Wood plastic composite material with mixed-color flow lines

A wood-plastic composite material and flow pattern technology, which is used in wood processing appliances, pretreatment of molding materials, household components, etc., can solve the problems of bacteria breeding, easy fading, dull color of wood-plastic composite materials, etc., to prevent mildew , bright color, not easy to fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

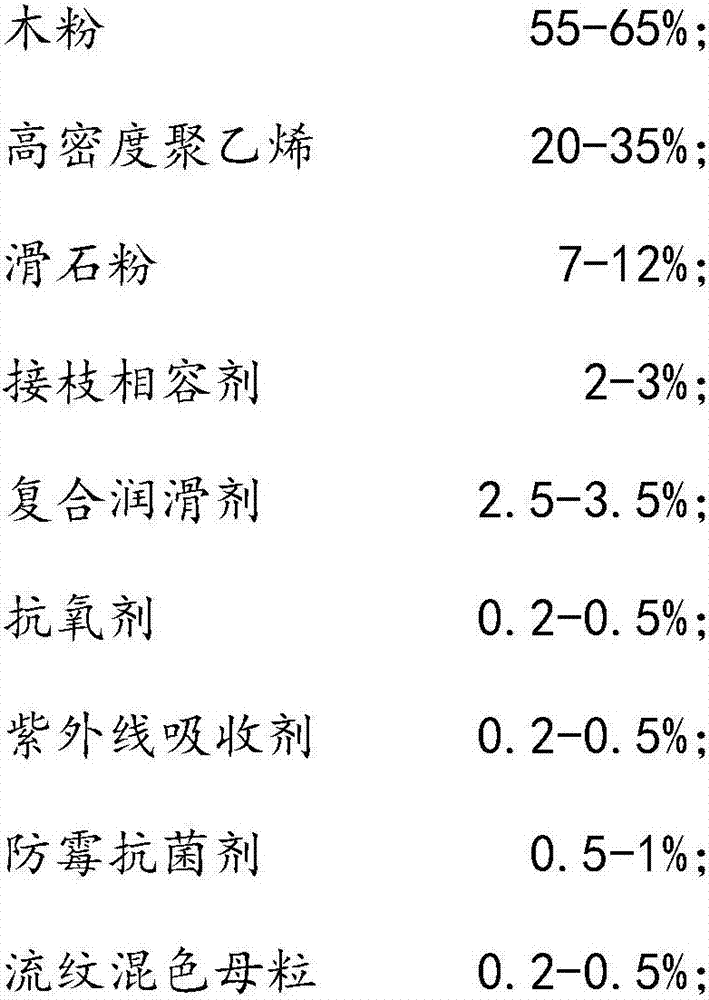

[0025] A flow pattern mixed color wood-plastic composite material, the specific steps are as follows:

[0026] Step 1: put wood flour with a mass fraction of 55% into a high-speed mixer, add 2.5% compound lubricant for high-speed mixing when the temperature is raised to 80°C, and mix well, then add 20% high-speed blender when the temperature rises to 105°C Density polyethylene, 7% talcum powder, 2% graft compatibilizer, 0.2% antioxidant, 0.2% ultraviolet absorber, 0.5% anti-mildew and antibacterial agent, continue to mix at a high speed to 120 ° C and cool down in the cold mixer ;

[0027] Step 2: The mixed and cooled material is pre-plasticized at 160°C by a special granulator, plasticized and extruded into lumps by parallel twin-screws, and then crushed into particles of a certain size by a crushing fan;

[0028] Step 3: Add the crushed particles and 0.2% rhyolite masterbatch into the low-speed mixer, and mix for 3 minutes at low speed;

[0029] Step 4: Extrude the mixed p...

Embodiment 2

[0032] A flow pattern mixed color wood-plastic composite material, the specific steps are as follows:

[0033] Step 1: Put the wood powder with a mass fraction of 60% into a high-speed mixer, add 3% compound lubricant for high-speed mixing when the temperature rises to 80-90°C, mix well, add 25% when the temperature rises to 110°C High-density polyethylene, 10% talcum powder, 2.5% graft compatibilizer, 0.3% antioxidant, 0.3% ultraviolet absorber, 0.7% anti-mold and antibacterial agent, continue to mix at a high speed to 125 ° C and then cool down machine cooling;

[0034] Step 2: The mixed and cooled material is pre-plasticized at 170°C by a special granulator, plasticized and extruded into lumps by parallel twin-screws, and then crushed into particles of a certain size by a crushing fan;

[0035] Step 3: Add the crushed particles and 0.4% rhyolite masterbatch into the low-speed mixer, and mix for 3 minutes at low speed;

[0036] Step 4: Extrude the mixed particles through a...

Embodiment 3

[0039] A flow pattern mixed color wood-plastic composite material, the specific steps are as follows:

[0040] Step 1: Put the wood powder with a mass fraction of 65% into a high-speed mixer, add 3.5% of the compound lubricant when the temperature rises to 90°C for high-speed mixing, and mix well, then add 35% of the high-speed mixer when the temperature rises to 115°C Density polyethylene, 12% filler, 3% graft compatibilizer, 0.5% antioxidant, 0.5% ultraviolet absorber, 1% anti-mold and antibacterial agent, continue to mix at a high speed to 130 ° C and cool down in the cold mixer ;

[0041] Step 2: The mixed and cooled material is pre-plasticized at 190°C by a special granulator, plasticized and extruded into lumps by parallel twin-screws, and then crushed into particles of a certain size by a crushing fan;

[0042] Step 3: Add the crushed particles and 0.5% rhyolite masterbatch into the low-speed mixer, and mix for 5 minutes at low speed;

[0043] Step 4: Extrude the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com