Patents

Literature

35results about How to "Wide performance range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

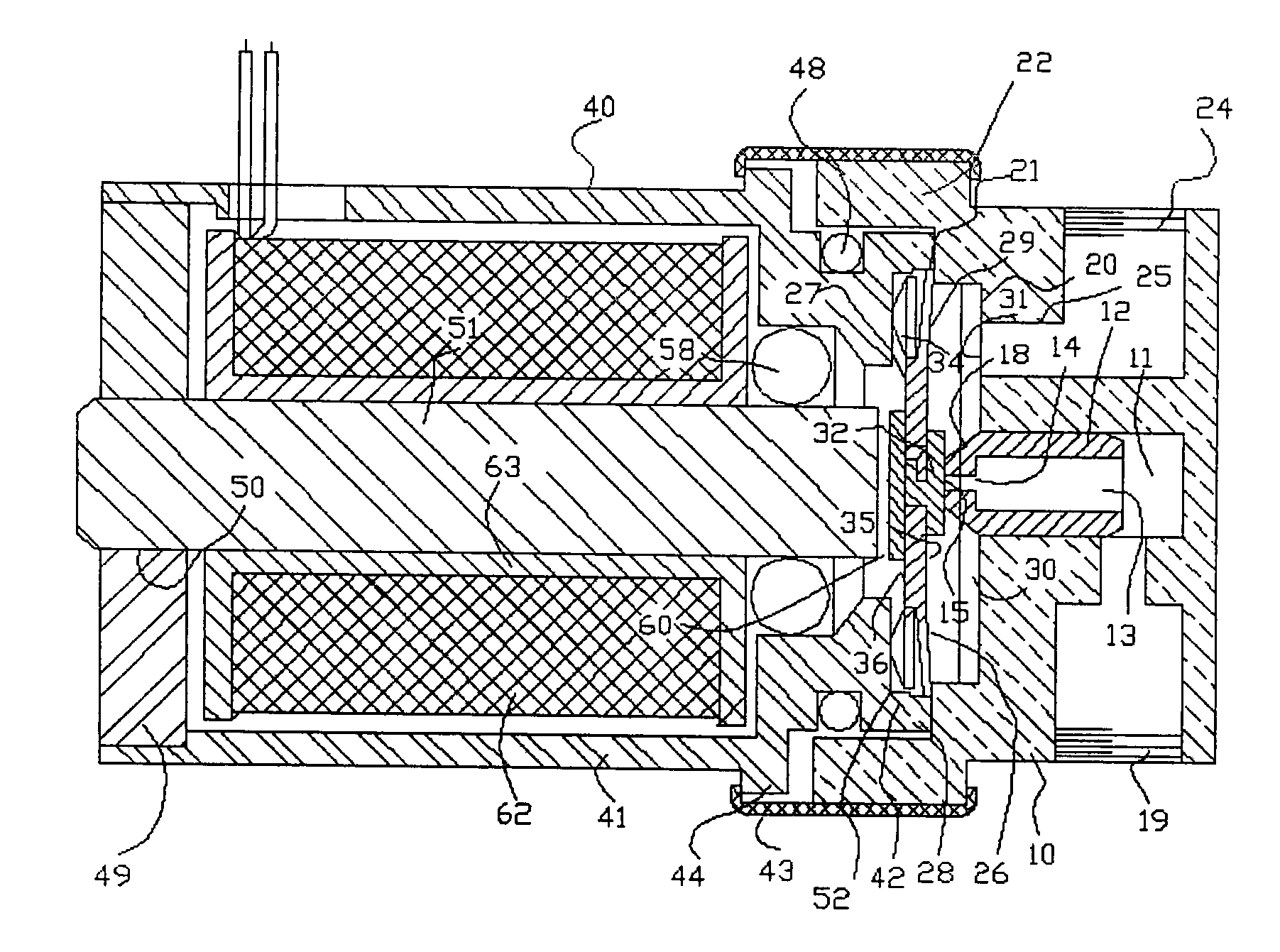

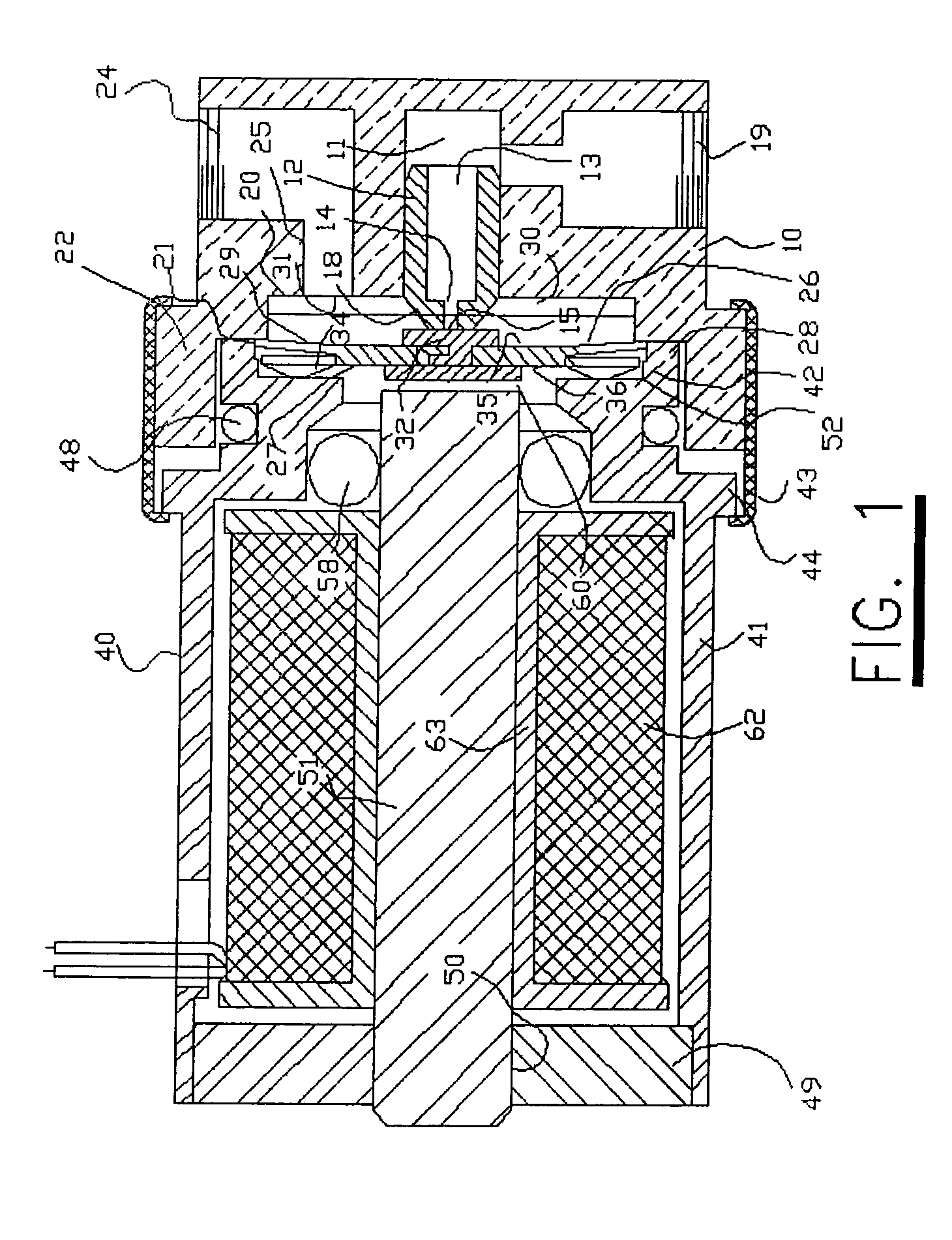

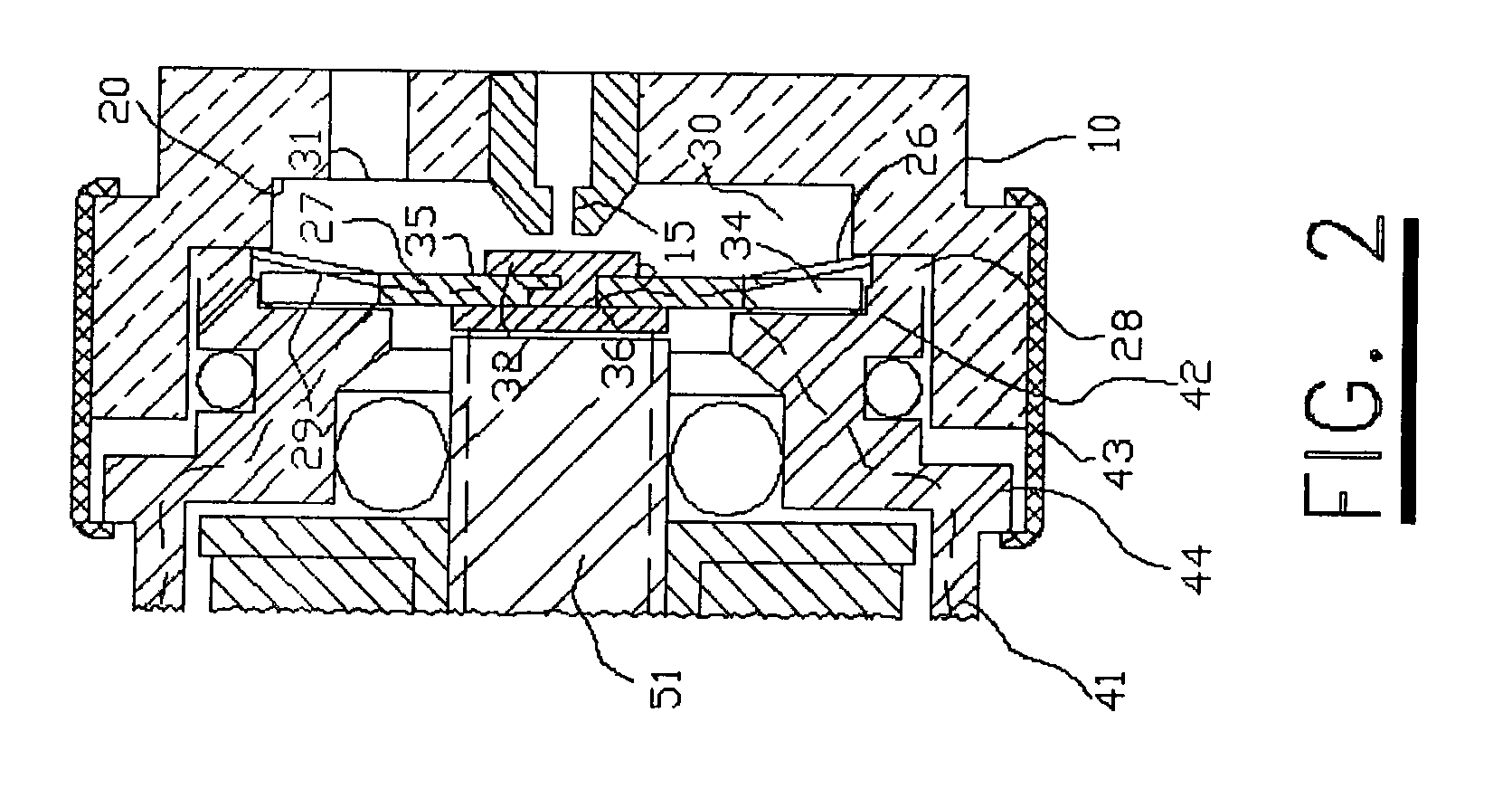

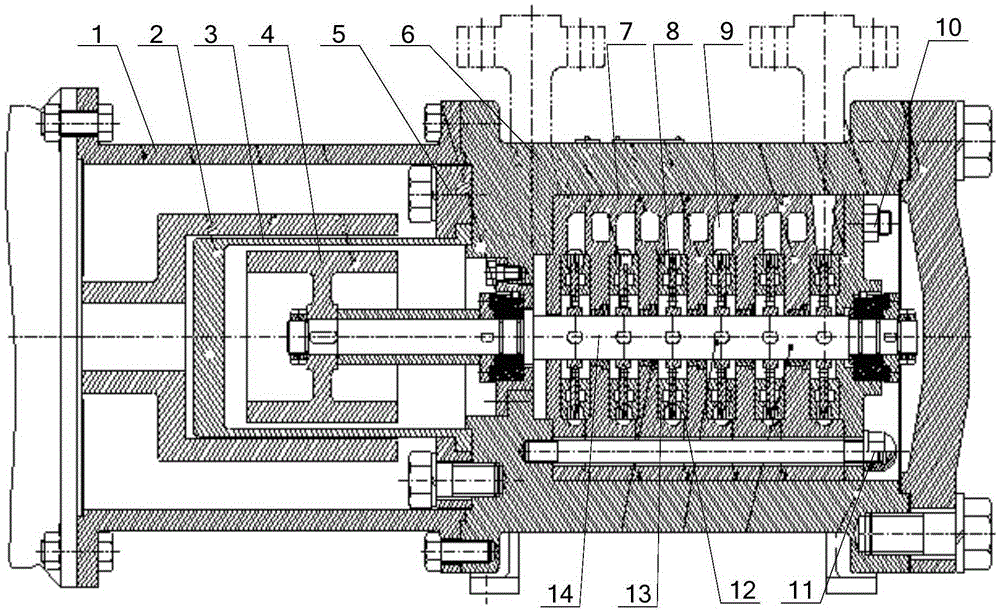

Electrically controlled proportional valve

ActiveUS7748683B1Large range of performanceHigh resolutionOperating means/releasing devices for valvesMachines/enginesElectric controlProportional valve

An electrically controlled proportional valve provides for precise control of armature movement using an armature which is positioned at the center of the valve by centering leaf springs. The armature is supported and biased axially by angled leaf springs that support the armature in an orbital fashion. These angled orbital leaf springs support the armature for elastic movement in the axial direction, and hold it biased against a first port, so that the armature functions as a valve element, which normally closes that port. A magnet coil is positioned so that when an electrical current passes through the coil, it exerts a force on the armature which overcomes the bias of the orbital leaf springs and draws the armature away from the first port and toward the magnet coil.

