Efficient energy-saving fan applied to feed, flour and rice system process

A high-efficiency, energy-saving, flour-based technology, applied to the components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., can solve the problems of fans that cannot be changed according to needs, performance requirements do not match, and maintenance is complicated. , to achieve the effect of saving electricity, reducing operating costs, and operating reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

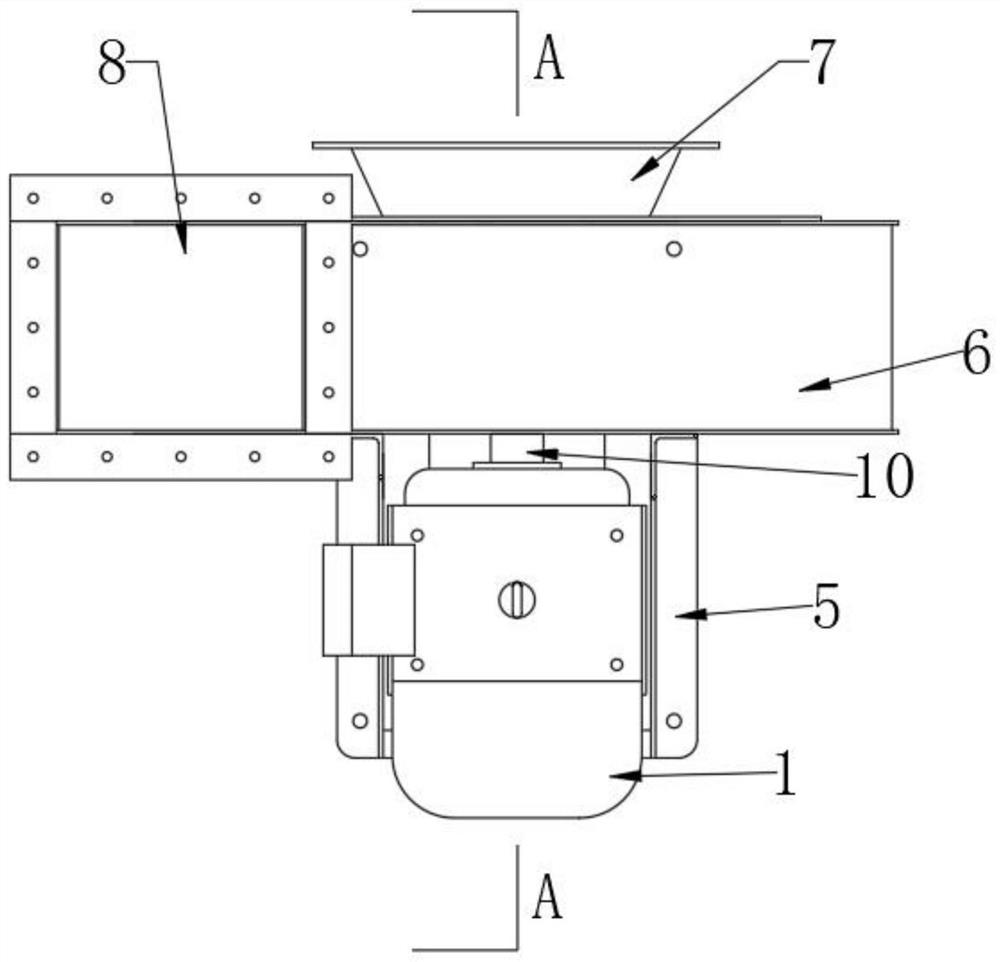

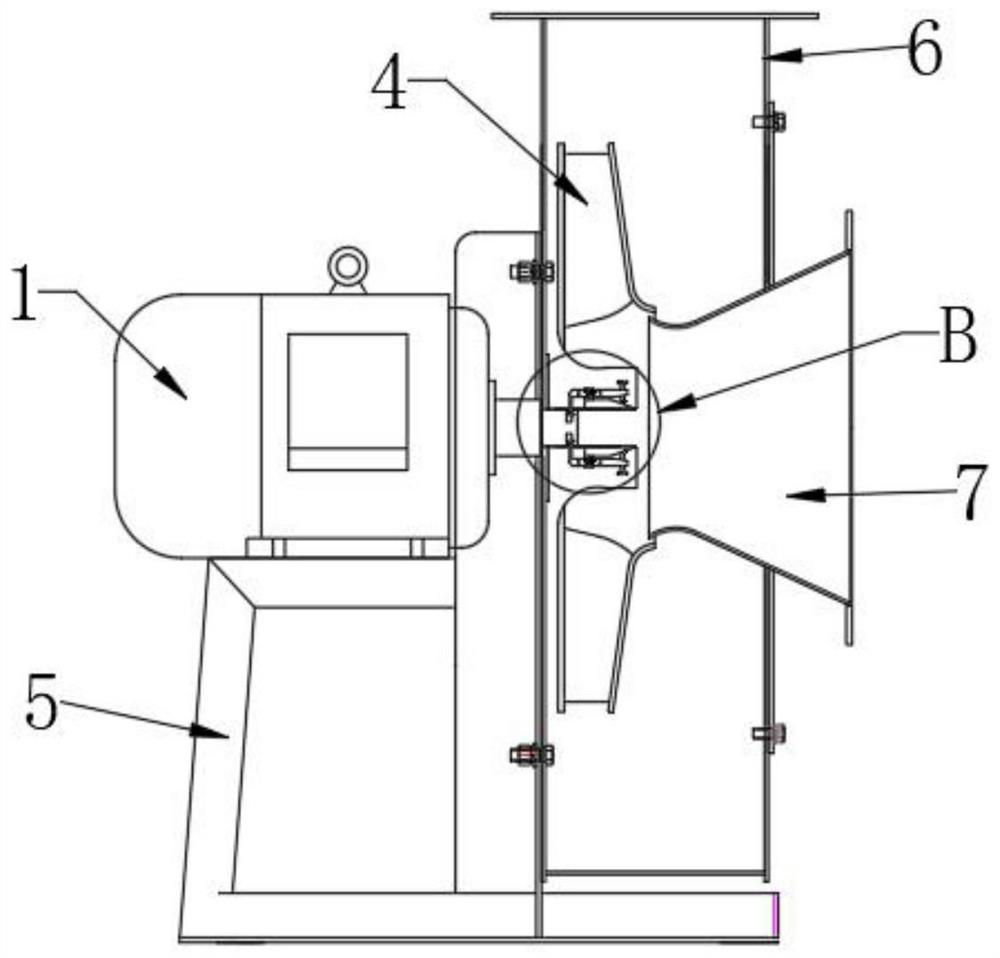

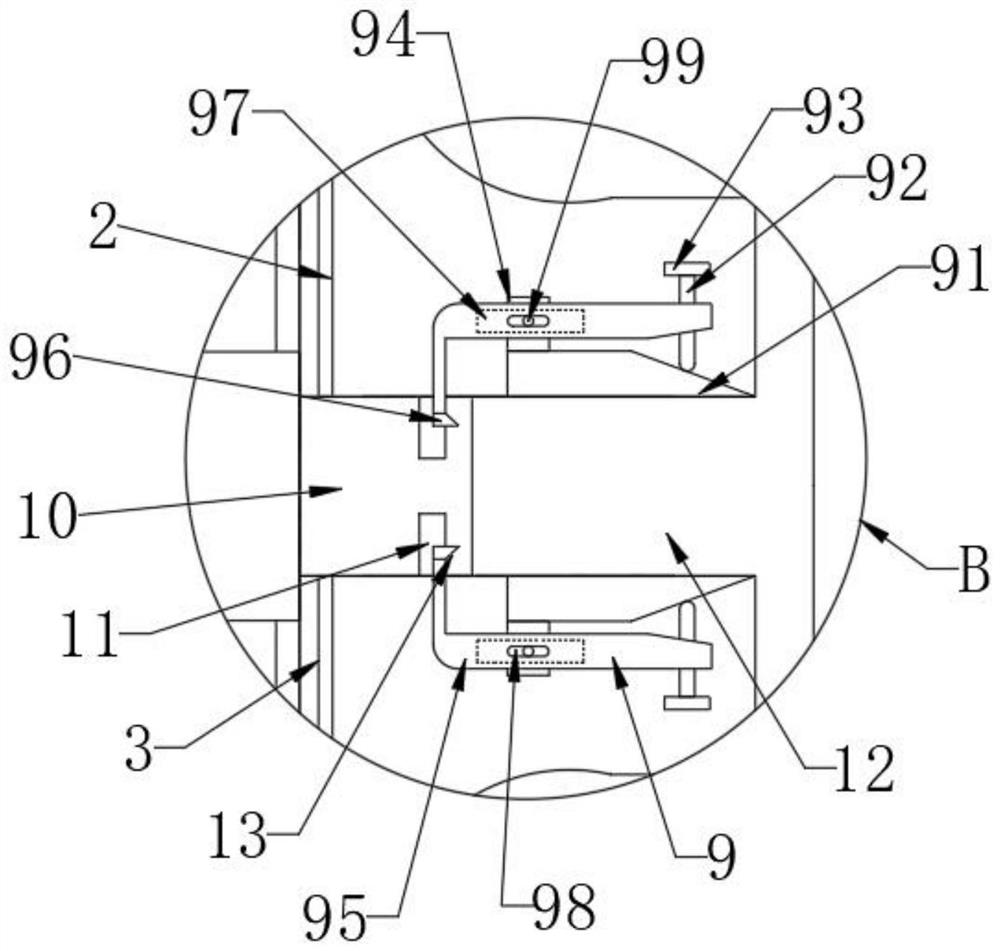

[0025] see Figure 1-3 , a high-efficiency energy-saving fan used in feed, flour, and rice system processes, including a machine base 5, the upper surface of the machine base 5 is fixedly connected with a motor 1, and the outlet end of the motor 1 is fixedly connected with a first rotating shaft 10, the first The other end of the rotating shaft 10 is fixedly connected with the second rotating shaft 12 through the connecting assembly 9, the outer wall of the second rotating shaft 12 is fixedly connected with the impeller 4, the outer side of the impeller 4 is provided with an organic casing 6, and the upper end of the casing 6 is provided with an air outlet 8 , the back of the casing 6 is fixedly connected with an air intake ring 7 .

[0026] In a further embodiment, through the design of the machine base 5, it is convenient to fix the motor 1, and at the same time, the machine base 5 plays a supporting role for the motor 1. The fan can meet the flow rate of 5200m3 / h, the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com