Patents

Literature

52results about How to "Loss of stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

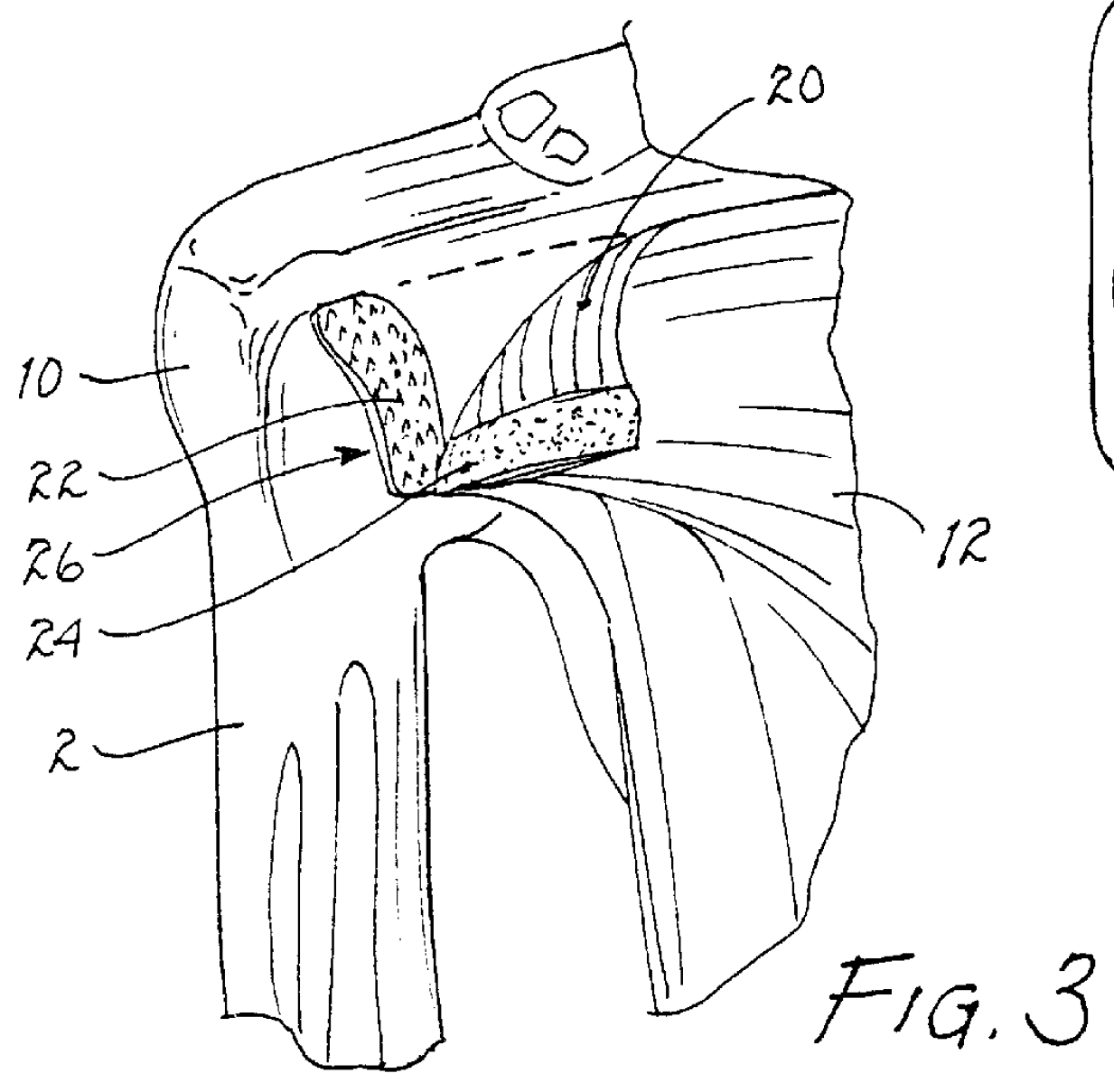

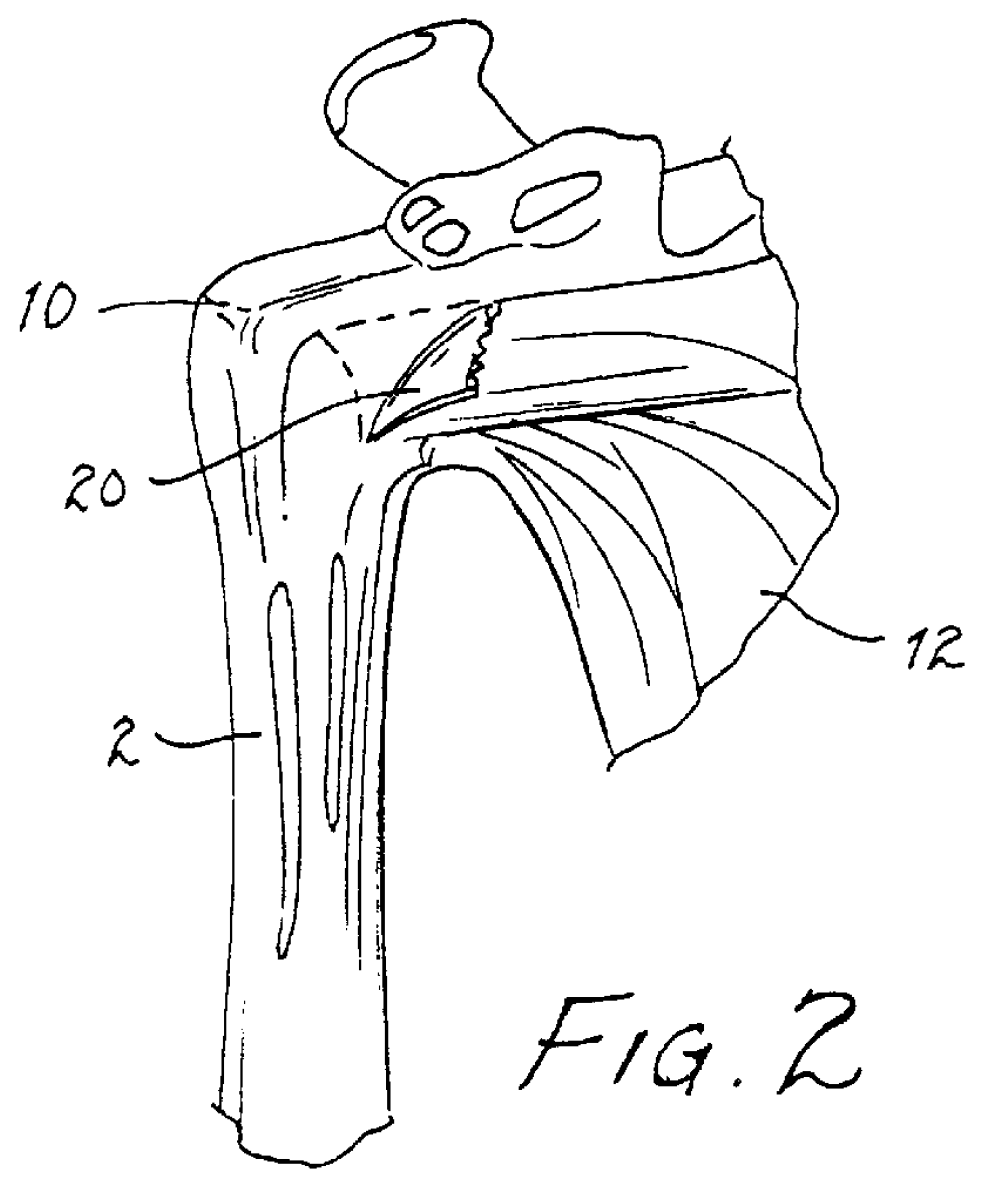

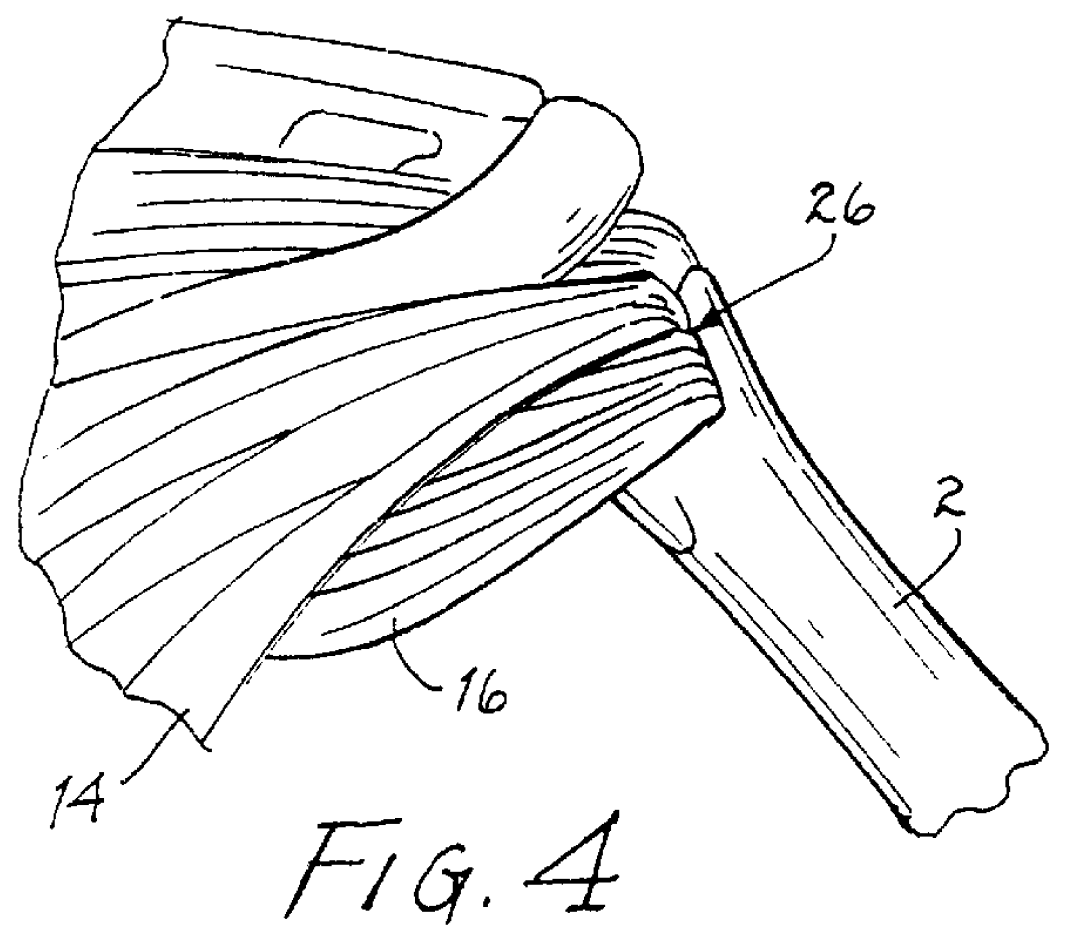

Method for surgical repair with hook-and-loop fastener

InactiveUS6039741APhysical recoveryRisk minimizationLigamentsMusclesSurgical repairLigament structure

Surgical repairs of torn or ruptured tendons and ligaments are made by re-fastening the torn or ruptured tendon or ligament with a biocompatible or bioabsorbable hook-and-loop fastener.

Owner:MEISLIN ROBERT J

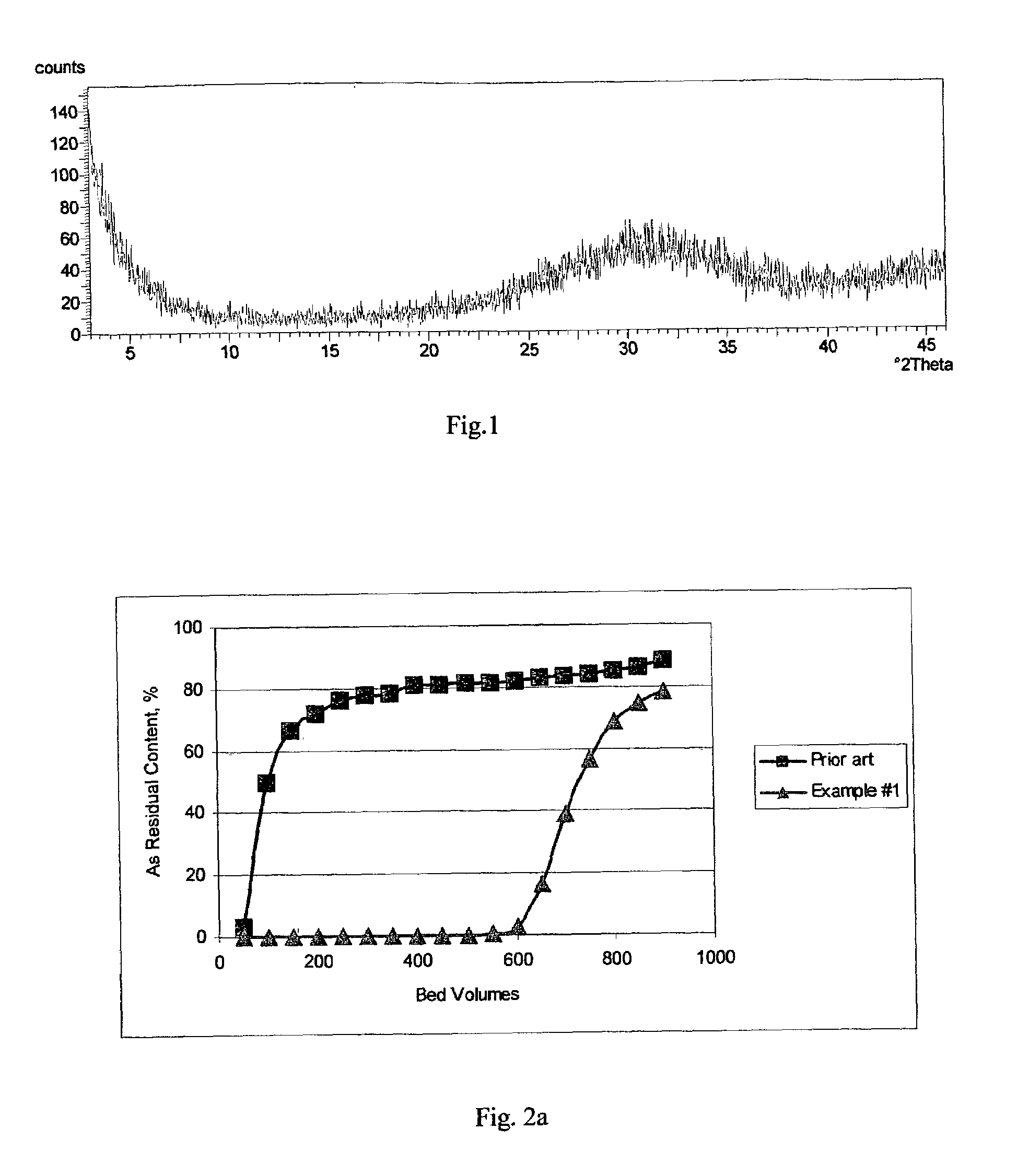

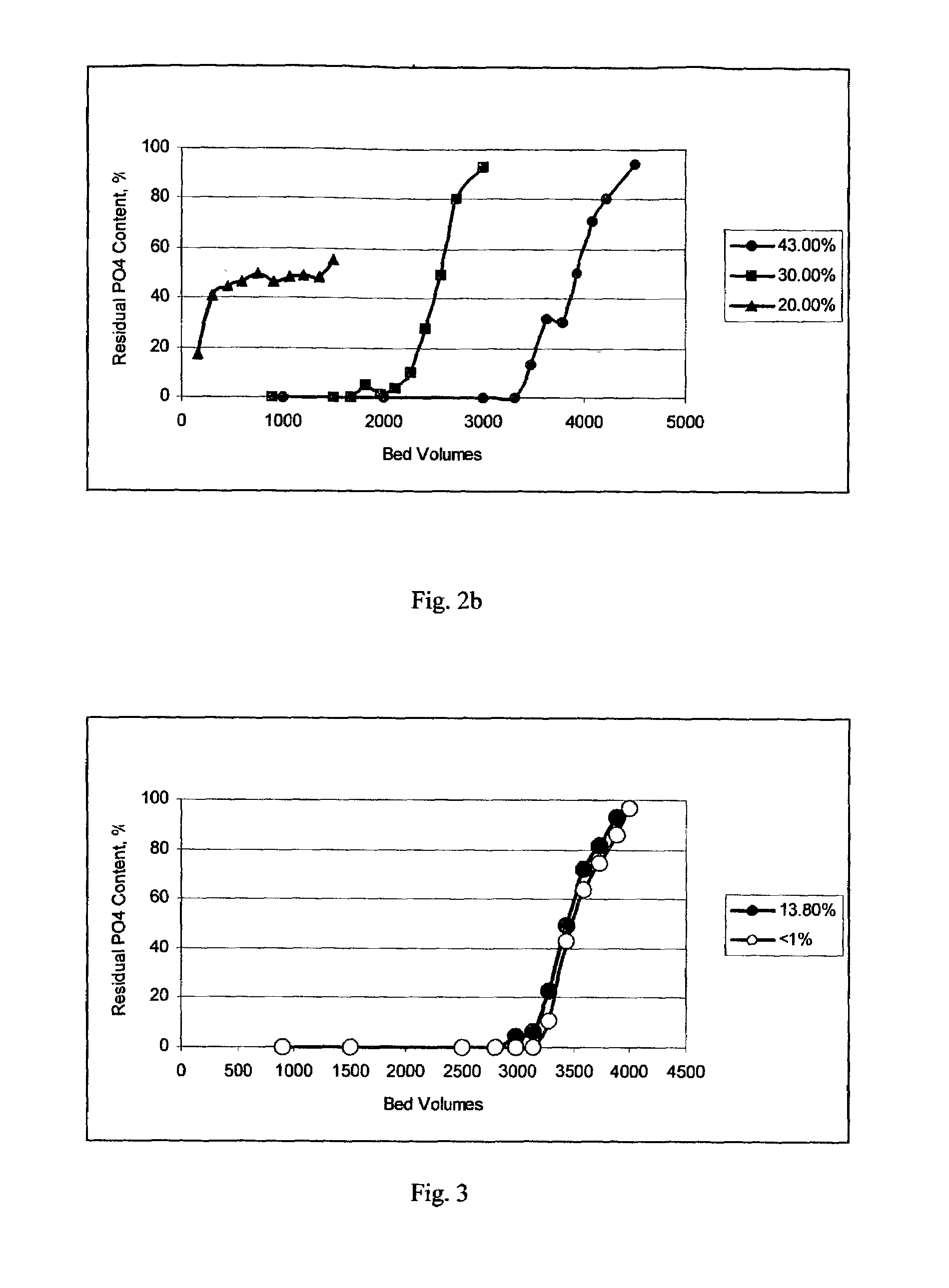

Hydrous zirconium oxide, hydrous hafnium oxide and method of making same

ActiveUS7252767B2Loss of stabilityDegree of reductionOther chemical processesSolid sorbent liquid separationIonIon exchange

The present invention features a method of making hydrous zirconium oxide having desirable properties, including resistance to moisture content, predetermined particle size, and developed porosity and surface area. The inventive material is suitable for use as an ion exchanger, a catalyst and a catalyst support. The process comprises providing a liquid comprising a zirconium compound and an alkali metal-containing reagent. The alkali metal-containing reagent may comprise a compound selected from the group consisting of MOH-M2SO4, MOH-M3PO4, and combinations thereof, where M is at least one of Li, Na and K. The zirconium compound may be treated with the alkali metal-containing reagent effective to form a mixture which achieves an uptake of alkali metal in an amount ranging from 0.5 to 2.5 meq / g. The mixture is reacted to form the hydrous zirconium oxide. A molar ratio of SO4 / Zr and PO4 / Zr in the mixture may range from 0.2-0.7:1. The mixture may be heated at a temperature ranging from 80 to 150° C. to produce a reaction product. The reaction product may be treated with acid having a pH ranging from 4 to 8 at a temperature ranging from 20 to 60° C. to form the hydrous zirconium oxide. Also featured is a method of making hydrous hafnium oxide. The inventive hydrous zirconium oxide and hydrous hafnium oxide are characterized by at least one of the following: stability against moisture loss, a particular surface area, a particular pore size distribution, an affinity towards anions including at least one of PO4, HPO4, H2PO4, AsO4, HAsO4, H2AsO4 and AsO3, oxoanions of Cr, Se, B, Mo,and W, and / or resistance against poisoning by SiO3 and SO4.

Owner:MEL CHEM

Absorbing agents and cover layer which is impermeable to active substances and which contains channel-formers or removable protective layer of a transdermal therapeutic system

InactiveUS7220473B2Reduce thicknessManufacturing cost be reduceSurgeryPretreated surfacesPolymer supportedThermoplastic

This present invention concerns a cover layer that is impermeable to the active substances and / or a removable protective layer of a transdermal therapeutic system, comprising a thermoplastic film which either directly contains the absorbing agents and channel-forming agents or is coated with a polymer support (thermoplast) containing these substances. The polymer support can either be applied over the entire surface of the film or in patterns, directly during production. The thermoplastic film that is used and the polymer support can be made from either the same or different materials.

Owner:HEXAL AG

Lipidic protein-transfer systems and cosmetic/dermatological use thereof

InactiveUS20070053852A1Improved lipid transferEmulsion stabilizationCosmetic preparationsHair cosmeticsLipid formationCarrier system

The present invention relates to compositions having bioactive transfer proteins in stable carrier systems. Such systems are above all suitable for influencing / changing lipid cell structures by means of improved lipid exchange, while at the same time having great stability. In this connection, not only transfer proteins and lipid components, but also protective colloids are used, by means of which an impairment of the transfer effect of the proteins and a loss of stability can be avoided. The compositions are suitable for external topical use for cleansing, care, dermatological and / or therapeutic treatment of the skin, hair, or mucous membranes.

Owner:MERZ PHARMA GMBH & CO KGAA

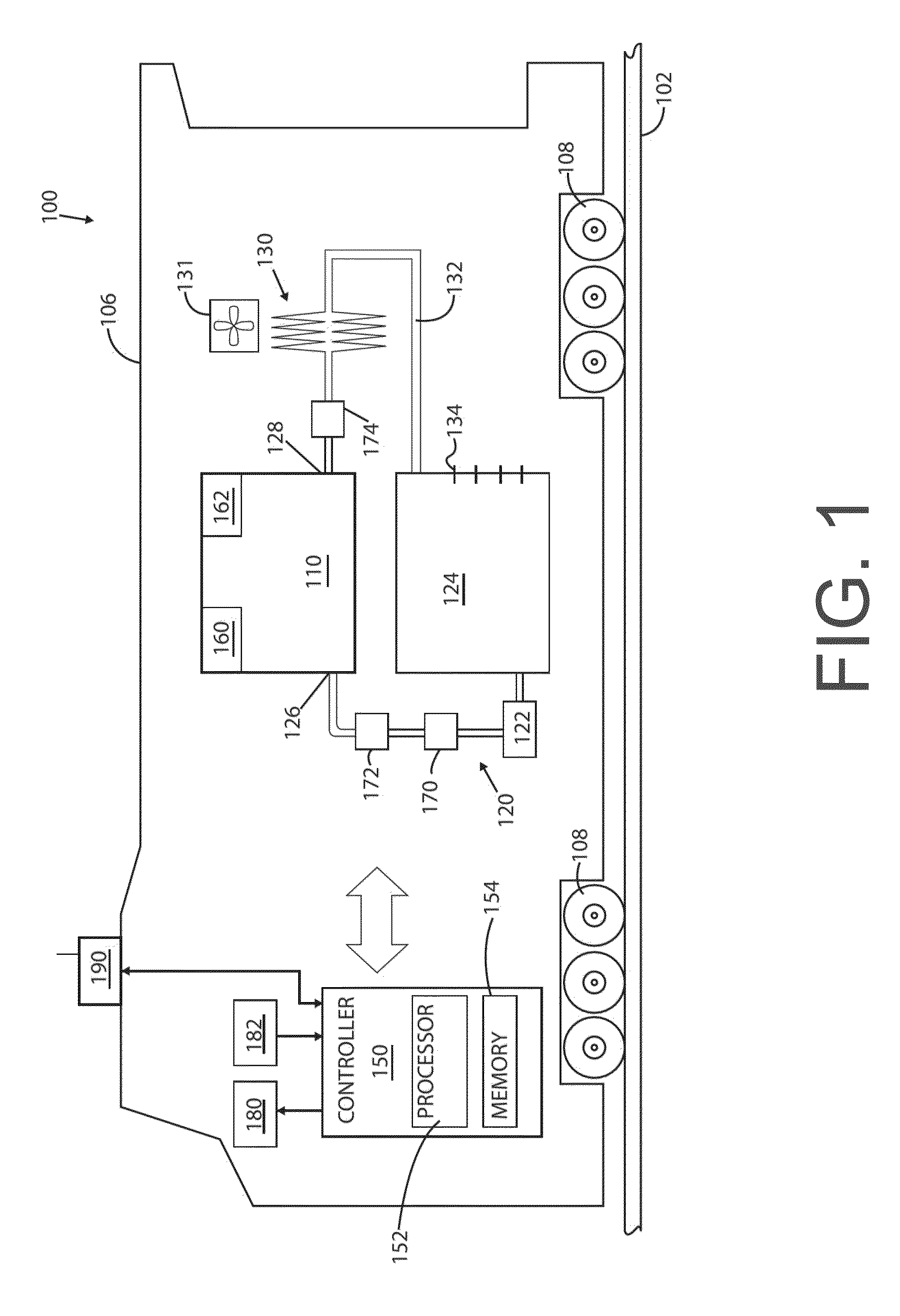

Systems and methods for diagnosing an engine

ActiveUS20130338899A1Loss of stabilityInternal-combustion engine testingAnalogue computers for vehiclesAutomotive engineeringPressure response

