One-step synthesis method for polyurethane material with gradually-changing modulus

A modulus gradient, polyurethane technology, applied in the preparation of polymer gradient materials, can solve the problems of high reaction curing temperature, increased contact with air, long reaction time and curing time, etc., to achieve the effect of expanding the performance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

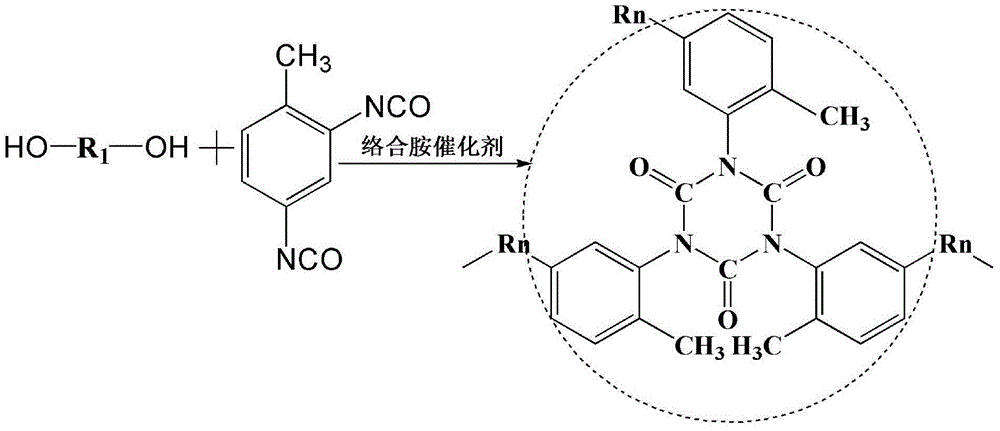

Method used

Image

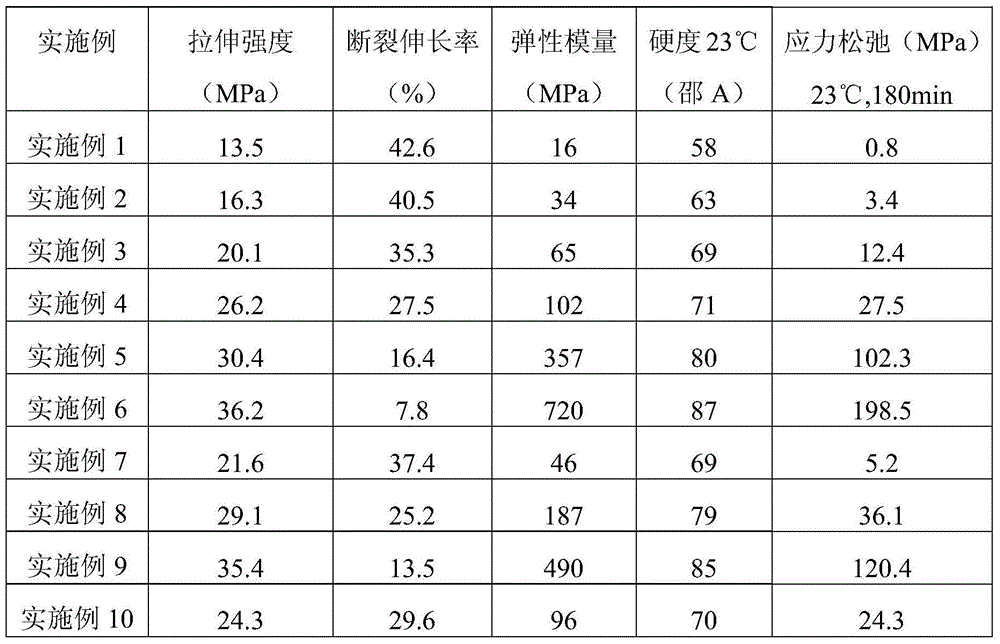

Examples

Embodiment 1

[0026]Add 170.00g (0.1mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-neck flask, dehydrate in vacuum at 110°C and -0.1MPa for 2 hours, and wait until the temperature drops to 50°C , start to configure the complex amine catalyst, add 0.18g N,N-dimethylbenzylamine (DMBA) and 3.60g bisphenol A diglycidyl ether (DGEBA) to 8.00g anhydrous acetone and stir to mix evenly, then add 34.80 g (0.2mol, 17wt%) of 2,4-toluene diisocyanate (2,4-TDI) was added to a three-necked flask together with the above-mentioned catalyst, and after the system was vacuumed and degassed for 10 minutes at 50°C, the solution was poured into poly The tetrafluoroethylene mold is placed in a vacuum drying oven, and the bulk polymerization is carried out in a vacuum state. The heating conditions are 60°C / 2h+80°C / 3h+100°C / 2h+120°C1h, and finally poly(urethane-isocyanate )The internet. Infrared analysis showed that the product was at 3540cm -1 The characteristic peak o...

Embodiment 2

[0029] Add 170.00g (0.1mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-neck flask, dehydrate in vacuum at 110°C and -0.1MPa for 2 hours, and wait until the temperature drops to 50°C , start to configure the complex amine catalyst, add 0.26g N,N-dimethylbenzylamine (DMBA) and 5.20g bisphenol A diglycidyl ether (DGEBA) to 10.92g anhydrous acetone and stir to mix evenly, then add 52.20 g (0.3mol, 23wt%) of 2,4-toluene diisocyanate (2,4-TDI) and the above-mentioned catalyst were added into a three-necked flask, and after the system was vacuumed and defoamed for 10 minutes at 50°C, the solution was poured into a poly The tetrafluoroethylene mold is placed in a vacuum drying oven, and the bulk polymerization is carried out in a vacuum state. The heating conditions are 60°C / 2h+80°C / 3h+100°C / 2h+120°C1h, and finally poly(urethane-isocyanate )The internet. Infrared analysis showed that the product was at 3540cm -1 The characteristic peak of t...

Embodiment 3

[0032] Add 120.00g (0.07mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-neck flask, dehydrate in vacuum at 110°C and -0.1MPa for 2 hours, and wait until the temperature drops to 50°C , start to configure the complex amine catalyst, add 0.24g N,N-dimethylbenzylamine (DMBA) and 4.80g bisphenol A diglycidyl ether (DGEBA) to 10.08g anhydrous acetone and stir to mix evenly, then add 48.72 g (0.28mol, 29wt%) of 2,4-toluene diisocyanate (2,4-TDI) and the above-mentioned catalyst were added into a three-necked flask, and after the system was vacuumed and defoamed for 10 minutes at 50°C, the solution was poured into a poly The tetrafluoroethylene mold is placed in a vacuum drying oven, and the bulk polymerization is carried out in a vacuum state. The heating conditions are 60°C / 2h+80°C / 3h+100°C / 2h+120°C1h, and finally poly(urethane-isocyanate )The internet. Infrared analysis showed that the product was at 3540cm -1 The characteristic peak of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com