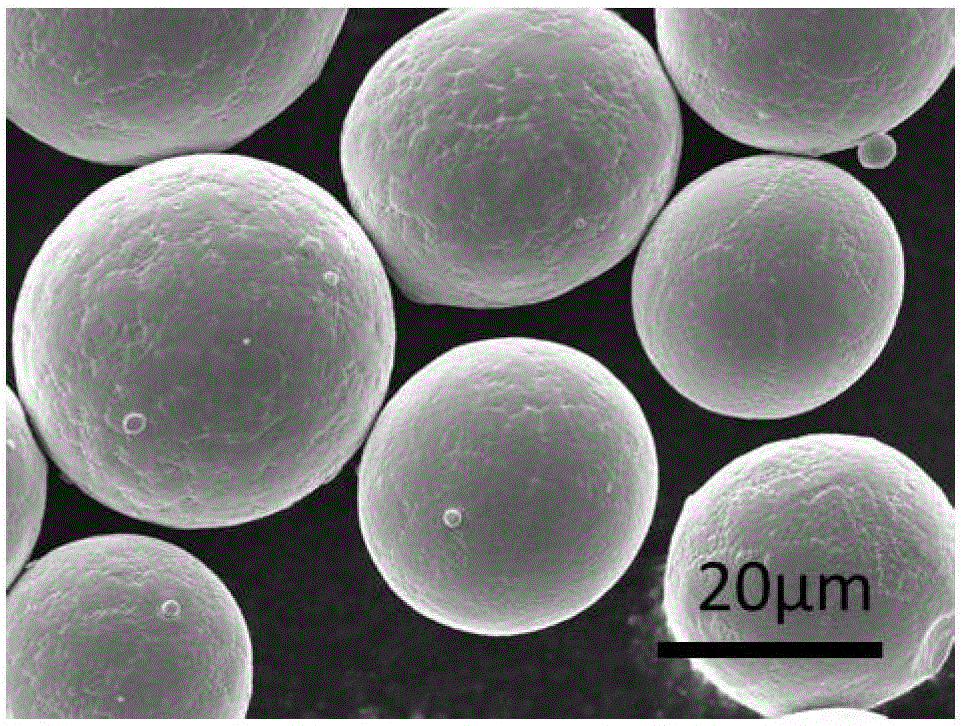

[0041] Use CAD software to design a grid whose unit body is a cube (Fig. 1(a), the grid side length is 2 mm). With Ti-6Al-4V alloy powder ( figure 2 , powder diameter is 50-80μm) as raw material, using ArcamA1 type electron beam melting equipment to prepare porous Ti-6Al-4V bulk material, electron beam scanning speed is 150mm / s, electron beam current is 1.5mA. The prepared Ti-6Al-4V porous material has a porosity of 77%, a pore size of 500 μm, and a density of 1.0 g / cm 3 ( image 3 ).

[0042] In this example, the prepared Ti-6Al-4V porous material is subjected to two-step heat treatment in the two-phase region:

[0043] (1) Two-phase zone annealing treatment Using a vacuum heat treatment furnace, the prepared porous material was heat treated at 800 °C for 1 h, and cooled to room temperature at a rate of 1 °C / min.

[0044] (2) The aging treatment in the two-phase zone uses a vacuum heat treatment furnace at a heat treatment temperature of 500°C for 3 hours, and cools to ro...

Embodiment 2

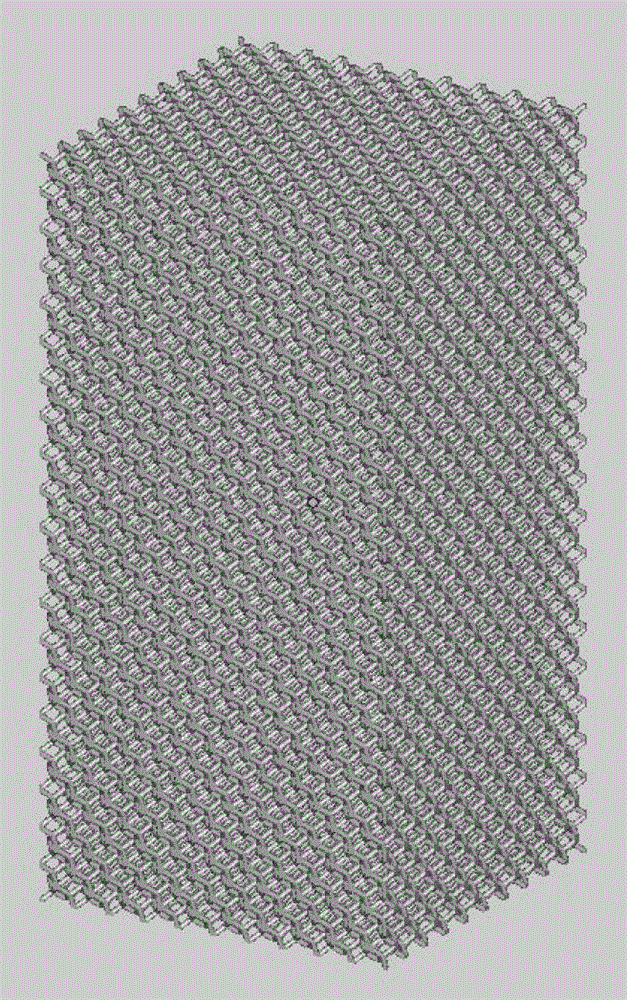

[0047] Use CAD software to design a grid whose unit body is a rhombic dodecahedron (Fig. 1(b), the grid side length is 2 mm). Using Ti-6Al-4V alloy powder as raw material ( figure 2 , the powder diameter is 50-80 μm), and the porous Ti-6Al-4V bulk material is prepared by ArcamA1 electron beam melting equipment, the electron beam scanning speed is 300m / s, and the electron beam current is 2mA. The prepared Ti-6Al-4V porous material has a porosity of 72%, a pore size of 400 μm, and a density of 1.2 g / cm 3 ( Figure 5 ).

[0048] In this example, the prepared Ti-6Al-4V porous material is subjected to two-step heat treatment in the two-phase region:

[0049] (1) Two-phase zone annealing treatment Using a vacuum heat treatment furnace, the prepared porous material was heat-treated at 900°C for 1.5h, and cooled to room temperature at a rate of 2°C / min.

[0050] (2) The aging treatment in the two-phase zone uses a vacuum heat treatment furnace at a heat treatment temperature of 60...

Embodiment 3

[0053] Use CAD software to design a grid whose unit body is a cube (Fig. 1(a), the grid side length is 2 mm). Using Ti-6Al-4V alloy powder as raw material ( figure 2 , the powder diameter is 50-80 μm), and the porous Ti-6Al-4V bulk material is prepared by ArcamA1 electron beam melting equipment, the electron beam scanning speed is 250mm / s, and the electron beam current is 3mA. The prepared Ti-6Al-4V alloy has a porosity of 80%, a pore size of 500 μm, and a density of 0.8 g / cm 3 .

[0054] In this example, the prepared Ti-6Al-4V porous material is subjected to two-step heat treatment in the two-phase region:

[0055] (1) Two-phase zone annealing treatment Using a vacuum heat treatment furnace, heat-treat the prepared porous material at 700°C for 3h, and cool it to room temperature at a rate of 1°C / min.

[0056] (2) The aging treatment in the two-phase zone uses a vacuum heat treatment furnace at a heat treatment temperature of 650°C for 3 hours, and cools to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com