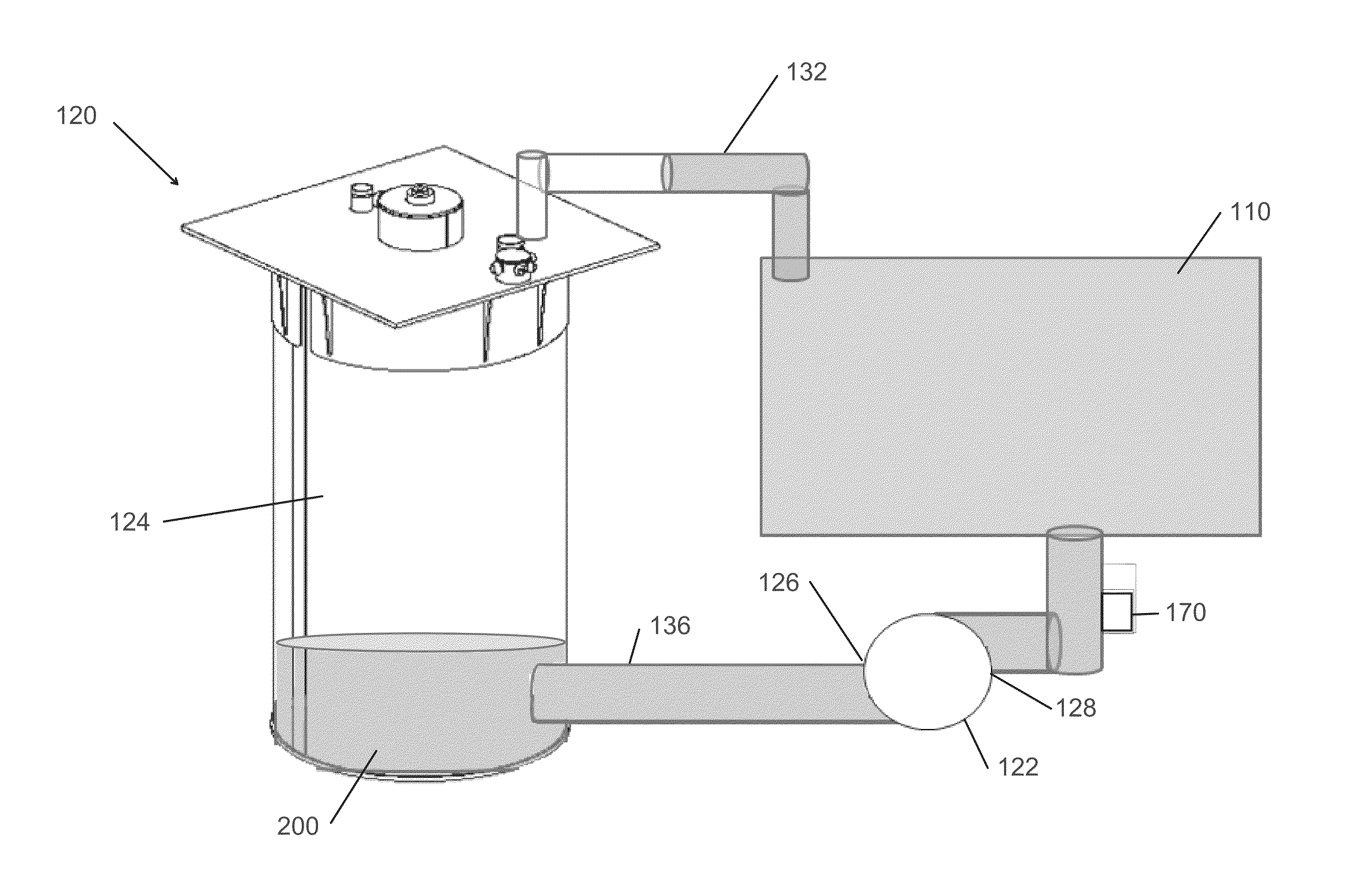

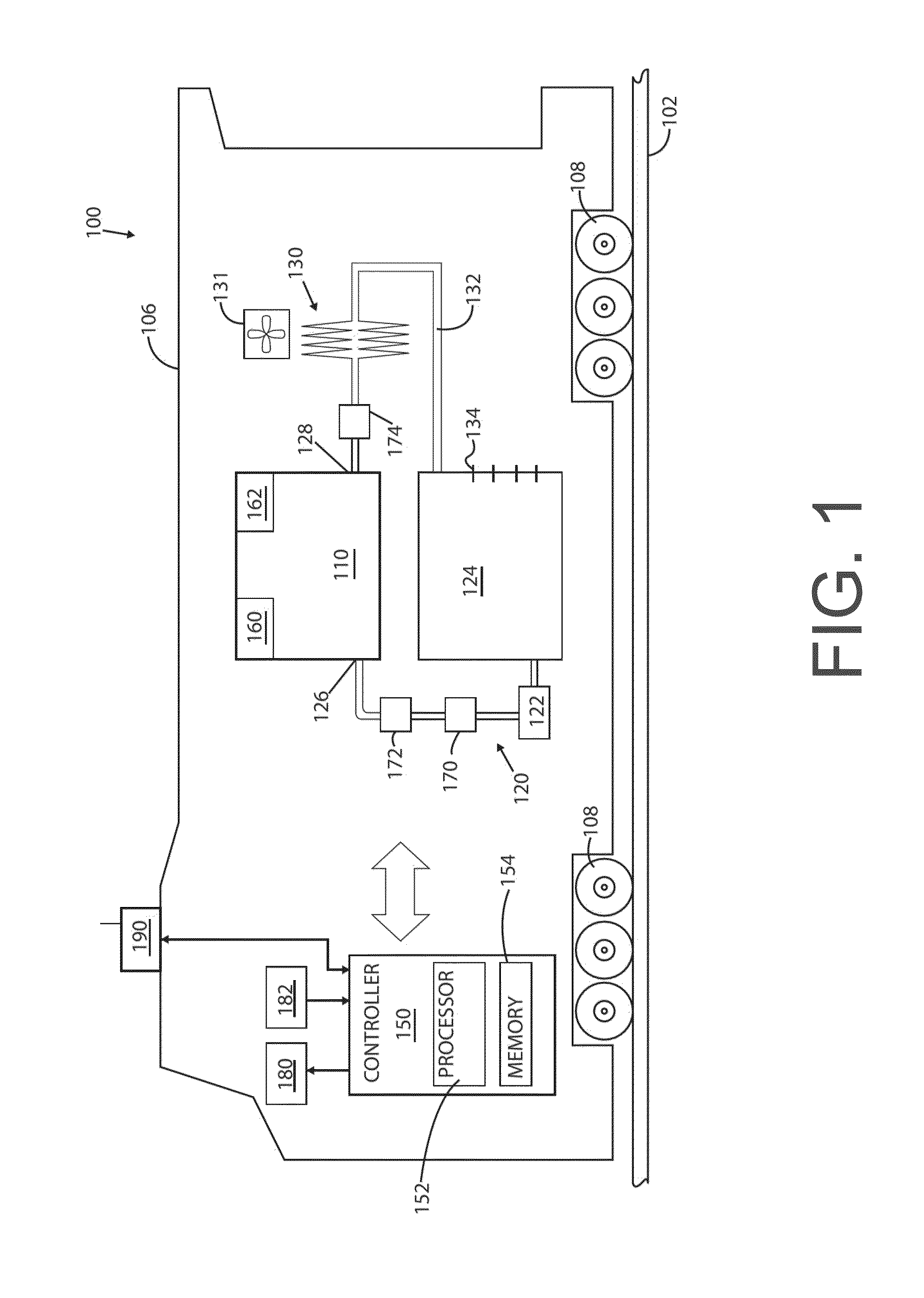

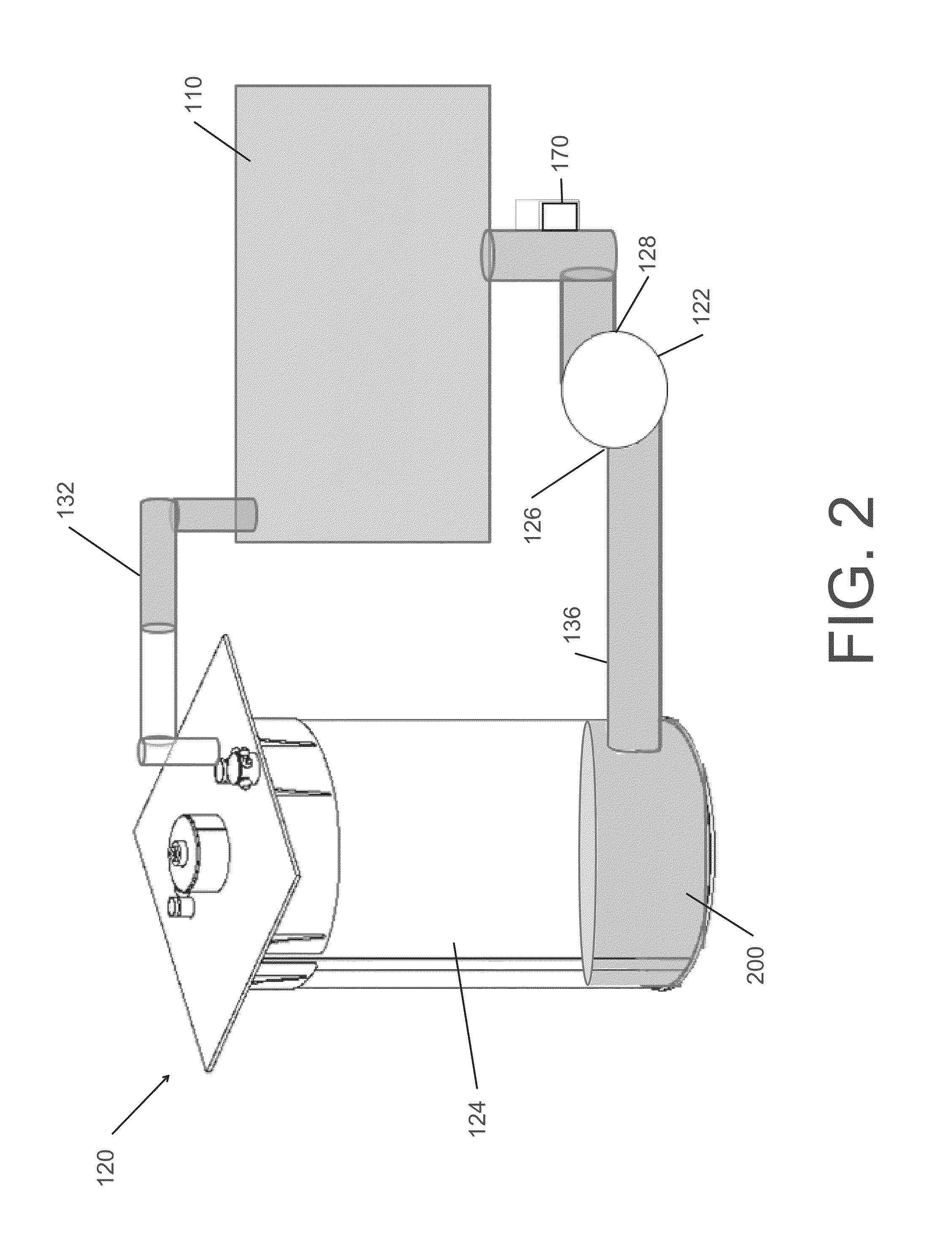

Presently disclosed are methods and systems for detecting and diagnosing a coolant leak of an engine. A method may include diagnosing a coolant leak of the engine based on a low frequency pressure response of a measured engine coolant pressure. A vehicle system is also disclosed, including an engine, a coolant system operatively connected to the engine. The coolant system includes a coolant reserve and a coolant pump between the engine and the coolant reserve. The vehicle also includes a coolant pressure sensor to measure coolant pressure, and a controller configured to measure an engine coolant pressure and diagnose a coolant leak of the coolant system based on a low frequency pressure response of the measured engine coolant pressure.

Owner:GE GLOBAL SOURCING LLC

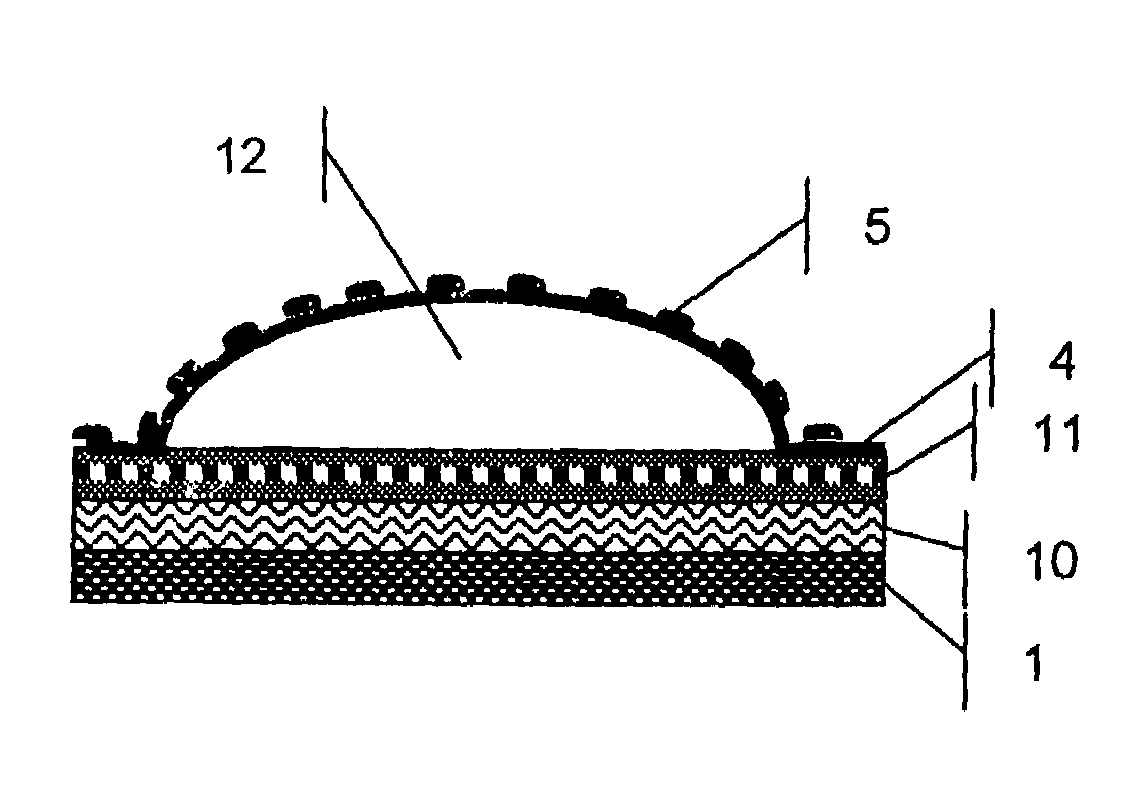

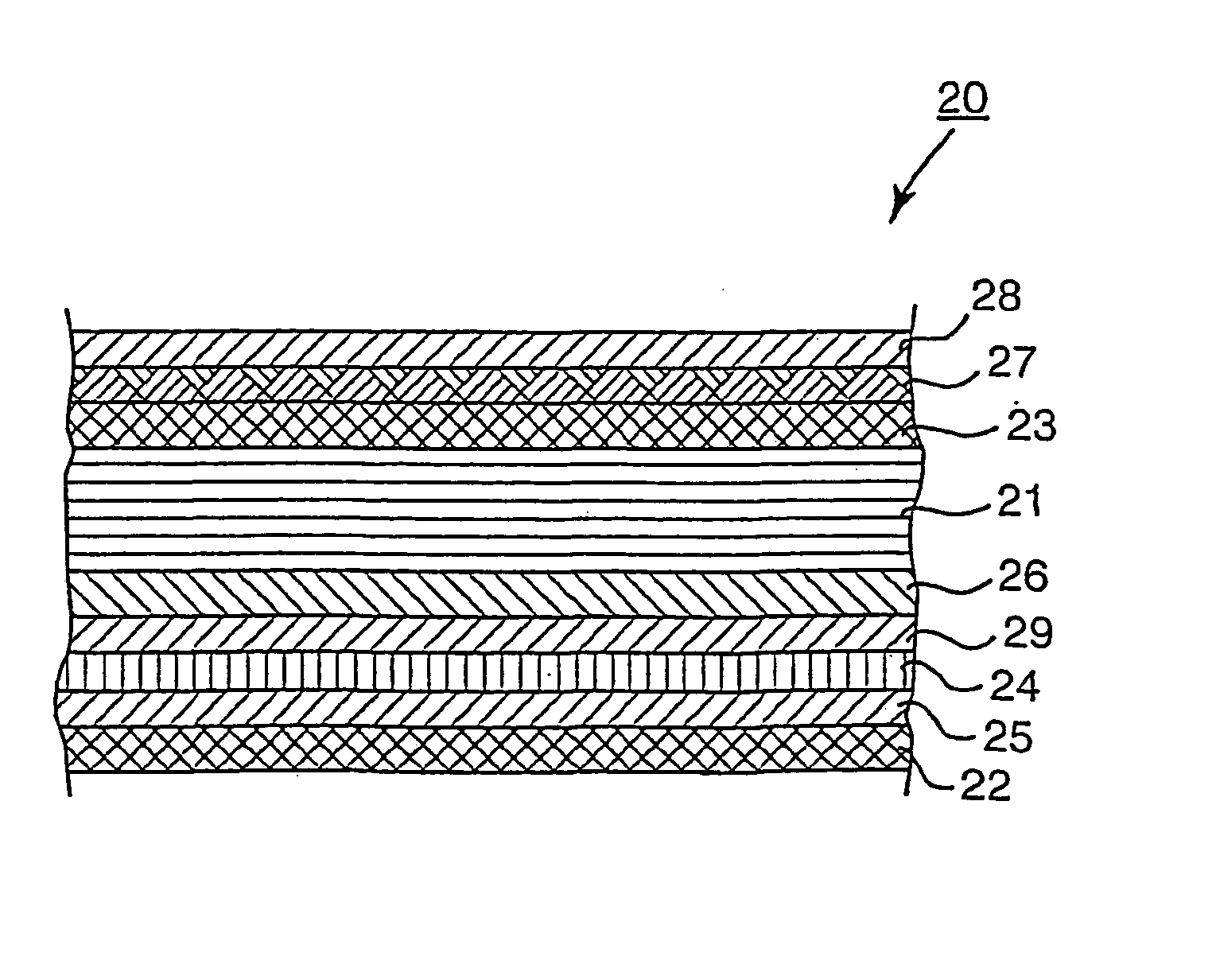

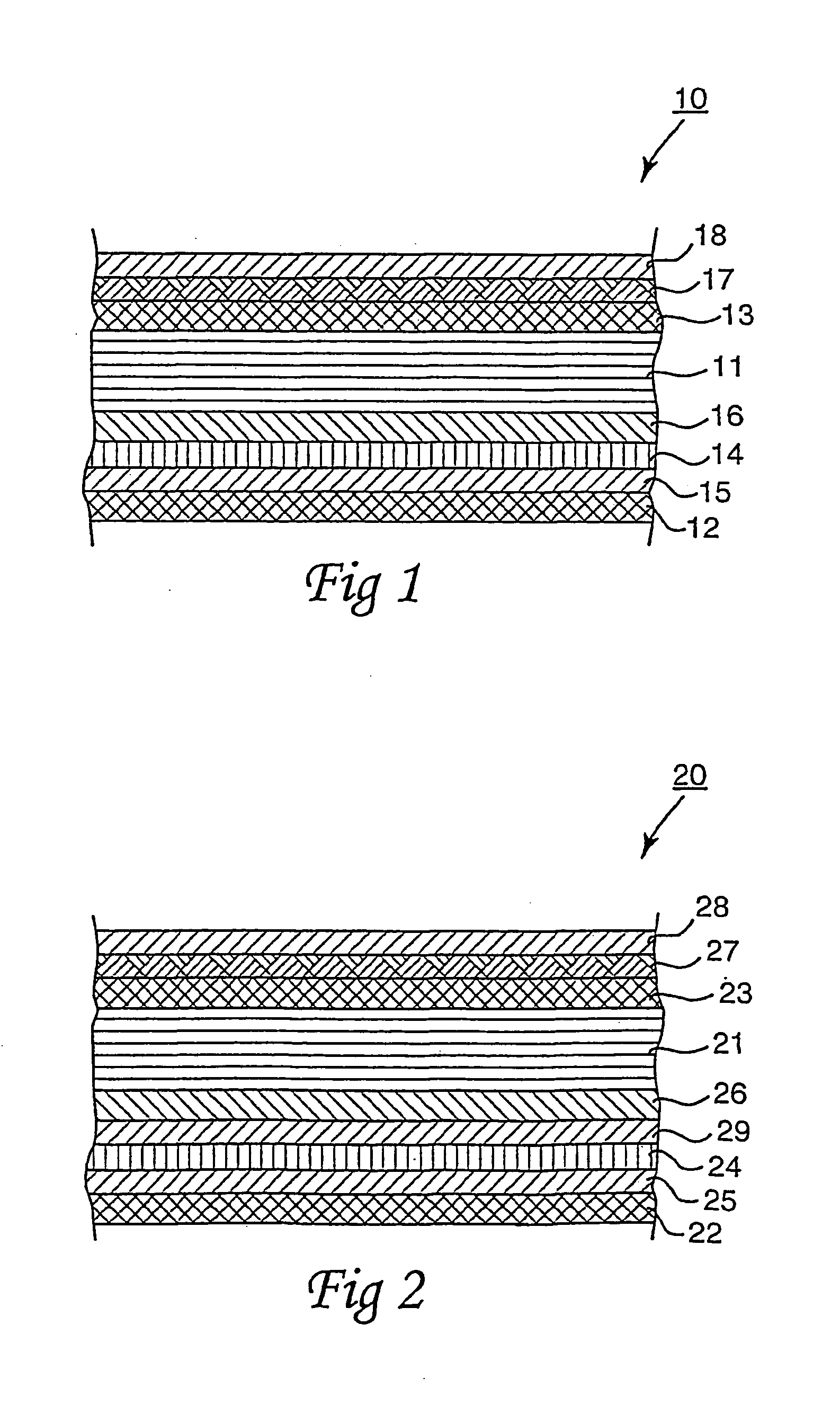

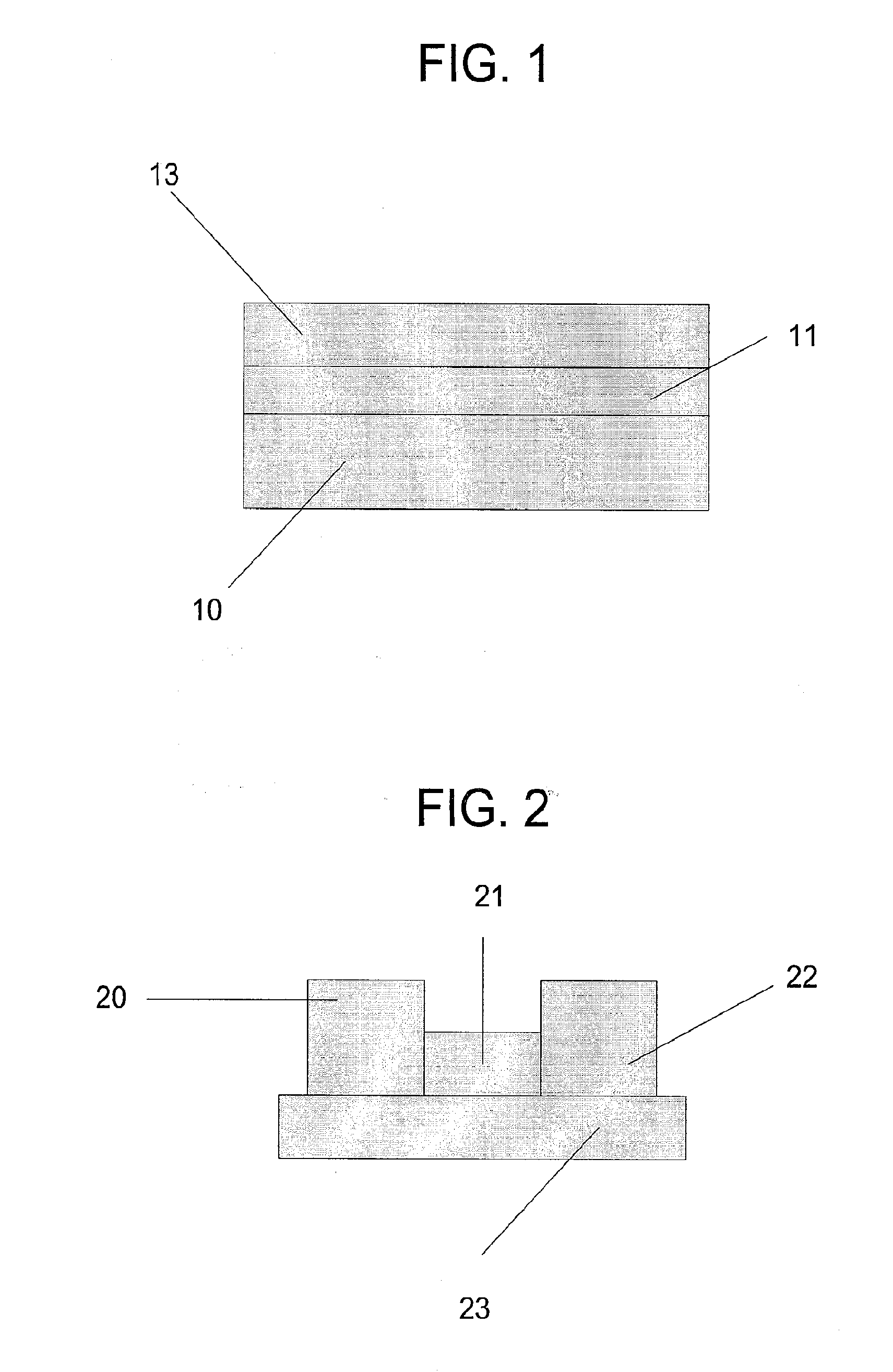

Packaging laminate for a retortable packaging container

InactiveUS20040023045A1Loss of configurational stabilityLoss of mechanical strengthFlexible coversWrappersPolypropyleneSealant

The disclosure relates to a packaging laminate for a retortable packaging container comprising a core layer (11), outer, liquid-tight coatings (12 and 13) and a gas barrier (14) disposed between the one coating (12) and the core layer (11). Between the gas barrier (14) and the core layer (11), there is a layer (16) of a lamination or sealing agent of such a nature that the lamination or sealing agent has a melting point which is higher than the maximum temperature to which the retortable packaging container is to be subjected during a normal heat treatment in a retort. The lamination or sealing agent in the layer (16) may, for example, be a polypropylene with a melting point of above 130° C.

Owner:TETRA LAVAL HLDG & FINANCE SA

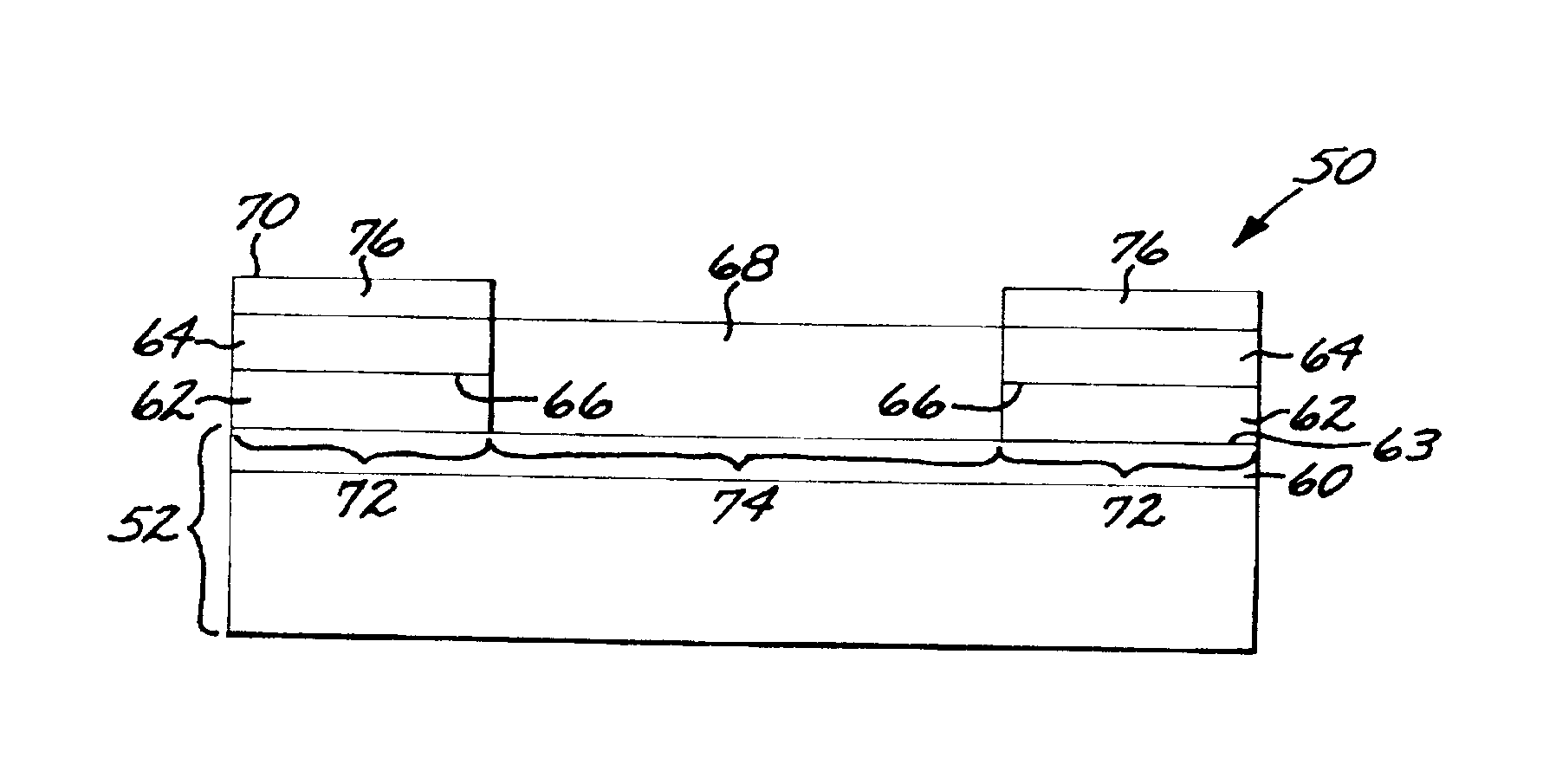

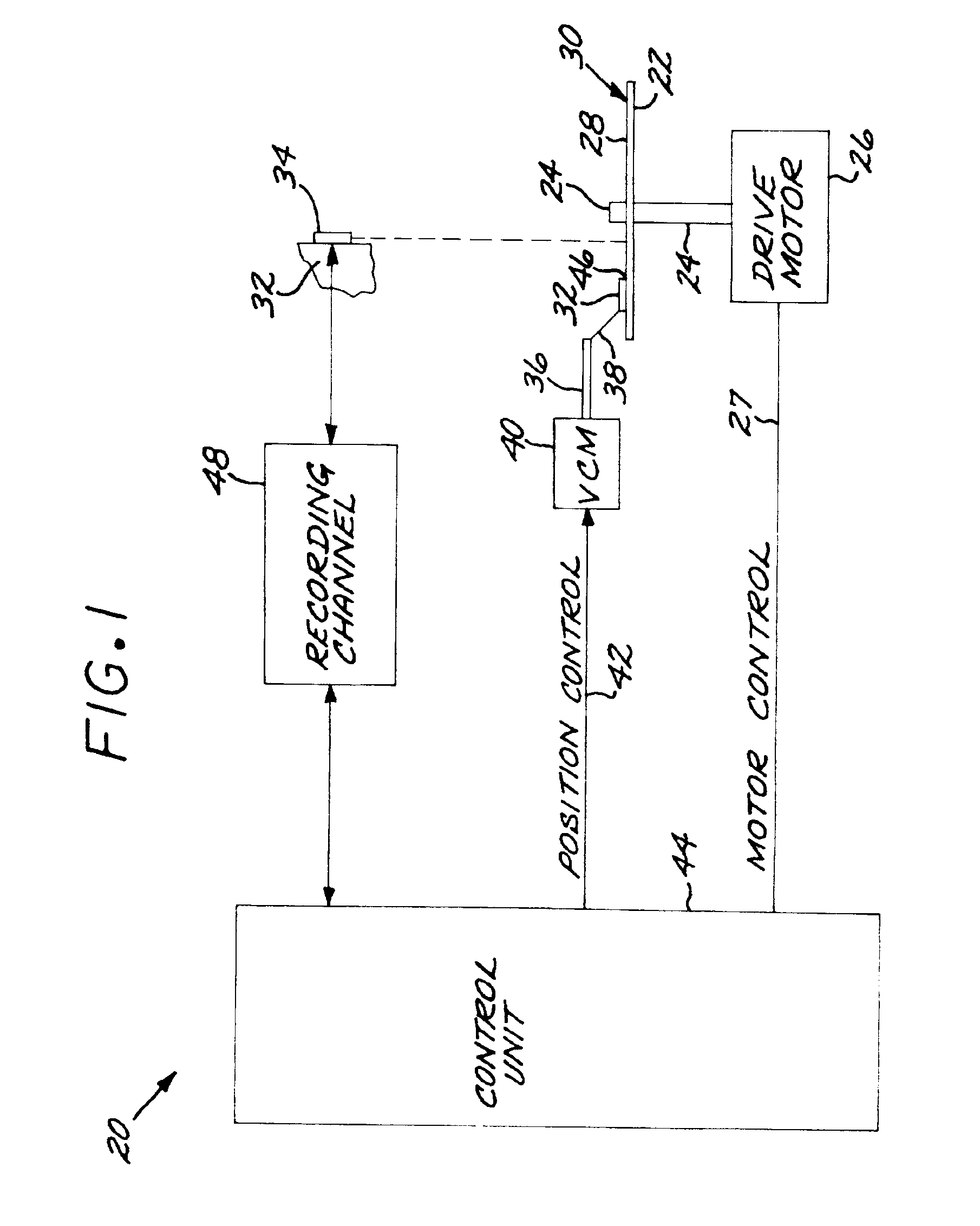

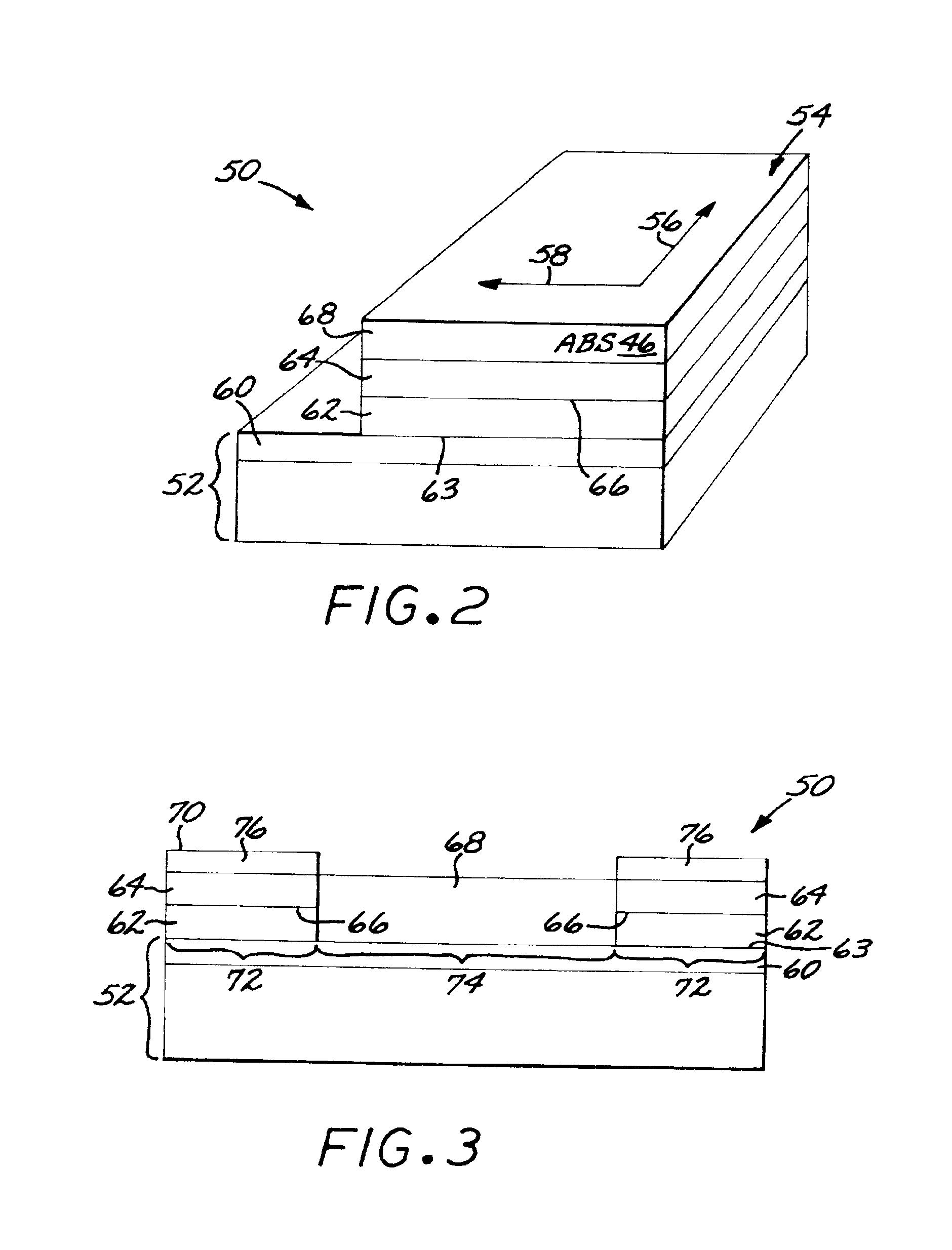

Magnetoresistance sensor having an antiferromagnetic pinning layer with both surfaces pinning ferromagnetic bias layers

InactiveUS6961225B2Increasing structural efficiency of structureReduce coupling strengthNanomagnetismNanoinformaticsGiant magnetoresistanceOptoelectronics

A magnetoresistance sensor structure includes a magnetoresistance sensor having a sensor surface plane and having a free layer. An upper antiferromagnetic layer overlies at least a portion of the free layer, and an upper ferromagnetic layer overlies and contacts at least a portion of the upper antiferromagnetic layer on a contact face lying parallel to the sensor surface plane, so that the upper antiferromagnetic layer lies between the upper ferromagnetic layer and the free layer. The magnetoresistance sensor may be a giant magnetoresistance sensor or a tunnel magnetoresistance sensor.