Owner:KELLY EDMUND F

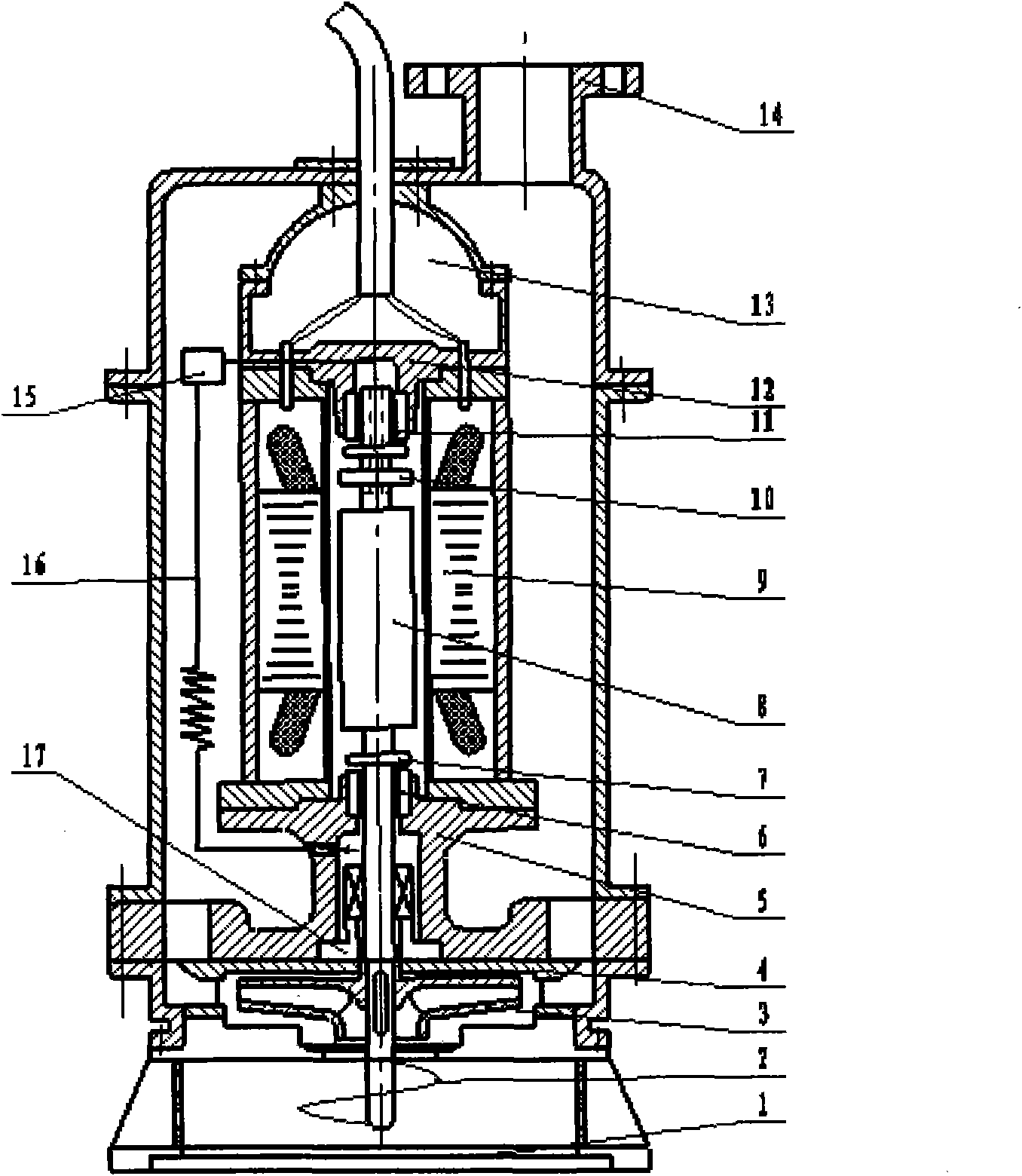

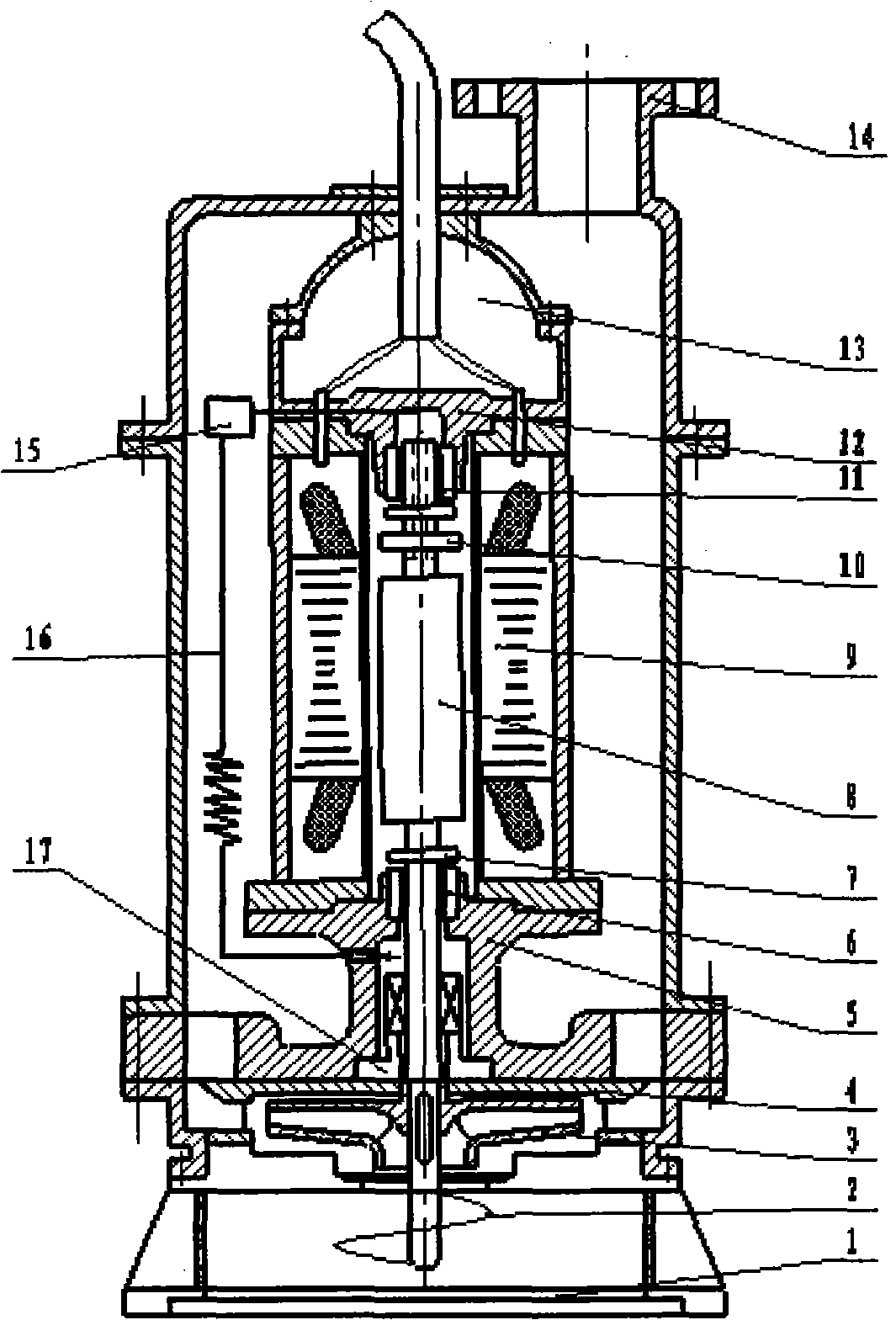

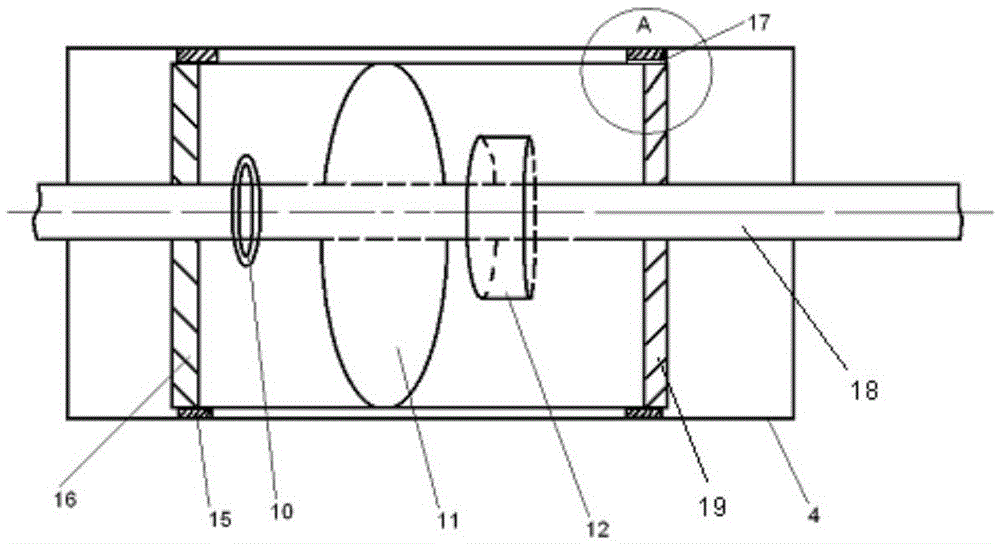

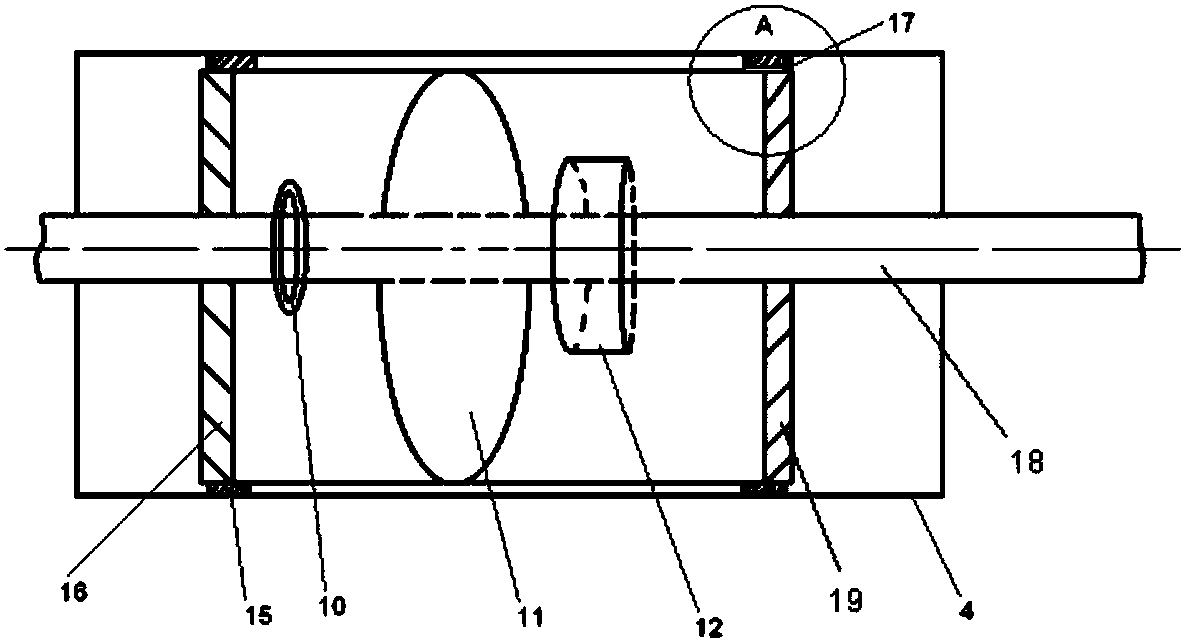

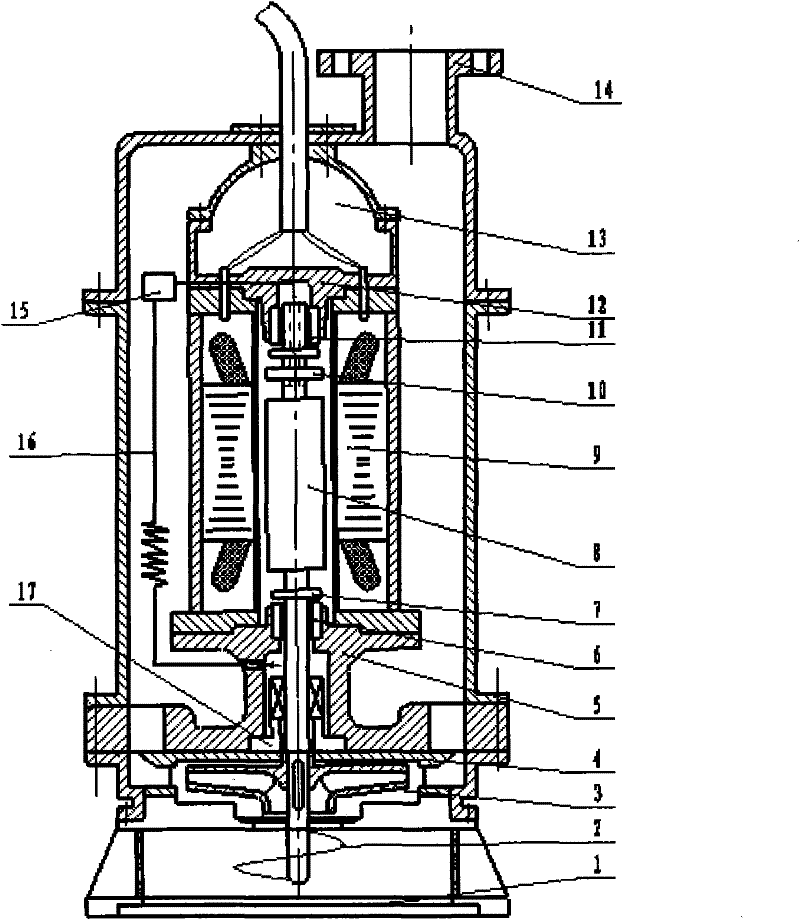

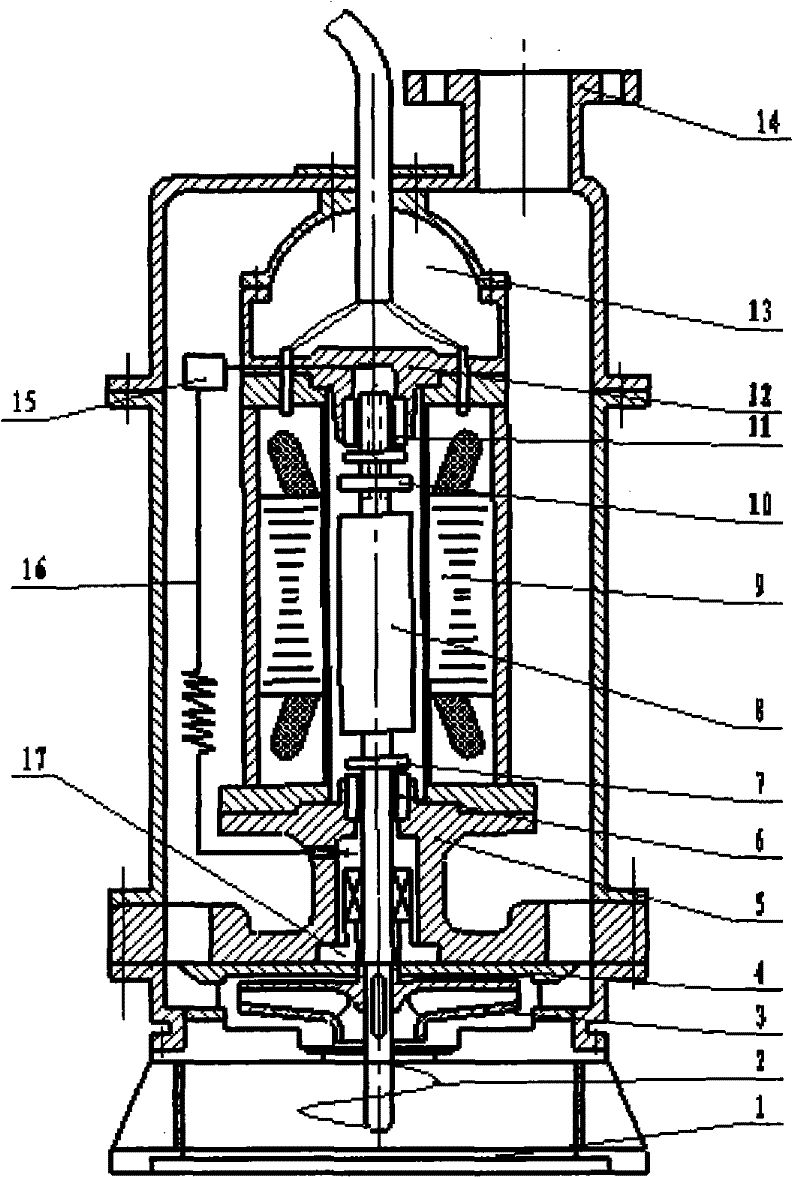

Frequency conversion high-speed wet type submersible pump

InactiveCN101846085AReduce volumeReduce weightPump componentsPump installationsImpellerFrequency conversion

The invention discloses a frequency conversion high-speed wet type submersible pump relating to a fluid mechanical submersible pump and comprising a base (1), an impeller (3), a guide blade (4), a rear pump cover (5), a front sliding bearing (6), a thrust plate (7), a motor, a rear sliding bearing (11), a rear end cover (12), an outlet flange (14), an induction wheel (2), an auxiliary impeller (10), a filter (15) and a cooling pipeline (16), wherein the impeller (3) is connected with a motor shaft and is in a partially flowing or eccentric structure, the front end of the impeller (3) is provided with the variable pitch induction wheel (2), the outlet of the impeller (3) is provided with the guide blade (4); and the motor adopts a frequency conversion motor. The frequency conversion high-speed wet type submersible pump is a novel industrial pump with the advantages of small size, light weight, large lift, high efficiency and wide performance range, and is used for mine production drainage, permeable emergence and rescue and emergence drainage of other occasions.

Owner:JIANGSU UNIV

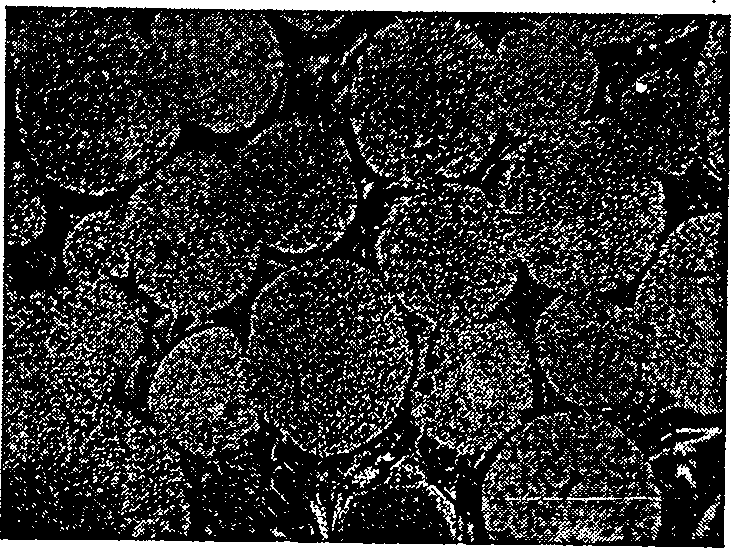

High heat conducting foam material of graphite, and fabricating method

This invention discloses a method for manufacturing high heat-conductive graphite foam material. The method comprises: (1) heating asphalt in a reactor at 1-5 deg.C / min to 260-400 deg.C; (2) pressurizing to 2-6 MPa; (3) heating at 1-2 deg.C / min to 350-550 deg.C; (4) keeping the temperature for 15-120 min, and discharging the gas to obtain asphalt foam material; (5) heating to 950-1100 deg.C under nitrogen protection to obtain carbonized asphalt foam material; (6) heating to 2600-3000 deg.C under nitrogen protection for carbonization, and cooling naturally to obtain high heat-conductive graphite foam material. The pore sizes are 80-800 mum, the density is 0.28-0.75 g / cu cm, the porosity is 55-85%, and the heat conductivity is 68-140 W / mK. The high heat-conductive graphite foam material can be widely used in radiator, heat exchanger, automobile, airplane brake block, catalyst carrier, gas adsorbent and composite material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

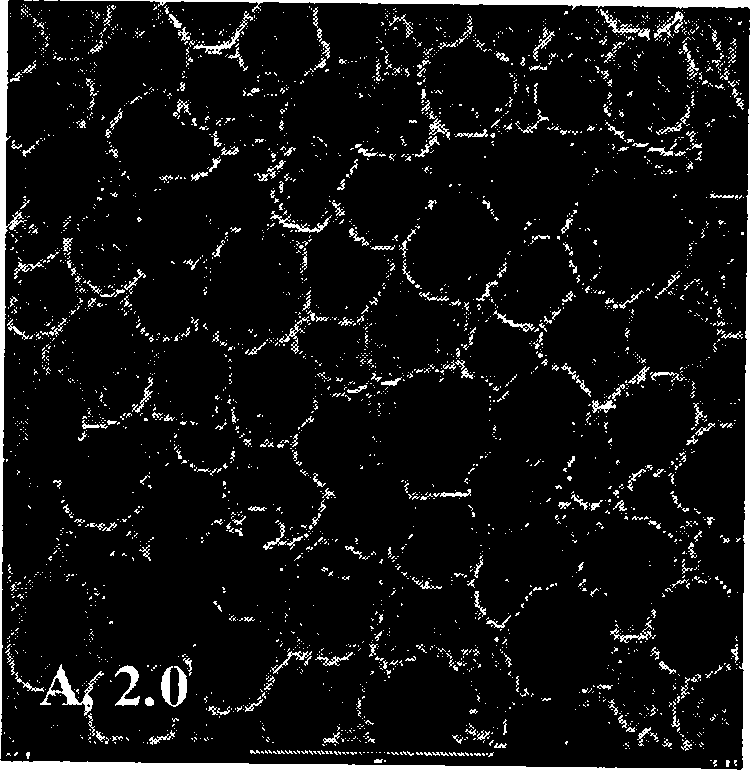

Method for manufacturing high heat conducting foam material of graphite with even apertures

This invention discloses a method for preparing graphite foam material with uniform pore sizes and high heat conductivity. The method comprises: (1) placing mesophase pitch into a high-pressure reactor, adding surfactant, mixing uniformly, vacuumizing, heating to 260-350 deg.C, pressurizing to 2-6.0 MPa, heating to 450-650 deg.C, keeping for 15 min-2 h, cooling, and exhausting to obtain pitch foam; (2) heating the pitch foam at a heating rate not higher than 1 deg.C / min to 950-1100 deg.C, and carbonizing under nitrogen protection to obtain carbonized pitch foam; (3) heating the carbonized pitch foam at a heating rate not higher than 1 deg.C / min to 2500-3000 deg.C under Ar protection, and cooling naturally to obtain graphite foam material with high heat conductivity. The obtained graphite foam material can be widely used in radiators, heat exchangers, brake pads of automobiles and planes, catalyst carriers, and gas adsorbents.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

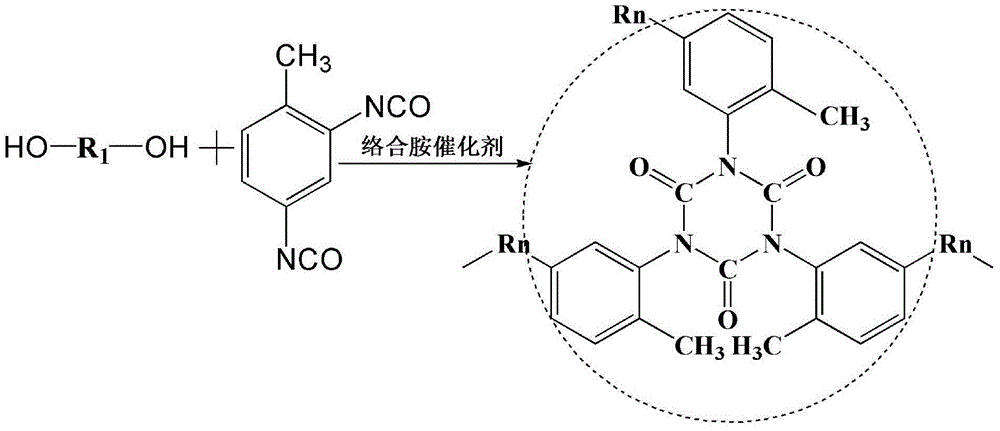

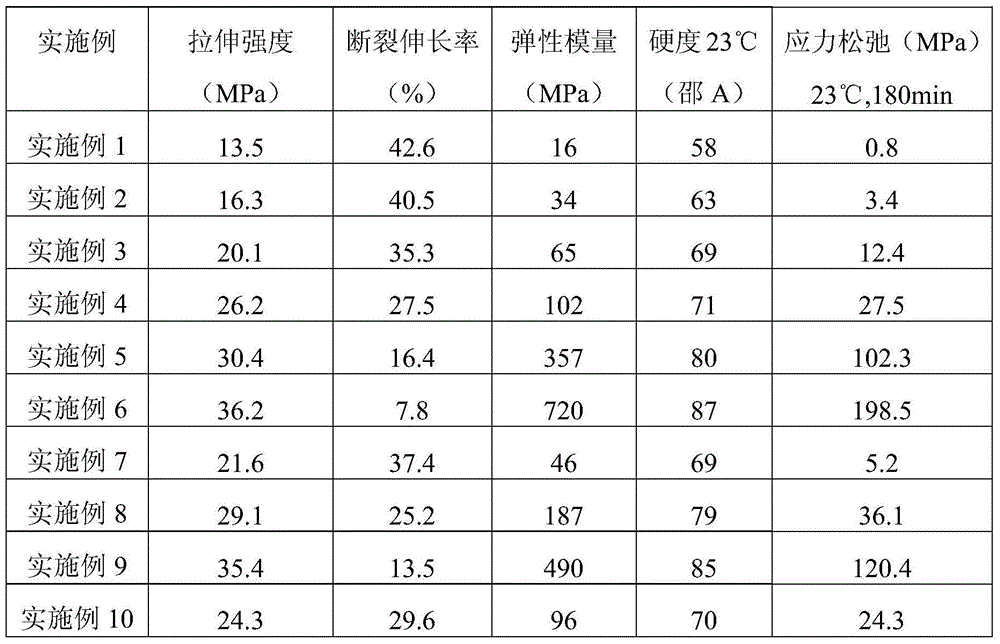

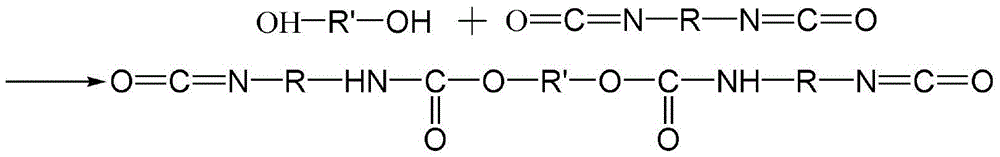

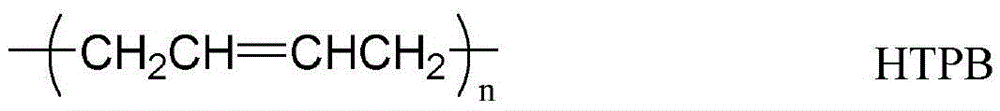

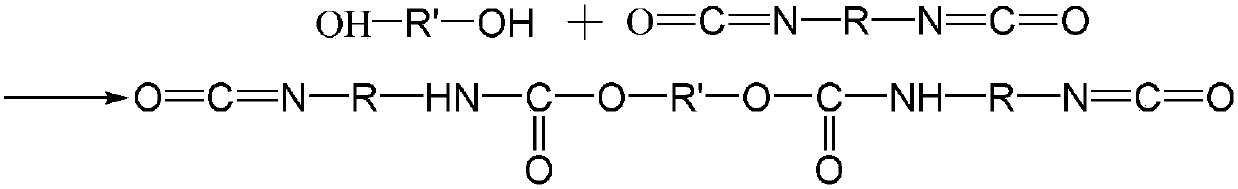

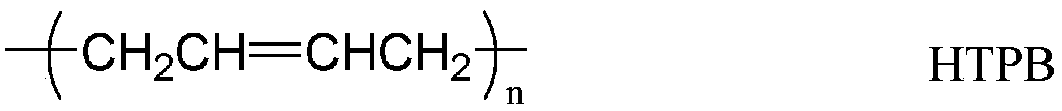

One-step synthesis method for polyurethane material with gradually-changing modulus

InactiveCN104961877AWide performance rangeArbitrary control of elastic modulusCross-linkSynthesis methods

The invention provides a one-step synthesis method for a polyurethane material with gradually-changing modulus. The prepared polyurethane material with gradually-changing modulus is an interpenetrating polymer network material with a gradually-changing component; the component is a single polyurethane component; and the polyurethane material does not contain an interface, and the elastic modulus and all the other physical properties of the polyurethane material continuously change along a length direction in a same sample. A highly cross-linked polymer network is composed of hard cross-linking points with large sizes and flexible short chains with prescribed length; and even without addition of a plasticizer and a filling material, the elastic modulus of the system is allowed to vary in a wide scope by changing the sizes of the cross-linking points. The synthesis method overcomes the problem of difficult block copolymerization process caused by great increase of system viscosity in a urethane formation phase in a two-step method and the problem of complex steps like dipping of a carrier, drying of the carrier after dipping and removal of a solvent in a manufacturing of a composite material via a solution method; and the synthesis method has high efficiency, is environment-friendly and has high industrial feasibility.

