High heat conducting foam material of graphite, and fabricating method

A technology of high thermal conductivity graphite and foam materials, which is applied in the field of manufacturing high thermal conductivity graphite foam and high thermal conductivity graphite foam, can solve the problem of no pressure release method, etc., and achieve low manufacturing cost, controllable density and porosity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put a certain amount of petroleum mesophase pitch powder into a high-temperature and high-pressure reactor, evacuate to 0.1Mpa, heat up to 260°C at a heating rate of 4°C / min, pressurize to 6.0Mpa, and then heat up to 2°C / min The temperature is 350°C, the temperature is kept constant for 15 minutes, after cooling to room temperature, the gas is released at a constant speed to normal pressure, and the asphalt foam is obtained;

[0030] Raise the temperature of the obtained asphalt foam to 950°C at a heating rate of 1°C / min, and carry out carbonization treatment under the protection of nitrogen throughout the process to obtain carbonized asphalt foam;

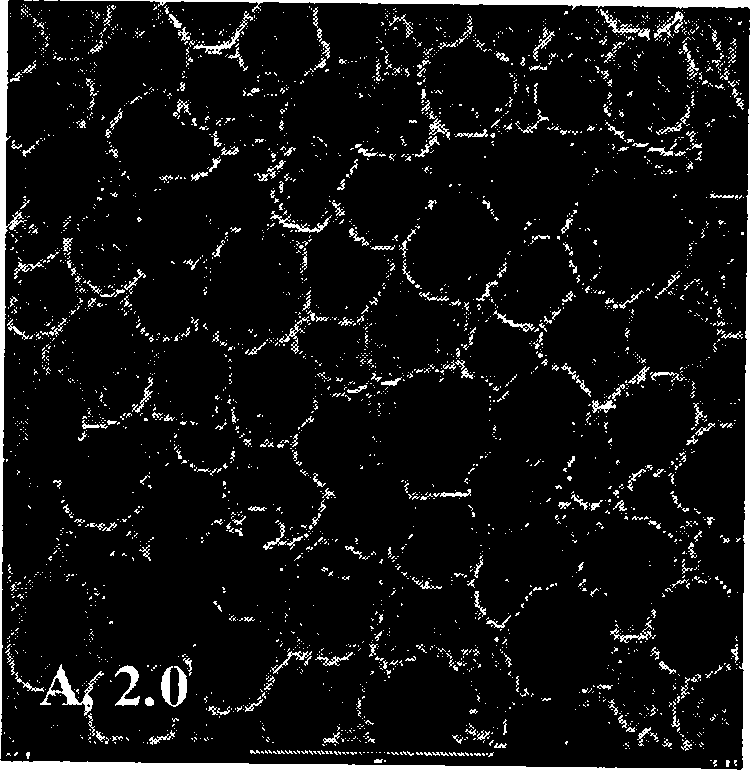

[0031] Under the protection of argon, the obtained carbonized bitumen foam is heated up to 2600°C at a heating rate of 1°C / min, and cooled naturally to obtain the following figure 2 Shown high thermal conductivity graphite foam material; After measuring, the density of the high thermal conductivity graphite foam material p...

Embodiment 2

[0033] Take a certain amount of coal tar pitch powder after high-temperature heat treatment and put it into a high-temperature and high-pressure reactor, evacuate to 0.08Mpa, heat to 350°C at a heating rate of 5°C / min, pressurize to 4Mpa, and then pressurize to 1°C / min The heating rate is raised to 450°C, after constant temperature for 1 hour, while cooling to room temperature at a cooling rate of 1-2°C / min, at the same time, the gas is released at a constant speed to reduce the temperature to the softening point of the raw material (that is, 300°C) to normal pressure; to obtain bituminous foam;

[0034] The resulting asphalt foam was heated up to 1050°C at a heating rate of 1°C / min, and carbonized under the protection of nitrogen throughout the process to obtain carbonized asphaltin foam.