Owner:IBM CORP

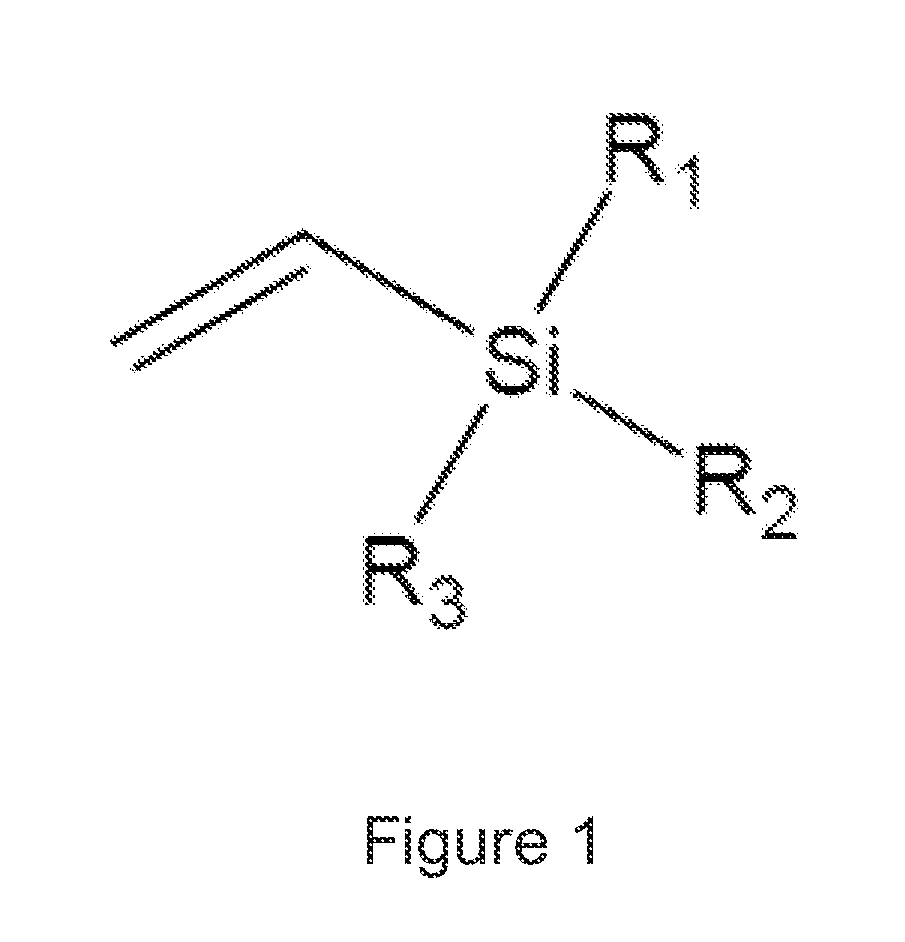

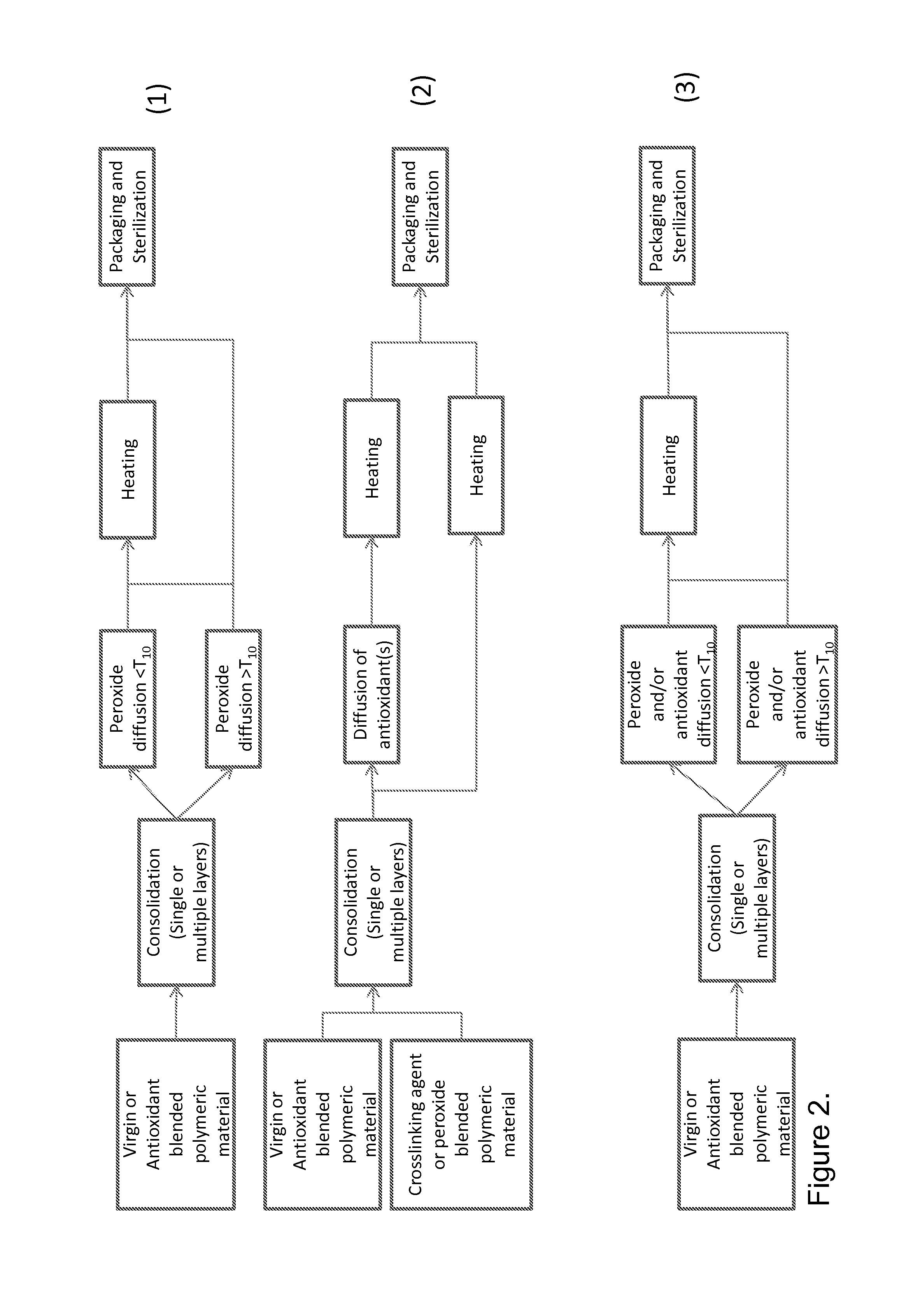

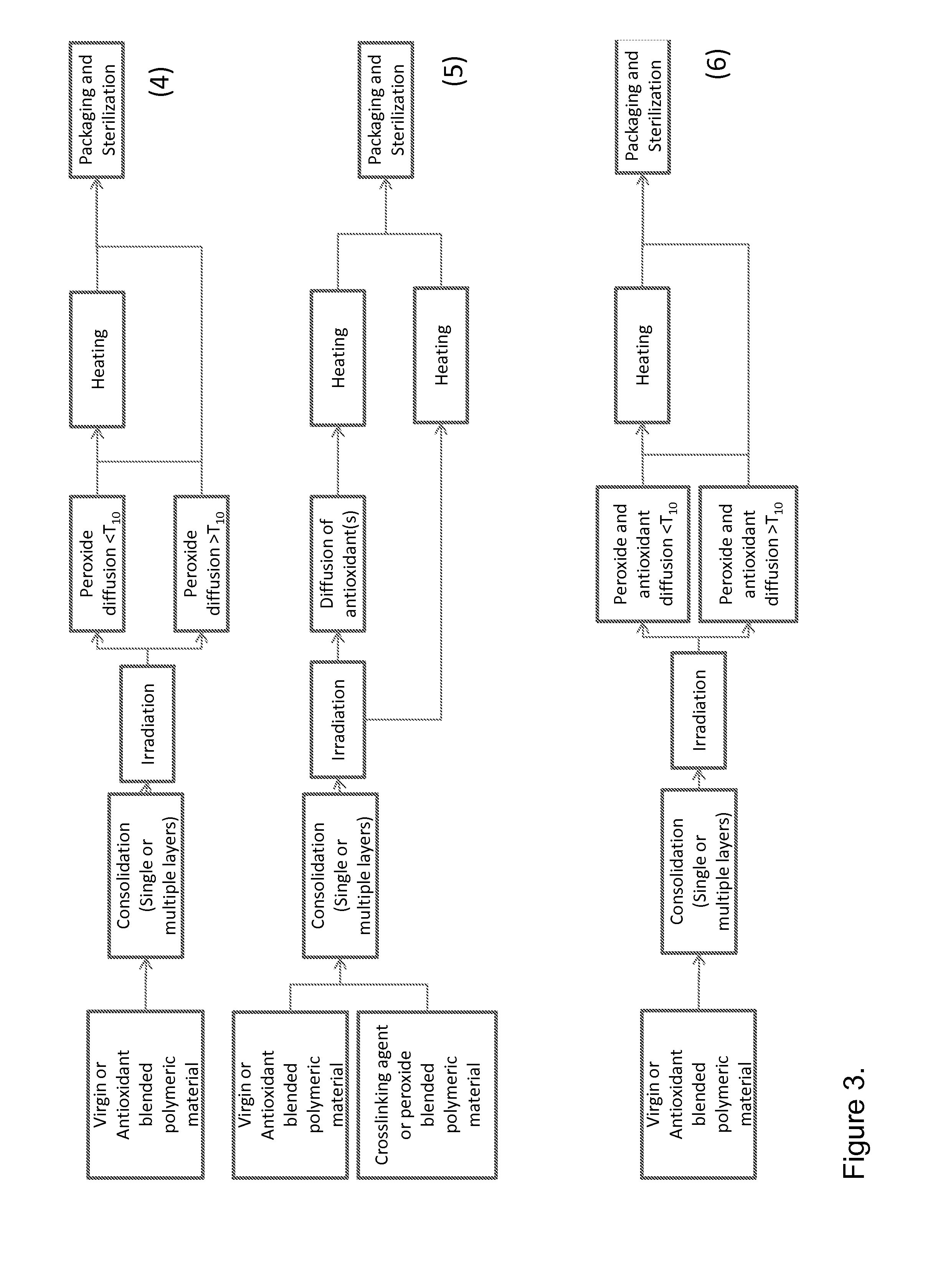

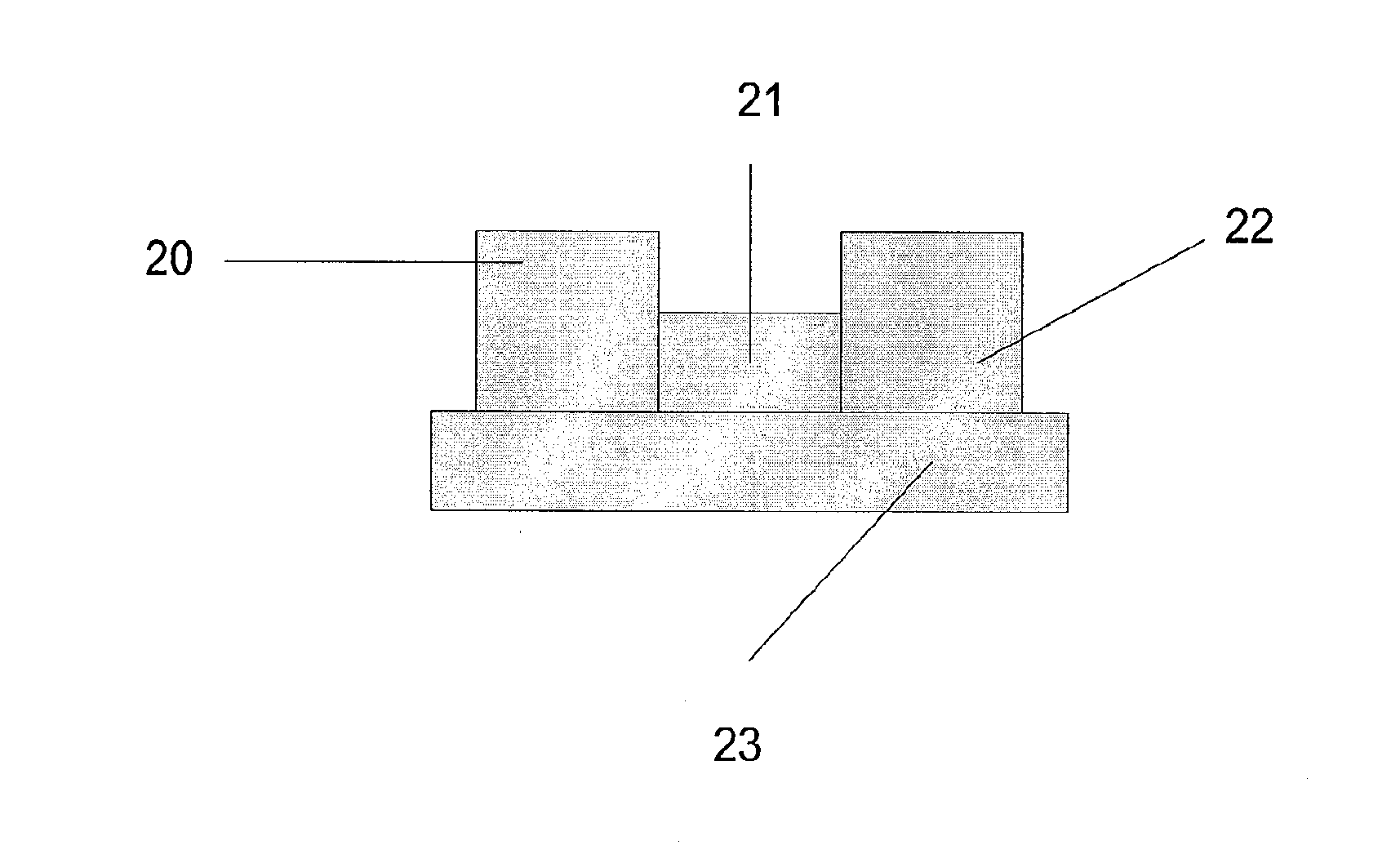

Peroxide cross-linking of polymeric materials in the presence of antioxidants

InactiveUS20160215117A1Avoid lostImprove wear resistanceSurgeryPackage sterilisationCross-linkSilanes

Methods of chemically cross-linking antioxidant-stabilized polymeric material are provided. In one example embodiment, peroxide cross-linking can be used to improve wear resistance and the addition of antioxidant can be used to improve oxidation resistance of ultra-high molecular weight polyethylene. A balance between the amounts of peroxide(s) and antioxidant(s) in the polymeric material can ensure that enough cross-linking is achieved for wear reduction and that enough antioxidant is incorporated for improved long-term oxidative stability. In one example embodiment, peroxide(s) can be diffused into a consolidated polymeric material for cross-linking. In another embodiment, polymeric material is consolidated with a vinyl silane, an antioxidant, and a free radical initiator, and the consolidated polymeric material is contacted with water thereby forming an oxidation resistant, cross-linked polymeric material. Such materials can be used in orthopedic applications such as bearing surfaces in total joint implants, including total hips, total knees, total shoulders, and other total joints.

Owner:THE GENERAL HOSPITAL CORP

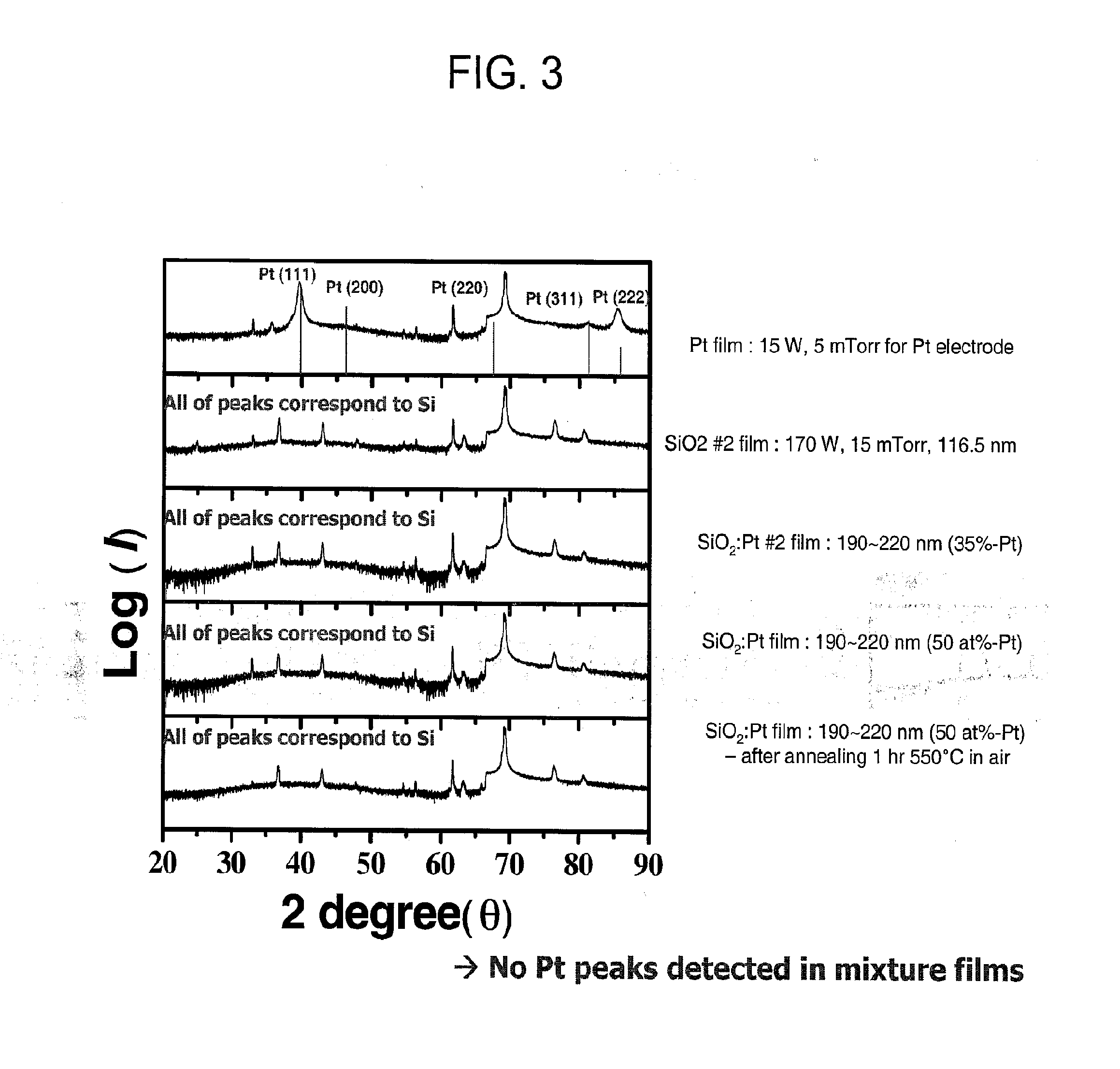

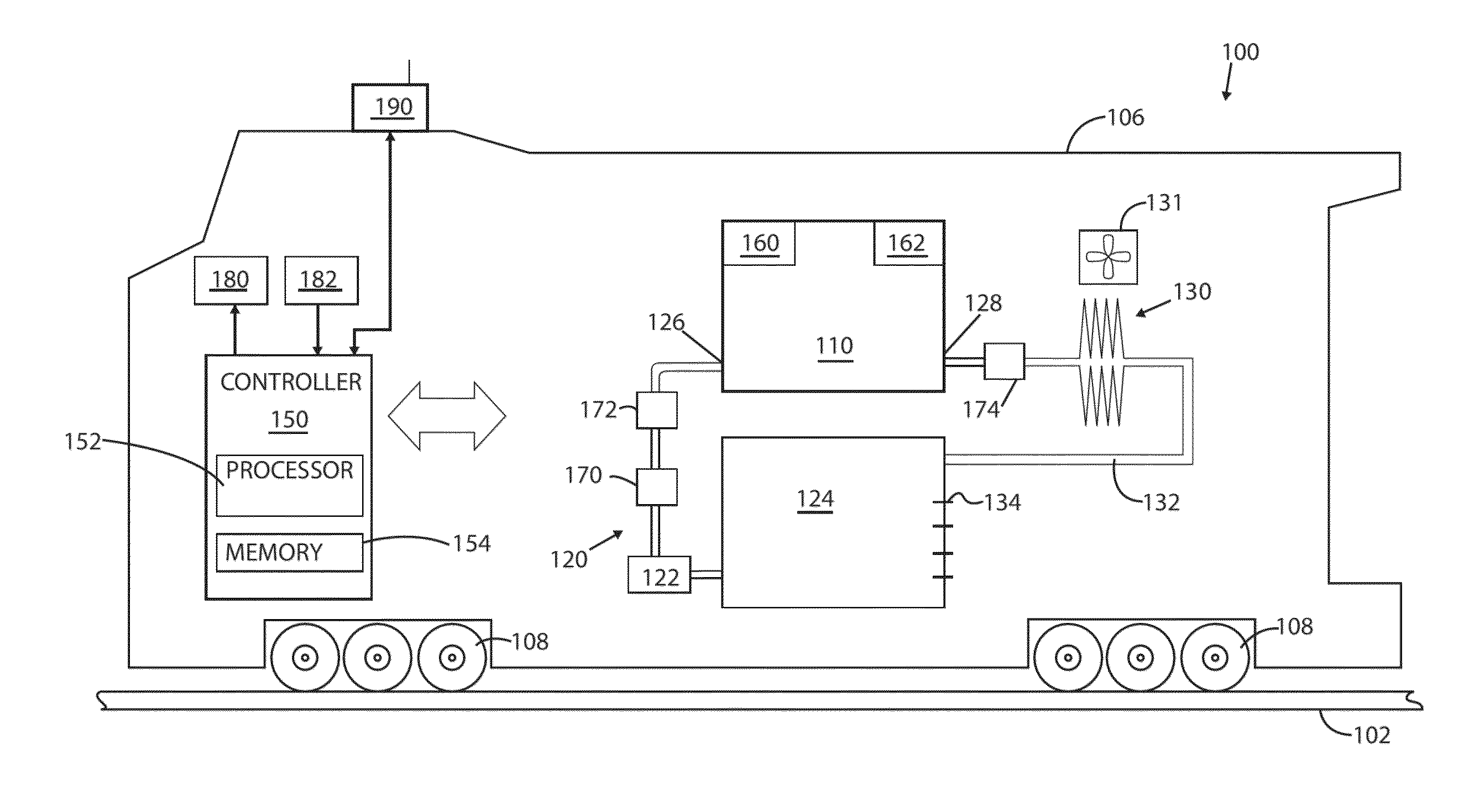

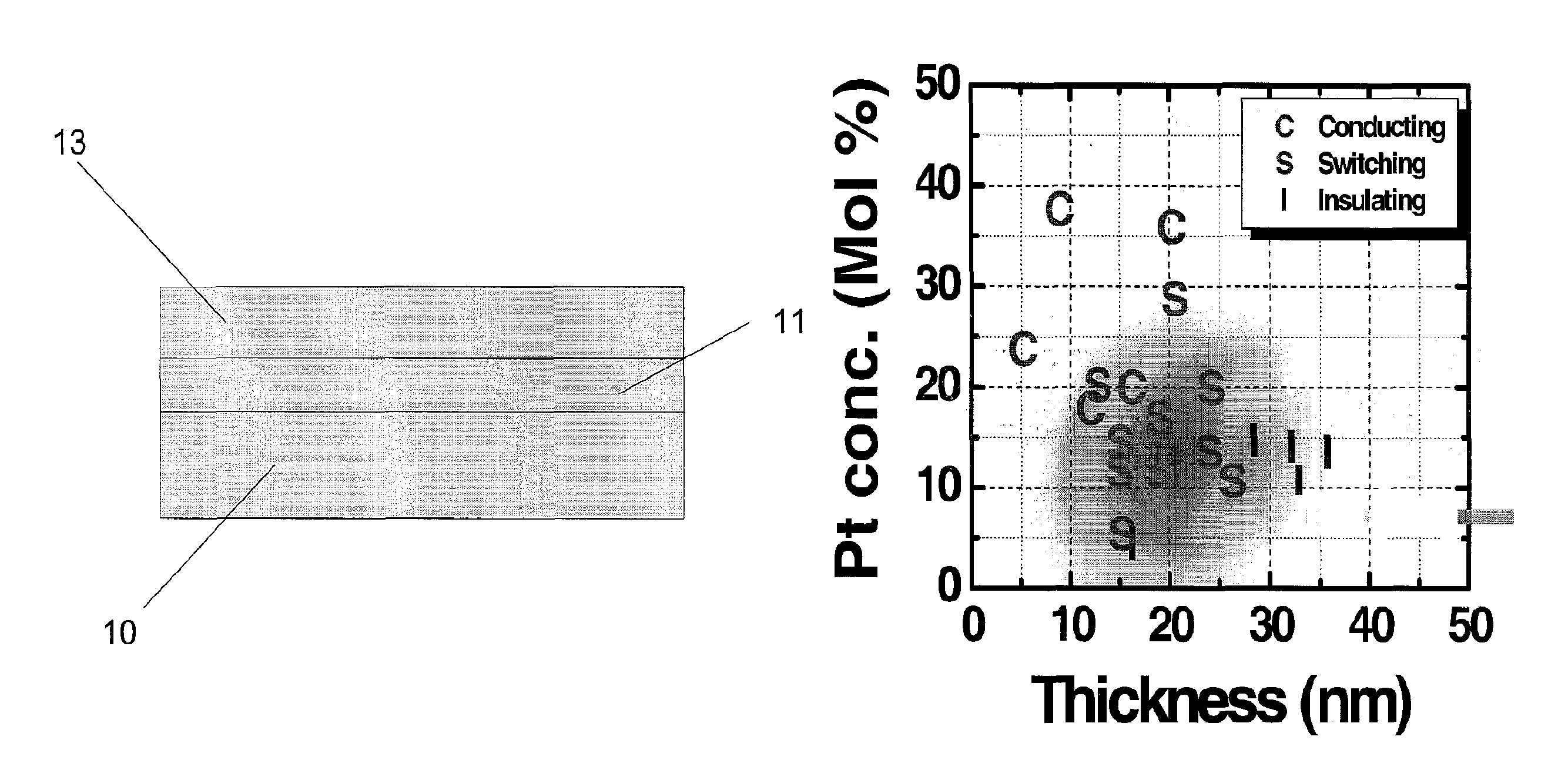

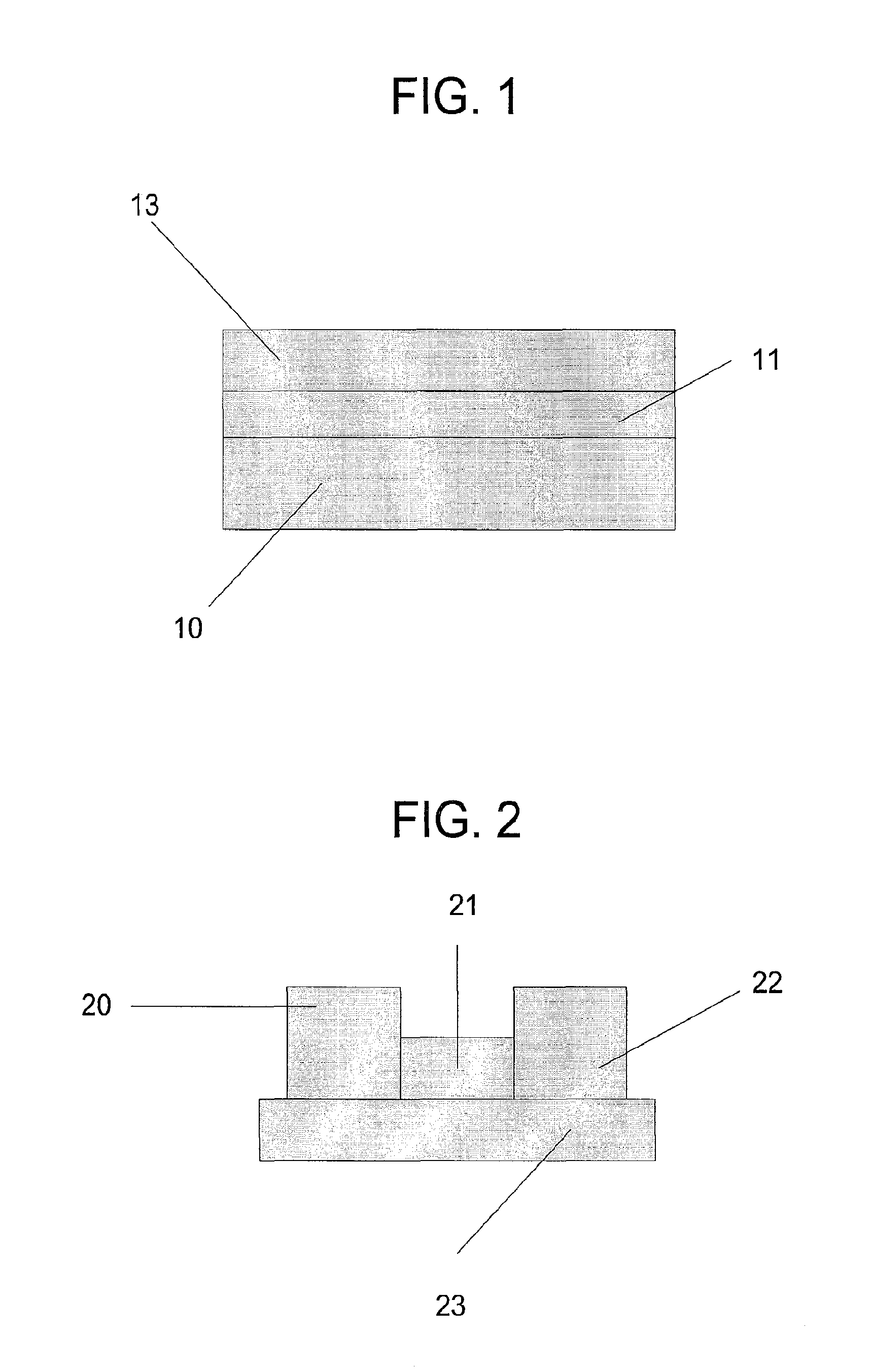

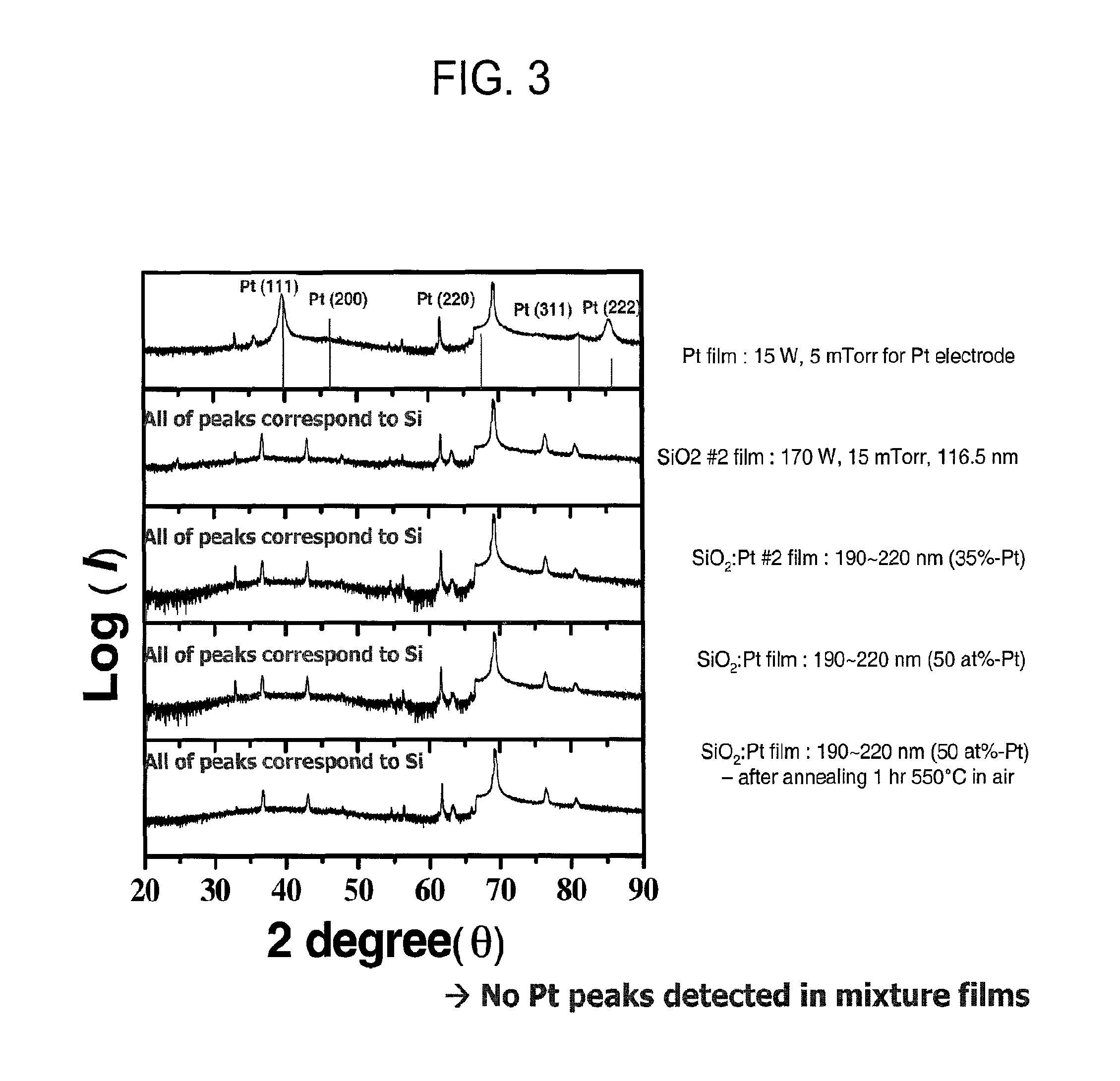

Non-volatile resistance-switching thin film devices

ActiveUS20110266512A1Loss of stabilityLoss of timeConductive materialSemiconductor/solid-state device manufacturingElectrical resistance and conductanceHemt circuits