Owner:BEIJING UNIV OF CHEM TECH +1

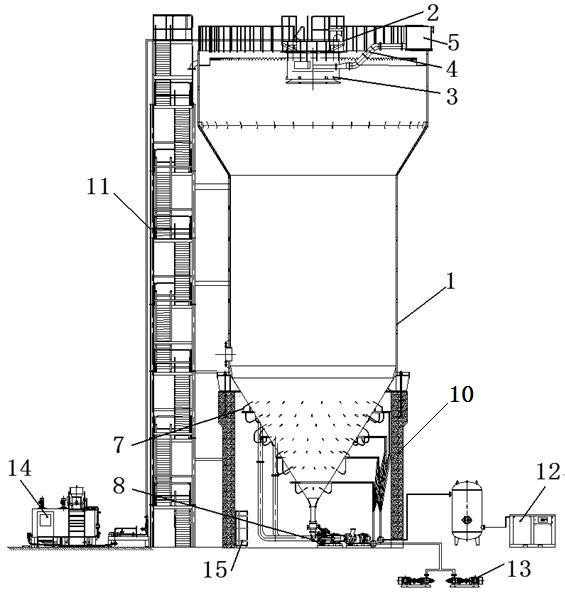

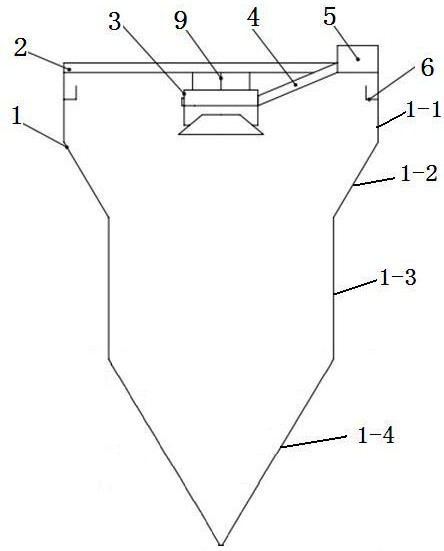

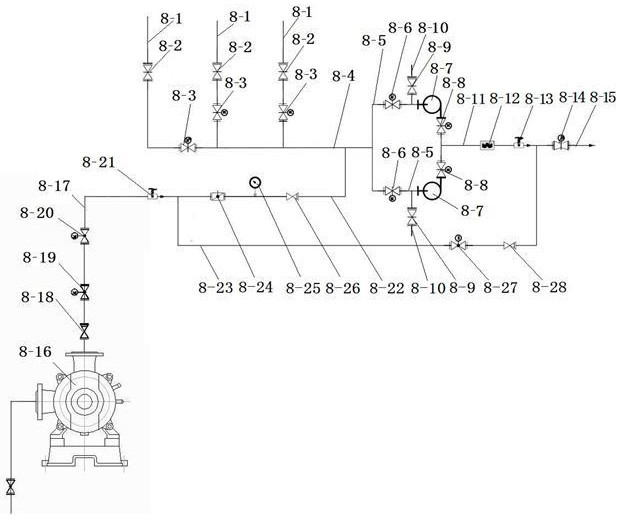

Fine-fraction high-concentration tailing filling and thickening device

ActiveCN113513363AImprove concentrationImprove the cycle efficiency of mining and chargingWaste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

The invention discloses a fine-fraction high-concentration tailing filling and thickening device which comprises a tank body part, a wind-water slurry making system, an underflow conveying system, an electric control system, a flocculating agent preparing and adding system and the like. The wind-water slurry making system comprises an annular water pipe group and an annular gas pipe group; annular water pipes of all layers of the annular water pipe group and annular air pipes of all layers of the annular air pipe group are located at different height positions and distributed in an inverted cone shape, the annular water pipes and the annular air pipes of each layer are respectively connected with a plurality of high-pressure rubber water (air) spraying pipes, valves and external water (wind) slurry making nozzles; and the annular water pipes are connected with a water supply and drainage header pipe, and the annular air pipes are connected with an air supply and exhaust header pipe. By means of the fine-fraction high-concentration tailing filling and thickening device, the material storage capacity is large, the mining and filling circulation efficiency of a mine is improved, no power part exists, fault points are few, power consumption is low, and the operation cost is low; and long-time continuous steady-state slurry discharging is achieved, the stability of technological parameters and the working efficiency of filling operation are improved, the concentration capacity of the thickening device is improved, and the continuity of filling operation of the thickening device is guaranteed.

Owner:山金重工有限公司

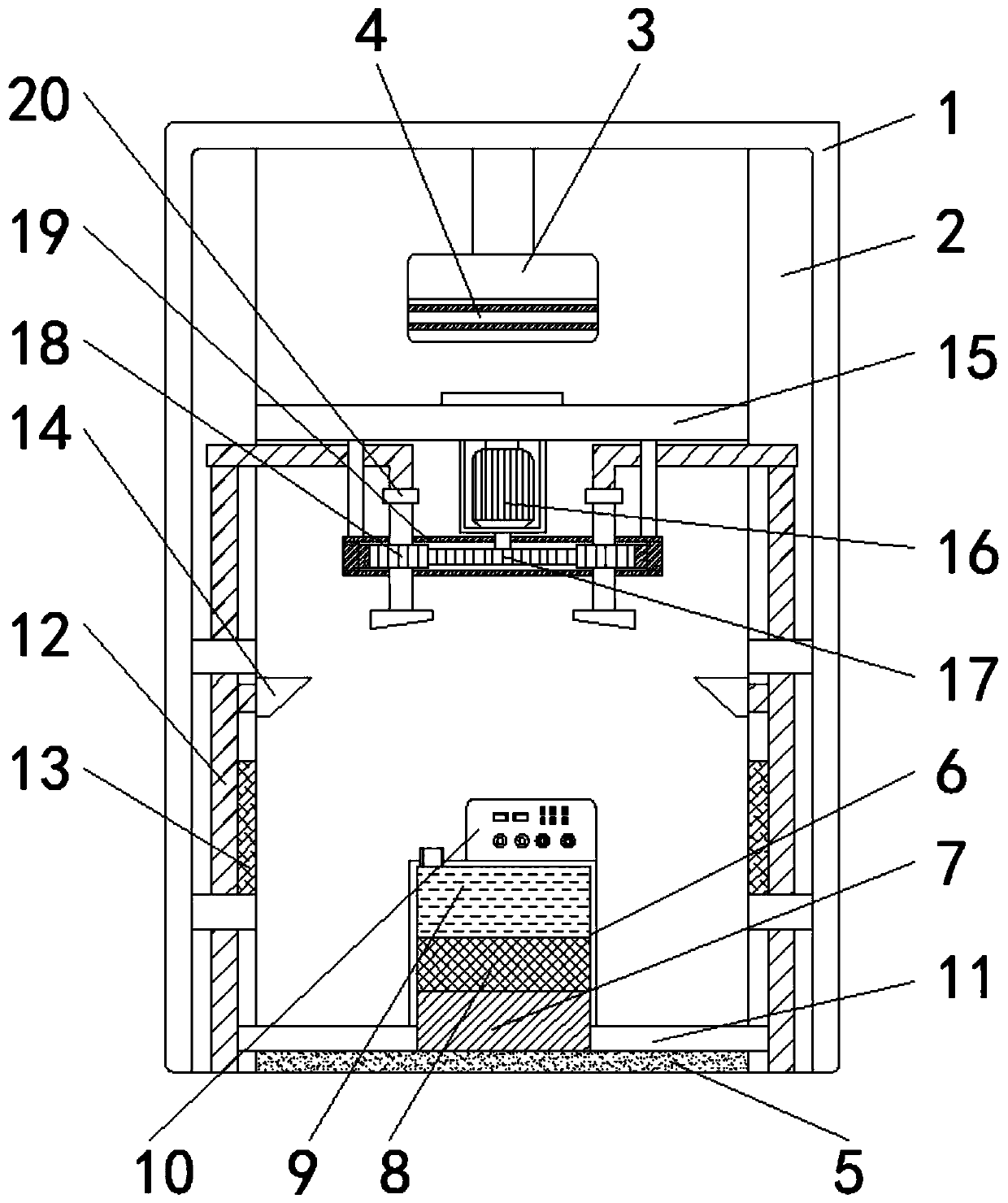

Automatic personnel disinfection channel

InactiveCN109718389AImprove retentionAvoid wastingLavatory sanitoryChemicalsAgricultural engineeringHigh pressure

The invention relates to the technical field of disinfection equipment, and discloses an automatic personnel disinfection channel. The disinfection channel comprises a channel, isolation plates are fixedly arranged on the left side and the right side of the inner wall of the channel, a fan is fixedly arranged on the inner top wall of the channel, a regulating plate is fixedly arranged on the bottom of the fan, a carpet is fixedly arranged on the inner bottom wall of the channel, a shell is fixedly arranged on the top of the carpet, a high-pressure machine is fixedly arranged in the shell, an atomizing machine is fixedly arranged in the shell and on the top of the high-pressure machine, a disinfection water tank is fixedly arranged in the shell and on the top of the atomizing machine, a control host is fixedly arranged on the top of the shell, shunt pipes are fixedly arranged on the left side and right side of the high-pressure machine, and the reverse sides of the two shunt pipes are fixedly connected to delivery pipes. The automatic personnel disinfection channel has the advantages of no dead angle, convenient use and no harm to human body.

Owner:江苏乾宝牧业有限公司

High-strength high-conductivity Cu-Fe-Al conductor material and preparation method thereof

InactiveCN101974699AWide performance rangeLow costMetal/alloy conductorsShrinkage rateRoom temperature

The invention discloses a high-strength high-conductivity Cu-Fe-Al conductor material and a preparation method thereof. The high-strength high-conductivity Cu-Fe-Al conductor material comprises the components in percentage by weight: 0.1-3 percent of Fe, 0.1-2 percent of Al and the balance of Cu. The preparation method comprises the following steps of: firstly, placing the Cu and the Al into a vacuum induction furnace; melting at atmospheric pressure which is lower than 0.1Pa; after standing to degas at the temperature of 1000-1100DEG C, inflating Ar into the vacuum induction furnace to the atmospheric pressure of 50-60kPa; adding and melting the Fe; evenly stirring in an electromagnetic manner and casting into a rod-shaped cast ingot with a specific diameter; hardening and cooling the cast ingot after heat treatment of 950-1000DEG C for 1-2 hours; carrying out aging treatment for 0.5-12 hours at the temperature of 200-500 DEG C; and next, coldly drawing an alloy with multi-passes at room temperature until a section shrinkage rate is 90-99 percent. The prepared Cu-Fe-Al alloy has strength of 400-80MPa and electrical conductivity of 60-95 percent IACS, comprises three metal elements of Cu, Fe and Al with rich storage and cheap cost, has an obvious price advantage and wide alloy performance range at the same time. The matching of various strengths and electrical conductivities can be obtained by regulating a preparation technology, thus the actual demands of application in all directions are satisfied.

Owner:CHINA JILIANG UNIV

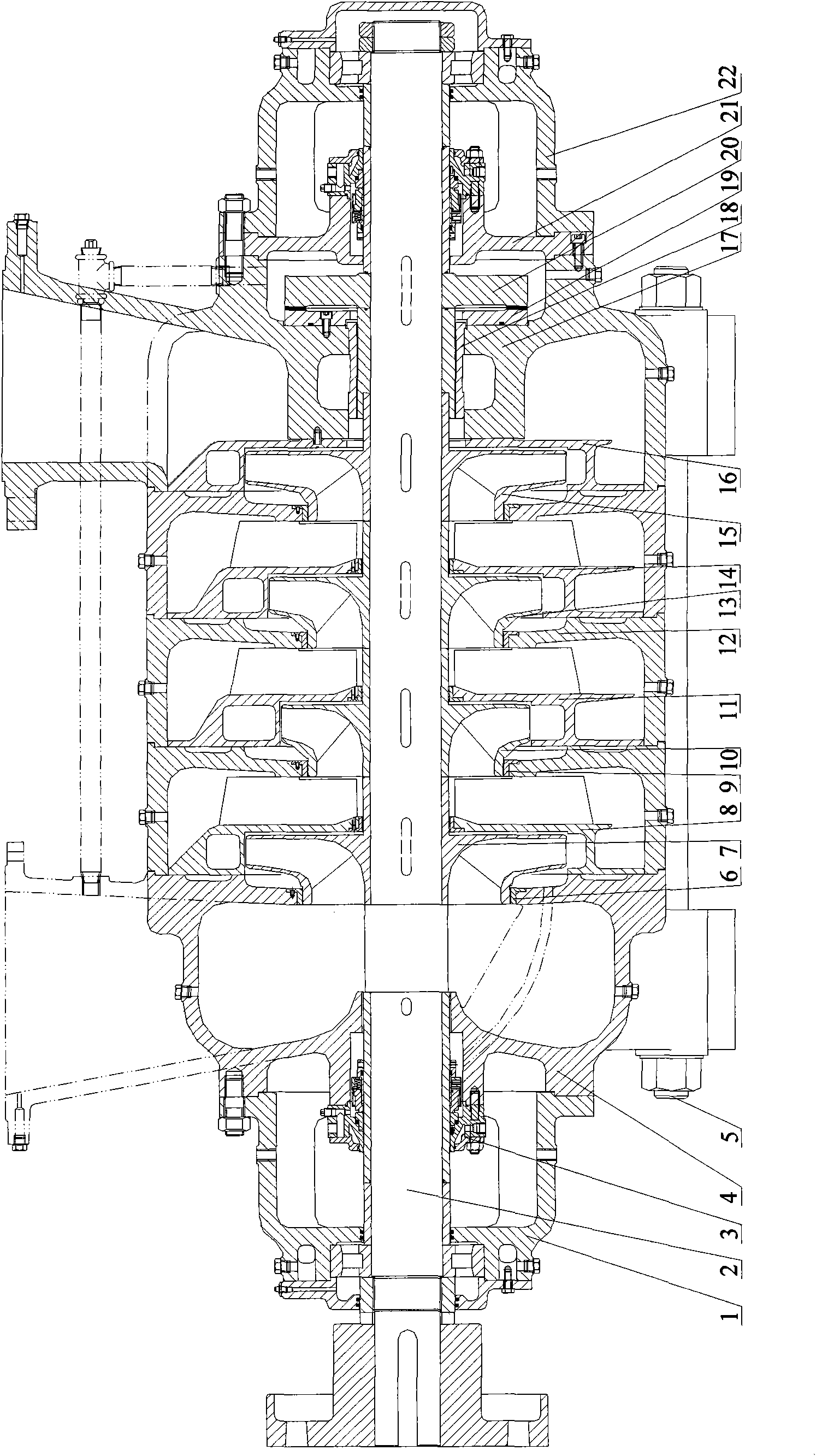

Multi-stage centrifugal pump with improved impeller arrangement

InactiveCN102465882AWide performance rangeImprove versatilityPump componentsRadial flow pumpsEngineeringSingle type

The invention relates to a multi-stage centrifugal pump with improved impeller arrangement. The centrifugal pump comprises impellers sheathed on a shaft of the centrifugal pump, wherein the impellers comprise a first-stage impeller, a 1 / 2-stage impeller, a 2 / 3-stage impeller and an inter-stage impeller, and the first-stage impeller, the 1 / 2-stage impeller, the 2 / 3-stage impeller and the inter-stage impeller are sequentially connected in series and are sheathed on the shaft of the centrifugal pump. Compared with the prior art, the multi-stage centrifugal pump has the advantages that the performance range of the single-type pump is greatly expanded, the product types are reduced, the universality is enhanced, the pump performance is similar to the actual work condition, the pump can operate in efficient regions, energy sources are saved, in addition, the one-time investment under the complicated work condition is reduced, and the adjustability of the product performance is enhanced.

Owner:上海福思特流体机械有限公司

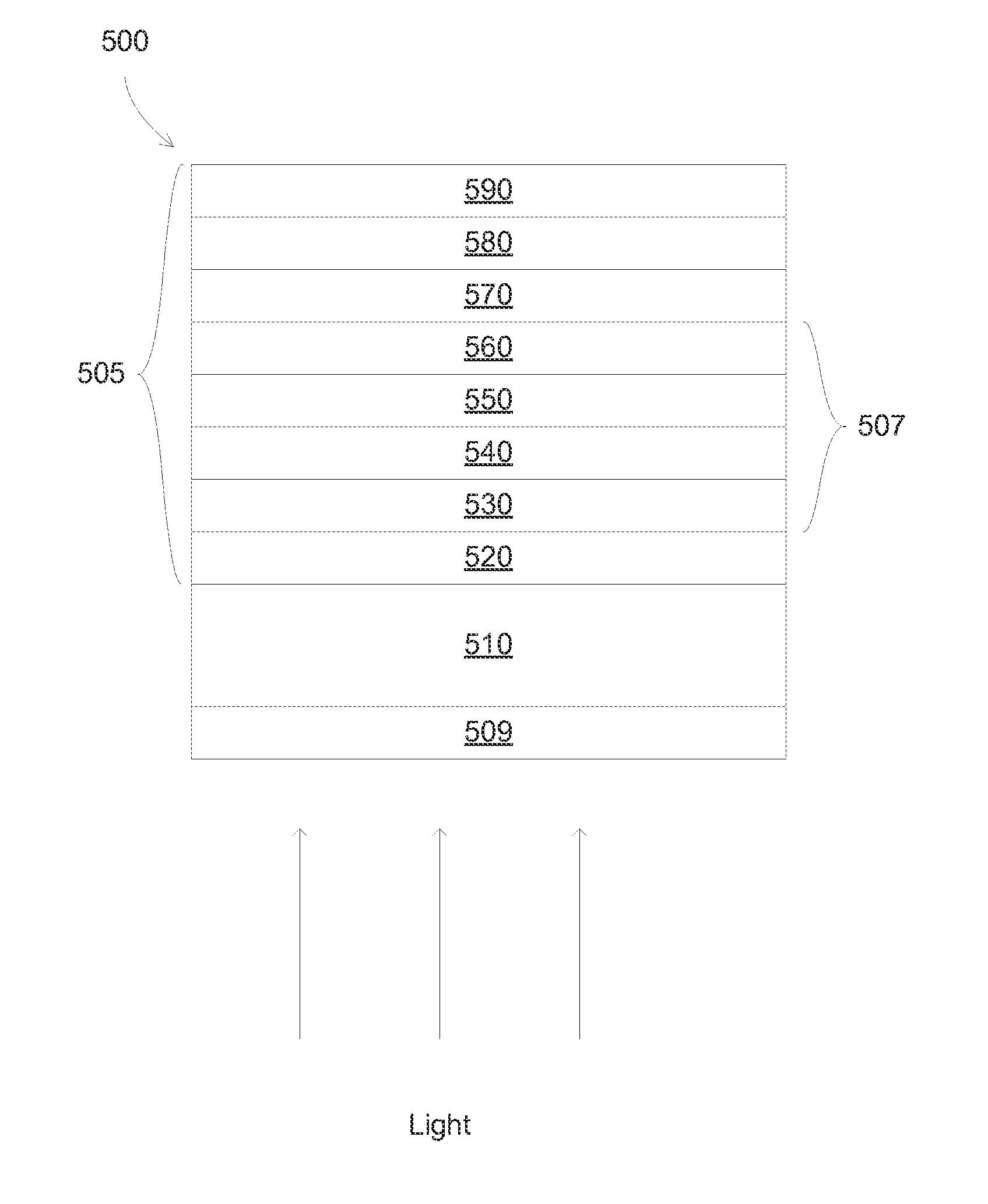

Low Emissivity Glass Incorporating Phosphorescent Rare Earth Compounds

InactiveUS20150291812A1Large range of performanceMinimal color changeLiquid surface applicatorsElectric discharge heatingRare-earth elementLow emissivity

Methods, and coated panels fabricated from the methods, are disclosed to form multiple coatings, (e.g., one or more infrared reflective layers), with minimal color change before and after heat treatments. The optical properties of the coating (e.g. the transmissivity and the IR emissivity) are generally coupled. In some embodiments, silicate materials are doped with rare earth elements. These doped silicate materials are able to absorb ultra-violet (UV) photons and emit photons in the visible range. This allows the transmissivity to be at least partially decoupled from the IR emissivity of the coated panel, resulting in a larger range of performance.