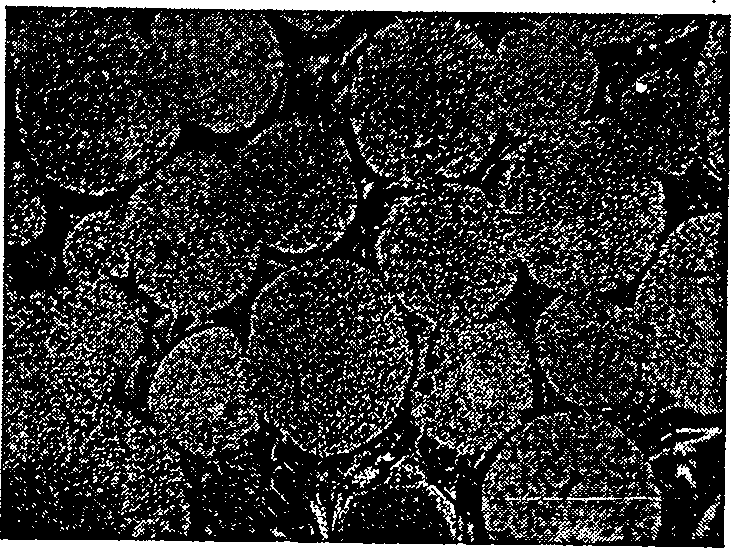

[0035] The obtained carbonized bitumen foam is heated up to 2800°C at a heating rate of 1°C / min under the protection of argon, and cooled naturally to obtain the following: figure 1 The h...

Embodiment 3

[0037] Take a certain amount of synthetic mesophase pitch particles and put them into a high-temperature and high-pressure reactor, evacuate to 0.08Mpa, heat up to 400°C at a heating rate of 1°C / min, pressurize to 2Mpa, and continue to heat up at a heating rate of 1°C / min to 550°C, keep the temperature constant for 2 hours, and after rapid and uniform degassing to normal pressure, cool down to room temperature at 1°C / min to obtain asphalt foam;

[0038] The obtained asphalt foam is heated up to 1100°C at a heating rate of 1°C / min, and carbonized under the protection of nitrogen throughout the process to obtain a carbonized asphalt foam.

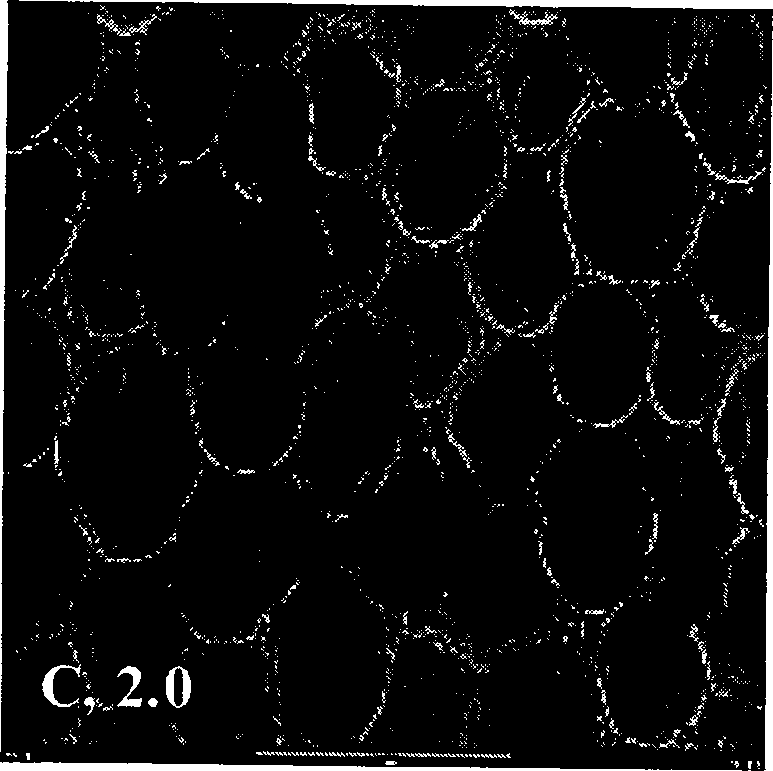

[0039] The obtained carbonized bitumen foam is heated up to 3000°C at a rate of 1°C / min under the protection of argon, and cooled naturally to obtain the following: image 3 The high thermal conductivity graphite foam material shown; the density of the high thermal conductivity graphite foam material obtained after measurement is 0.28g / cm 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com