Disclosed herein is a resistive switching device having an amorphous layer comprised of an insulating silicon-containing material and a conducting material. The amorphous layer may be disposed between two or more electrodes and be capable of switching between at least two resistance states. Circuits and memory devices including resistive switching devices are also disclosed, and a composition of matter involving an insulating silicon-containing material and a conducting material comprising between 5 and 40 percent by molar percentage of the composition is disclosed herein as well. Also disclosed herein are methods for switching the resistance of an amorphous material.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Air cleaning agent containing catalytic agent

InactiveCN108014360AGood weather resistanceImprove purification effectGas treatmentDispersed particle separationEnvironmental resistanceAir cleaning

The invention provides an air cleaning agent containing a catalytic agent, and relates to the technical field of environment-friendly material air cleaning. In order to solve the technical problems that an existing air cleaning agent containing a photocatalyst on the market has a single function and poor in weather fastness, cannot achieve purification or freshness for a long time, and is low in cleaning efficiency, the air cleaning agent containing the catalytic agent is prepared, the air cleaning agent adopts the catalytic agent as a main purification object, natural plant components and other auxiliaries are adopted, the air cleaning agent is prepared through the reasonable proportion, use is safe and convenient, the performance of the components are brought into full play and utilized,photocatalyst particles have the good weather fastness and can have the maximum purification effect in actual application, formaldehyde and other hazardous gas in air can be effectively removed, andthe deodorization, sterilization and anti-fouling performance can be achieved.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

Systems and methods for diagnosing an engine

ActiveUS20160010537A1Loss of stabilityInternal-combustion engine testingAnalogue computers for vehiclesPressure responseEngineering

In one aspect, a method for detecting and diagnosing a coolant leak of an engine may include diagnosing a coolant leak of the engine based on a low frequency pressure response of a measured engine coolant pressure. In another aspect, an engine system (e.g., for a vehicle) includes an engine and a coolant system operatively connected to the engine. The coolant system includes a coolant reserve and a coolant pump between the engine and the coolant reserve. The engine system also includes a coolant pressure sensor to measure coolant pressure, and a controller configured to measure an engine coolant pressure and diagnose a coolant leak of the coolant system based on a low frequency pressure response of the measured engine coolant pressure.

Owner:GE GLOBAL SOURCING LLC

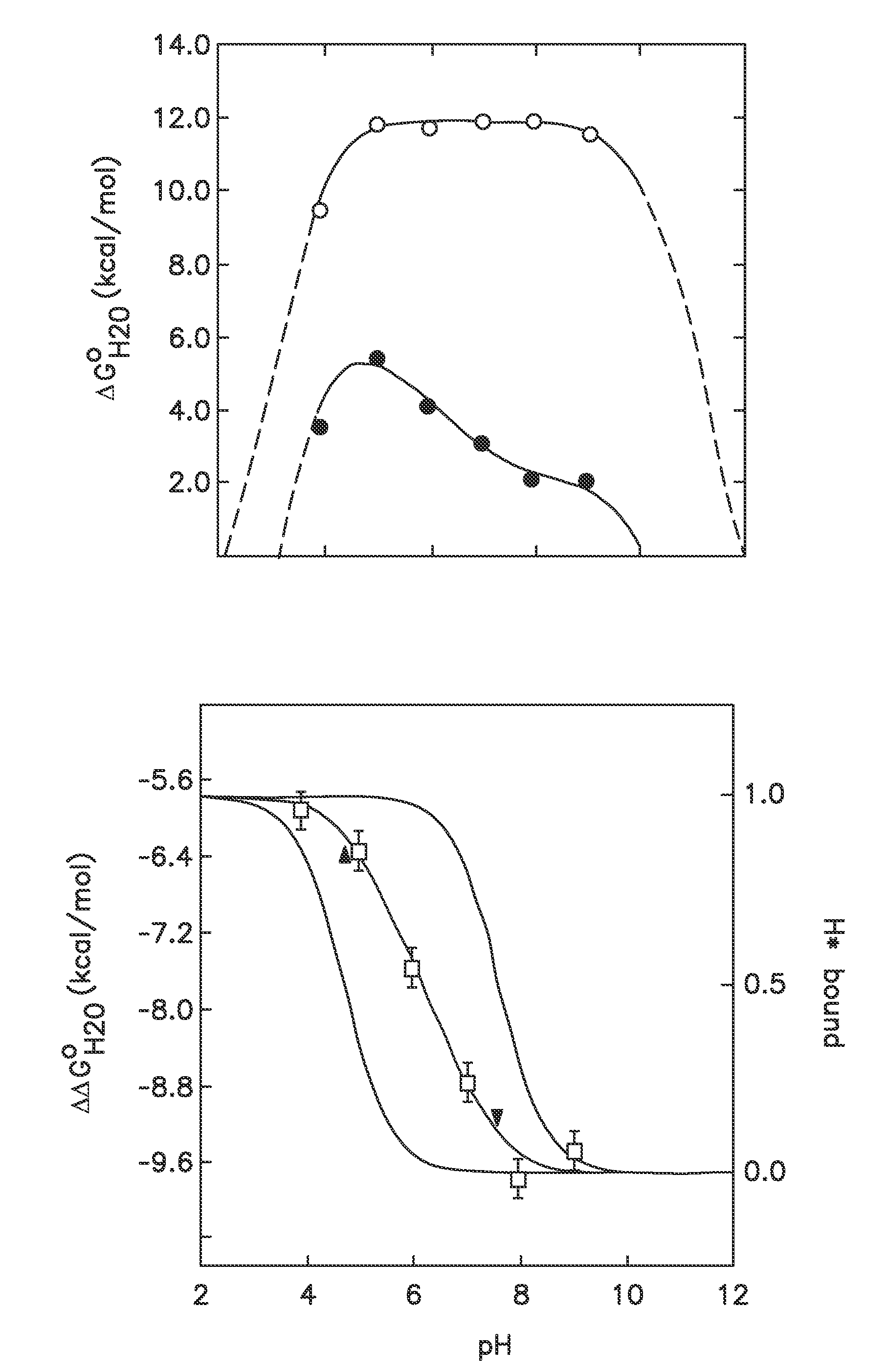

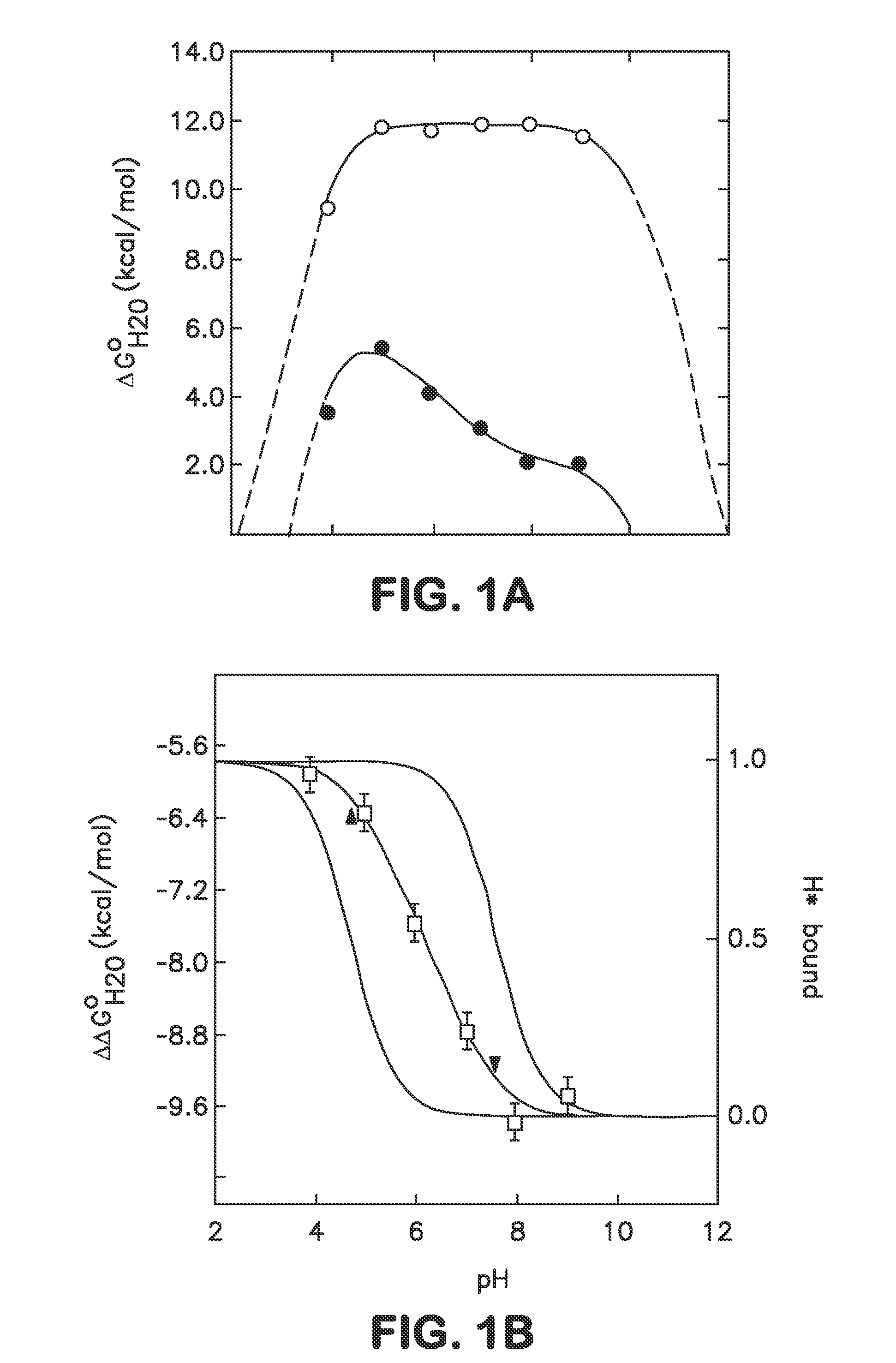

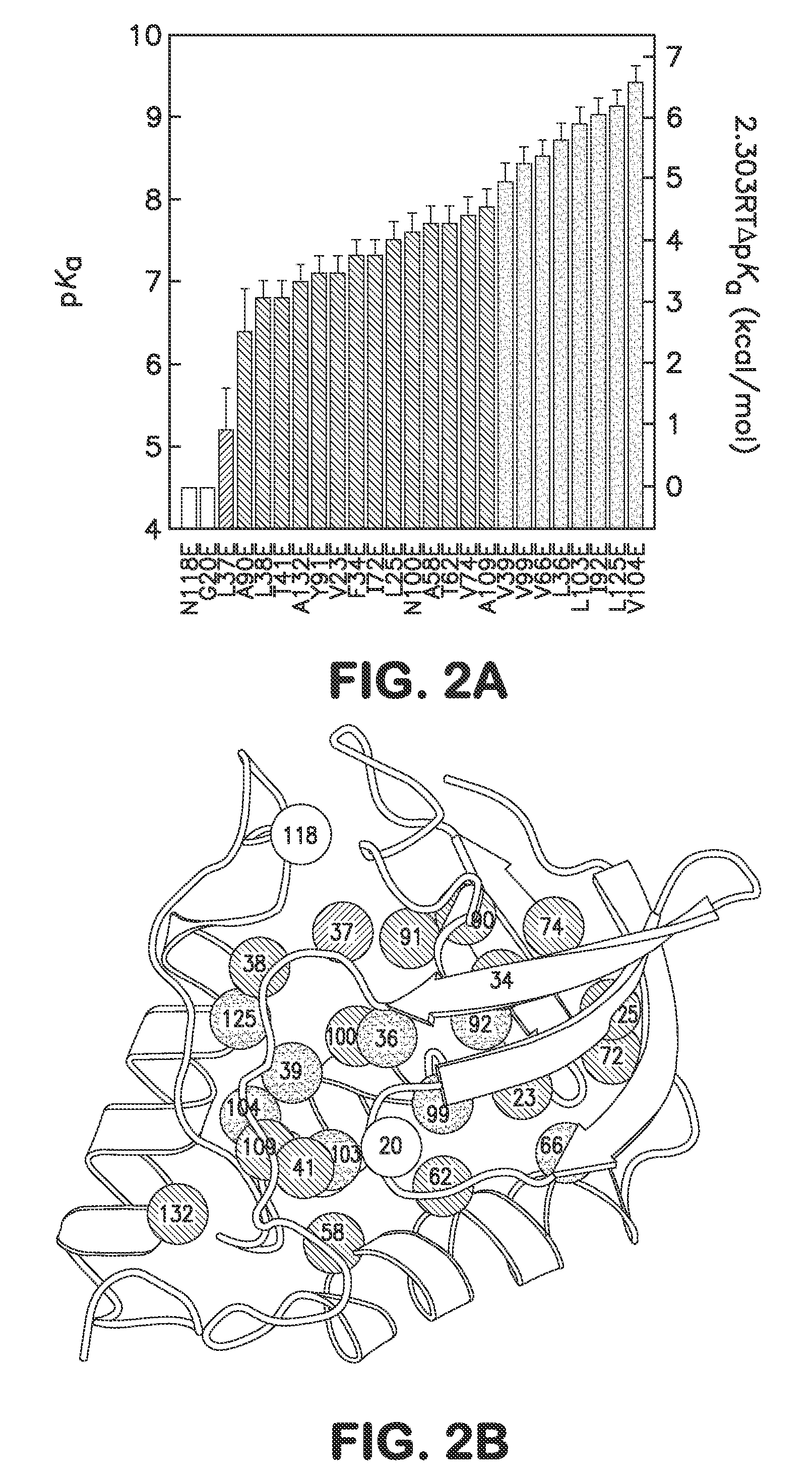

Method for Incorporating Internal Polar and Ionizable Groups in Proteins

ActiveUS20120258518A1High thermodynamic stabilityImprove accuracyHydrolasesPeptide preparation methodsElectricityCrystallography

Internal polar and ionizable groups are essential for enzymatic catalysis, proton transport, redox reactions, and many other functional properties of proteins. To engineer novel enzymes or to modify the function of existing ones, and to build switches that can be used to modify the stability of proteins in response to changes in pH, it is necessary to introduce polar or ionizable groups or to modify the properties of existing ones. However, internal polar and ionizable groups usually destabilize proteins. The disclosure provides new methods that allow the introduction of polar and ionizable groups into the interior of proteins, as well as new methods for improving the accuracy of pKa of an internal amino acid of a protein, and methods for mapping the folding free energy landscape of a protein.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

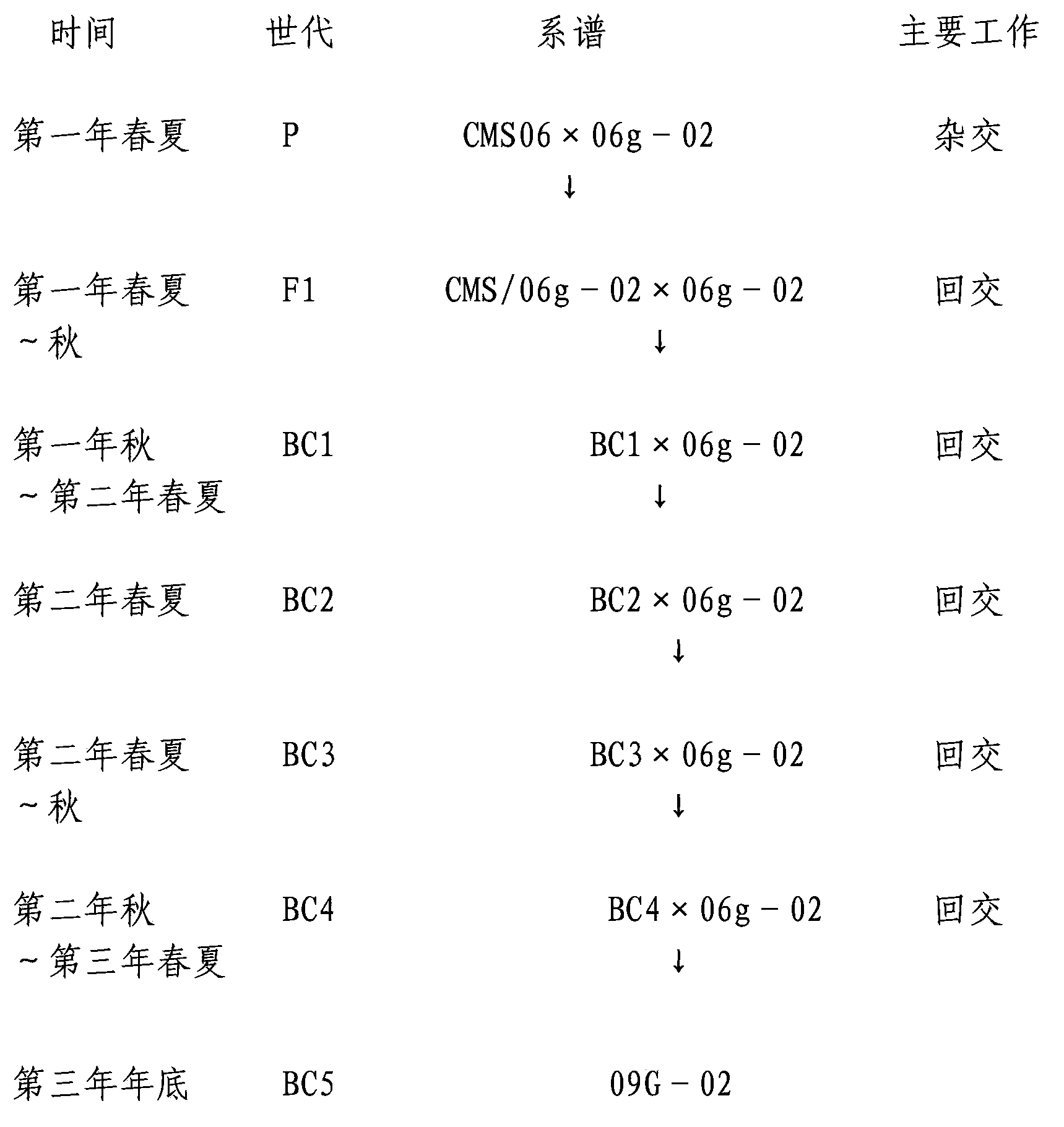

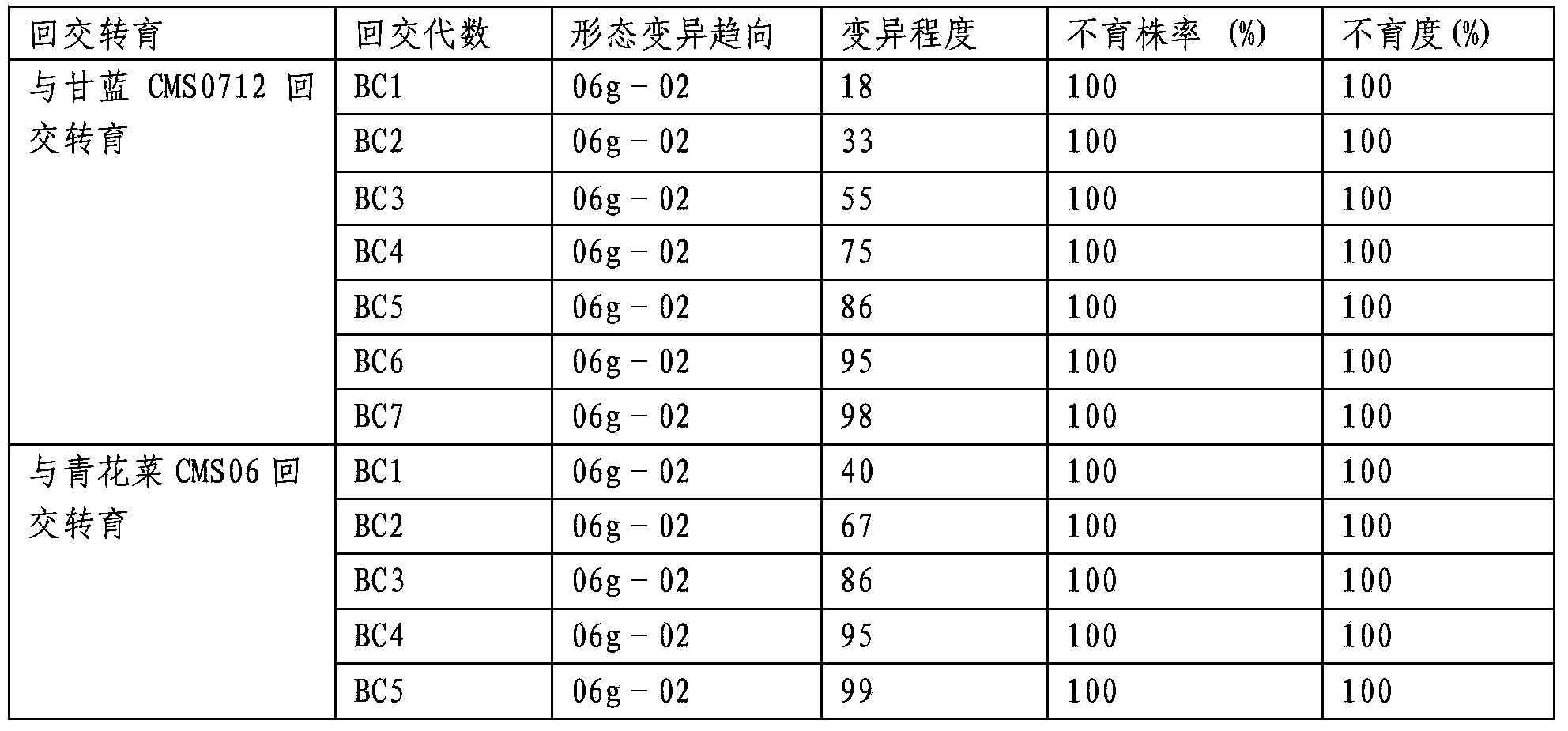

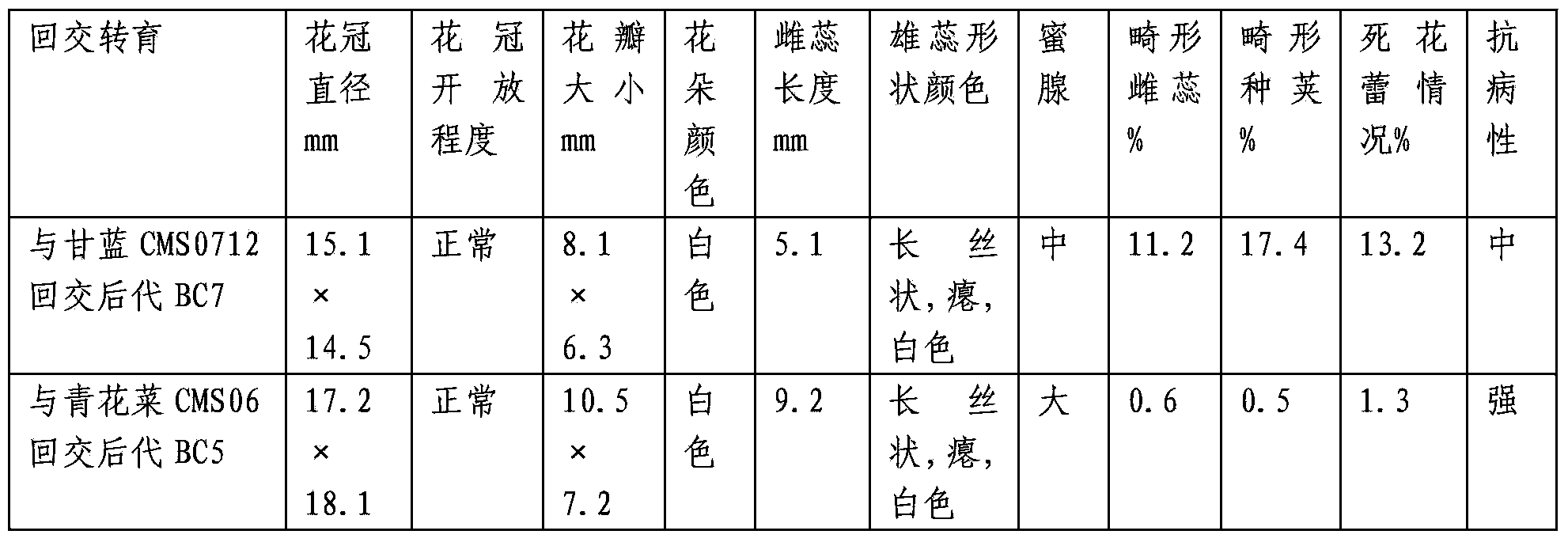

Method for transforming sterile line of Chinese kale by utilizing vernalization and generation adding

The invention relates to a method for transforming a sterile line of Chinese kale by utilizing vernalization and generation adding. The method comprises the following steps of: carrying out hybridization by taking a male sterile line of broccoli cytoplast as a female parent and a selfing line of the Chinese kale as a male parent, so as to obtain hybridized seeds; after the hybridized seeds are planted in summer, carrying out vernalization on plants, and meanwhile, selecting the sterile plants by utilizing pollen microscopic examination or single-plant bagging selfing; and taking the selfing line of the Chinese kale as a recurrent parent, carrying out 3-5-generation backcross with the recurrent parent and the sterile plants, so as to obtain the male sterile line of Chinese kale cytoplast. According to the method, the sterile line of the Chinese kale is transformed by utilizing the male sterile line of broccoli cytoplast, biological characters of the sterile line of the Chinese kale are stable, stamens degenerate, petals and pistils develop normally, nectaries develop well, and seed pods develop normally; the sterile line can be subjected to generation adding propagation under a normal growth condition of the plants, the transformation process is accelerated, the procedures are simplified, the cost is saved, and the purity of the Chinese kale can be improved.