Owner:INTERMOLECULAR +1

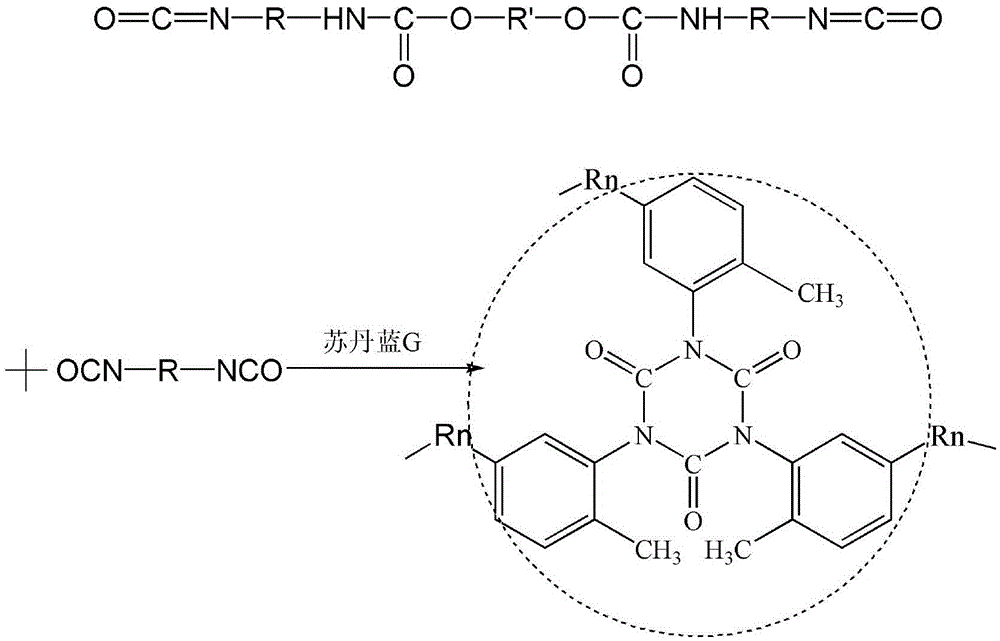

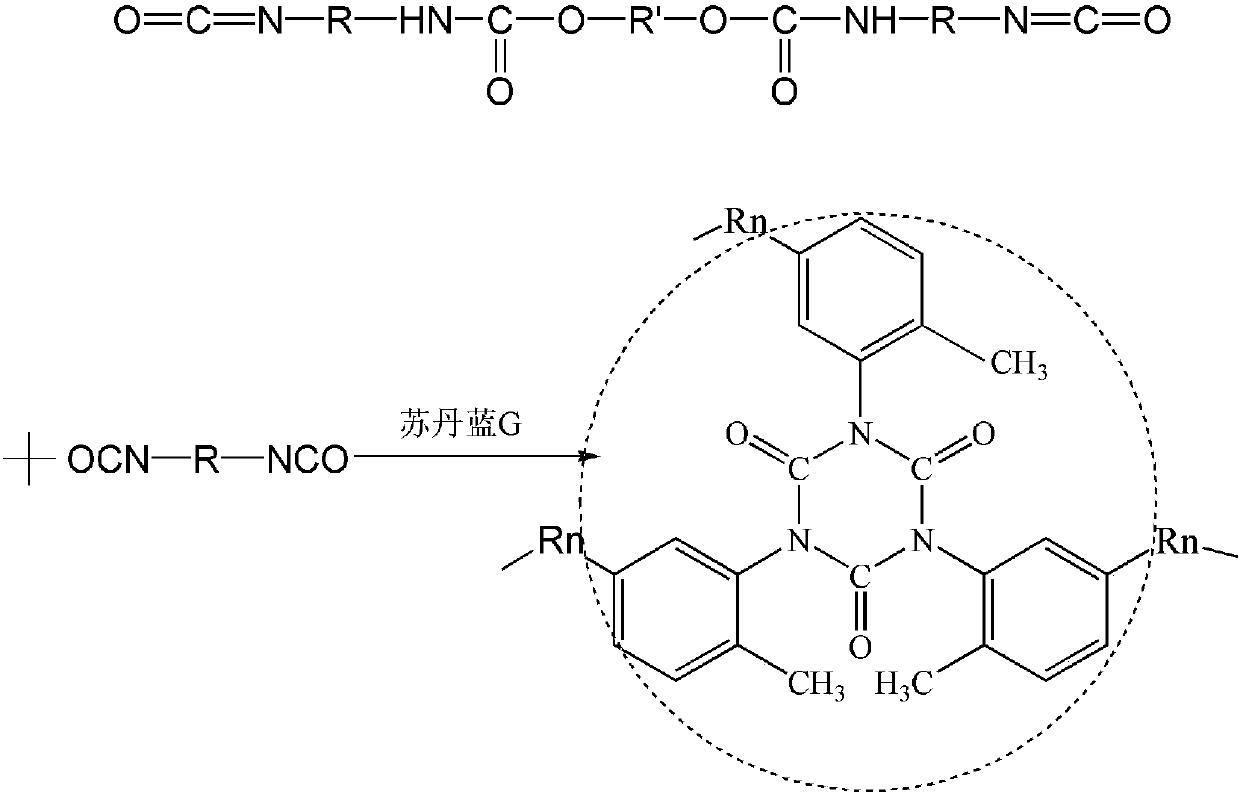

Preparation method of polyurethane-polyisocyanurate thin-film graded material

The invention discloses a preparation method of a polyurethane-polyisocyanurate thin-film graded material. The preparation method comprises the steps that aromatic diisocyanate and oligomer diol are used as raw materials, organic tin and Sudan blue are used as catalysts, a polyurethane-polyisocyanurate cross-linked network is prepared through urethane forming reaction and polycyclic trimerization reaction, and then a solution containing a reactor and the catalysts is poured into a hydrophobic mold to obtain a thin film through curing. Reaction mixture solutions different in proportion are poured onto a horizontal polycyclic surface, so that one surface of the prepared graded thin film is higher in elasticity modulus, the other surface of the prepared graded thin film is lower in elasticity modulus, the elasticity modulus in the thickness direction of the thin film changes from one surface to the other surface in a graded mode, no interface exists, the gradient change from soft rubber to rigid plastic of the prepared thin film in the thickness direction is presented macroscopically, the shortcomings of the brittleness and fragility of plastic thin films can be overcome, and the problem that the elasticity modulus of the rubber thin film changing with strain change can be also solved.

Owner:YANCHENG INST OF TECH

Fabricating method of high heat conducting foam material of graphite

This invention discloses a method for manufacturing high heat-conductive graphite foam material. The method comprises: (1) heating asphalt in a reactor at 1-5 deg.C / min to 260-400 deg.C; (2) pressurizing to 2-6 MPa; (3) heating at 1-2 deg.C / min to 350-550 deg.C; (4) keeping the temperature for 15-120 min, and discharging the gas to obtain asphalt foam material; (5) heating to 950-1100 deg.C under nitrogen protection to obtain carbonized asphalt foam material; (6) heating to 2600-3000 deg.C under nitrogen protection for carbonization, and cooling naturally to obtain high heat-conductive graphite foam material. The pore sizes are 80-800 mum, the density is 0.28-0.75 g / cu cm, the porosity is 55-85%, and the heat conductivity is 68-140 W / mK. The high heat-conductive graphite foam material can be widely used in radiator, heat exchanger, automobile, airplane brake block, catalyst carrier, gas adsorbent and composite material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

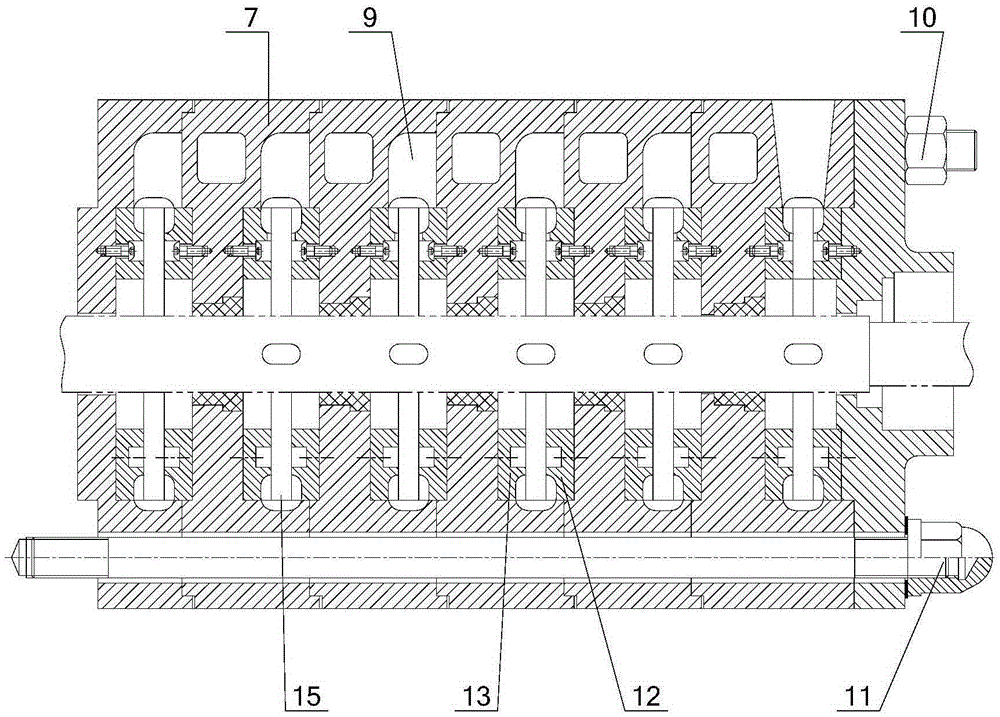

Magnetically driven horizontal vortex pump

InactiveCN105332909AWide performance rangeMeet water injection needsDynamo-electric gearsRotary piston pumpsCouplingEngineering

The invention discloses a magnetically driven horizontal vortex pump. The magnetically driven horizontal vortex pump comprises a pump housing with a water inlet and a water outlet, a rotor module, a stator module and a driving device, wherein the rotor module comprises a pump shaft which is arranged in the pump housing in a penetrating manner and is provided with two vortex wheels at least; the stator module comprises a pump unit consisting of at least two pump bodies arranged in the axial direction of the pump shaft, annular pump runners and a space transition runner used for communicating all the annular pump runners are arranged on the pump body, and the annular pump runners of the pump bodies at the two ends of the pump unit are respectively communicated with the water inlet and the water outlet of the pump housing; and the driving device is connected with the pump shaft through a magnetic coupling. The vortex pump has the characteristics of small flow and high lift. Through a spacer sleeve, an inner magnetic rotor and a medium are isolated from an outer magnetic rotor, so that full seal is realized. As long as the vortex wheels are increased or reduced according to requirements, the magnetically driven horizontal vortex pump can safely and reliably run so as to meet different water injecting requirements, and the performance range of the vortex pump is enlarged. Due to the adoption of a modular structure, the magnetically driven horizontal vortex pump is convenient to disassemble and maintain and low in use cost.

