Multi-stage centrifugal pump with improved impeller arrangement

A centrifugal pump and impeller technology, which is applied to the components, pumps, pump elements, etc. of the pumping device for elastic fluid, which can solve the problem of unfavorable versatility, the cutting capacity of a single impeller is not enough to meet the adjustment needs, and the head difference is large. and other problems, to achieve the effect of reducing one-time investment, reducing product models, and expanding performance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

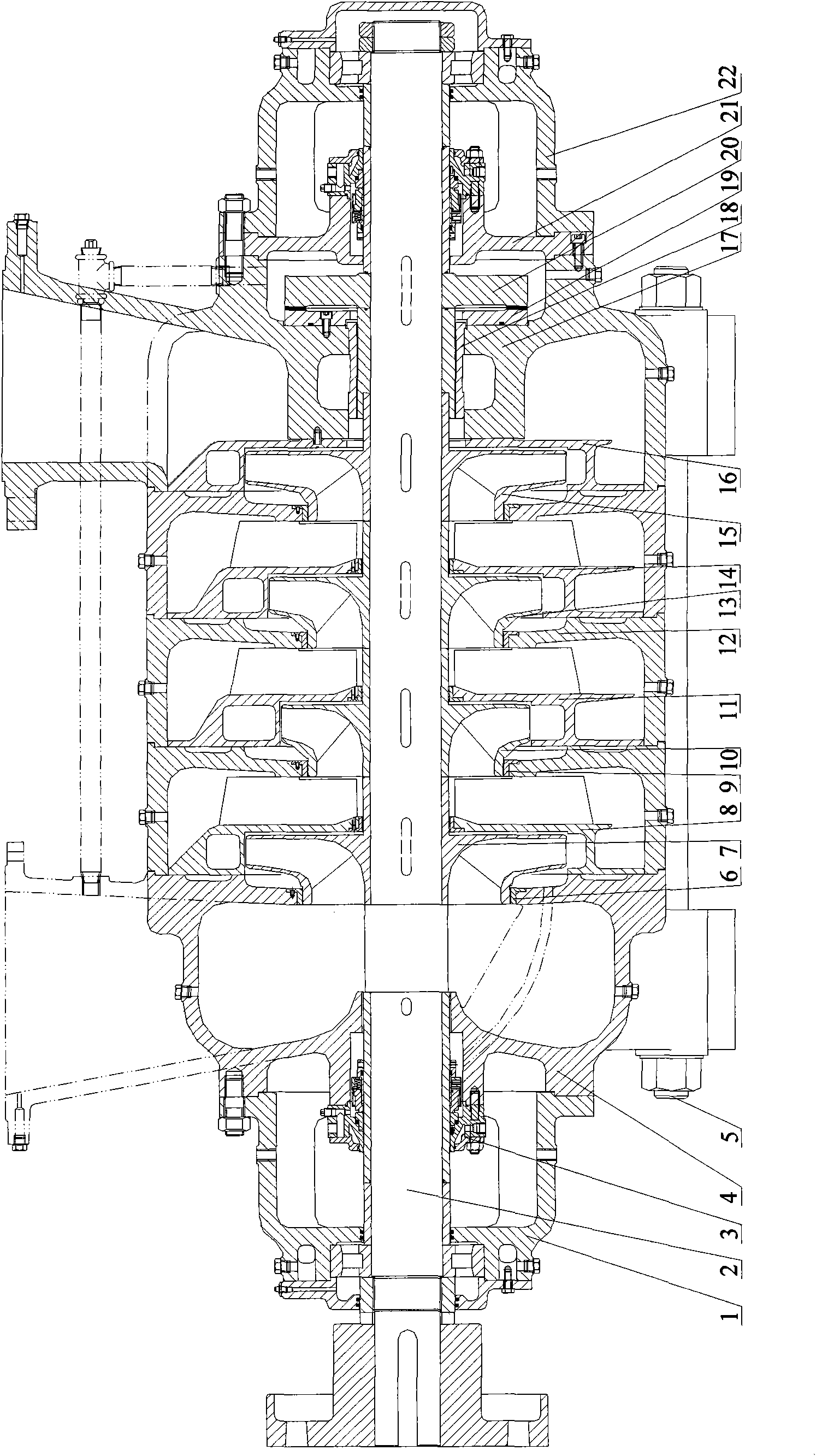

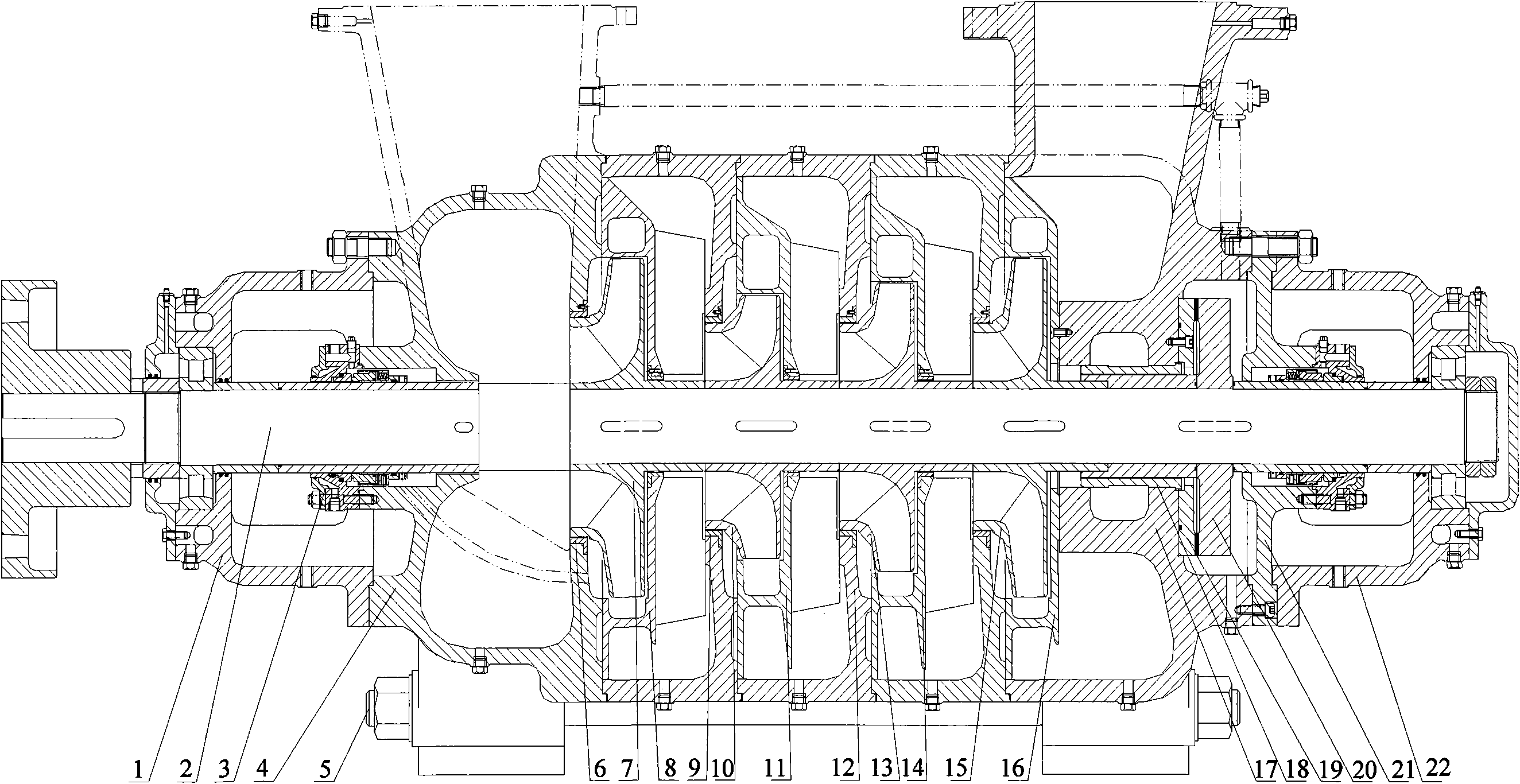

[0023] A multi-stage centrifugal pump with improved impeller arrangement, its structure is as follows figure 1 As shown, the centrifugal pump includes left bearing part 1, shaft 2, mechanical seal part 3, water inlet section 4, tension bolt 5, inlet seal ring 6, primary impeller 7, guide vane 8, secondary seal ring 9, 1 / 2 stage impeller 10, 1 / 2 stage guide vane 11, middle section 12, 2 / 3 stage impeller 13, 2 / 3 stage guide vane 14, interstage impeller 15, final stage guide vane 16, water outlet section 17, throttling Sleeve 18, balance ring 19, balance plate 20, tail cover 21, right bearing part 22, left bearing part 1 and right bearing part 22 are arranged on the left and right sides of shaft 2 of the centrifugal pump, water inlet section 4, first stage impeller 7 , guide vane 8, 1 / 2 stage impeller 10, 1 / 2 stage guide vane 11, middle section 12, 2 / 3 stage impeller 13, 2 / 3 stage guide vane 14, interstage impeller 15, final stage guide vane 16, water outlet Section 17, throttli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com