Owner:ZHENJIANG SUIHAN AGRI

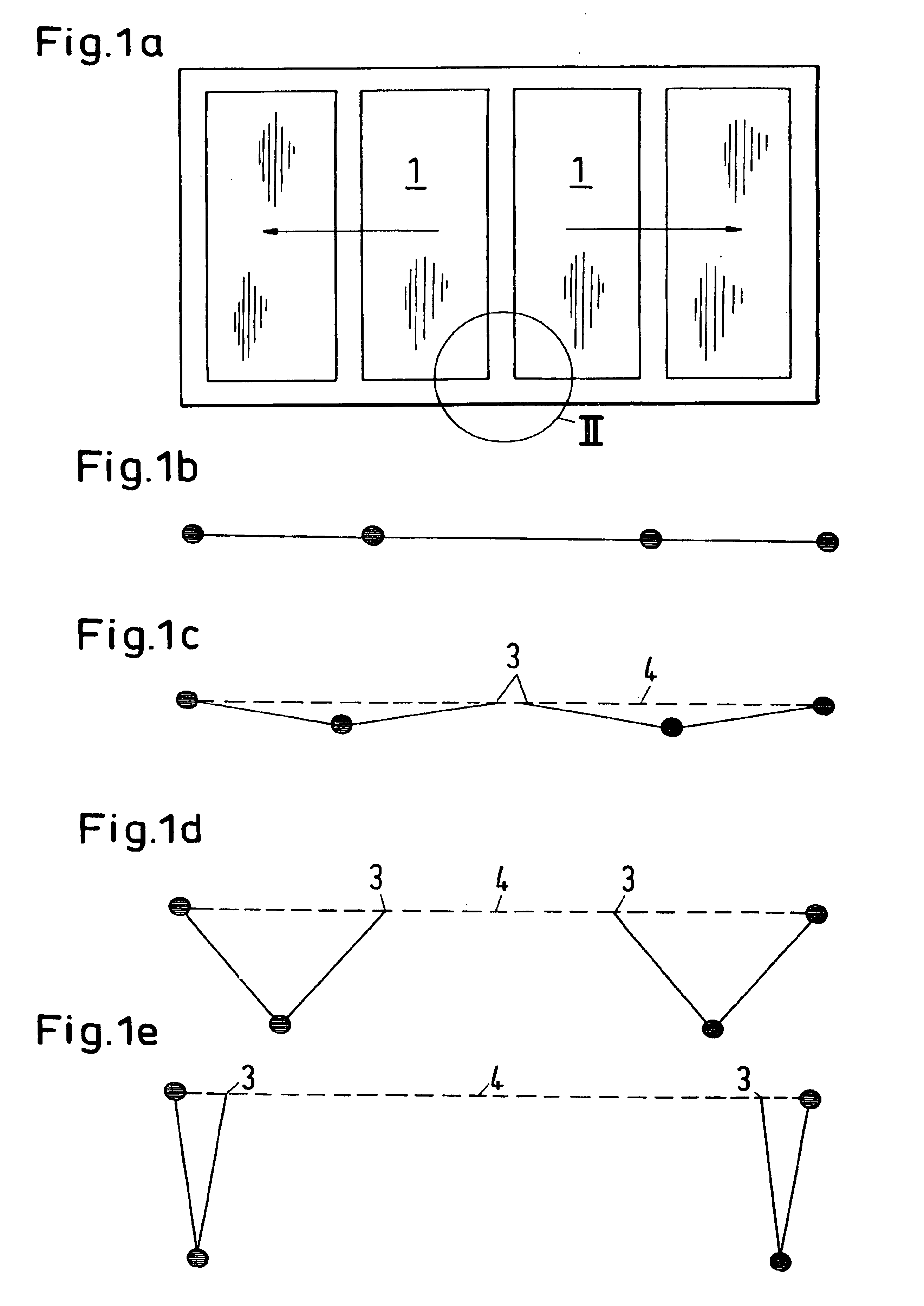

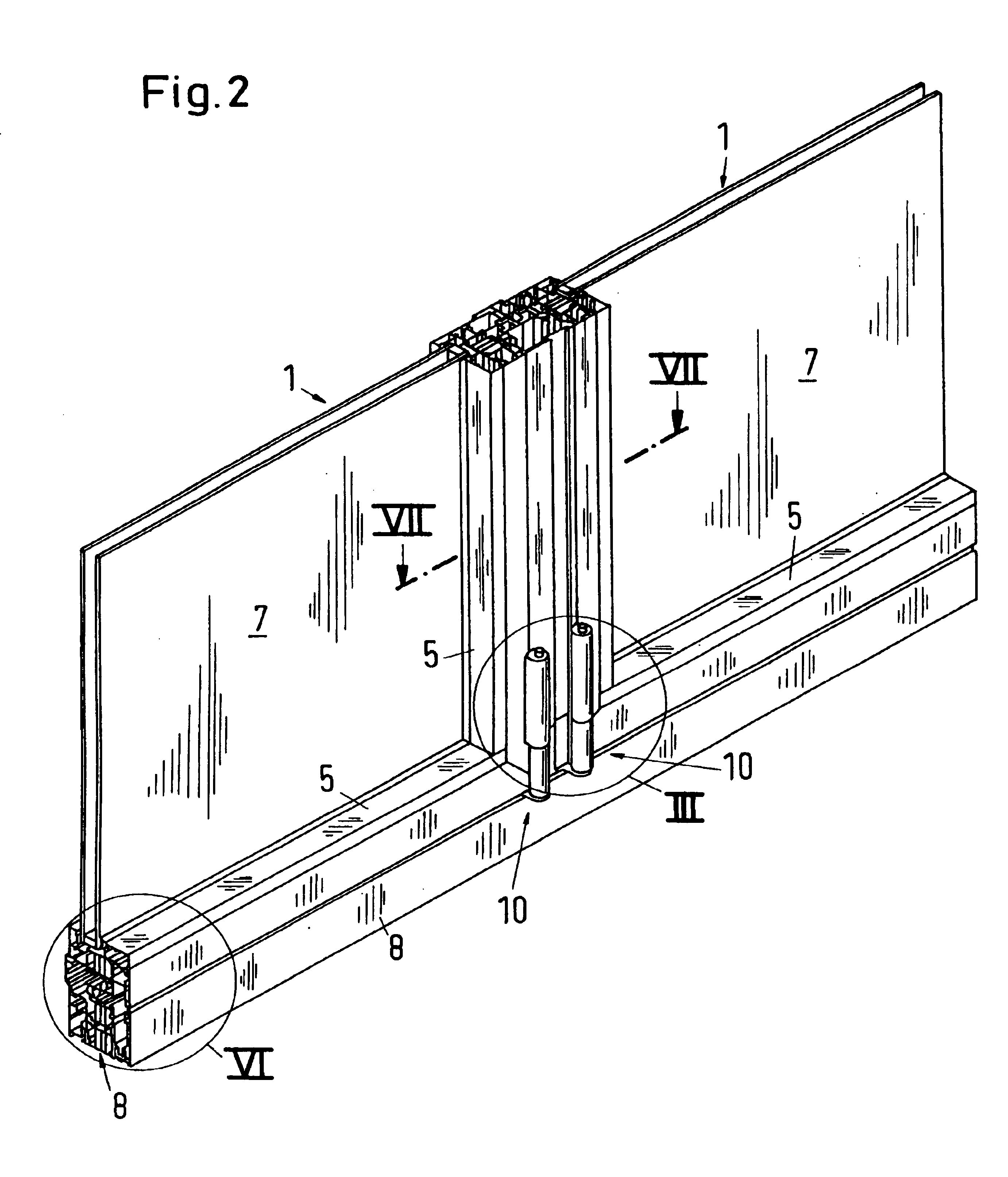

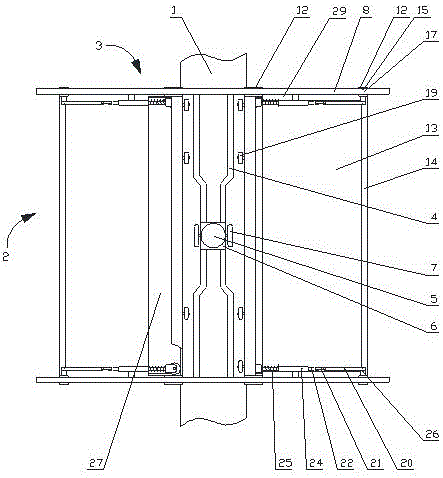

Folding device as room divider or room closure

InactiveUS6920908B2Loss of stabilityEliminate useSealing arrangementsWing arrangementsAerospace engineering

Owner:SOLARLUX ALUMINUM SYST

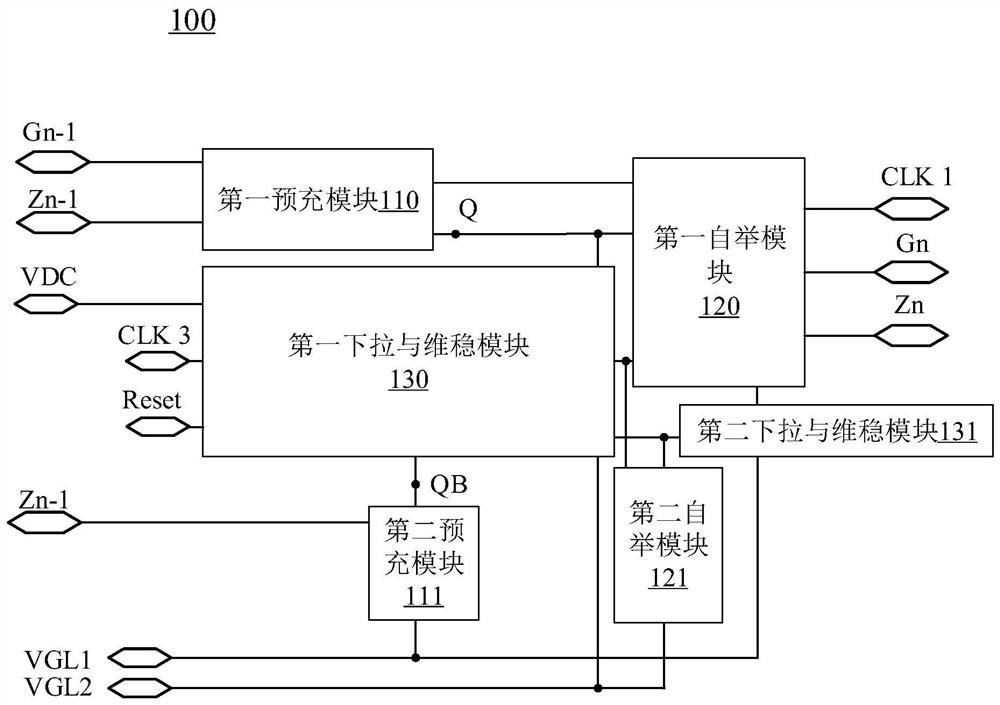

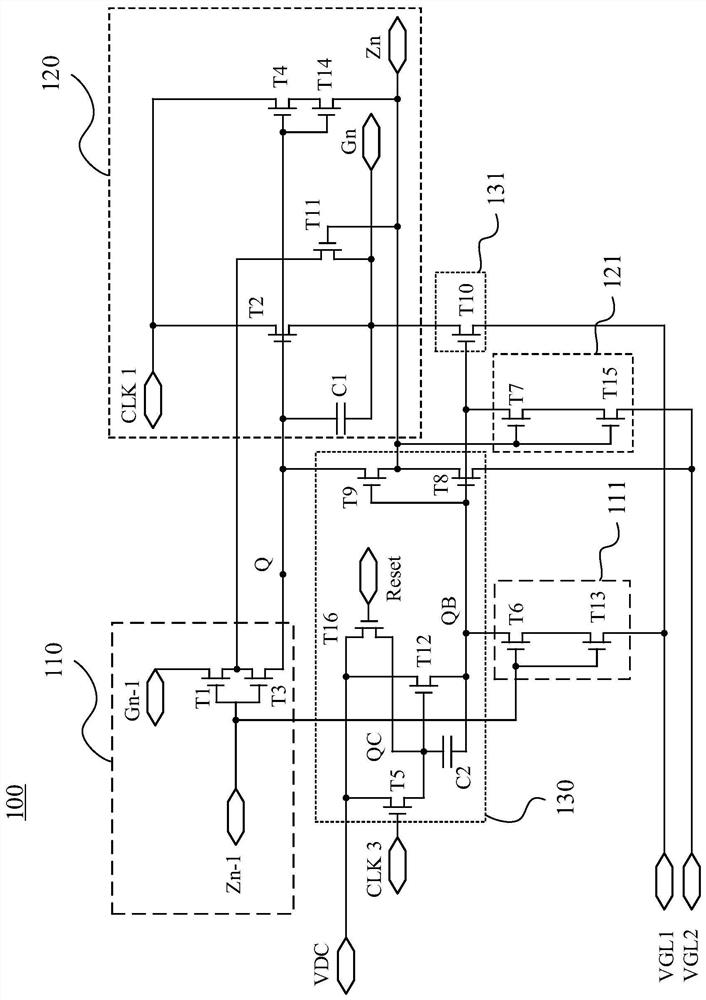

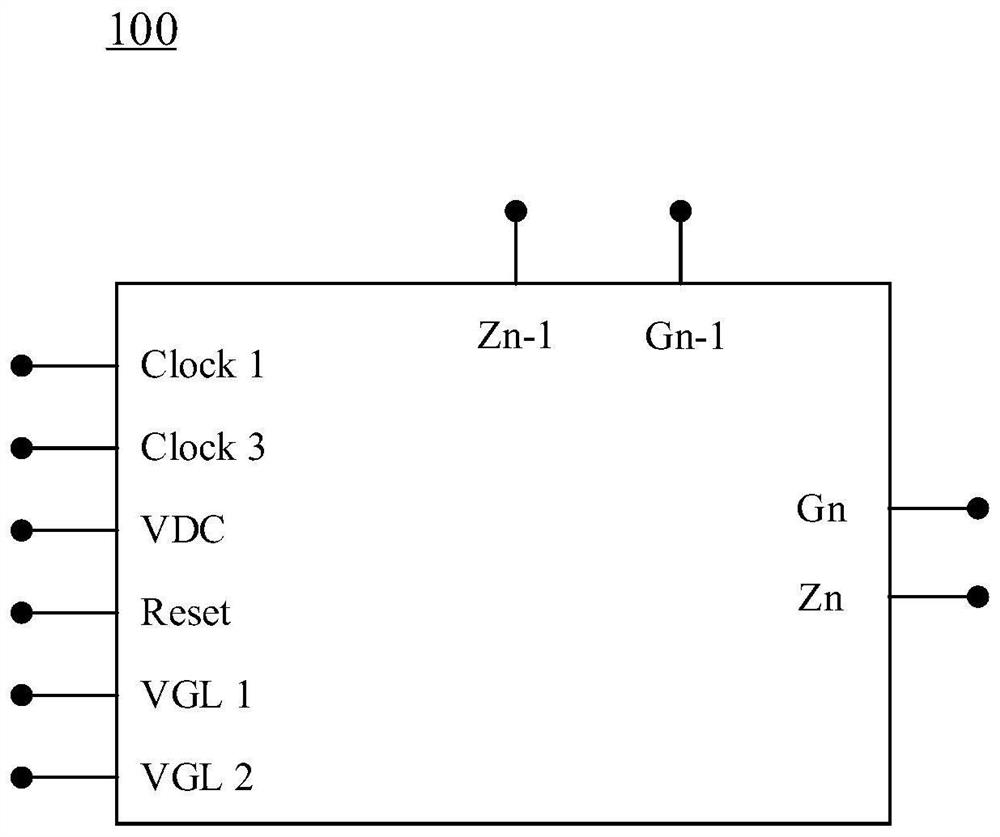

Gate drive circuit and display device

ActiveCN112908276APrevent leakageImprove stabilityStatic indicating devicesDriver circuitDisplay device

The invention discloses a gate drive circuit and a display device. The gate drive circuit disclosed by the invention comprises a first pre-charging module for charging a first node according to a starting signal; a second pre-charging module used for discharging the second node according to the transmission signal; a first bootstrap module which is connected with the first node and is used for generating and outputting a current-stage transmission signal and a current-stage driving signal according to a first clock signal; a second bootstrap module used for bootstrapping the second node according to the second low-level signal; a first pull-down and stability maintaining module which stabilizes the signal of the first node and the signal of the bootstrap module according to the third clock signal; and a second pull-down and stability maintenance module which is respectively connected with the first low-level signal input end, the second node and the bootstrap module, and stabilizes the bootstrap module according to the first low-level signal. According to the gate drive circuit and the display device disclosed by the invention, the bootstrap module and the pull-down and stability maintaining module are designed, and the gate drive circuit can be suitable for the IGZO process.

Owner:KUSN INFOVISION OPTOELECTRONICS

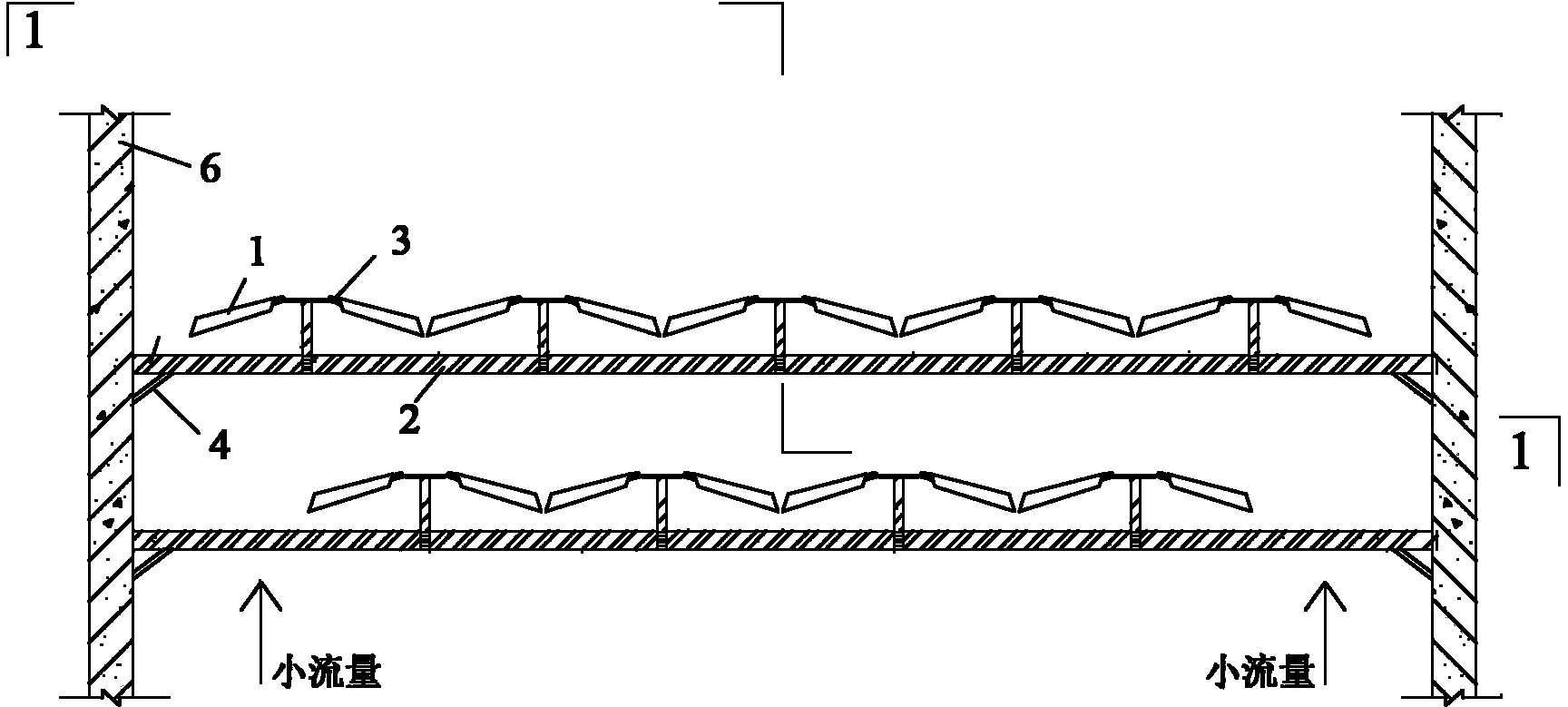

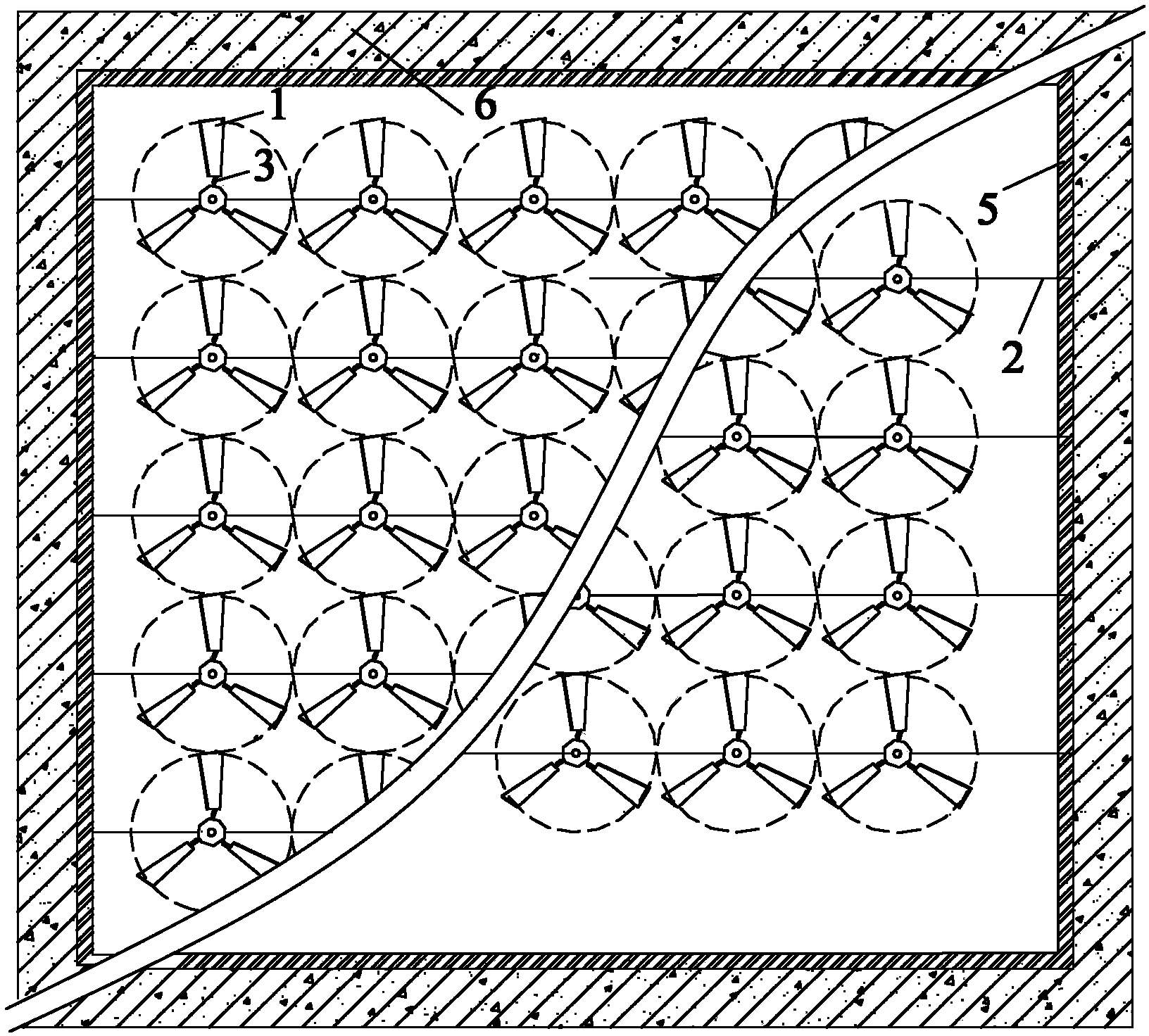

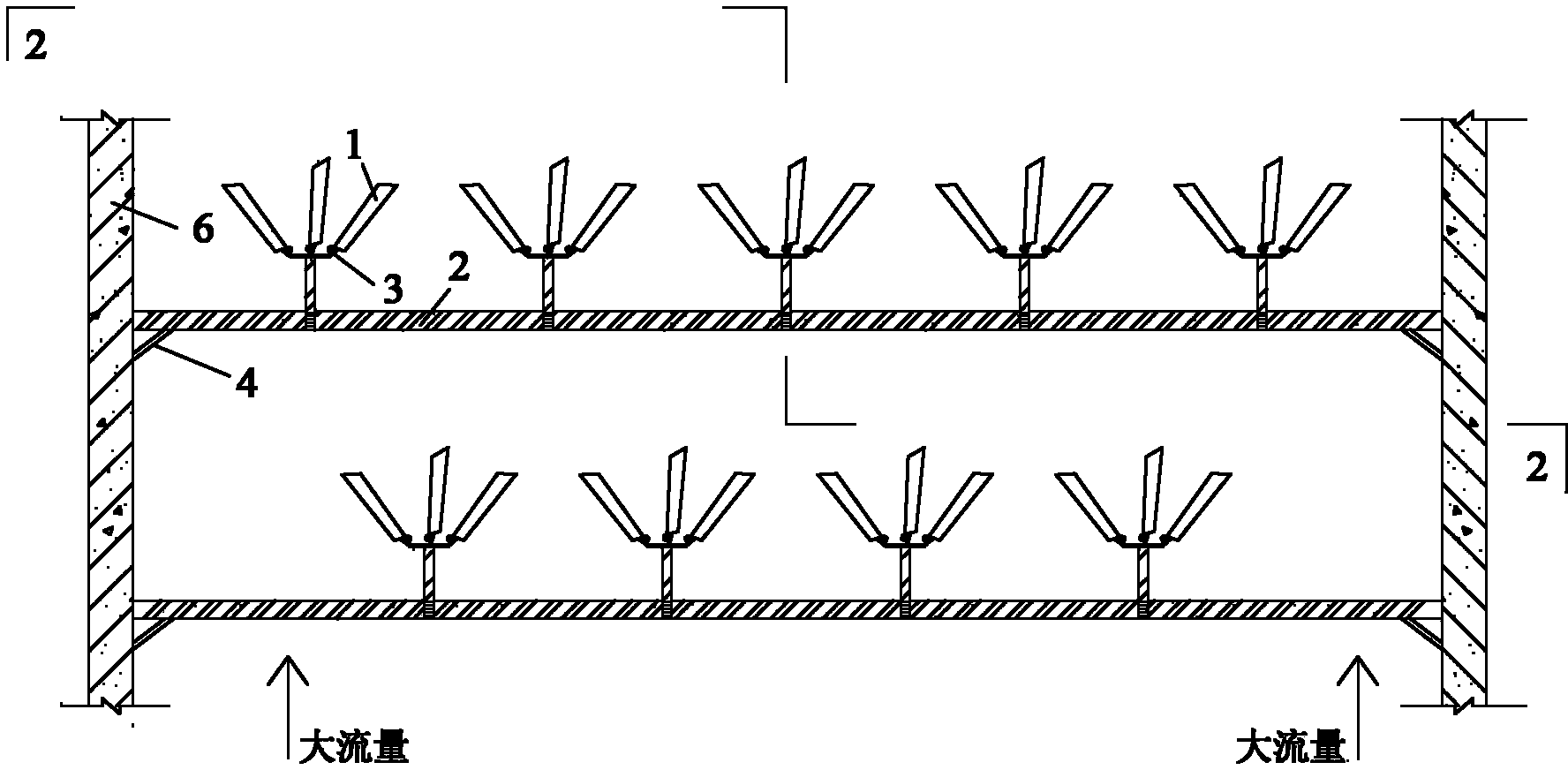

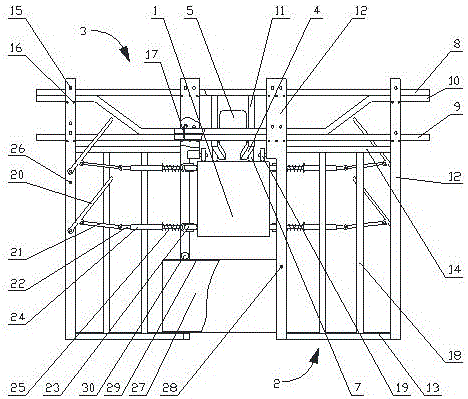

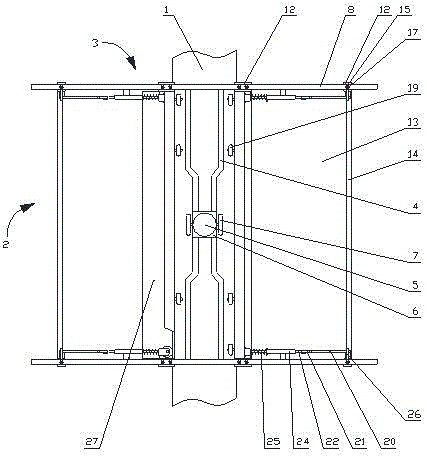

Flocculation reaction framed bent device equipped with flexibly-connected impellers

InactiveCN103382043AReduce lossesLoss of stabilityWater/sewage treatment by flocculation/precipitationFlocculationImpeller

The invention discloses a flocculation reaction framed bent device equipped with flexibly-connected impellers. The device comprises framed bents composed of a plurality of lattice bars which are parallel to each other. The framed bents are fixed by a framework. A plurality of flexibly-connected impellers are installed on each lattice bar. Each impeller is composed of a main shaft, a wheel hub and blades. The blades and the wheel hub are connected through springs. Under the impact of current, blades drive the wheel hub to rotate around the main shaft. The framed bents are installed in pairs. The lattice bars on upper and lower framed bents are arranged in a staggered pattern. Impellers on each framed bents are arranged side by side. That is to say, the maximum rotation radiuses of adjacent impellers tangent to each other, and the installation point of each impeller on the lower framed bent is right facing the central gap in the middle of four impellers on the upper framed bent. When current flows through the impellers, the impellers rotate so as to guarantee turbulent fluctuation performance of flocculation. When the flow increases, the rotation radius of the impellers will be reduced under the impact force of current, flow area is increased, and flow velocity is reduced. Thus, head loss is decreased, and it is ensured that head loss is basically stable when the flow increases.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Non-volatile resistance-switching thin film devices

ActiveUS9236118B2Loss of stabilityLoss of timeDigital storageBulk negative resistance effect devicesResistive switchingConductive materials

Disclosed herein is a resistive switching device having an amorphous layer comprised of an insulating silicon-containing material and a conducting material. The amorphous layer may be disposed between two or more electrodes and be capable of switching between at least two resistance states. Circuits and memory devices including resistive switching devices are also disclosed, and a composition of matter involving an insulating silicon-containing material and a conducting material comprising between 5 and 40 percent by molar percentage of the composition is disclosed herein as well. Also disclosed herein are methods for switching the resistance of an amorphous material.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