Owner:兰州海兰德泵业有限公司

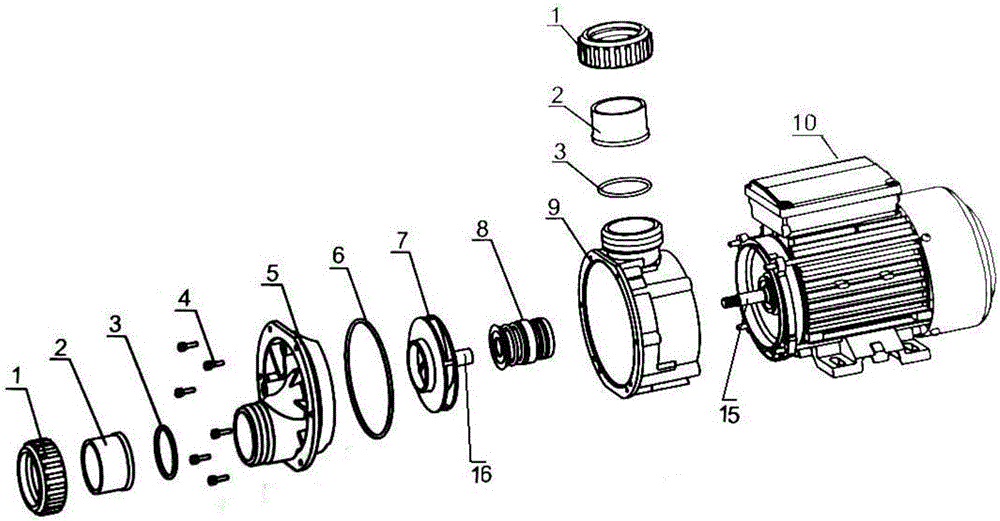

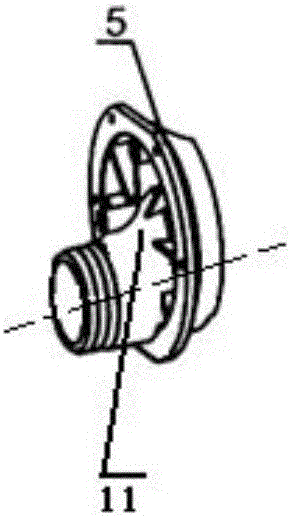

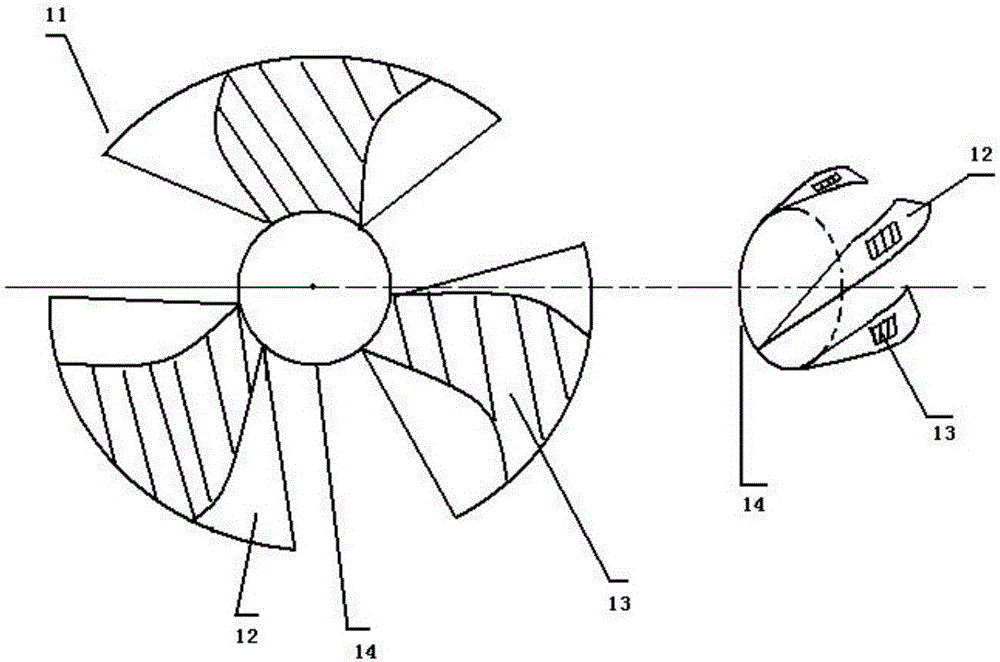

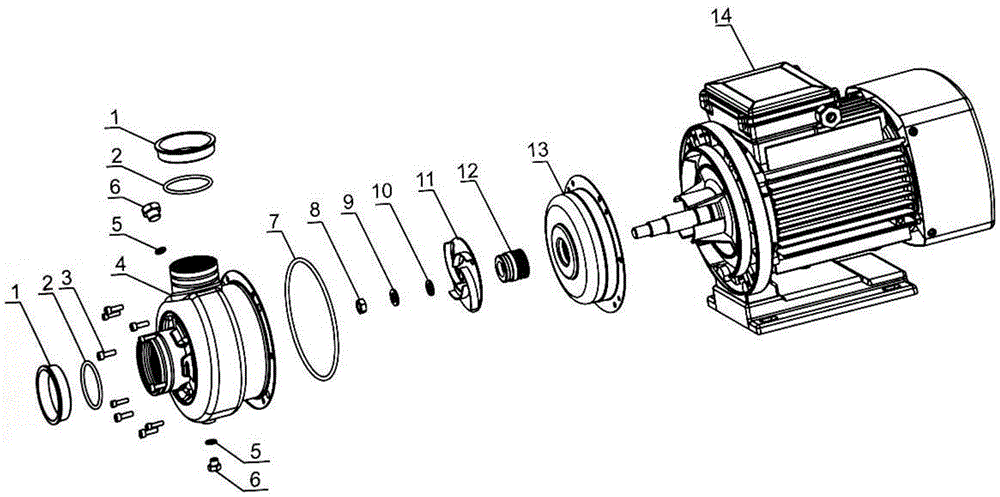

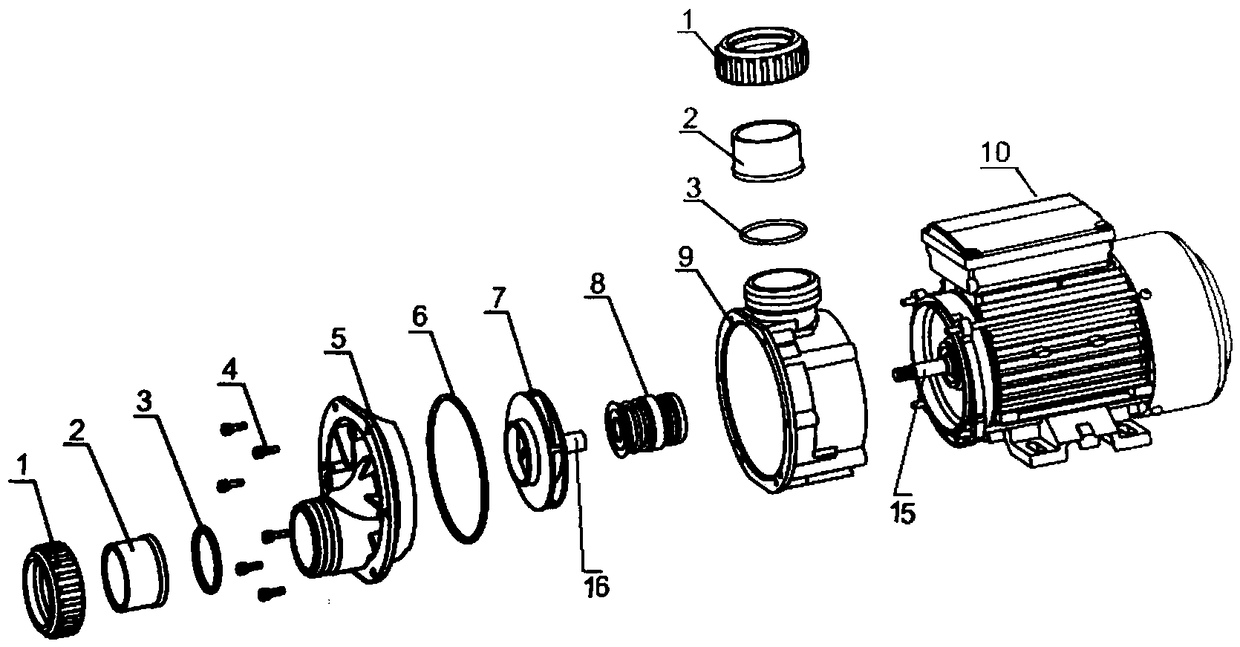

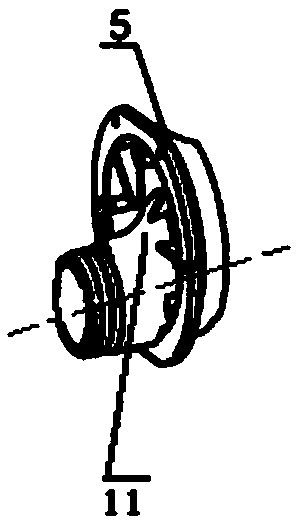

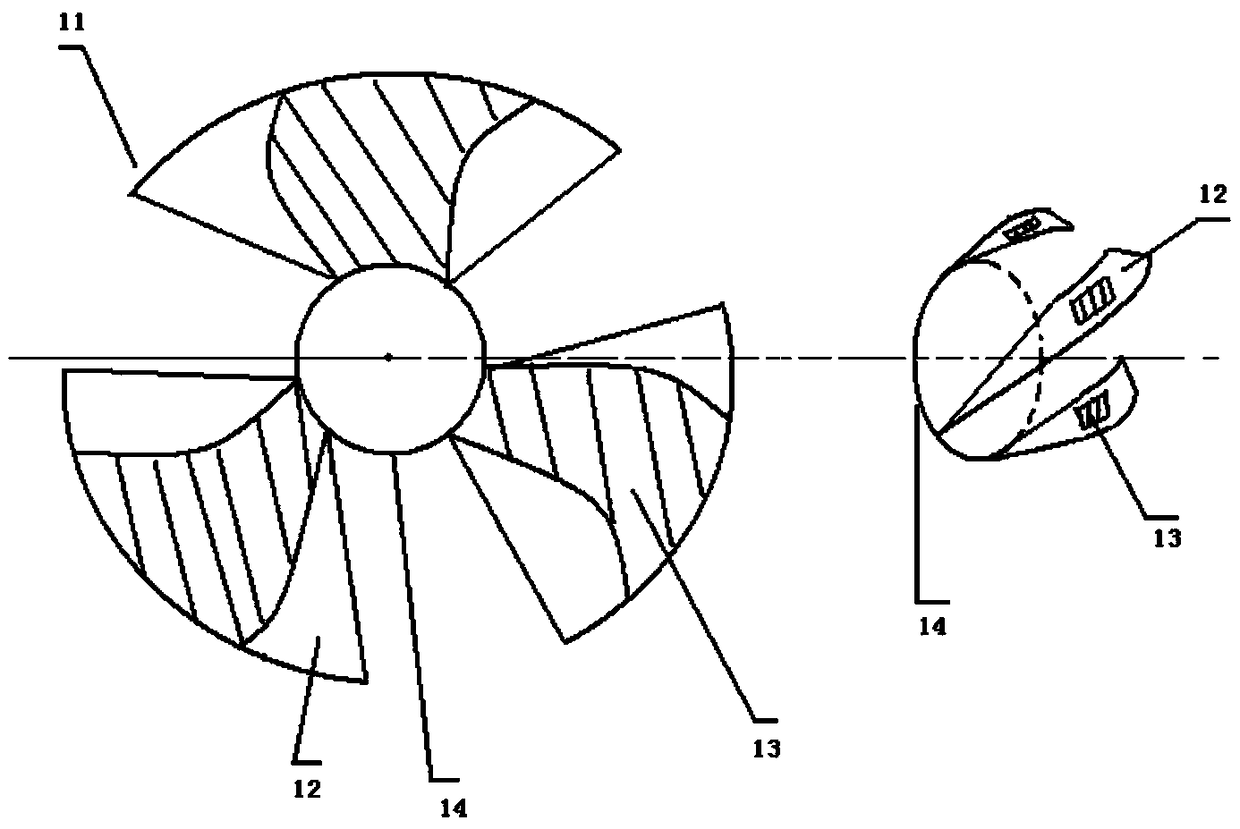

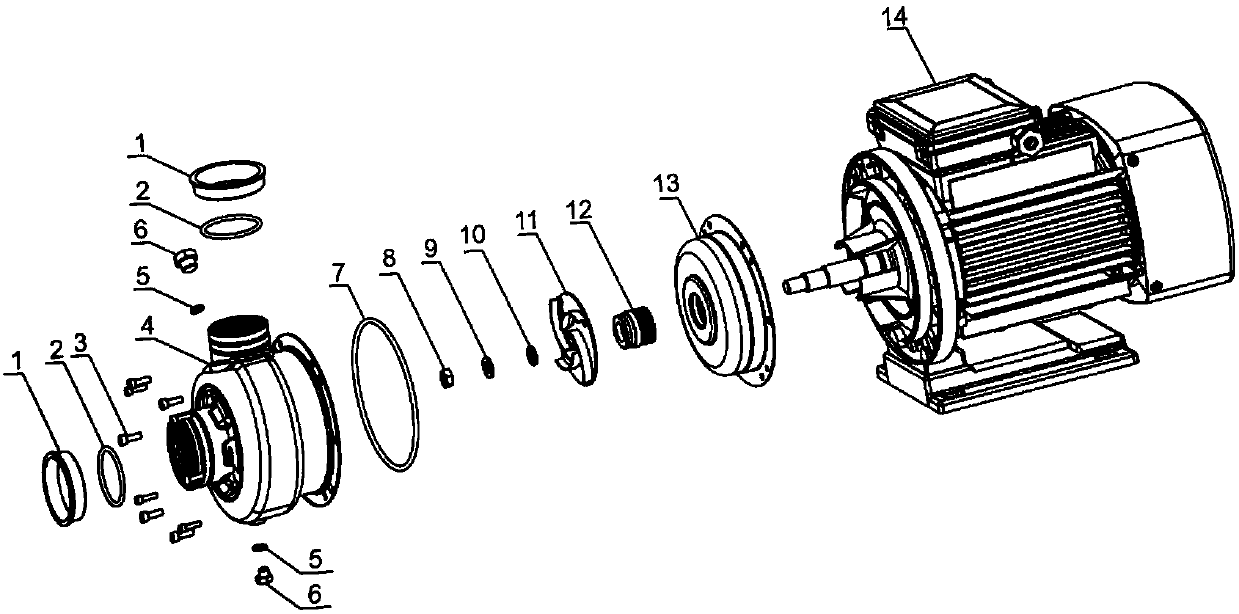

Massage bathtub pump

ActiveCN106438382AFix the leakExpand the scope of actionPump componentsPump installationsImpellerWater flow

The invention provides a massage bathtub pump which comprises a pump shell assembly, an impeller, a bearing, a pump cover assembly and an electric motor, wherein the impeller sleeves the bearing by a shaft sleeve; one side of the impeller is in a sealed connection with the pump cover assembly by a large O-shaped ring, and the other side is connected to the pump shell assembly through mechanical sealing; the shaft sleeve passes through the mechanical sealing and is in a sleeved connection with the bearing; the pump cover assembly is composed of a suction section, a cover shell and a lead-in component; the lead-in component is composed of three guide blades which are connected by round sleeve rings and bent in a certain direction; the guide blades are shaped like sectorial rings; the three guide blades cover a gradually expanded suction pipe of the suction section; and a raised guide block is disposed on each guide blade. The massage bathtub pump is characterized in that flow guide sheets are installed, so that water flows can enter the pump body smoothly; water flow pressure is reduced; collision of the water flows to the pump cover is reduced; efficiency is increased, and noise is reduced; local wear is avoided; a pump performance scope is expanded; and operations are convenient.

Owner:GUANGDONG LINGXIAO PUMP IND

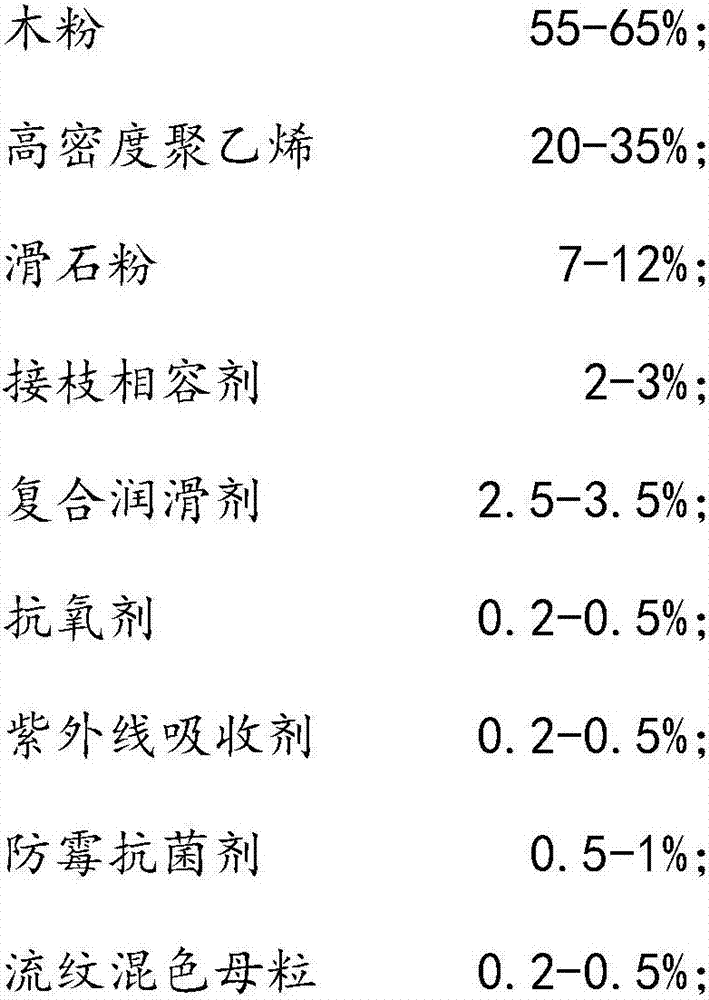

Wood plastic composite material with mixed-color flow lines

The invention discloses a wood plastic composite material with mixed-color flow lines. The wood plastic composite material is prepared from the raw materials comprising the following components: 55 to 65% of wood powder, 20 to 35% of high-density polyethylene, 7 to 12% of talcum powder, 2 to 3% of a grafted compatibility, 2.5 to 3.5% of a composite lubricant, 0.2 to 0.5% of an antioxidant, 0.2 to 0.5% of an ultraviolet adsorbent, 0.5 to 1% of a mould-proof antibacterial agent, and 0.2 to 0.5% of mixed-color flow line master batch. According to the wood plastic composite material disclosed by the invention, the prepared mixed-color flow line master batch is added in a production process of the wood plastic composite material, so that the color of the wood plastic composite material can be changed; and moreover, the prepared wood plastic composite material is bright in color and cannot fade under a long-term using condition.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