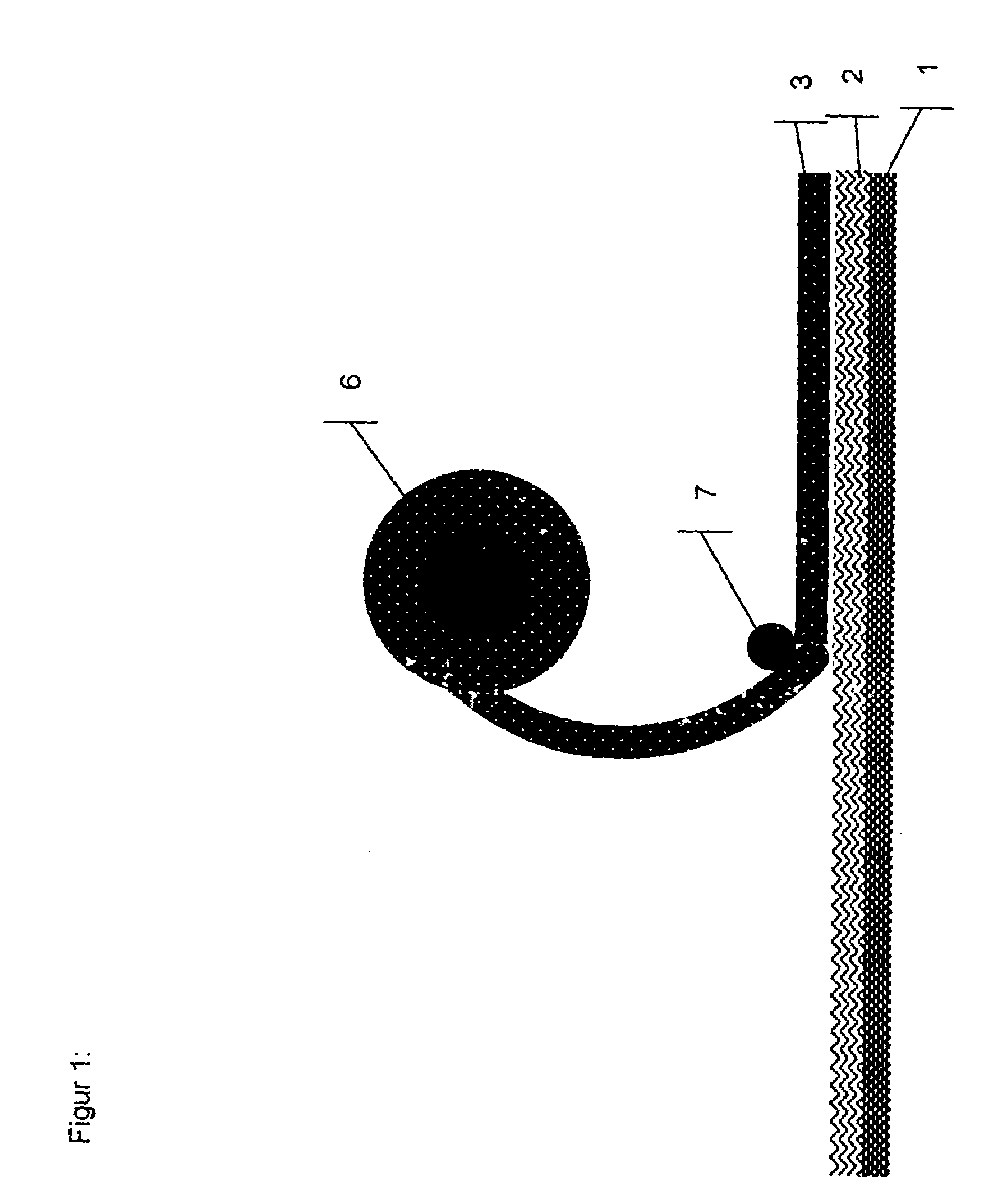

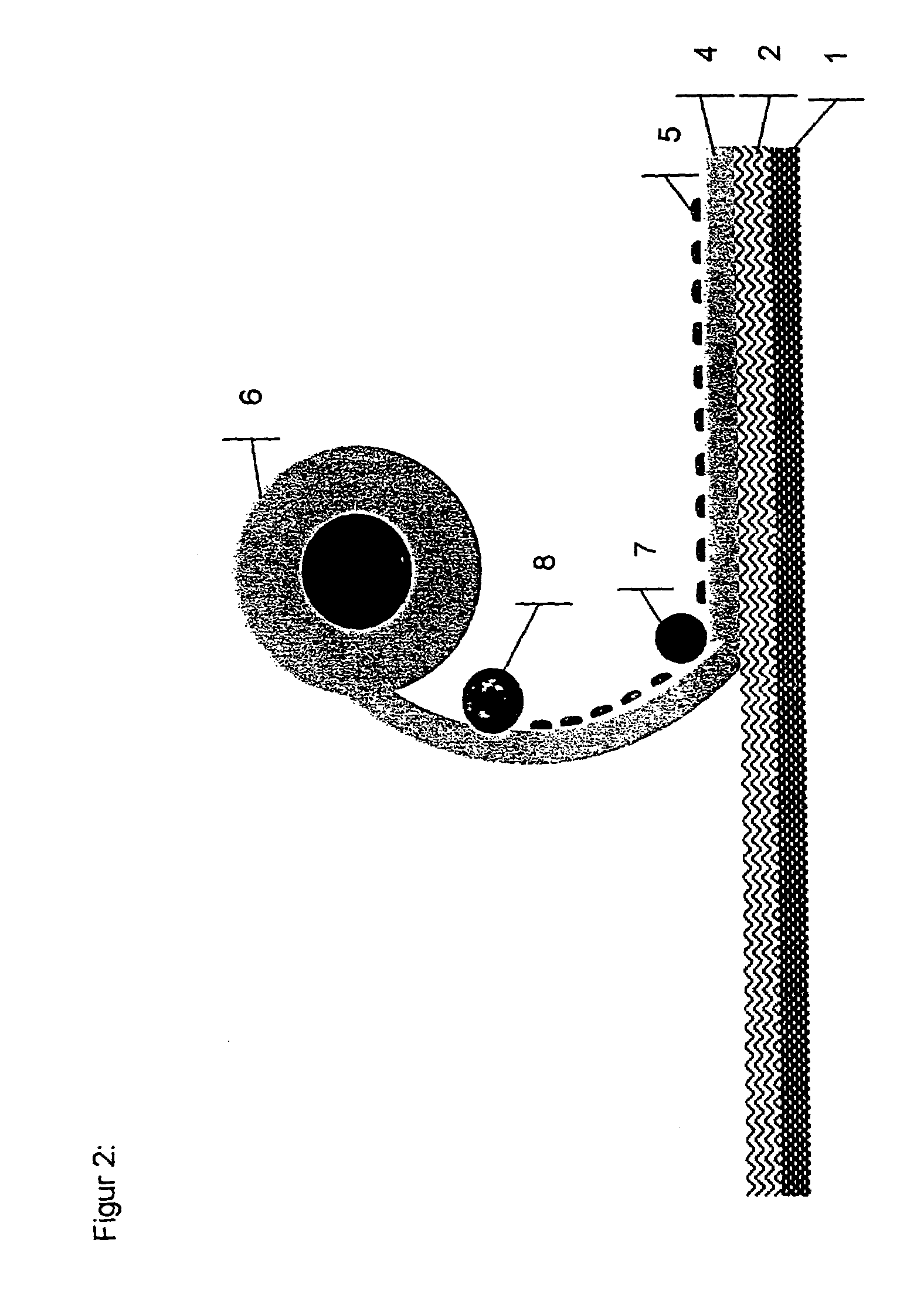

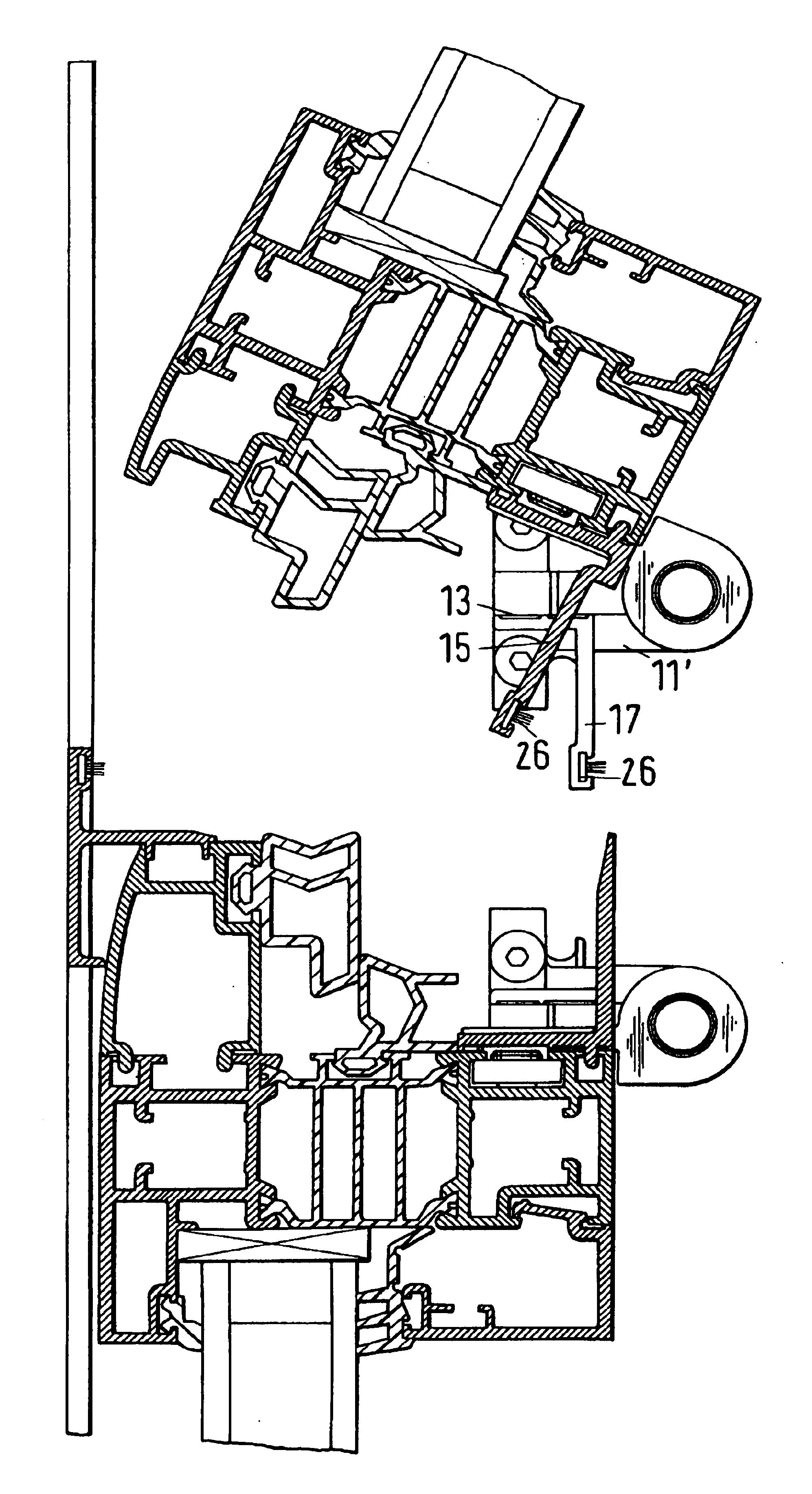

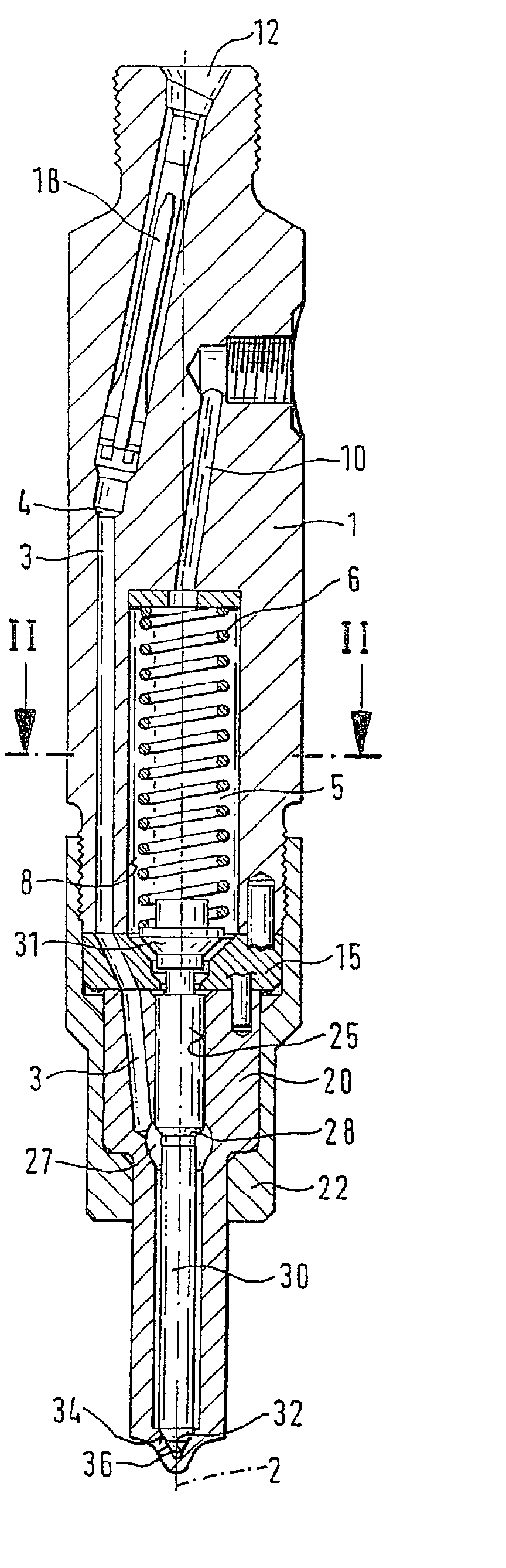

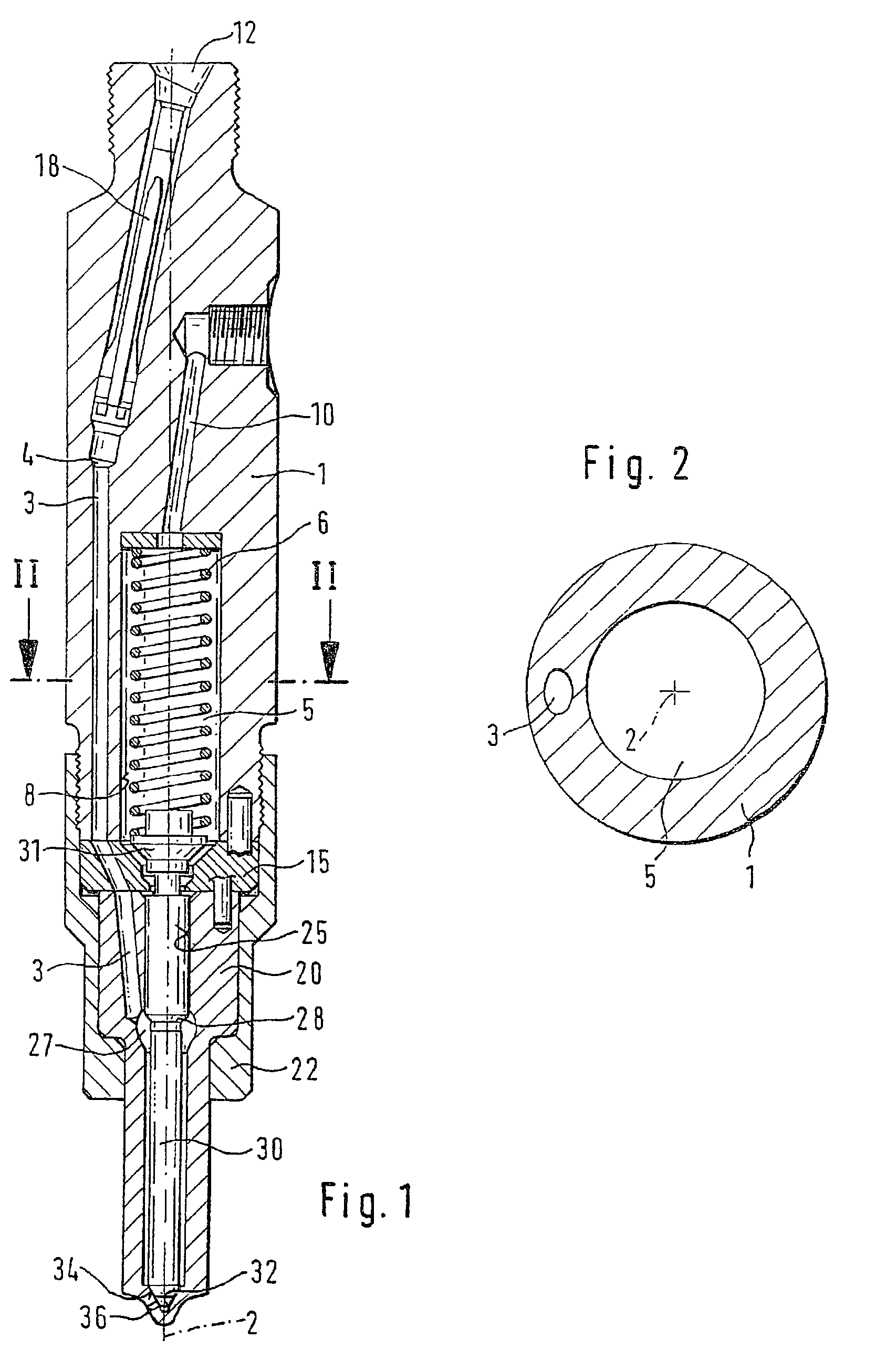

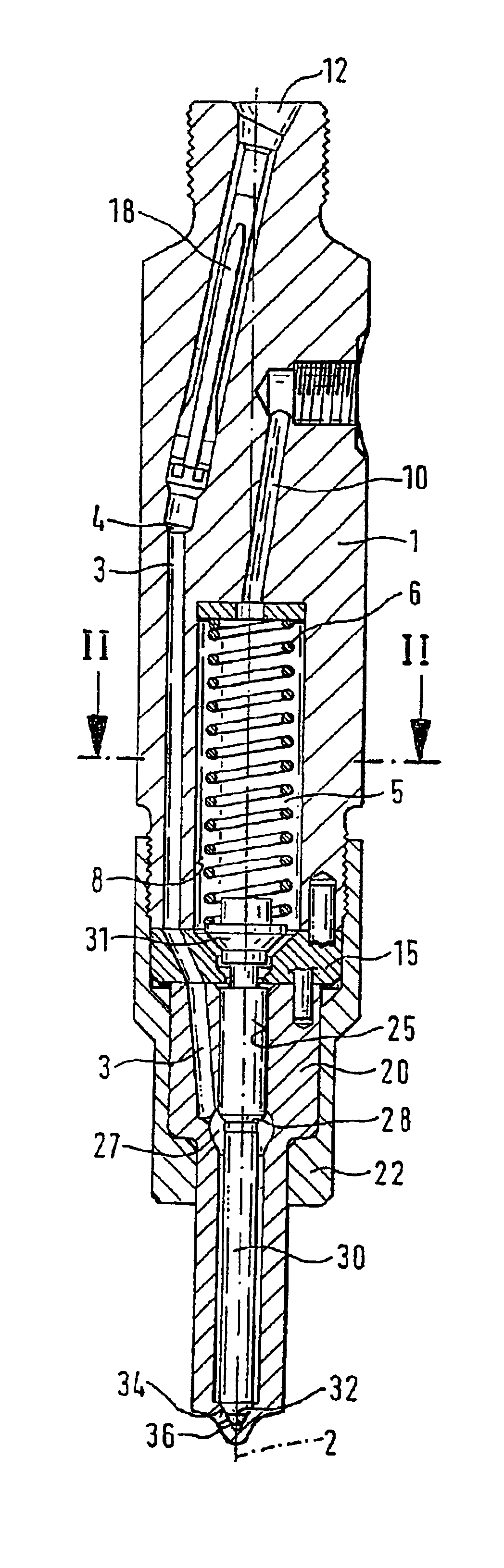

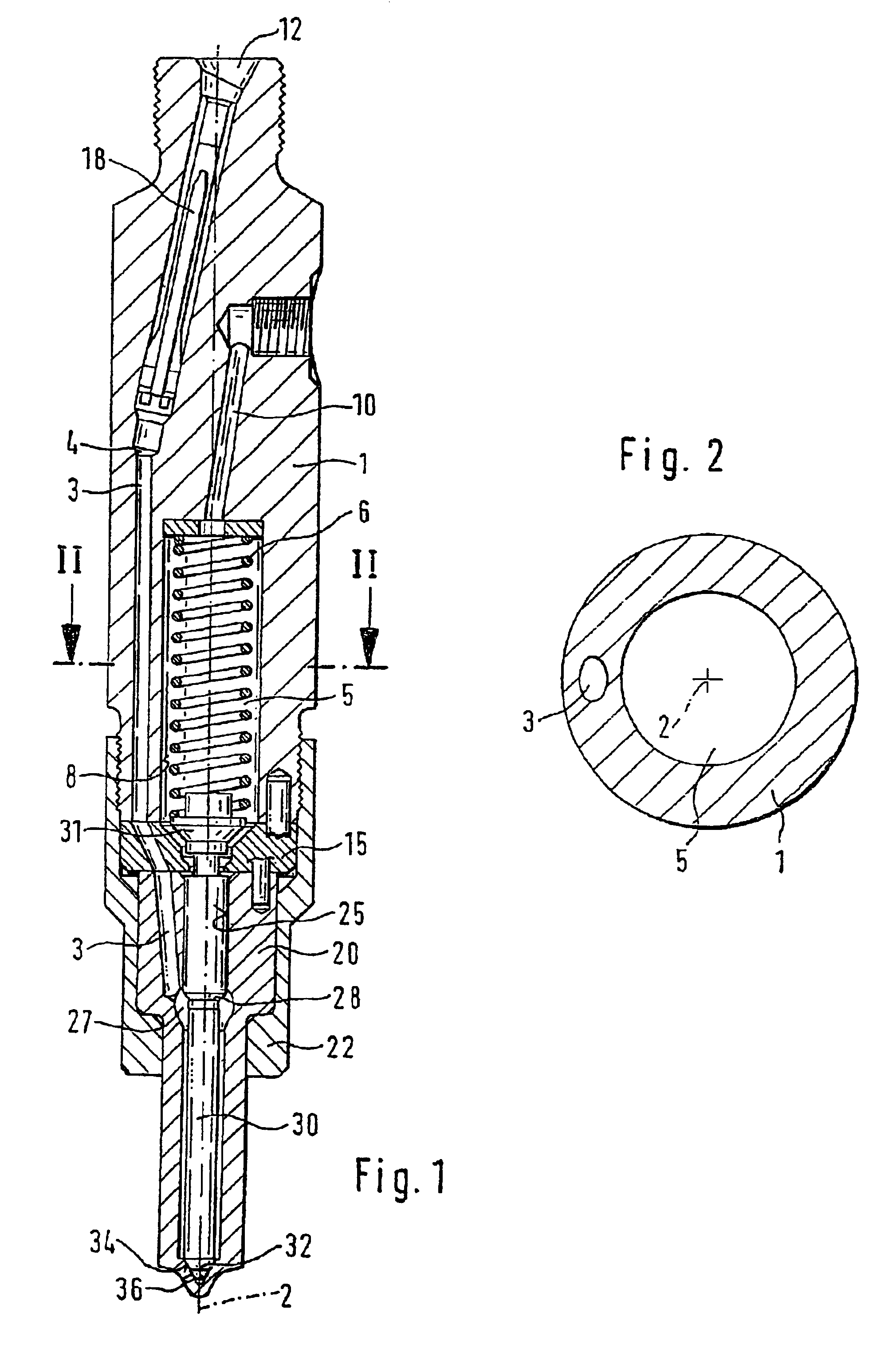

Fuel injection valve for internal combustion engines, and a method for producing same

InactiveUS20030071145A1Reduce the cross-sectional areaIncrease fuel pressureSpray nozzlesMachines/enginesCombustionInternal combustion engine

A fuel injection valve having a valve retaining body (1), which has a longitudinal axis (2) and in which a central spring chamber (5) is embodied. In this spring chamber (5), a closing spring (6) is disposed, which transmits a closing force to a valve member (30), which valve member (30) cooperates with a valve seat (32) for controlling at least one injection opening (36). In the wall of the spring chamber (5), an inlet conduit (3) extends parallel to the longitudinal axis (2) of the valve retaining body (1), and by way of this conduit, fuel at high pressure can be delivered to the at least one injection opening (36). The cross section of the inlet conduit (3) has a greater length in the circumferential direction than in the radial direction, so that the wall region between the inlet conduit (3) and the spring chamber (5), or the outer jacket face of the valve retaining body (1), is larger than in the case of an inlet conduit (3) with the same size of cross-sectional area and a circular cross-sectional contour (FIG. 1).

Owner:ROBERT BOSCH GMBH

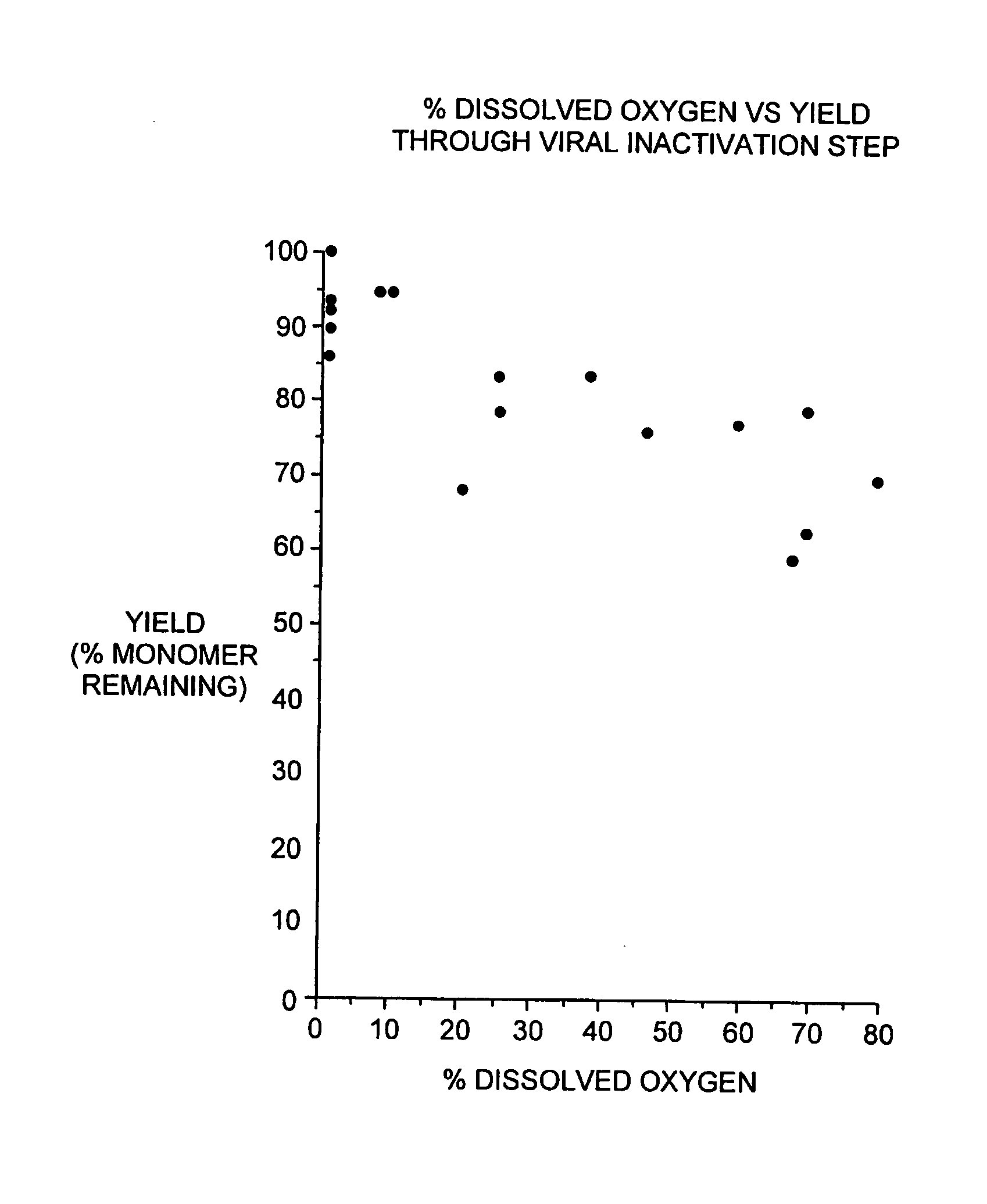

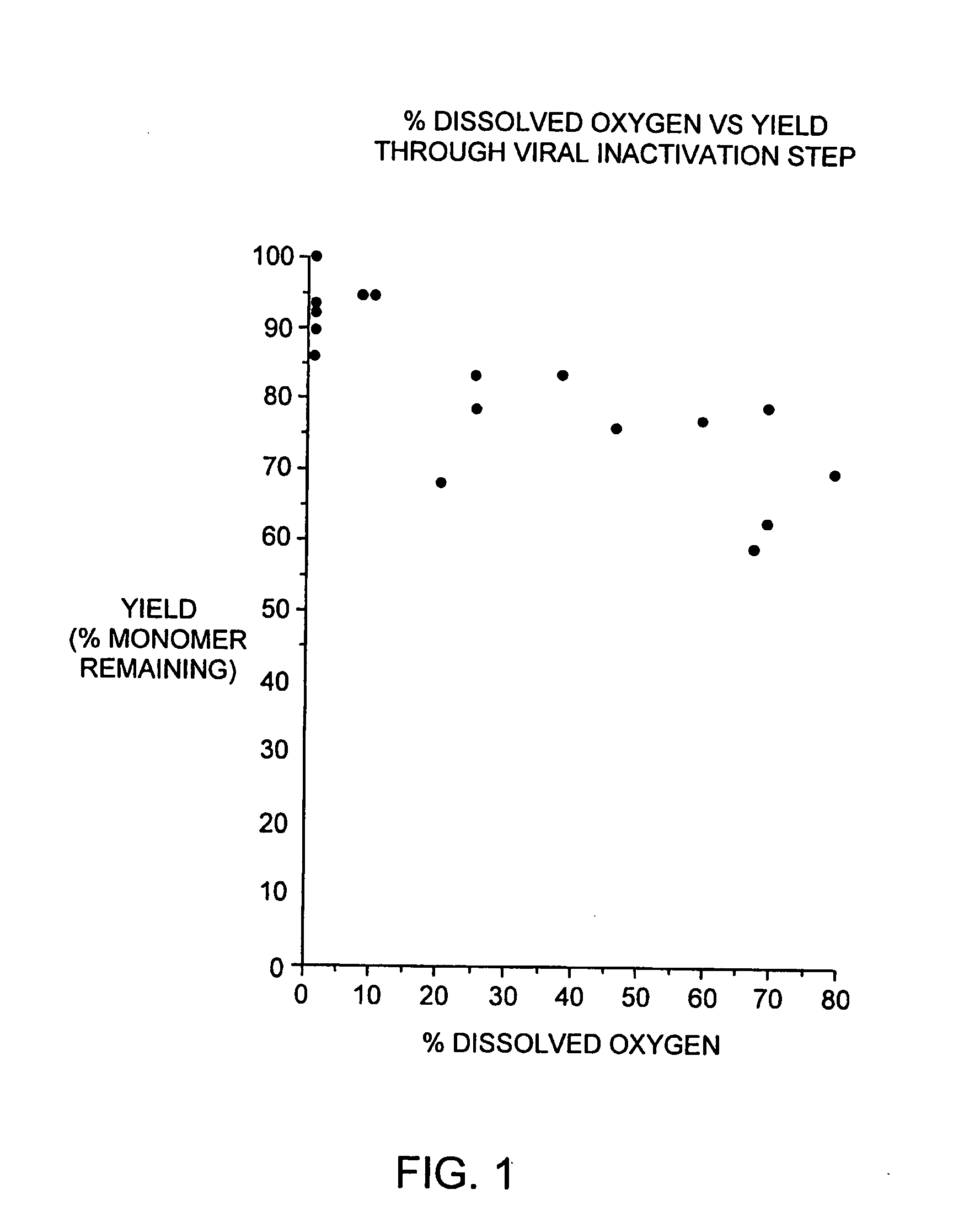

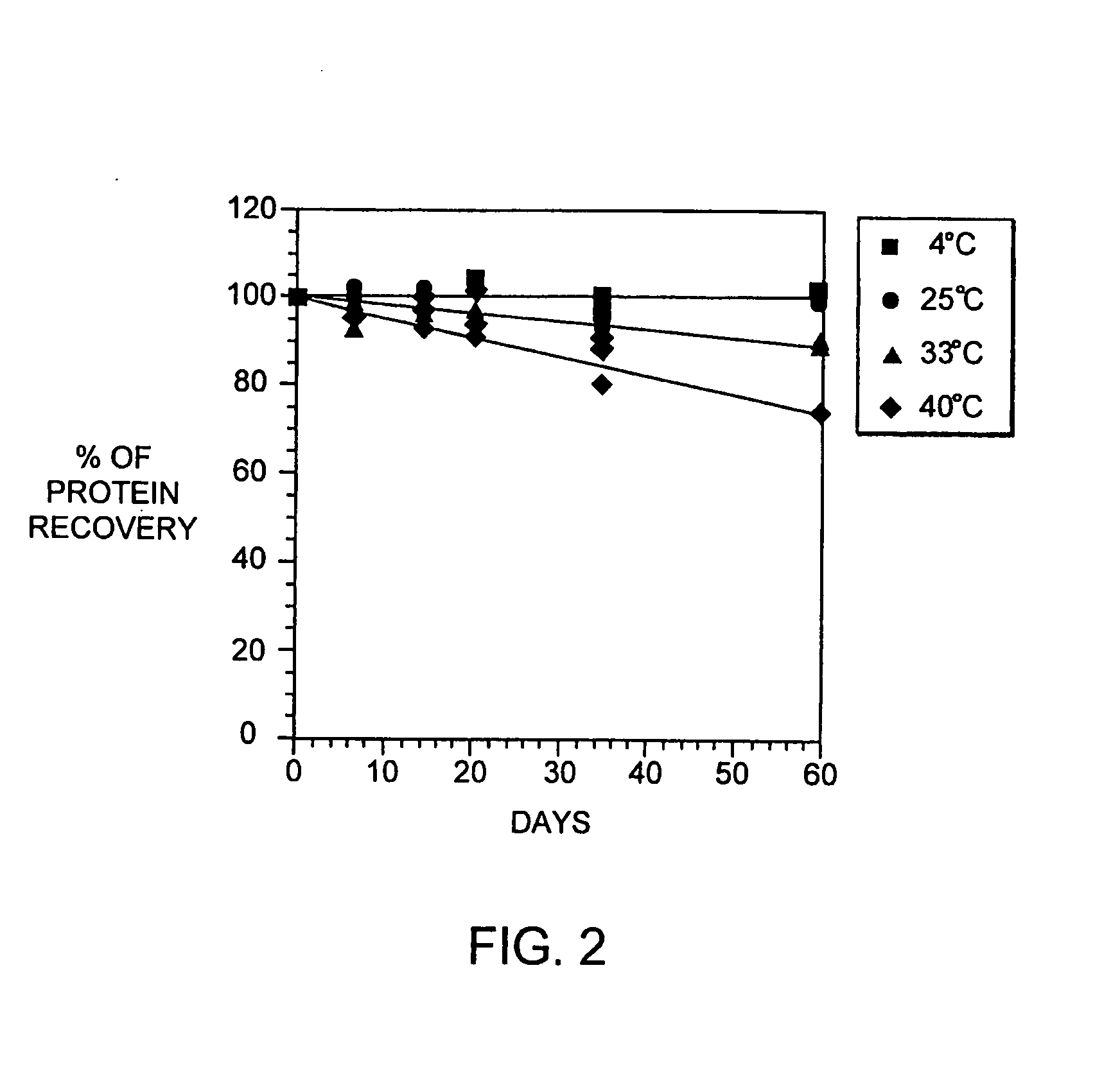

Stable liquid interferon formulations

InactiveUS20080050338A1Reduce chanceInjection volume is smallPeptide/protein ingredientsPharmaceutical delivery mechanismGlycineIonic strength

Liquid interferon compositions having a pH between 4.0 and 7.2 are described. The compositions comprise interferon-beta and a stabilizing agent at between about 0.3% and 5% by weight which is an amino acid selected from the group consisting of acidic amino acids, arginine and glycine. If needed, salt is added to provide sufficient ionic strength. The liquid composition has not been previously lyophilized or previously cavitated. The liquid is preferably contained within a vessel having at least one surface in contact with the liquid that is coated with a material inert to adsorption of interferon-beta. A kit for parenteral administration of a liquid interferon formulation and a method for stabilizing liquid interferon compositions are also described.