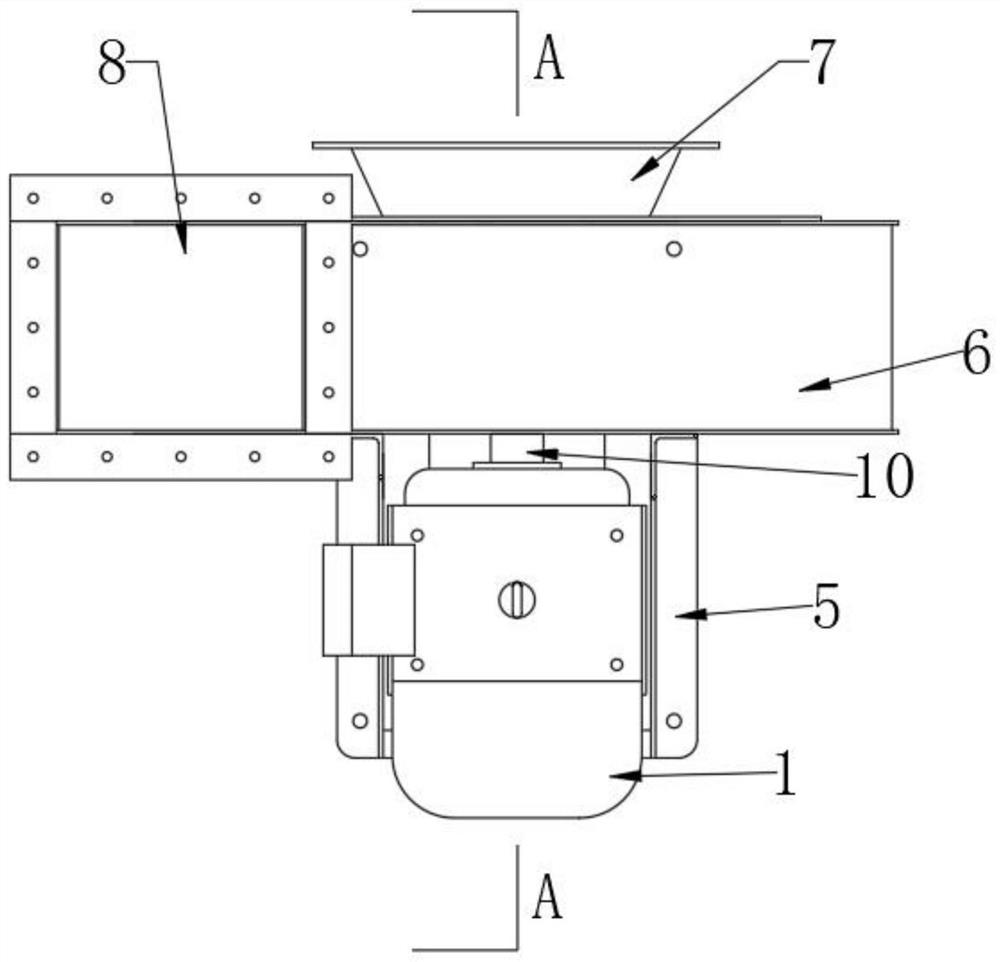

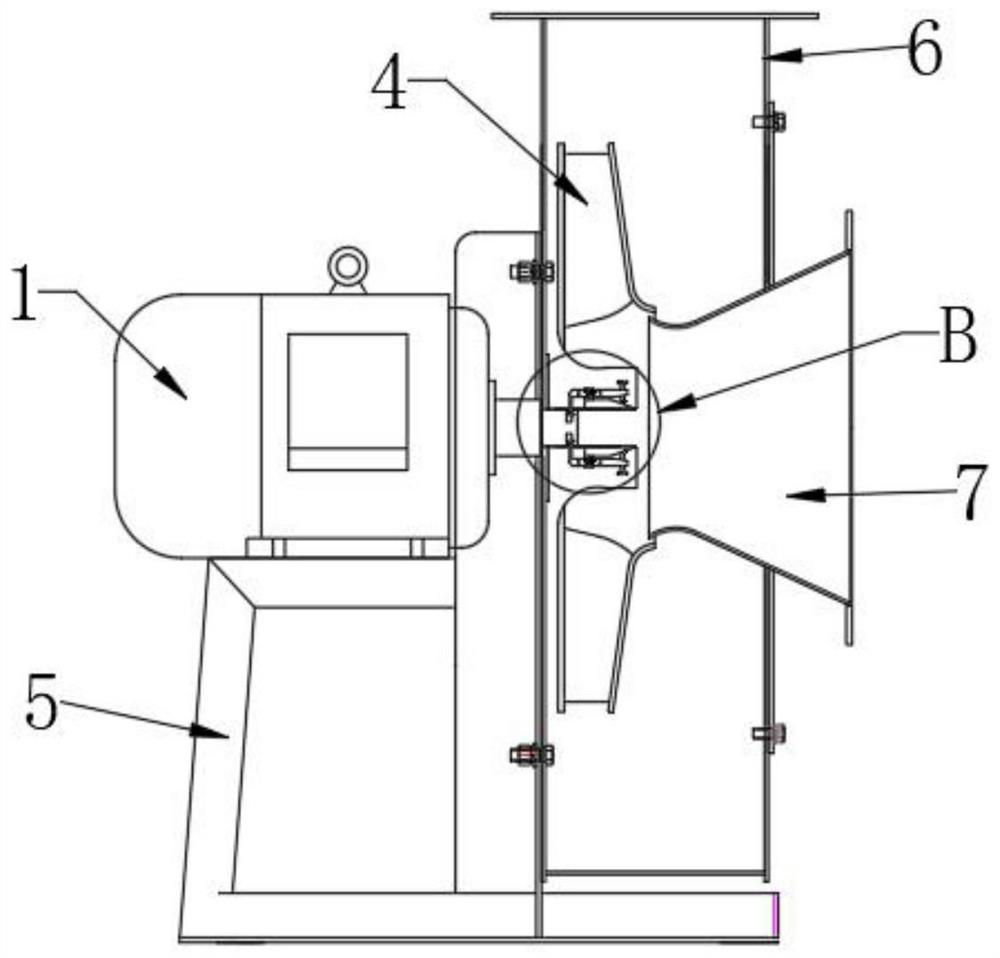

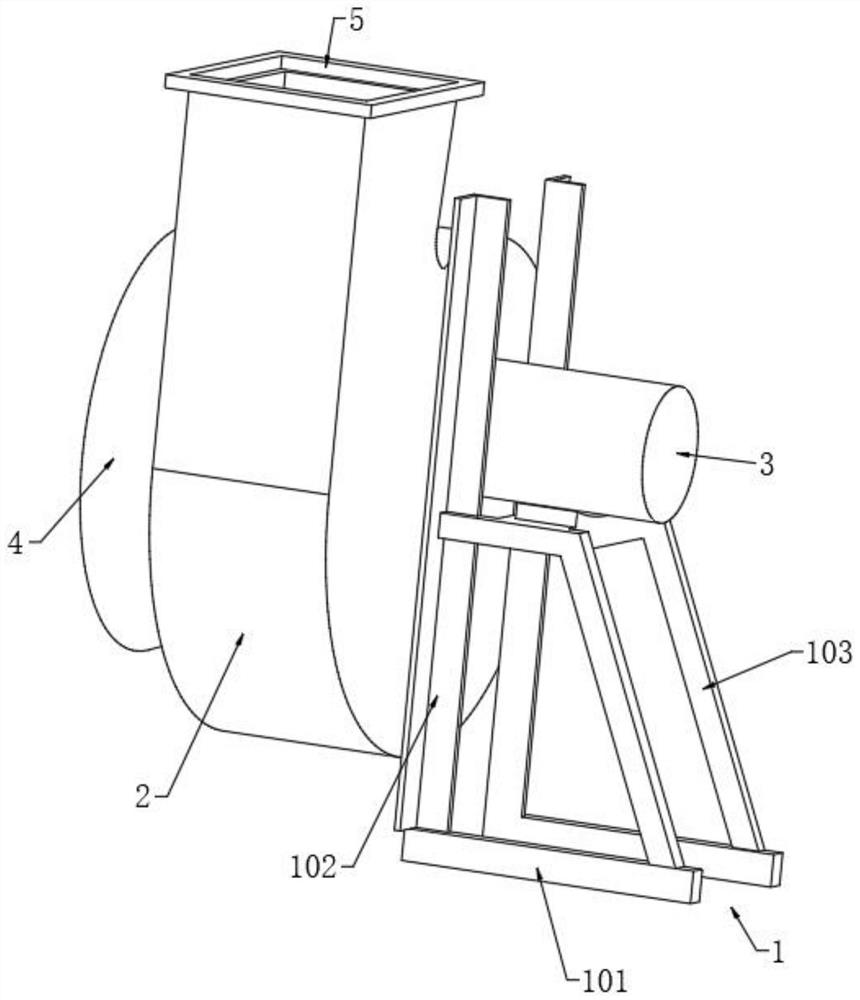

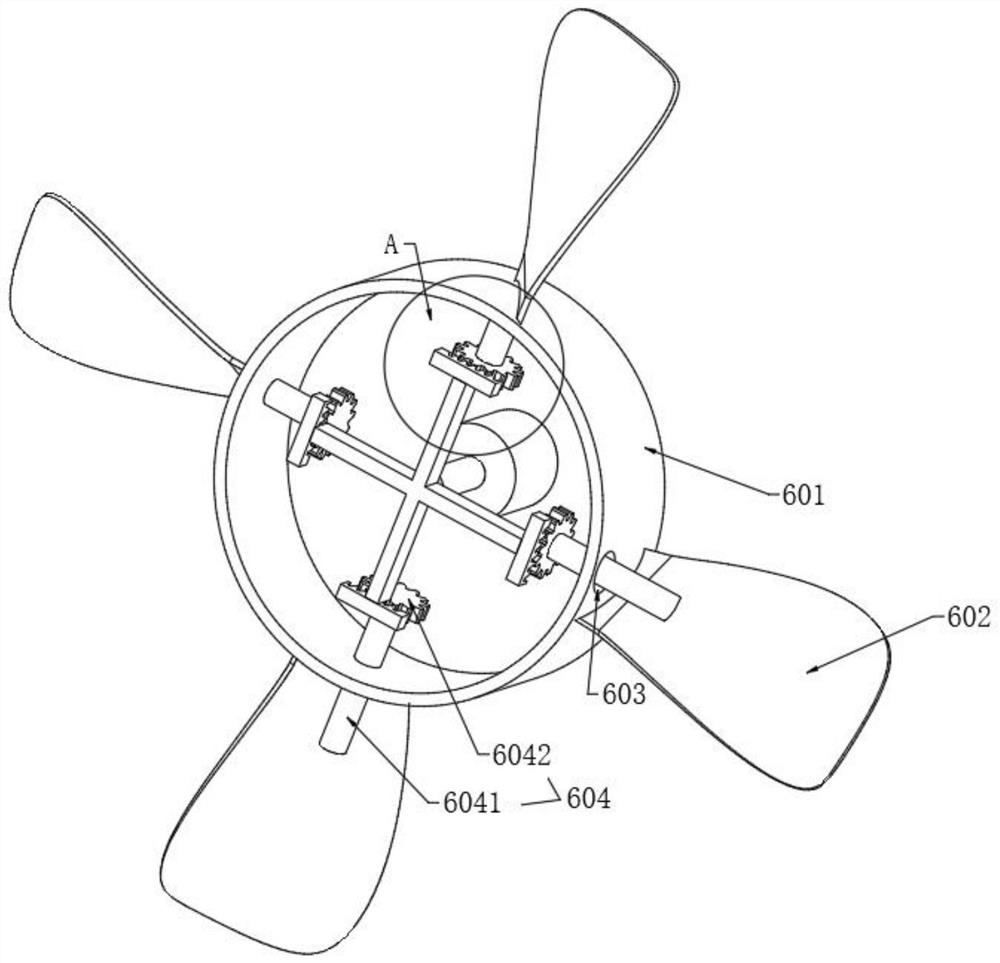

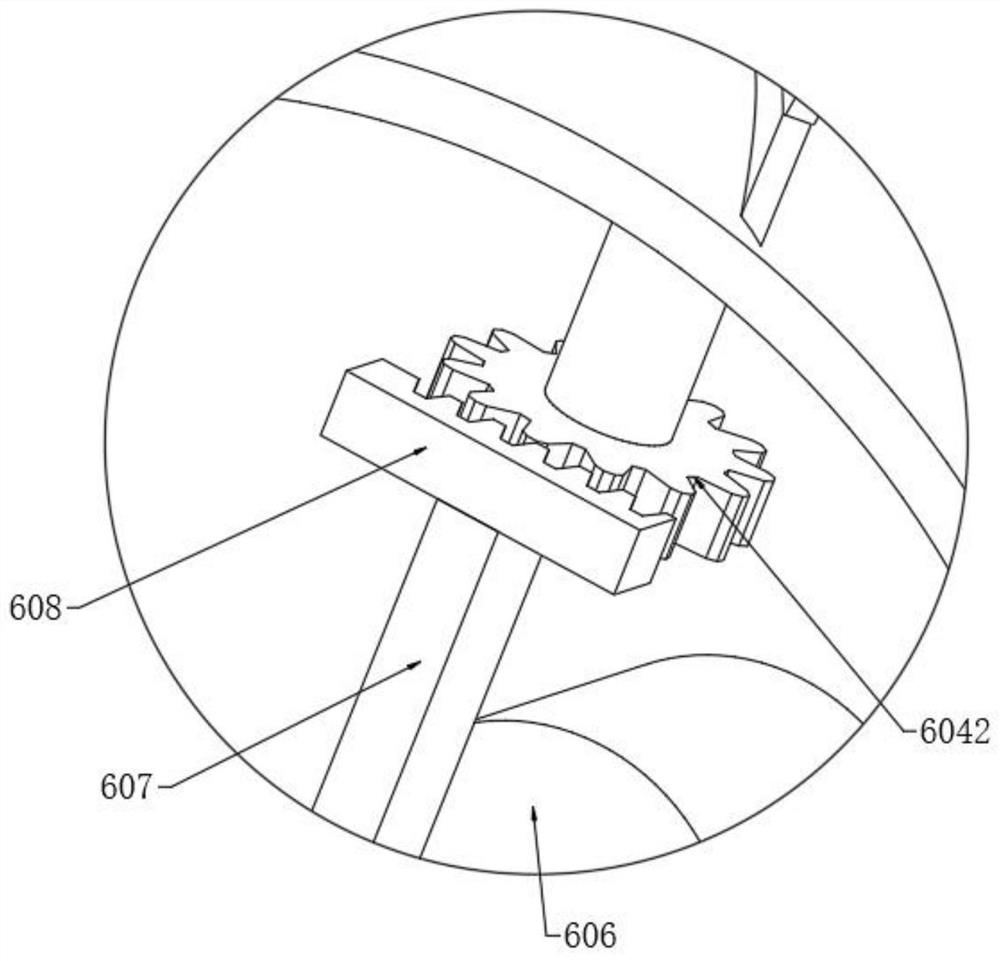

Efficient energy-saving fan applied to feed, flour and rice system process

PendingCN113339288AImprove efficiencyUse battery saverPump componentsPump installationsImpellerControl engineering

The invention discloses an efficient energy-saving fan applied to the feed, flour and rice system process. The fan comprises a machine base, wherein a motor is fixedly connected to the upper surface of the machine base, a first rotating shaft is fixedly connected to the outlet end of the motor, a second rotating shaft is fixedly connected to the other end of the first rotating shaft through a connecting assembly, the outer wall of the second rotating shaft is fixedly connected with an impeller, the outer side of the impeller is provided with a machine shell, the upper end of the machine shell is provided with an air outlet, and the back face of the machine shell is fixedly connected with an air inlet ring. The fan adopts an A type transmission structure and is compact in structure and small in size, the fan is equipped with no bearing box and is convenient and easy to maintain and overhaul, a backward impeller motor is stable in current and stable in performance, through the design of a connecting assembly, C type, D type or other transmission modes can be manufactured according to needs, the motor is started to drive the impeller to rotate, airflow enters a machine shell from an air inlet ring and finally flows out of the air outlet, and a stable airflow channel is formed in the machine shell.

Owner:ZHENJIANG DANTU DISTRICT FOOD FACTORY

Anti-static efficient energy-saving fan

PendingCN113250980AImprove conductivityAvoid Electrostatic Discharge PhenomenaPump componentsPump installationsWater storageEngineering

The invention relates to the technical field of fans, in particular to an anti-static efficient energy-saving fan. The fan comprises a device body; the device body comprises a supporting frame; and an exhaust bin is fixedly mounted on one side of the supporting frame. By arranging a wetting cylinder, a water storage annular sleeve, a kinetic energy fan, a mounting sleeve and a water distribution rods, a kinetic energy fan is driven to rotate by utilizing air pressure formed after an air inlet fan is started, so that multiple water distribution rods are driven to rotate, and the water distribution rods drive water in a water storage annular sleeve to form a certain amount of water curtain, so that a water curtain can adsorb dust in the air to a certain degree, the density of the dust entering the air inlet fan is reduced, the density of the dust capable of being adsorbed on the fan blades is reduced, and the influence of dust attachment on the air inlet fan is reduced; meanwhile, the water curtain is used for wetting airflow, so that the conductivity of the air is enhanced, and electric charges entering the surface of the fan are brought away when air is in contact with the fan blades.

Owner:ZHENJIANG DANTU DISTRICT FOOD FACTORY

Direct aging method for preparing high-strength high-conductivity Cu-Ni-Al conductor material

The invention discloses a method for preparing a high-strength high-conductivity Cu-Ni-Al conductor material. By taking Cu-0.4 percent (mass percent, the same below) Ni-0.4 percent Al for example, an alloy raw material is smelted and poured into a water-cooled copper mold, is directly subjected to cold rolling to produce certain deformation, and is aged at the temperature of between 200 and 600 DEG C for 0.1 to 10 hours. The strength of the Cu-Ni-Al alloy is 450 to 900MPa, and the conductivity is 70 to 90 percent international annealed copper standard (IACS). The method is short in production flow, simple in process and suitable for large-scale industrial production. Meanwhile, the prepared alloy has a wide performance range, can achieve various strengths and conductivities by adjusting an aging process, and meets the actual requirements of application in various aspects.

Owner:CHINA JILIANG UNIV

Direct aging method for preparing high-strength high-conductivity Cu-Ni-Al conductor material

InactiveCN102041366AAvoid problems such as oxidation and overburningEasy to processAge methodWater cooling

The invention discloses a method for preparing a high-strength high-conductivity Cu-Ni-Al conductor material. By taking Cu-0.4 percent (mass percent, the same below) Ni-0.4 percent Al for example, an alloy raw material is smelted and poured into a water-cooled copper mold, is directly subjected to cold rolling to produce certain deformation, and is aged at the temperature of between 200 and 600 DEG C for 0.1 to 10 hours. The strength of the Cu-Ni-Al alloy is 450 to 900MPa, and the conductivity is 70 to 90 percent international annealed copper standard (IACS). The method is short in productionflow, simple in process and suitable for large-scale industrial production. Meanwhile, the prepared alloy has a wide performance range, can achieve various strengths and conductivities by adjusting an aging process, and meets the actual requirements of application in various aspects.

Owner:CHINA JILIANG UNIV

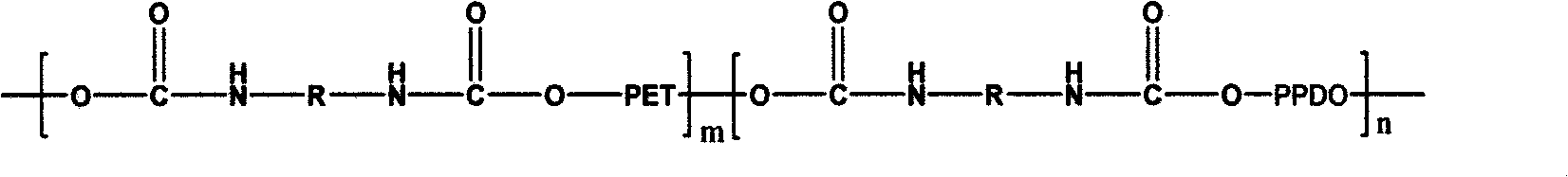

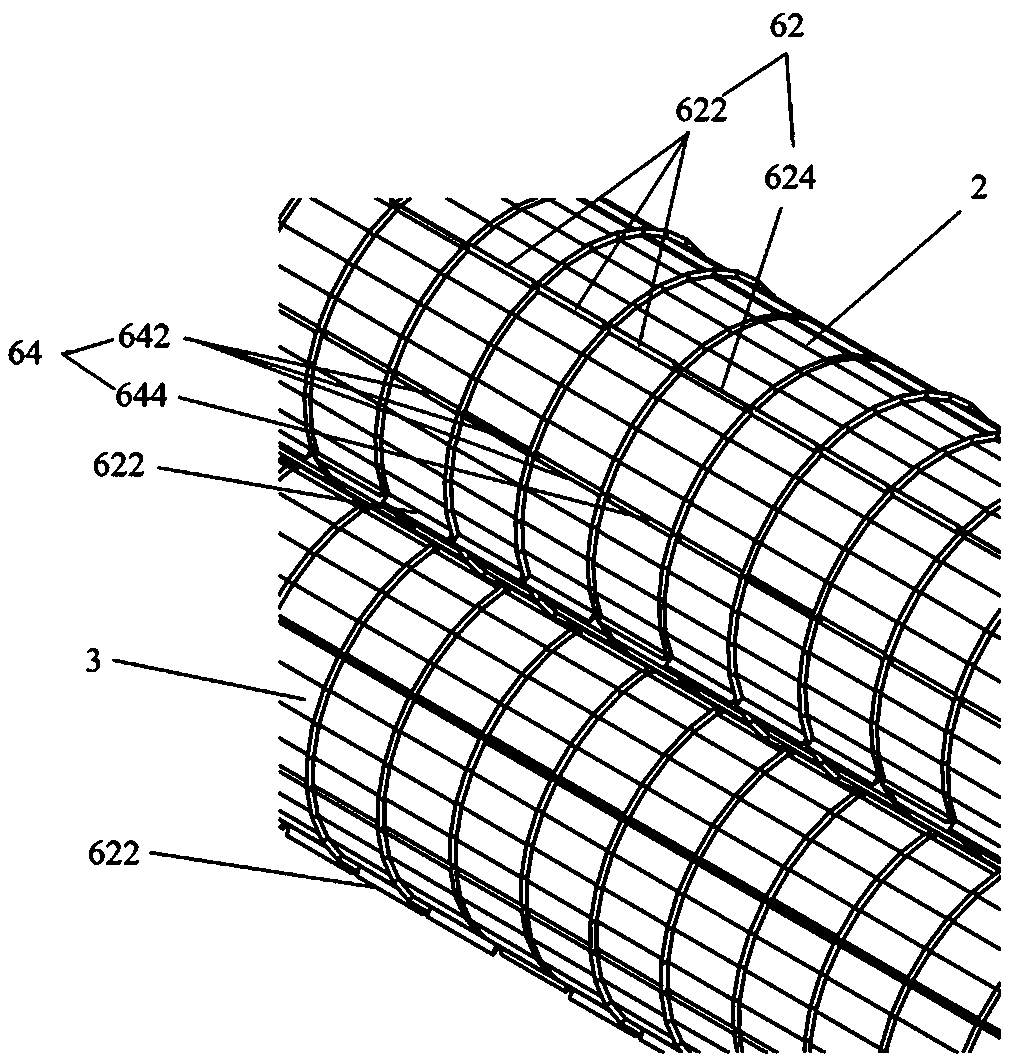

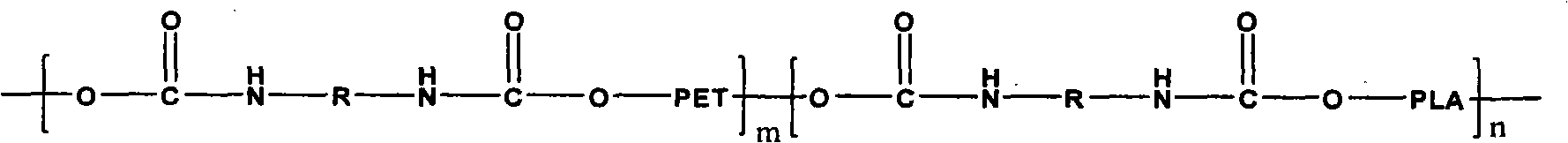

Segmented copolymer of poly-p-dioxanone/polyethylene glycol terephthalate and preparation method thereof

ActiveCN101550227BHigh molecular weightEasily control chain lengthPolymer sciencePolyethylene glycol

The invention disclosess a segmented copolymer of poly-p-dioxanone / polyethylene glycol terephthalate; the copolymer is characterized of being prepared by dropping coupling agent diisocyanates in a fused mass formed by melting modified low-melting polyethylene glycol terephthalate pre-polymers whose melting point is not greater than 210 degrees centigrade, the limiting viscosity number is not greater than 1.5 dL / g and both ends are hydroxyl groups, and poly-p-dioxanone whose the limiting viscosity number is not greater than 0.8 dL / g and both ends are hydroxyl groups at a certain temperature, the limiting viscosity number of the copolymer is 0.5 to 2.5 dL / g, and the melting point is at 100 to 180 degrees centigrade. The invention further discloses a method for preparing the copolymer. The segmented copolymer discloseed by the invention has high molecular weight and excellent thermal stability and machinability, and has excellent biodegradability of poly-p-dioxanone, which lays the foundation for the materials as commercial macromolecular material. The invention is simple in process and easy to control the reaction, thereby realizing large-scale and continuous industrial production.

Owner:SICHUAN UNIV

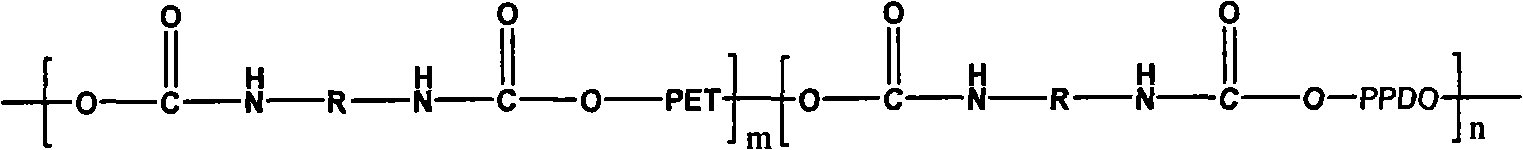

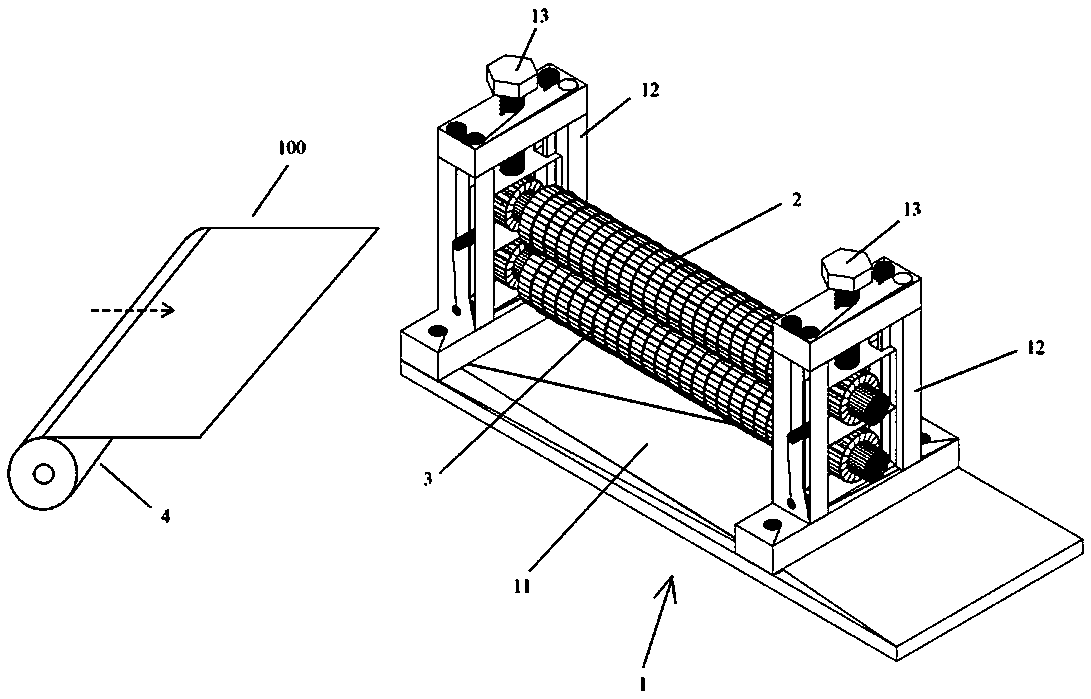

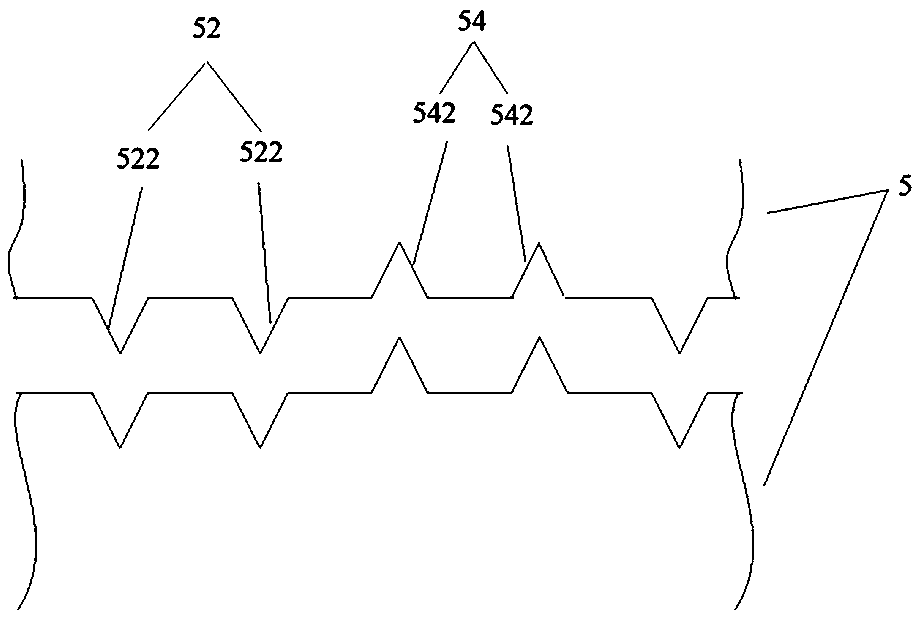

A preparation device for folding honeycomb precursor and its use method

ActiveCN109822649BWide performance rangeReduce manufacturing costMetal working apparatusFiberAnnular cutter