Owner:BIOGEN MA INC

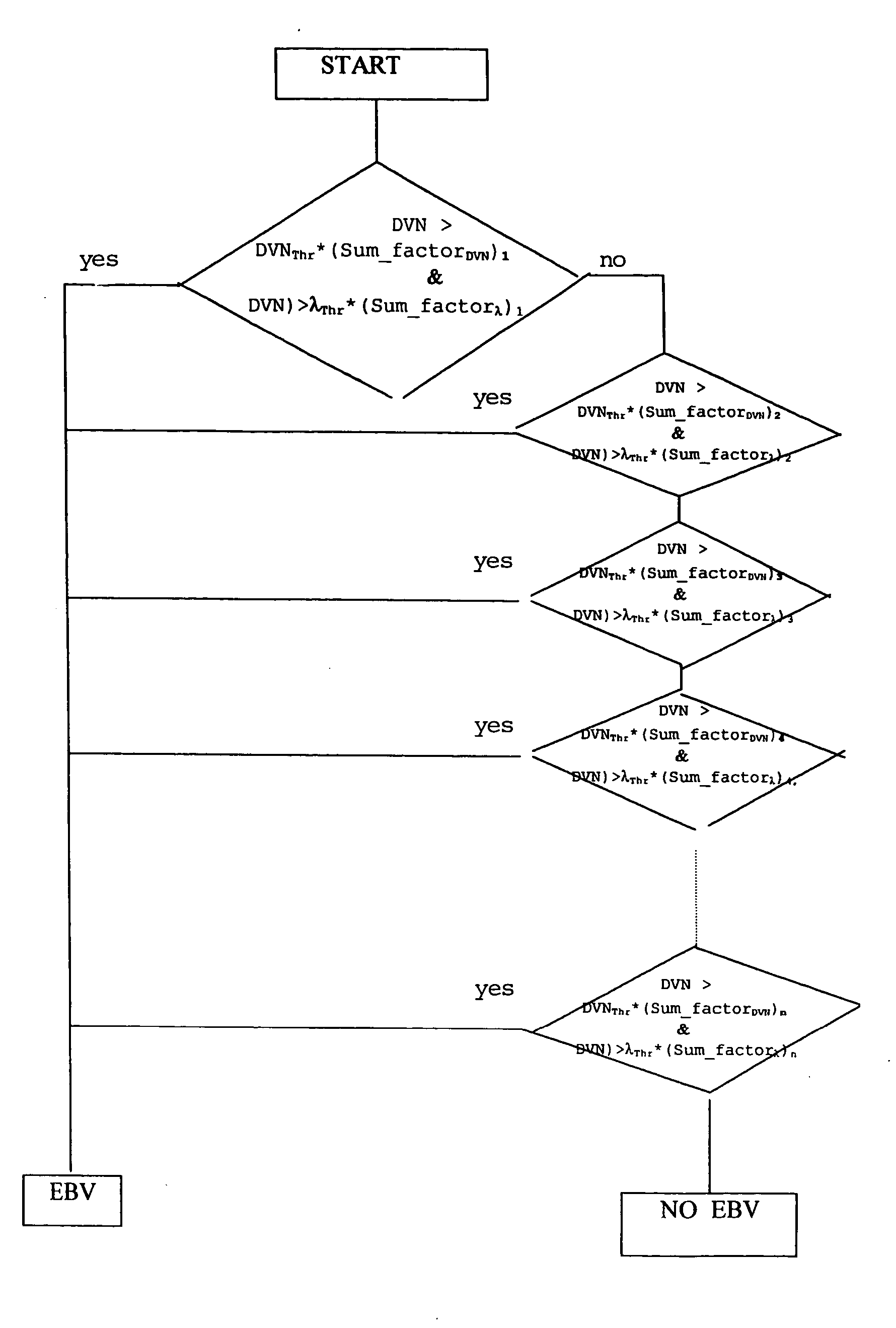

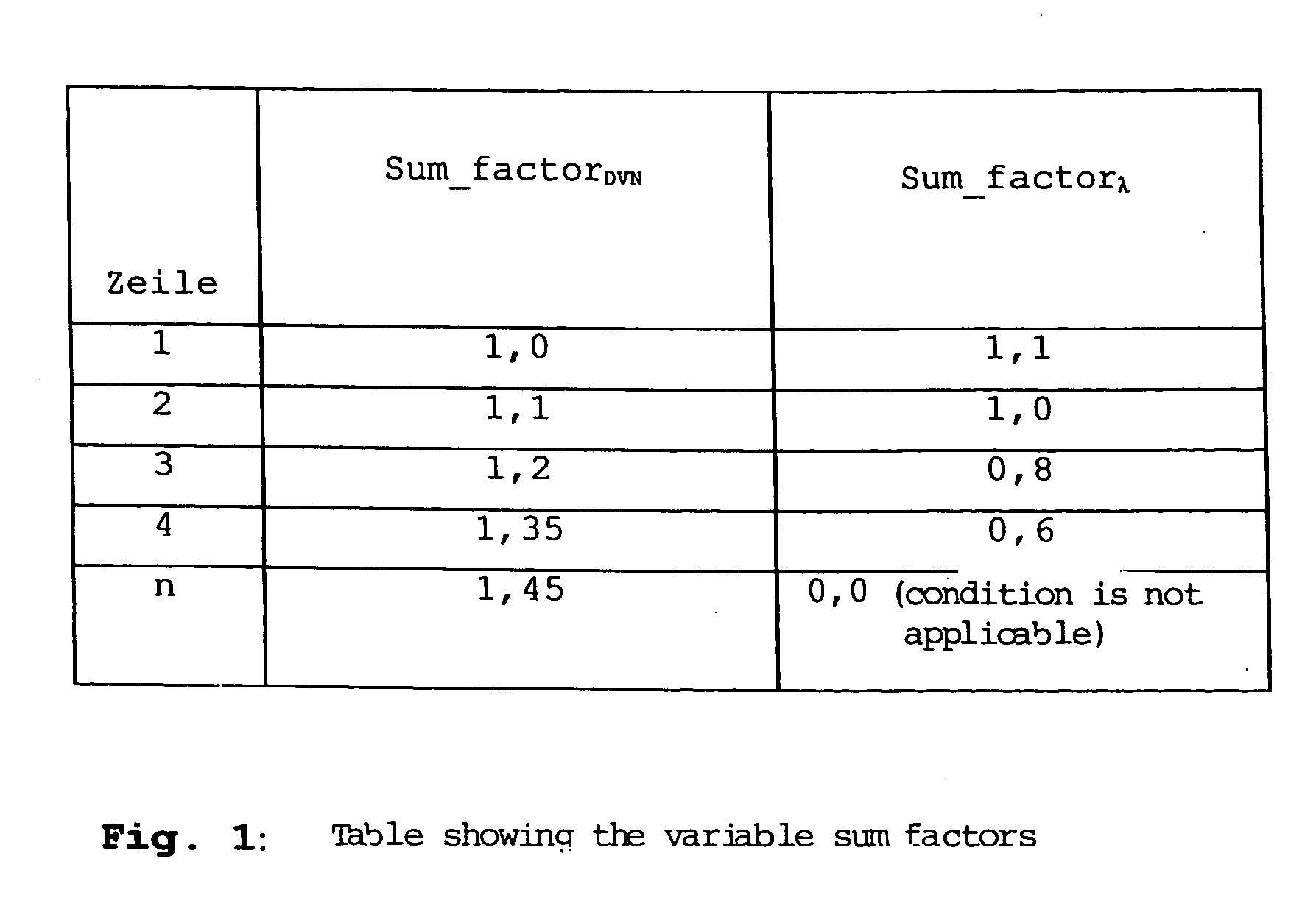

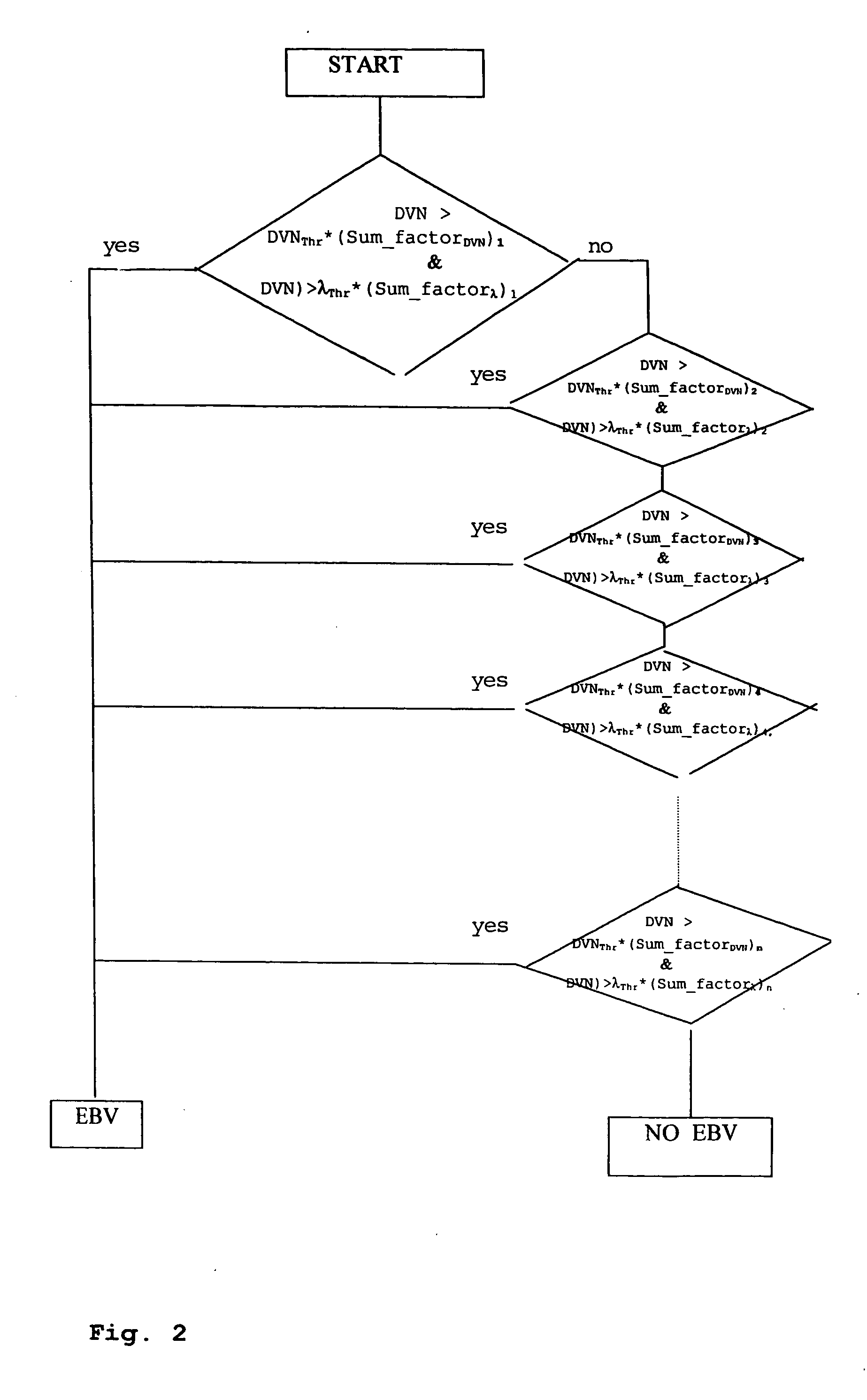

Method for electronically regulating brake-power distribution

InactiveUS20050242662A1Increase success rateImprove overall utilizationBraking systemsControl theoryMotorized vehicle

The present invention relates to a method for electronically regulating brake force distribution to the front axle and the rear axle of a motor vehicle (EBV control), wherein the rotational behavior of the vehicle wheels is determined, compared with the vehicle speed or vehicle reference speed and / or with the changes of these variables, and evaluated to limit the slip on the rear-wheel brakes by modulating the braking pressure. The brake force distribution is controlled in dependence on the sum signals obtained by addition of acceleration values determined on each individual rear wheel and / or by addition of slip values determined on each individual rear wheel. It is particularly arranged for to weight the sum signals with variable sum factors and evaluate them as a criterion for triggering the EBV control (so-called EBV plus control).

Owner:CONTINENTAL TEVES AG & CO OHG

Fuel injection valve for internal combustion engines, and a method for producing same

InactiveUS6983897B2Reduce the cross-sectional areaIncrease fuel pressureSpray nozzlesMachines/enginesCombustionExternal combustion engine

A fuel injection valve having a valve retaining body, which has a longitudinal axis and in which a central spring chamber is embodied. In this spring chamber, a closing spring is disposed, which transmits a closing force to a valve member, which valve member cooperates with a valve seat for controlling at least one injection opening. In the wall of the spring chamber, an inlet conduit extends parallel to the longitudinal axis of the valve retaining body, and by way of this conduit, fuel at high pressure can be delivered to the at least one injection opening. The cross section of the inlet conduit has a greater length in the circumferential direction than in the radial direction, so that the wall region between the inlet conduit and the spring chamber, or the outer jacket face of the valve retaining body, is larger than in the case of an inlet conduit with the same size of cross-sectional area and a circular cross-sectional contour.

Owner:ROBERT BOSCH GMBH

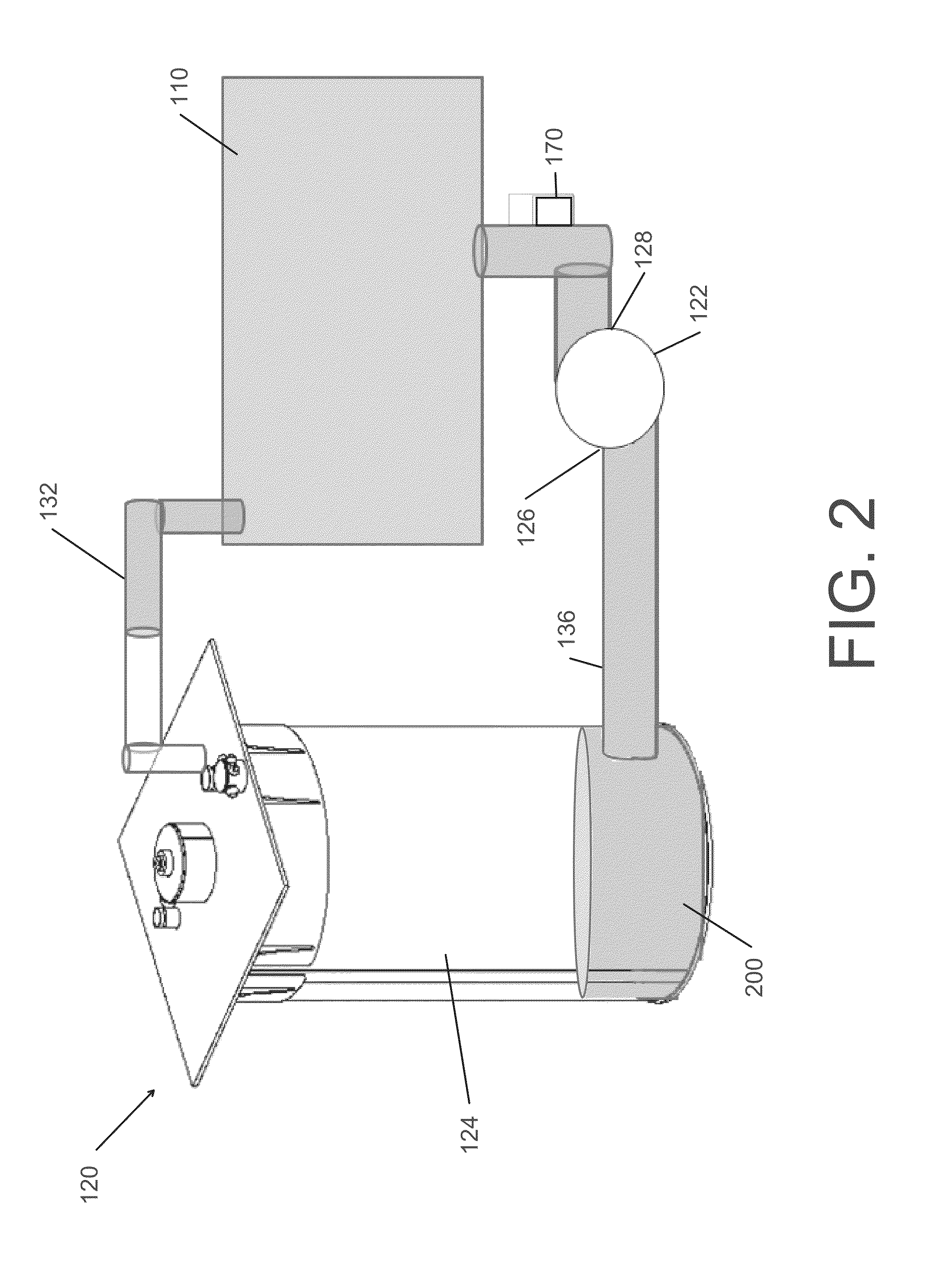

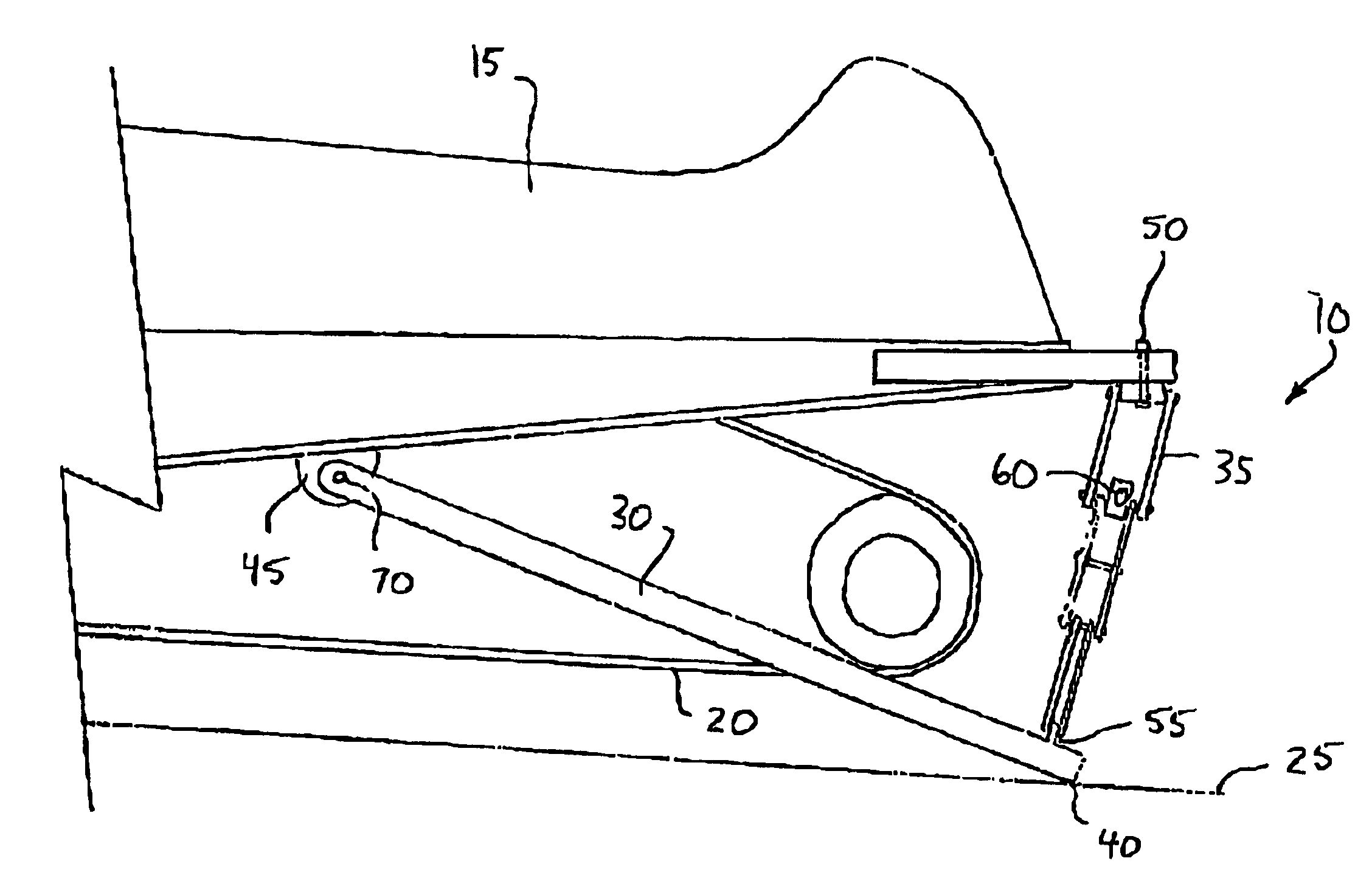

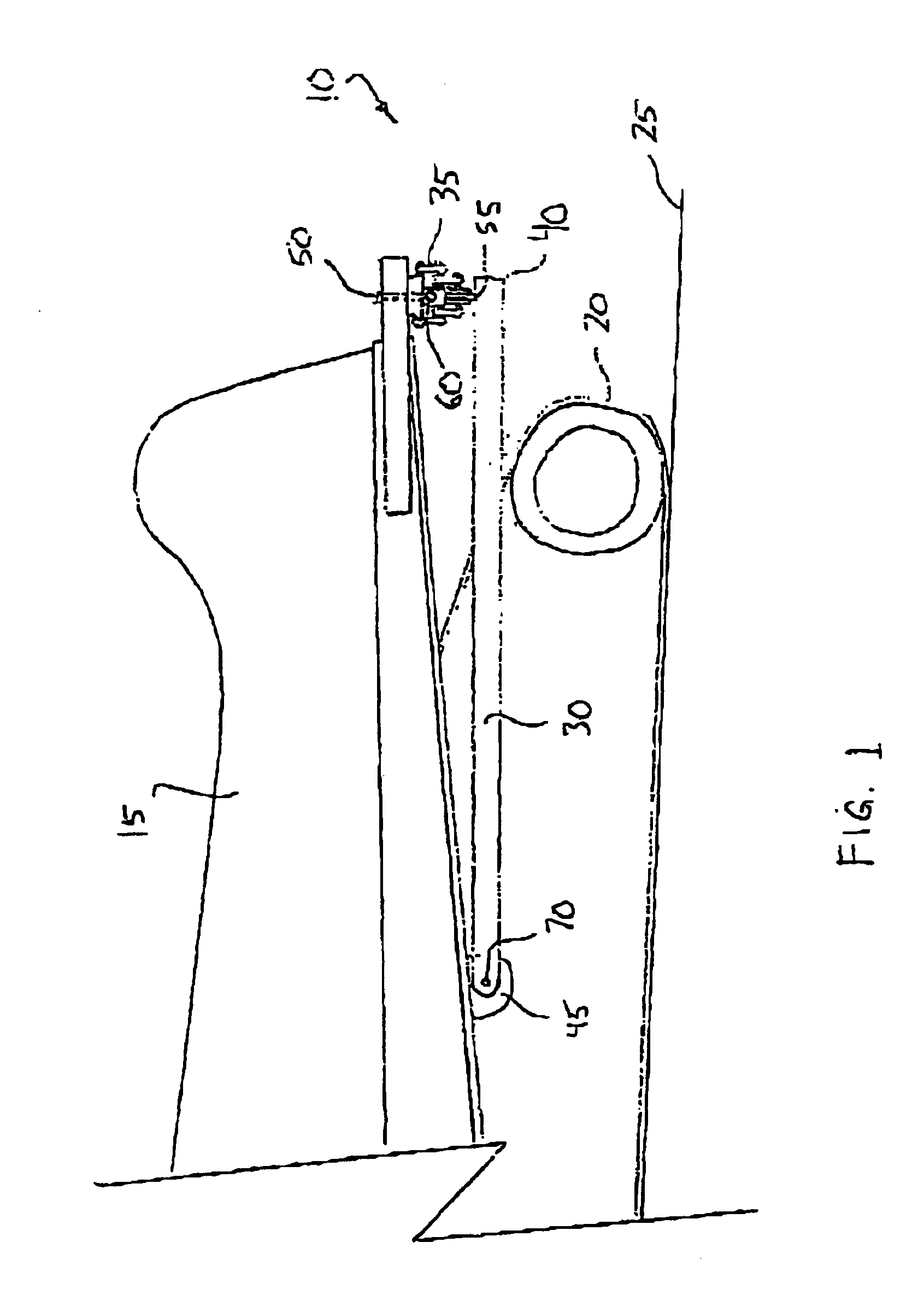

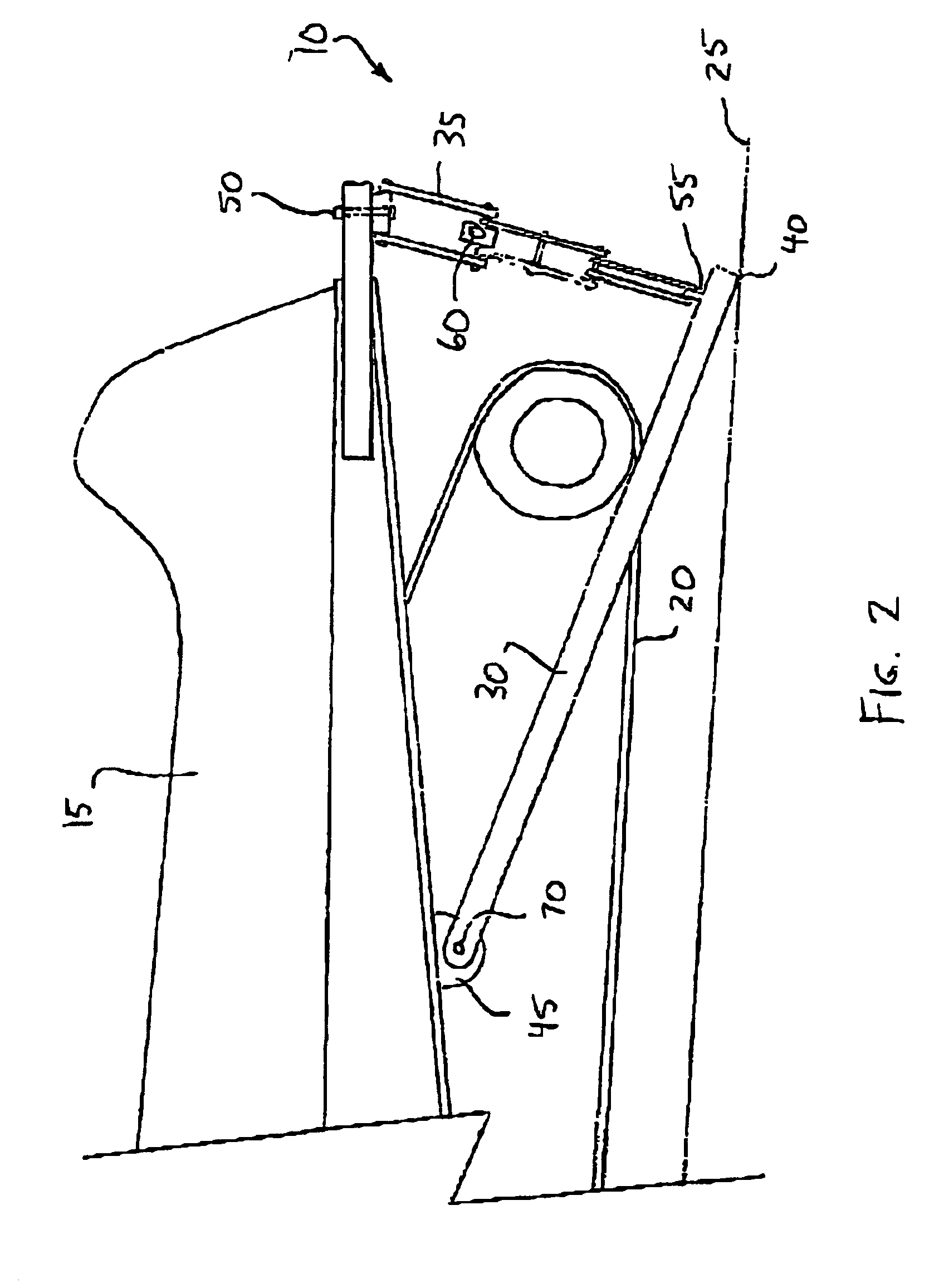

Snowmobile elevation mechanism

InactiveUS6913287B2Safely elevating a snowmobile into a stable positionAvoid refreezingVehicle fittings for liftingVehicle cleaning apparatusEngineering