The invention relates to a manufacturing device and a manufacturing method for a folding honeycomb precursor. The device comprises a rack, an upper roller press cutter wheel, a lower roller press cutter wheel, a feeding mechanism and a control mechanism, wherein the upper roller press cutter wheel and the lower roller press cuter wheel are fixed on the rack, the feeding mechanism and the control mechanism are arranged on one side of the rack, the upper roller press wheel and the lower roller press cutter wheel are oppositely arranged, the feeding mechanism is used for feeding a plastic sheet between the upper roller press cutter wheel and the lower roller press cutter wheel, annular cutter structures are arranged on the upper roller press cutter wheel and the lower roller press cutter wheel in the circumferential direction of the upper roller press cutter wheel and the lower roller press cutter wheel, horizontal cutter structures are arranged on the upper roller press cutter wheel andthe lower roller press cutter wheel in the length direction of the upper roller press cutter wheel and the lower roller press cutter wheel, the upper roller press cutter wheel and the lower roller press cutter wheel rotate under the control of the control mechanism, and the plastic sheet is machined into the folded honeycomb precursor with a target shape through the annular cutter structures and the horizontal cutter structures. According to the manufacturing device and the manufacturing method, a honeycomb core material with reinforced fibers can be rapidly and continuously produced, the performance range of the plastic honeycomb core is widened, the production cost is reduced, the production efficiency is improved, and the production requirements of high efficiency and low cost are met.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

A kind of method for preparing polyurethane-polyisocyanurate film gradient material

The invention discloses a preparation method of a polyurethane-polyisocyanurate thin-film graded material. The preparation method comprises the steps that aromatic diisocyanate and oligomer diol are used as raw materials, organic tin and Sudan blue are used as catalysts, a polyurethane-polyisocyanurate cross-linked network is prepared through urethane forming reaction and polycyclic trimerization reaction, and then a solution containing a reactor and the catalysts is poured into a hydrophobic mold to obtain a thin film through curing. Reaction mixture solutions different in proportion are poured onto a horizontal polycyclic surface, so that one surface of the prepared graded thin film is higher in elasticity modulus, the other surface of the prepared graded thin film is lower in elasticity modulus, the elasticity modulus in the thickness direction of the thin film changes from one surface to the other surface in a graded mode, no interface exists, the gradient change from soft rubber to rigid plastic of the prepared thin film in the thickness direction is presented macroscopically, the shortcomings of the brittleness and fragility of plastic thin films can be overcome, and the problem that the elasticity modulus of the rubber thin film changing with strain change can be also solved.

Owner:YANCHENG INST OF TECH

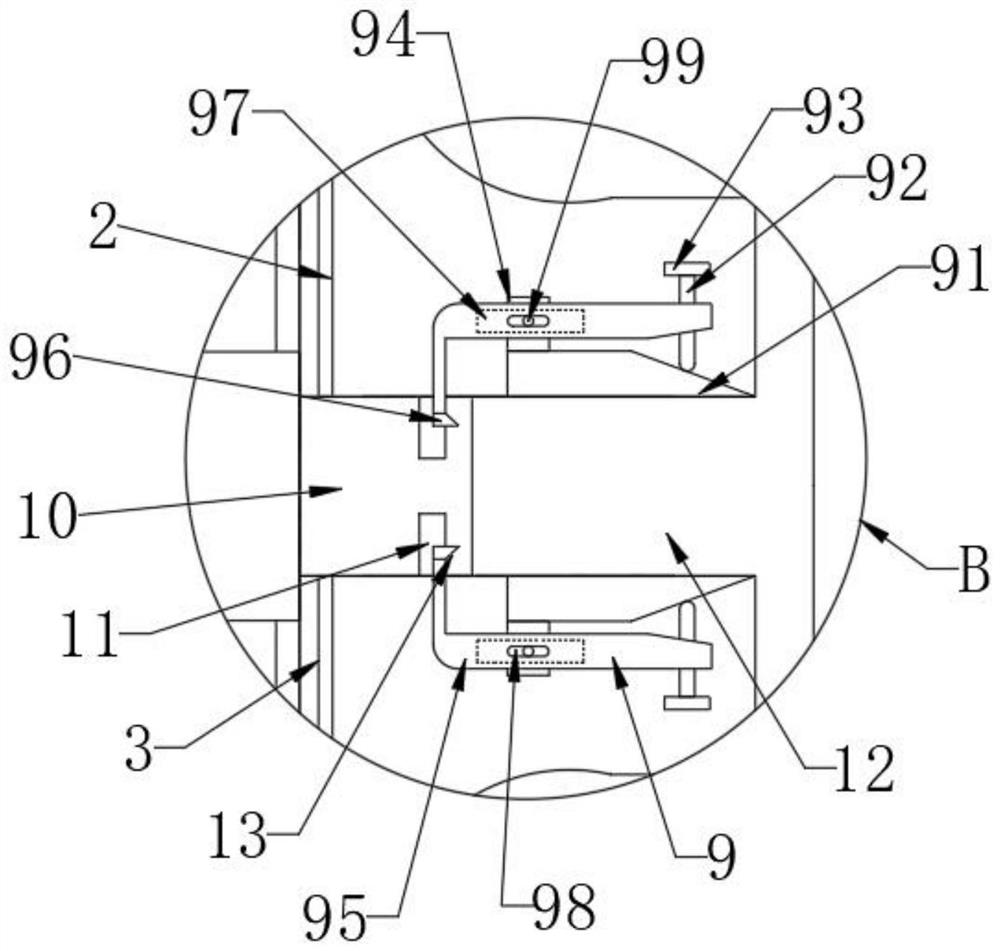

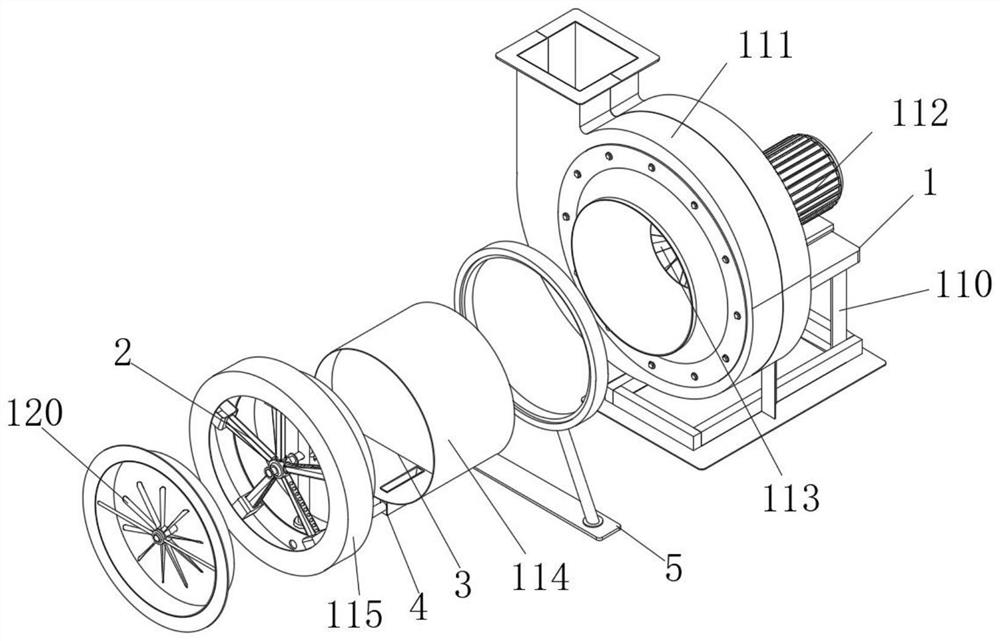

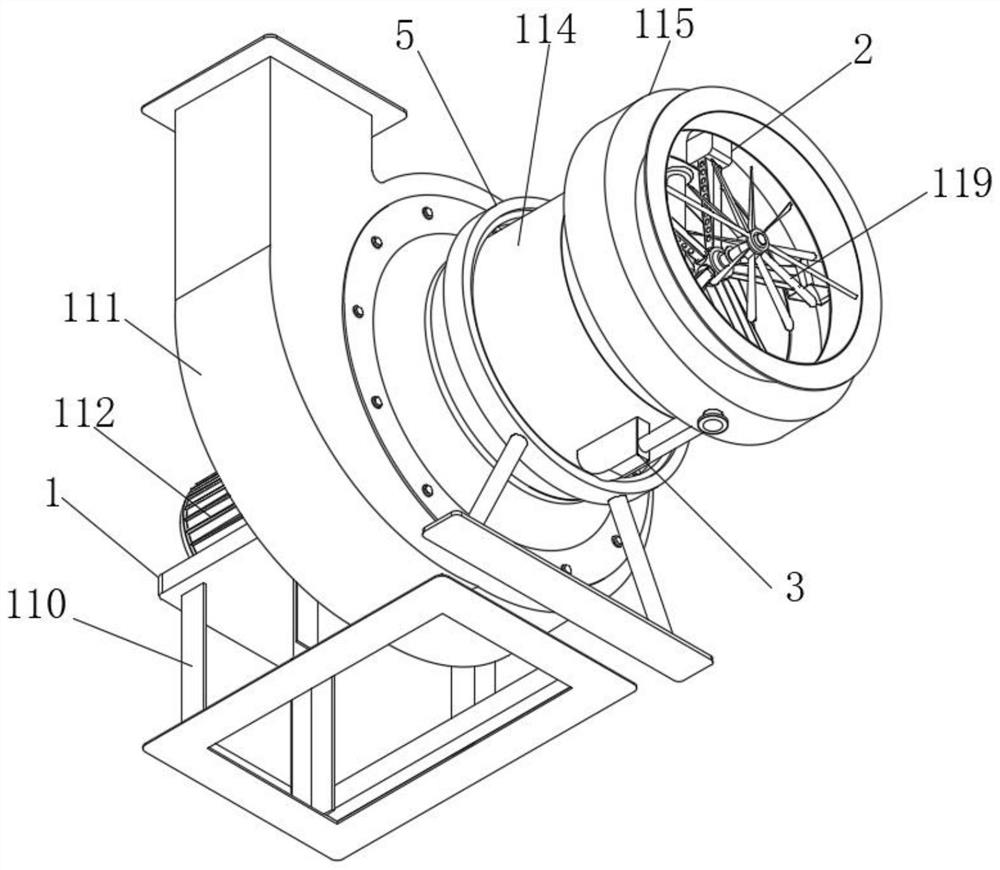

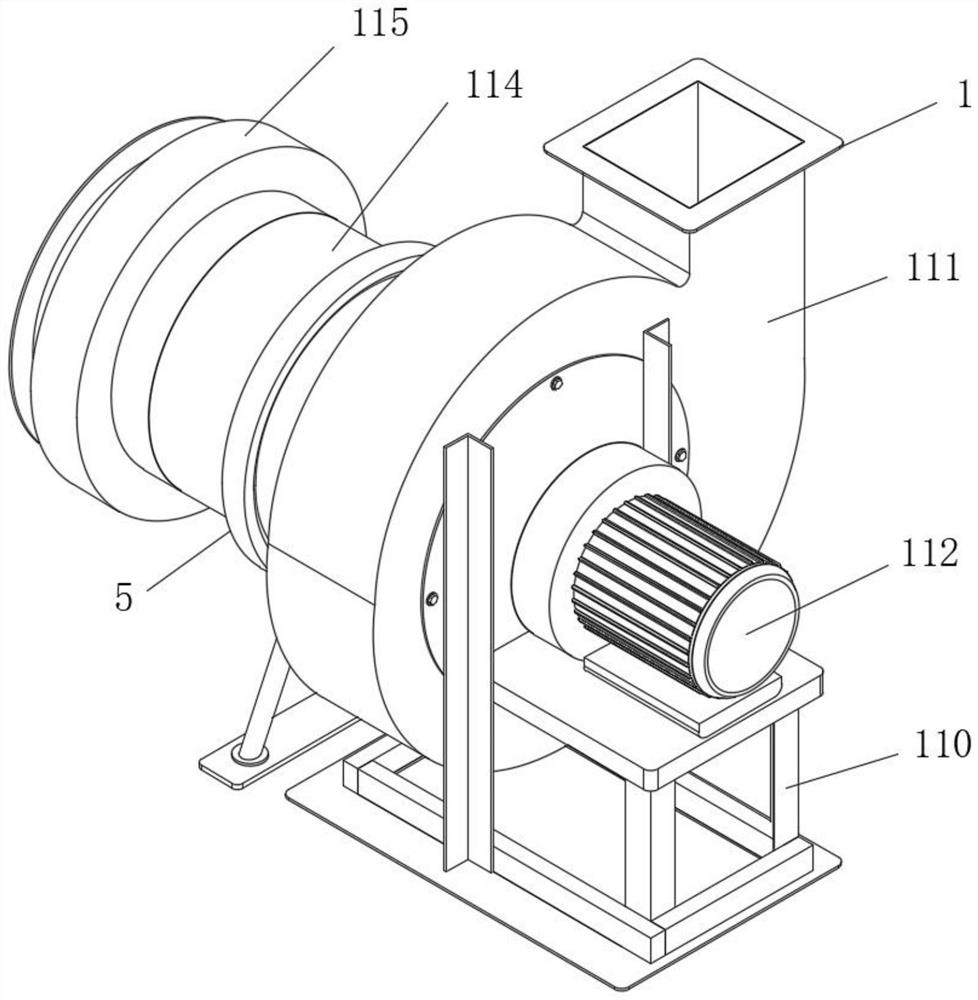

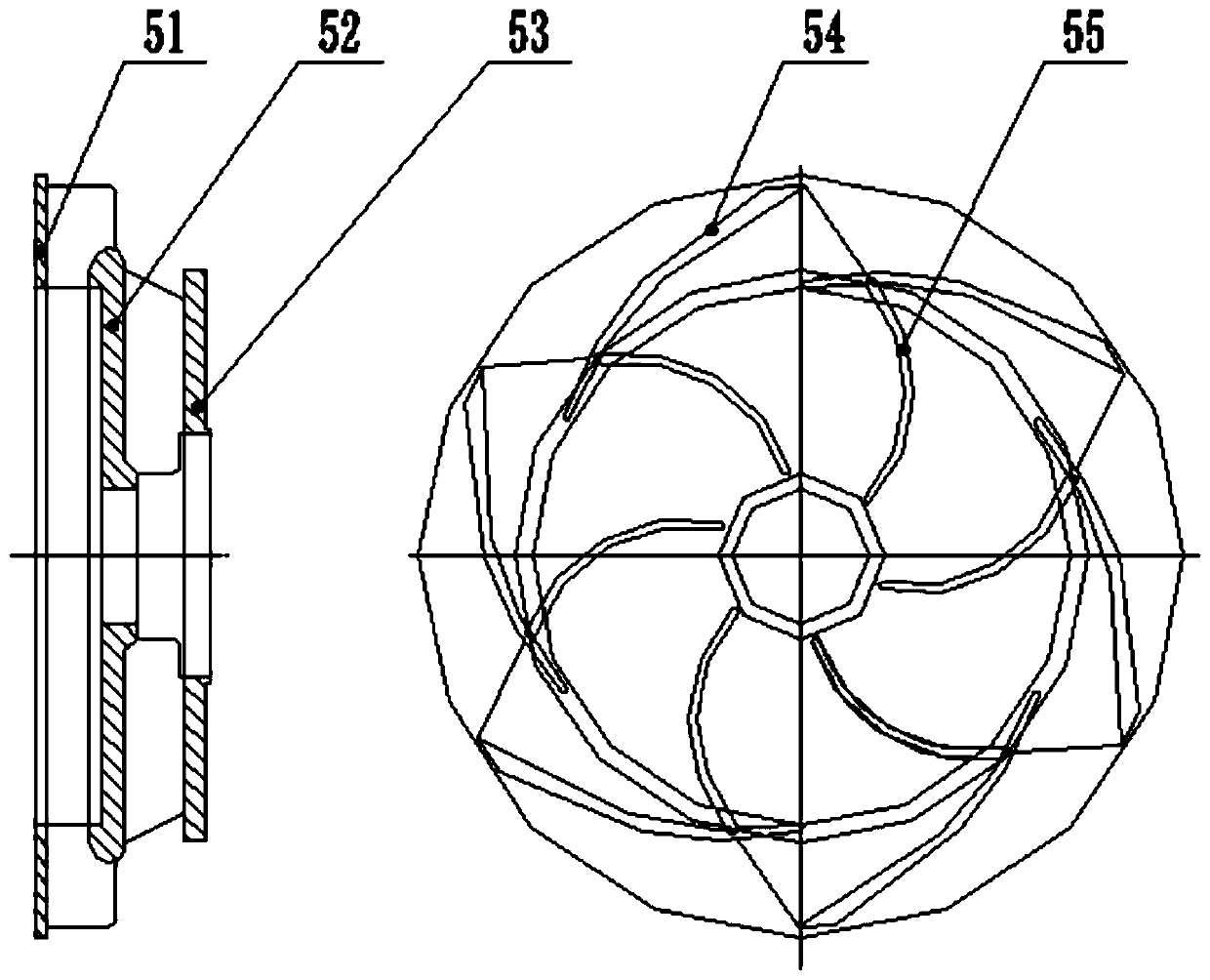

Efficient energy-saving fan with wide performance range

PendingCN113279980AReduce matching powerCompact structurePump componentsPump controlElectric machineMachine

The invention provides an efficient energy-saving fan with a wide performance range, and belongs to the technical field of fan equipment. The efficient energy-saving fan with the wide performance range comprises a machine base, wherein a machine shell and a motor are fixedly installed on the machine base through bolts, the output end of the motor is formed in the machine shell, an adjusting device is connected to the output end of the motor, an outlet flange is fixedly installed on the machine shell through bolts, and an air inlet ring is fixedly installed on the side, far away from the motor, of the machine shell. The matched power of the motor is low, an A-type transmission structure is compact, the size is small, a bearing box is not arranged, maintenance and overhaul are convenient and simple, the current of the motor is stable, and the performance is stable; and the efficient energy-saving fan can be manufactured into a C-type, D-type or other transmission modes according to other working conditions with temperature, humidity and the like, so that electricity is saved, and the operation cost is reduced.

Owner:ZHENJIANG DANTU DISTRICT FOOD FACTORY

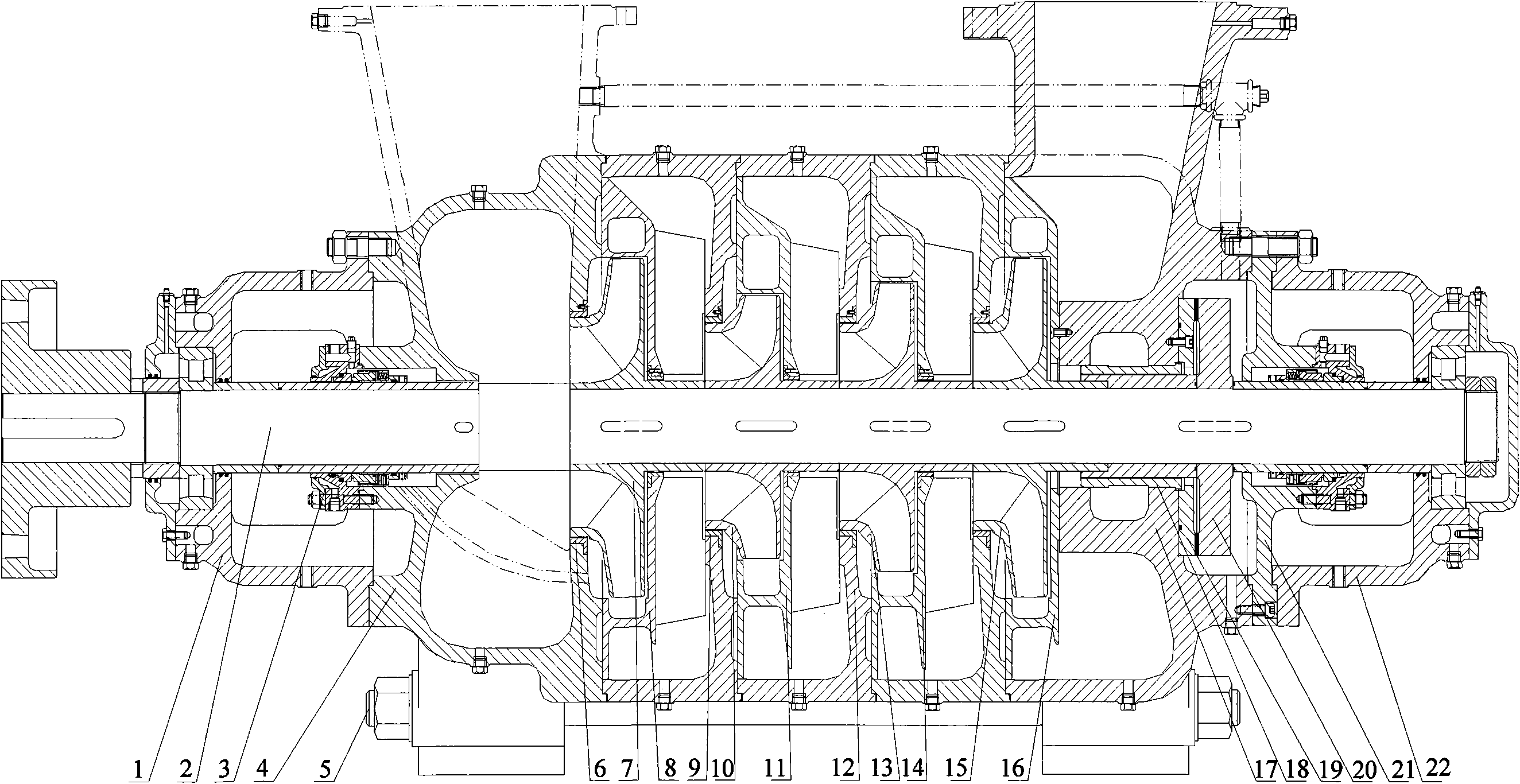

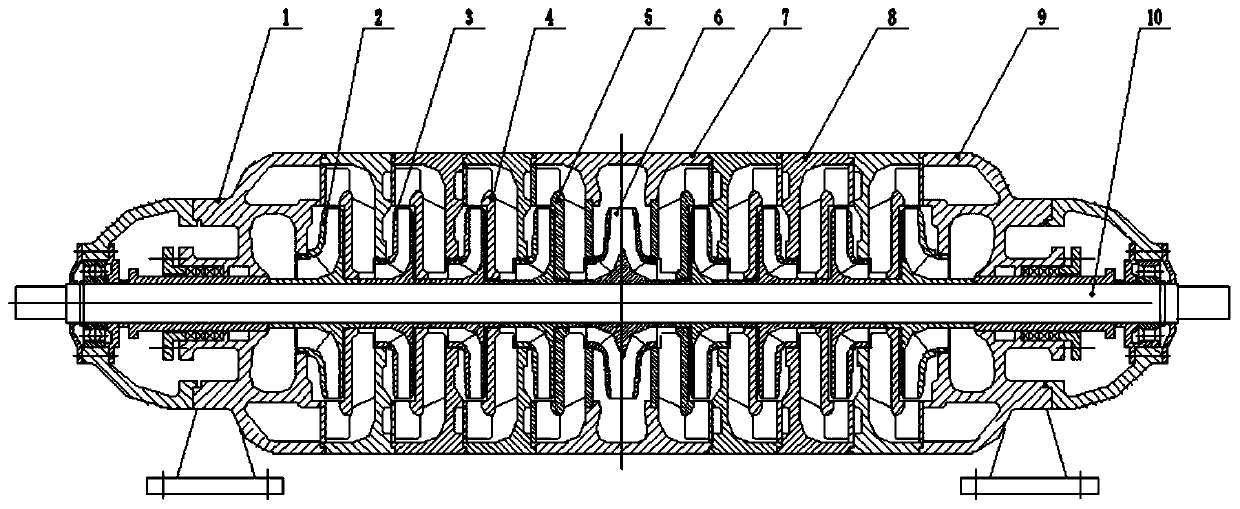

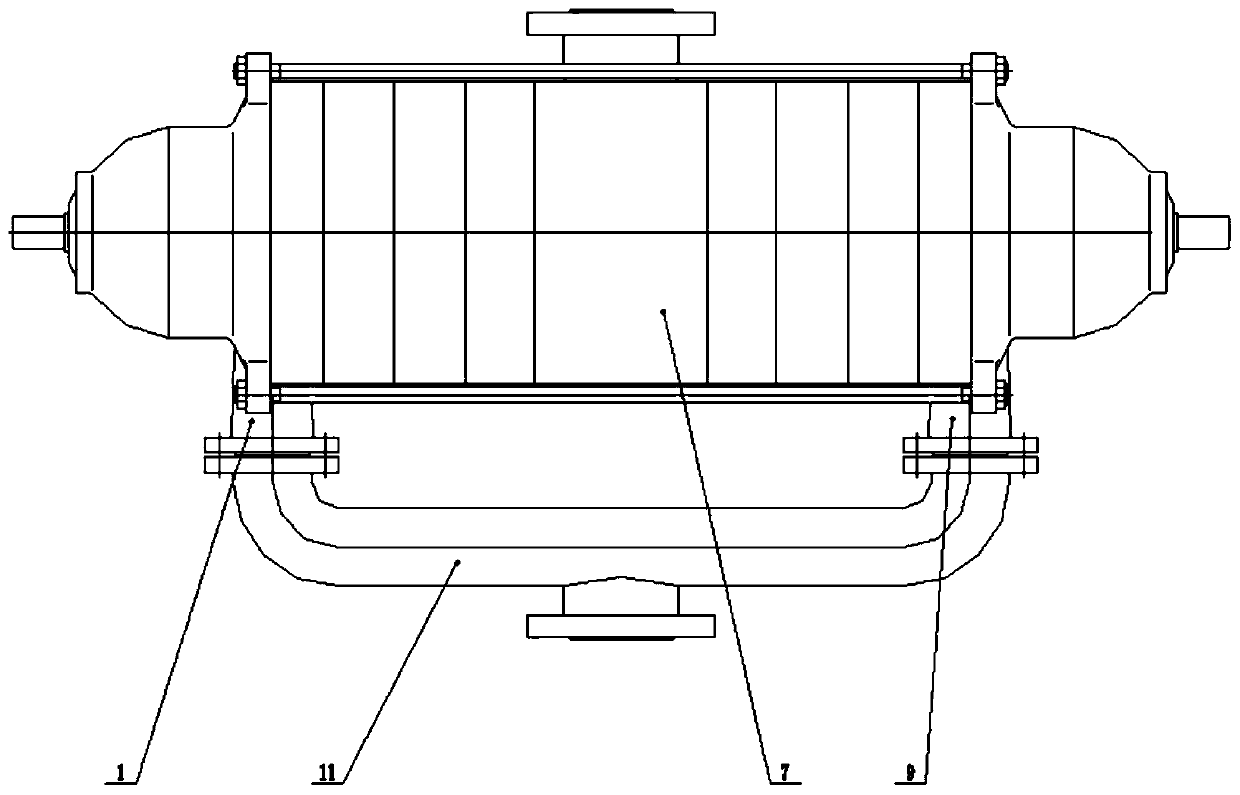

Double-suction type holosymmetrical multi-stage pump

PendingCN110630507AHigh trafficWide performance rangePump componentsRadial flow pumpsImpellerCavitation

The invention discloses a double-suction type holosymmetrical multi-stage pump. The double-suction type holosymmetrical multi-stage pump comprises secondary impellers, a double-suction impeller and adouble-suction pump body, the double-suction pump body is arranged outside the double-suction impeller, the double-suction impeller is of a holosymmetrical structure, and the double-suction pump bodyis located on the coaxial line of the double-suction impeller. According to the double-suction type holosymmetrical multi-stage pump, the multi-stage double-suction pump can be conveniently assembledon the premise that existing single-suction type multi-stage pump parts are utilized to the maximum limit, the flow of the pump is multiplied, and the performance range of the pump is widened; primaryimpellers, the secondary impellers and the double-suction impeller are arranged in a holosymmetrical manner, therefore, the axial force is thoroughly balanced, and the theoretical axial force is equal to zero; the flow passing area of the primary impellers is increased compared with that of the secondary impellers, and therefore the cavitation performance of the pump is improved; through use of the double-suction impeller and the double-suction pump body, liquid collection and confluence are convenient, and the hydraulic efficiency of the pump is improved; and a double shaft extension schemeis adopted, therefore, driving can be achieved from any one end, and the diversity requirements of pump installation are met.

Owner:湖南自平衡多级泵制造有限公司

Half-opened impeller stainless steel centrifugal pump

ActiveCN105673512AWide performance rangeAvoid concentrated wearSpecific fluid pumpsPump componentsEngineeringCentrifugal pump

The invention provides a half-opened impeller stainless steel centrifugal pump. The centrifugal pump comprises a pump shell component (4), an impeller (11), a bearing (18), a pump cover (13) and a motor (14). The bearing (18) is sleeved by the impeller (11) by virtue of a shaft sleeve; and one side of the impeller (11) makes contact with a slide stop sleeve I (16) through a spring washer (10), and the other side of the impeller (11) makes contact with a slide stop sleeve II (19) through a mechanical seal (12). The mechanical seal (12) can penetrate through the slide stop sleeve II (19) to be clamped in a cylindrical clamping groove in the pump cover (13); a gap between the slide stop sleeve I (16) and the impeller (11) is adjusted through a stop sleeve nut I (15); and a gap between the slide stop sleeve II (19) and the impeller (11) is adjusted through a stop sleeve nut II (17). The centrifugal pump provides adjustable and controllable impeller gaps, prevents local wear, widens the performance range, and is scientific in design and convenient for operation.

Owner:GUANGDONG LINGXIAO PUMP IND

Polylactic acid/polyethylene terephthalate multi-block copolymer, method for preparing same and uses

ActiveCN101338025BHigh molecular weightImprove thermal stabilityMonocomponent copolyesters artificial filamentAdhesivesPolymer sciencePolyethylene terephthalate glycol

The invention discloses pla / polyethylene terephthalate segmented copolymer, which is characterized in that the copolymer is prepared by the melting reaction of low melting point polyethylene terephthalate with the melting point of 110 to 210 DEG C and the intrinsic viscosity of 0.3 to 1.5dl / g and hydroxyl at two ends and pla-prepolymer with hydroxyl at two ends and the intrinsic viscosity of 0.05to 0.5dL / g under the presence of the coupling agent of diisocyanate. The intrinsic viscosity of the copolymer is 0.3 to 2.5 dL / g, the melting point is 110 to 210 DEG C. The invention also discloses apreparation method for the copolymer. The segmented copolymer which is provided by the invention not only has high molecular weight and good thermal stability as well as machinability, but also has excellent biodegradability of PLA and establishes the basis for the materials as the general type polymer materials. The segmented copolymer has simple method and process, low cost by adopting the direct melting method to prepare lactic acid and easy controlled reaction, and thereby can realize the scale and continuous industrial production.

Owner:SICHUAN UNIV

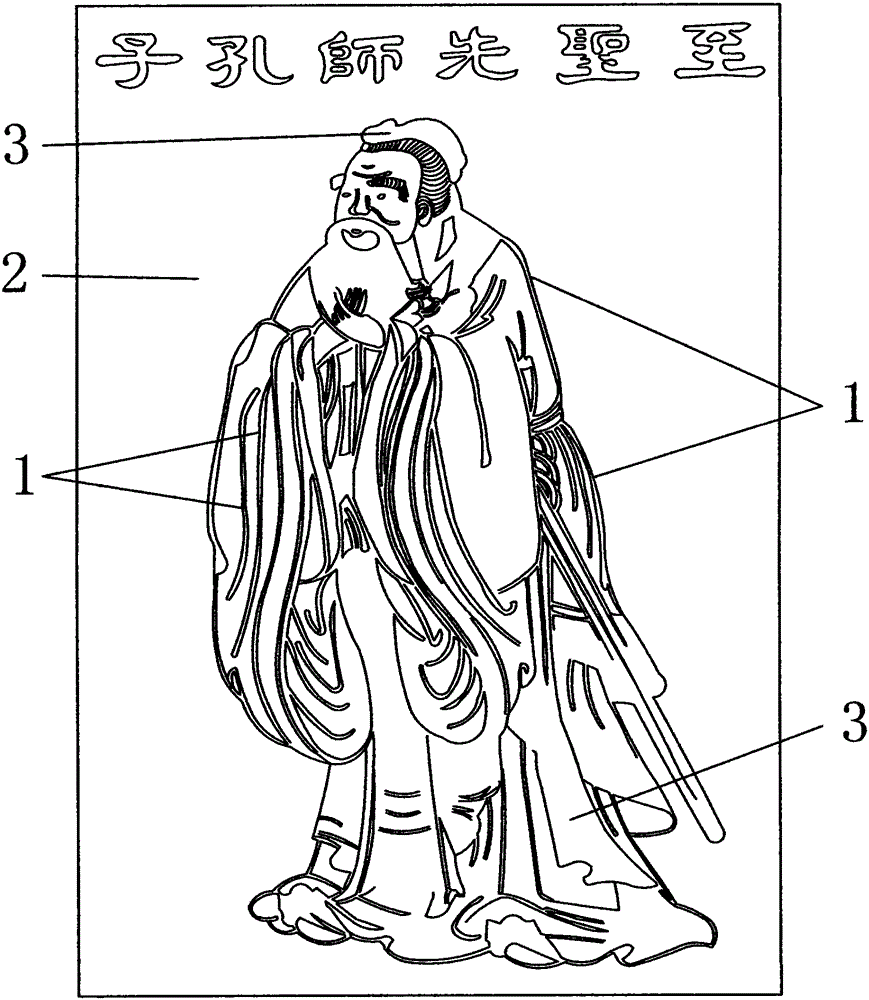

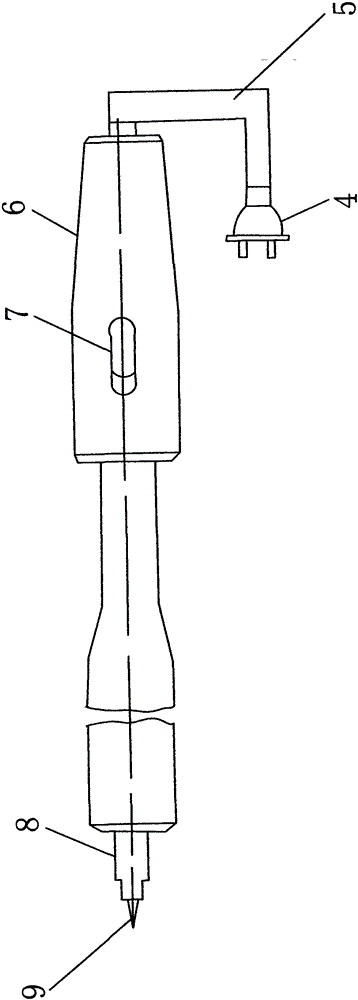

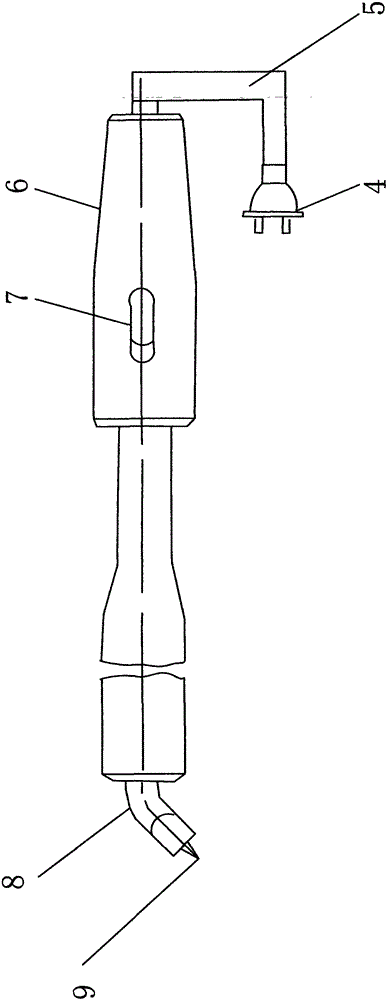

Method for making cloth carving and painting and special electric soldering iron

ActiveCN102963205BUnique artistic effectWide range of materialsBranding equipmentDecorative surface effectsEngineeringMechanical engineering

Belonging to the field of artware making, the invention discloses a making method a cloth engraved painting and a special electric soldering iron. The method includes the steps of: 1. selecting a cloth material and treating it; 2. selecting a painting heart color according to a pattern, and conducting back adhesive treatment on the painting heart; 3. cutting the painting heart according to the pattern size, and ironing the painting heart onto the back and belly according to a mounting proportion; 4. covering the painting heart with a drawing, taking out the pattern cloth, selecting a picture needed color, putting the cloth below the drawing, and performing tracing; 5. carrying out engraving with the electric soldering iron according to a contour line; 6. tearing off the excess cloth; 7. re-engraving the picture; 8. pasting the outer contour with a silk thread and a glue; and 9. performing mounting treatment according to requirements. The invention also discloses the electric soldering iron, and its soldering iron can be in a variety of shapes and is retractable. The product made by the method provided in the invention is beautiful, and has strong sense of appreciation, as well as high artistic value and collection value.

Owner:任雪青

A jacuzzi pump

ActiveCN106438382BFix the leakExpand the scope of actionPump componentsPump installationsImpellerMassage

The invention provides a massage bathtub pump which comprises a pump shell assembly, an impeller, a bearing, a pump cover assembly and an electric motor, wherein the impeller sleeves the bearing by a shaft sleeve; one side of the impeller is in a sealed connection with the pump cover assembly by a large O-shaped ring, and the other side is connected to the pump shell assembly through mechanical sealing; the shaft sleeve passes through the mechanical sealing and is in a sleeved connection with the bearing; the pump cover assembly is composed of a suction section, a cover shell and a lead-in component; the lead-in component is composed of three guide blades which are connected by round sleeve rings and bent in a certain direction; the guide blades are shaped like sectorial rings; the three guide blades cover a gradually expanded suction pipe of the suction section; and a raised guide block is disposed on each guide blade. The massage bathtub pump is characterized in that flow guide sheets are installed, so that water flows can enter the pump body smoothly; water flow pressure is reduced; collision of the water flows to the pump cover is reduced; efficiency is increased, and noise is reduced; local wear is avoided; a pump performance scope is expanded; and operations are convenient.

Owner:GUANGDONG LINGXIAO PUMP IND

A semi-open impeller stainless steel centrifugal pump

ActiveCN105673512BWide performance rangeAvoid concentrated wearSpecific fluid pumpsPump componentsSemi openCentrifugal pump

Owner:GUANGDONG LINGXIAO PUMP IND

Frequency conversion high-speed wet type submersible pump

InactiveCN101846085BReduce volumeReduce weightPump componentsPump installationsImpellerFrequency conversion

The invention discloses a frequency conversion high-speed wet type submersible pump relating to a fluid mechanical submersible pump and comprising a base (1), an impeller (3), a guide blade (4), a rear pump cover (5), a front sliding bearing (6), a thrust plate (7), a motor, a rear sliding bearing (11), a rear end cover (12), an outlet flange (14), an induction wheel (2), an auxiliary impeller (10), a filter (15) and a cooling pipeline (16), wherein the impeller (3) is connected with a motor shaft and is in a partially flowing or eccentric structure, the front end of the impeller (3) is provided with the variable pitch induction wheel (2), the outlet of the impeller (3) is provided with the guide blade (4); and the motor adopts a frequency conversion motor. The frequency conversion high-speed wet type submersible pump is a novel industrial pump with the advantages of small size, light weight, large lift, high efficiency and wide performance range, and is used for mine production drainage, permeable emergence and rescue and emergence drainage of other occasions.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com