Owner:LEITNER KENNETH

Auxiliary device for construction of dangling cross beam

ActiveCN106499165ALoss of stabilitySimple structureBuilding support scaffoldsSupport pointBuilding construction

Owner:STATE GRID CORP OF CHINA +2

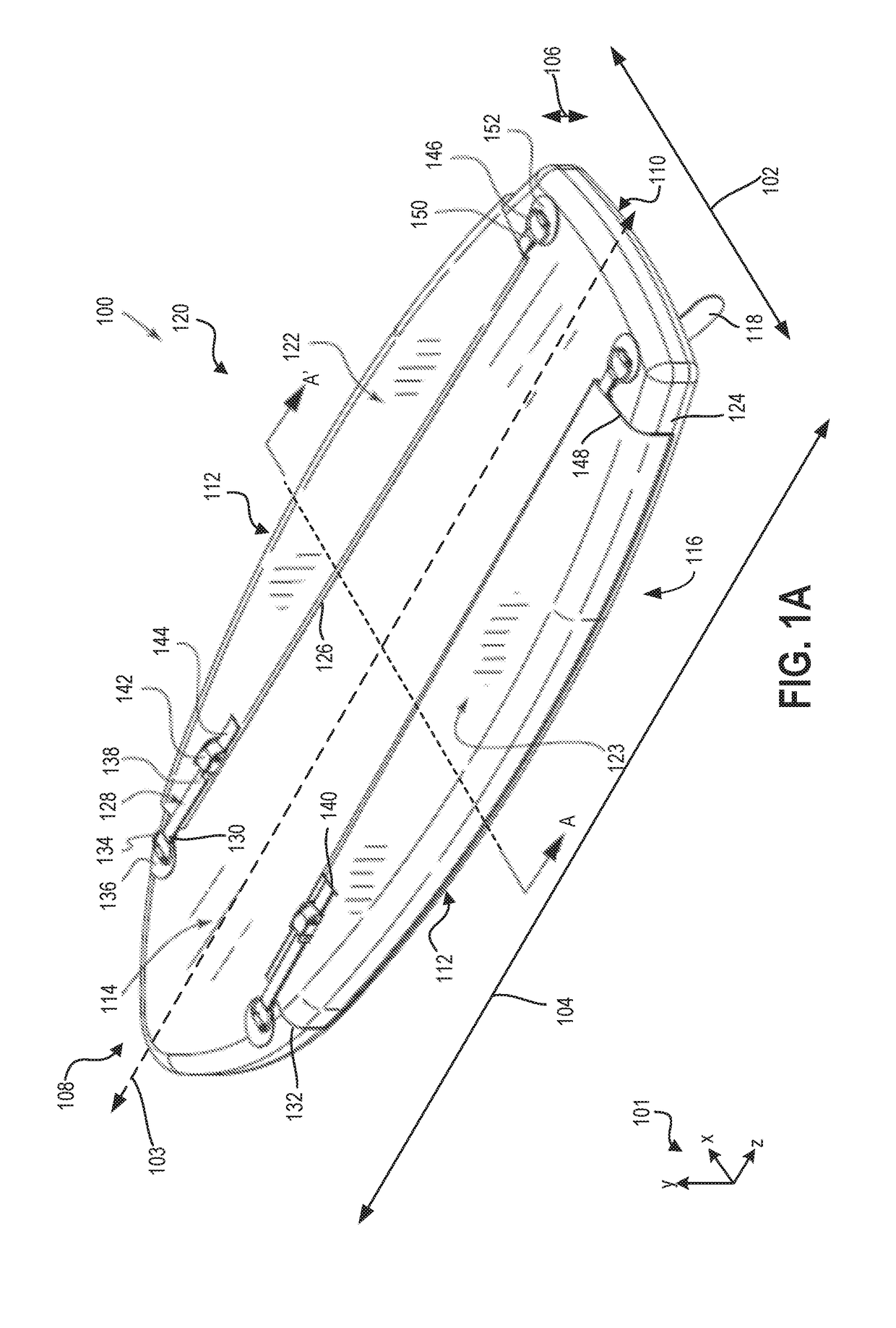

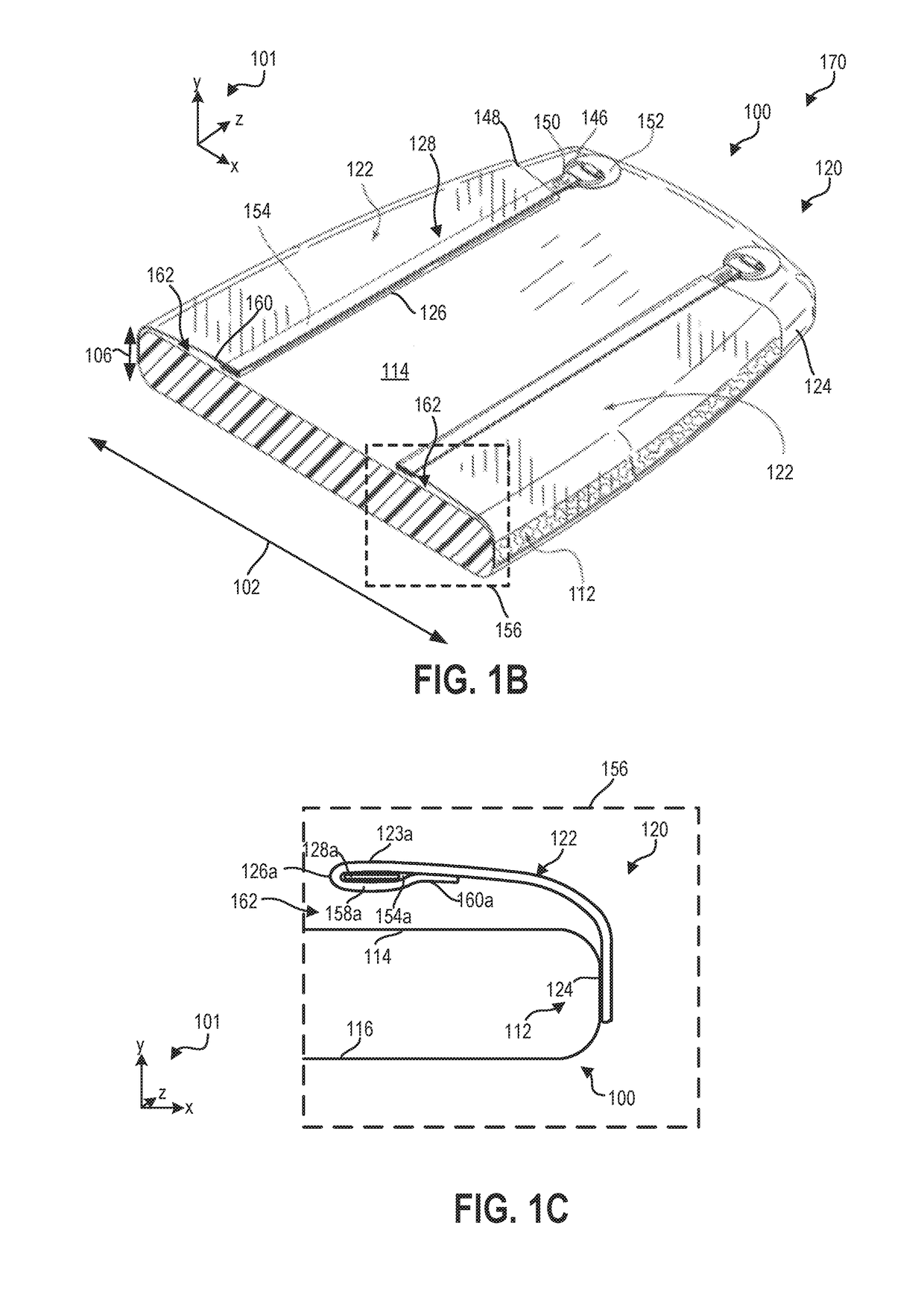

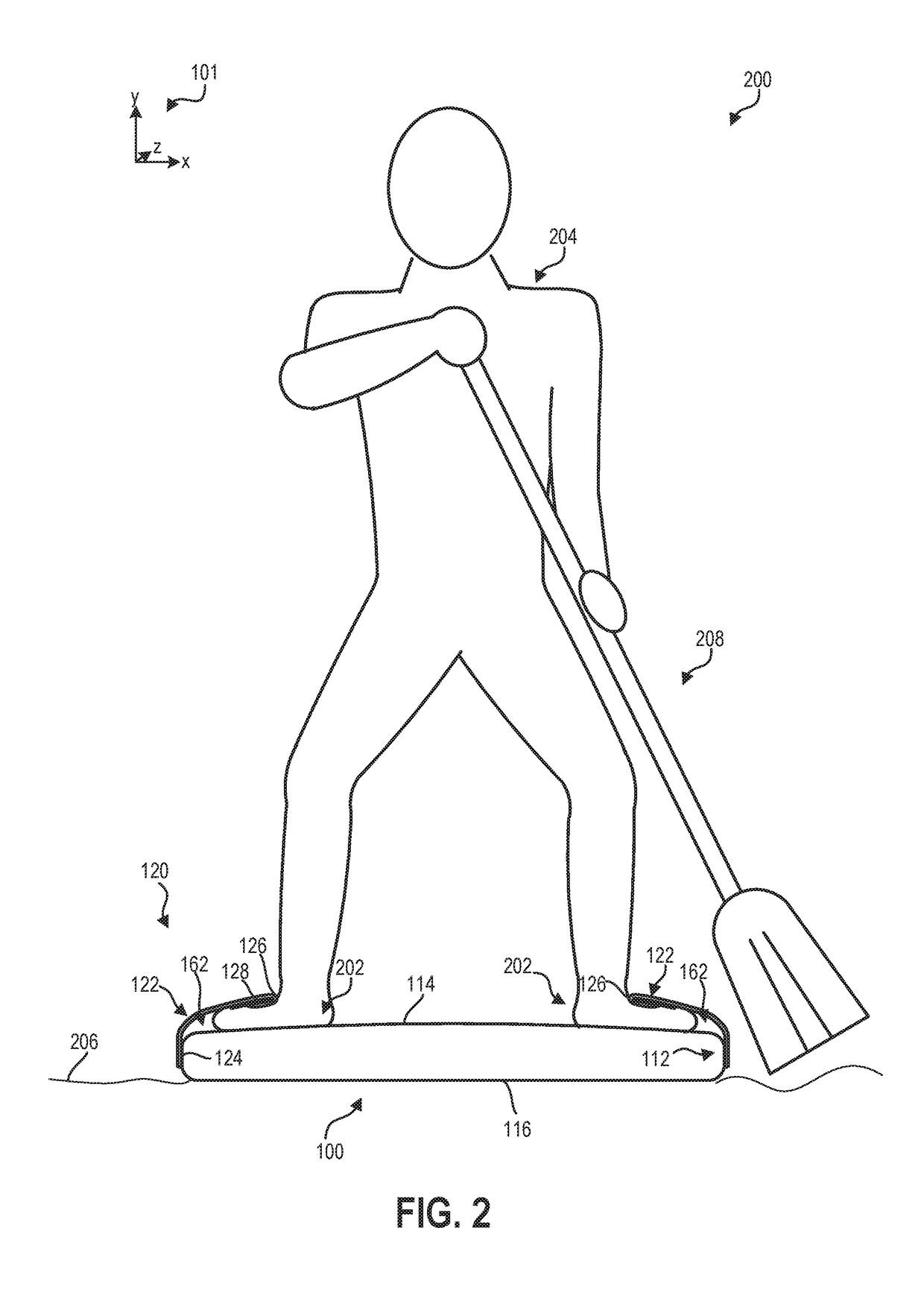

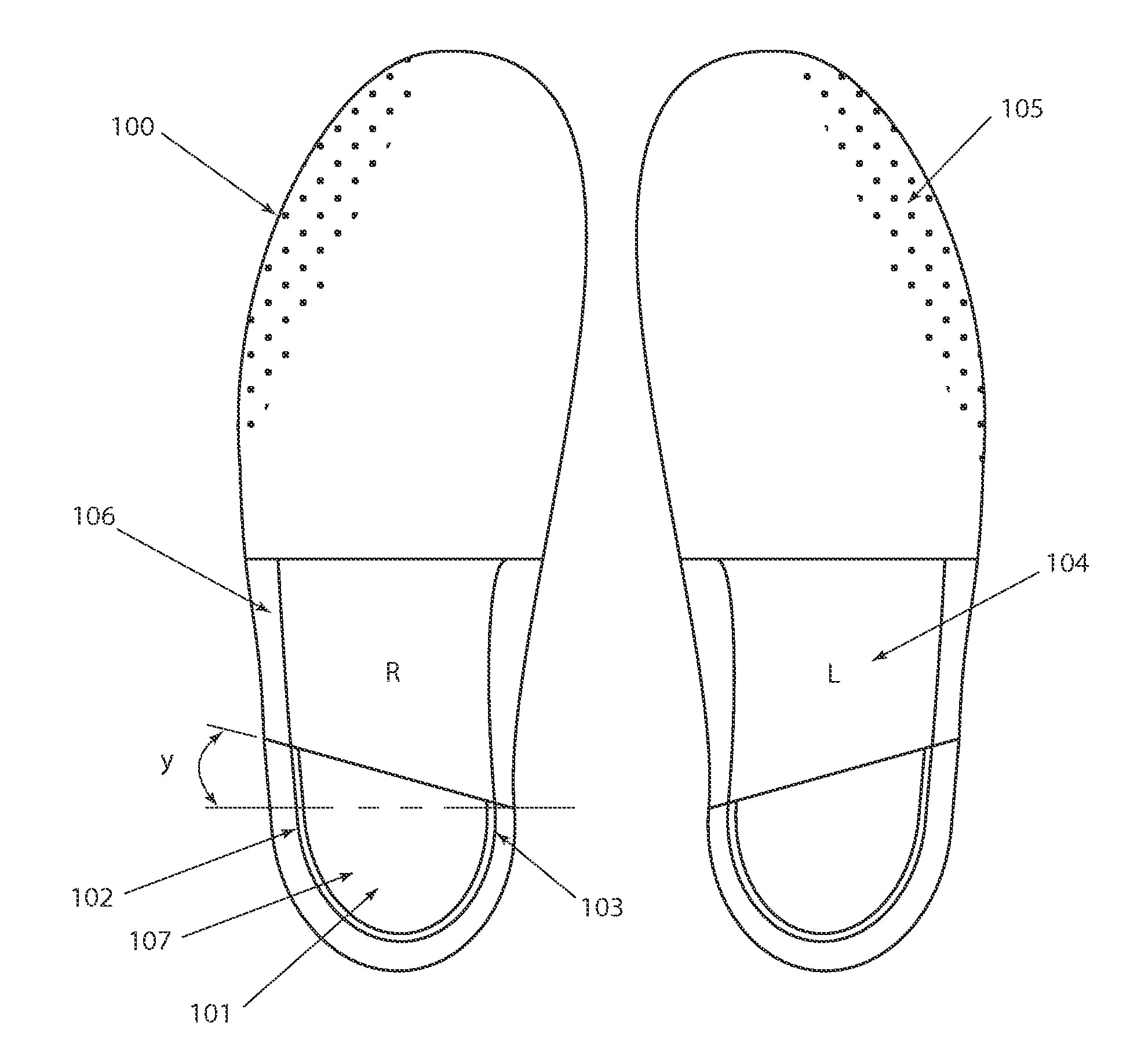

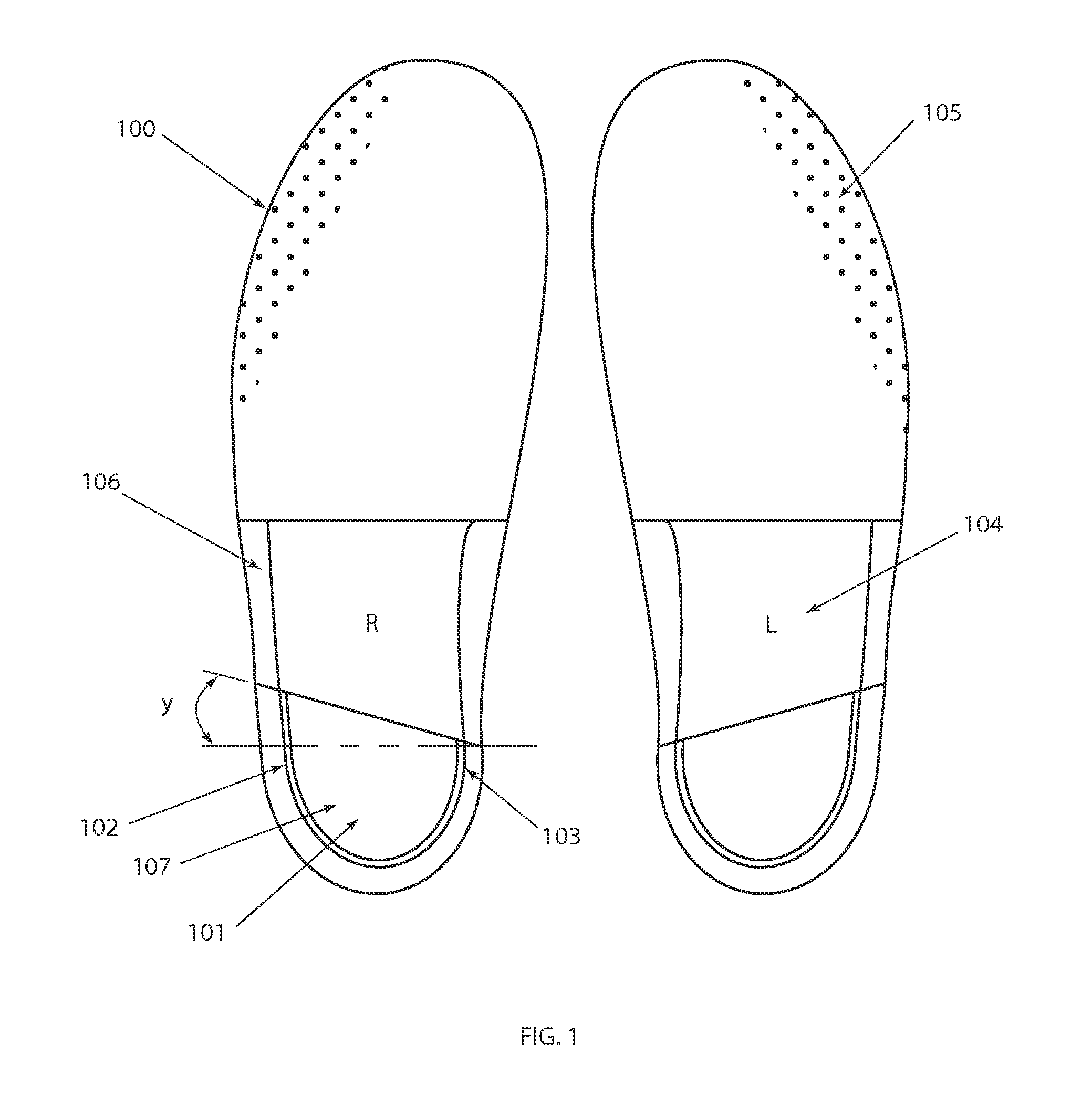

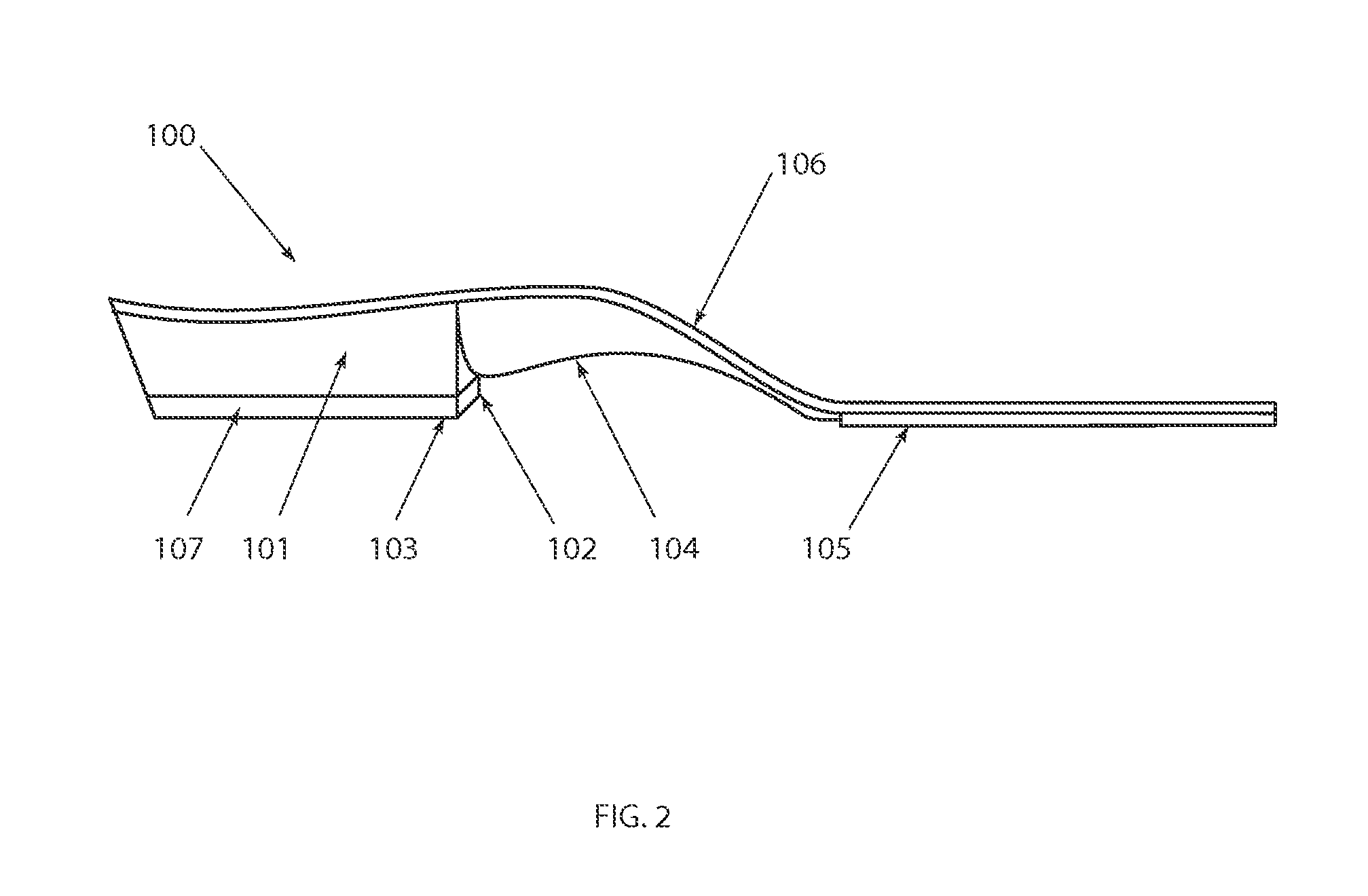

Foot binding assembly for standup paddleboards

ActiveUS20190054984A1Maintain balanceFacilitate maneuveringWater sport boardsMarine propulsionEngineeringAlong edge

A stand-up paddleboard (SUP) may be configured with a non-retentive binding system to secure a user's foot positioning. In one example, the binding system may include pockets formed from panels extending continuously along edges of the paddleboard, and straps to provide tension on the pockets, to reduce a likelihood of undesired sliding of the user's feet. The pockets of the binding system may allow the user to reposition the user's feet to multiple secured footholds within the binding system, thereby allowing the user's stance and balance to be maintained.

Owner:SAEVITZ RYAN ALEXANDER

Golf orthotic and method of use

InactiveUS8312648B2Solid stabilityEncourages properSolesNon-surgical orthopedic devicesEngineeringFoot Orthoses

A foot orthotic for golf that provides solid stability and encourages proper foot bracing and release during the golf swing. The orthotic having a semi-rigid shell, compliant top cover, anti-skid forefoot pad and a heel post. The heel post having a short medial edge to encourage proper bracing and release and an extended lateral edge to resist foot rolling or supination during the golf swing.

Owner:BALLANTYNE JOHN K

Stable liquid interferon formulations

InactiveUS20080050339A1Reduce chanceInjection volume is smallPeptide/protein ingredientsPharmaceutical delivery mechanismGlycineIonic strength

Liquid interferon compositions having a pH between 4.0 and 7.2 are described. The compositions comprise interferon-beta and a stabilizing agent at between about 0.3% and 5% by weight which is an amino acid selected from the group consisting of acidic amino acids, arginine and glycine. If needed, salt is added to provide sufficient ionic strength. The liquid composition has not been previously lyophilized or previously cavitated. The liquid is preferably contained within a vessel having at least one surface in contact with the liquid that is coated with a material inert to adsorption of interferon-beta. A kit for parenteral administration of a liquid interferon formulation and a method for stabilizing liquid interferon compositions are also described.

Owner:BIOGEN MA INC

Aerial work safeguard device

ActiveCN106545152ALoss of stabilitySimple structureBuilding support scaffoldsEngineeringSupport point

The invention discloses an aerial work safeguard device which comprises a protective basket arranged on the side face of a suspension transverse beam and a movable framework. The movable framework comprises side edge beams arranged in the direction of the suspension transverse beam; the side edge beams are provided with a mobile power mechanism; end beams are arranged at the two ends of the side edge beams; the two ends of the end beams are connected with the protective basket; the protective basket comprises stand columns; bottom fences are connected with the lower ends of the stand columns; reinforcing fences are arranged among the bottom fences; and a bottom board is arranged on the upper side of the bottom fences and the reinforcing fences. Based on the scheme, it can be learnt that the aerial work safeguard device has the beneficial effects that the structure is simple, design is reasonable, construction safety is provided, constructors have supporting points during construction, and therefore the construction precision and efficiency are improved.

Owner:STATE GRID CORP OF CHINA +2

Compositions comprising lipase and sulfite

ActiveUS11078445B2Reduced stabilityLoss of stabilityInorganic/elemental detergent compounding agentsHydrolasesAmino acid replacementEnzyme variant

Owner:NOVOZYMES AS

Method for reinforcing grafted diene rubber by in-situ sol-gel method

ActiveCN102344638BGuaranteed stabilityLoss of stabilitySilicaSpecial tyresBenzoyl peroxideRolling resistance

The invention discloses a method for reinforcing grafted diene rubber by an in-situ sol-gel method. The method comprises the following steps of: adding vinyl siloxanes and benzoyl peroxide into diene rubber latex, reacting for 2 to 6h at the temperature of between 68 and 80 DEG C to obtain vinyl siloxanes grafted and modified diene rubber latex, and adding tetraethoxysilane into the vinyl siloxanes grafted and modified diene rubber latex at the temperature of between 68 and 80 DEG C and performing sol-gel reaction to obtain in-situ reinforced butadiene styrene rubber. The silica-reinforced rubber prepared by the method has higher pure rubber and vulcanized rubber strength and good processability, and has a great significance for the processes of the rubber such as mixing, transportation, storage and the like. The problem of incompatibility of polar silica and rubber is solved to a certain degree, and a theoretical basis is provided for overcoming the contradiction between the reduction of rolling resistance of tyres and the improvement on wet skid resistance.

Owner:PETROCHINA CO LTD +1

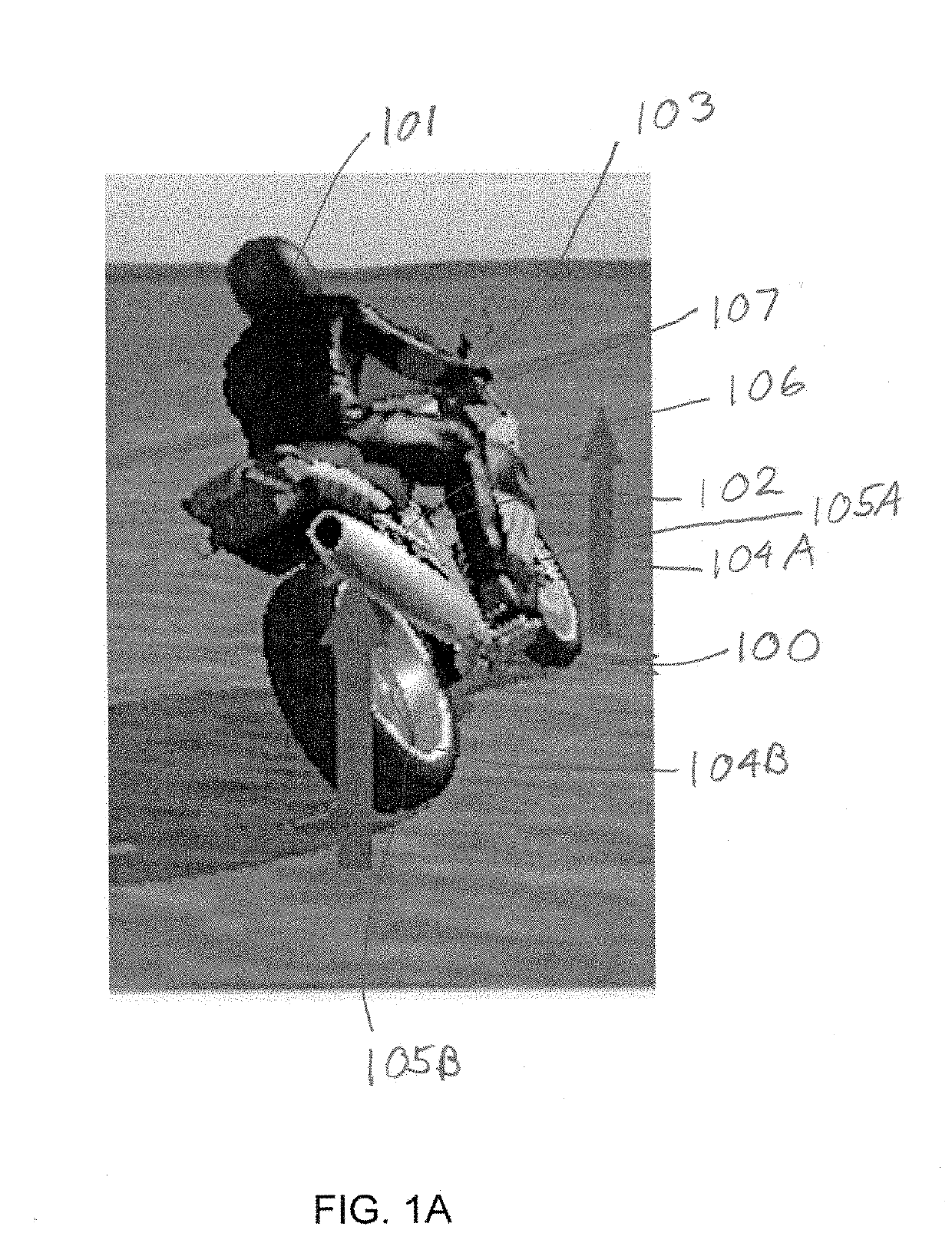

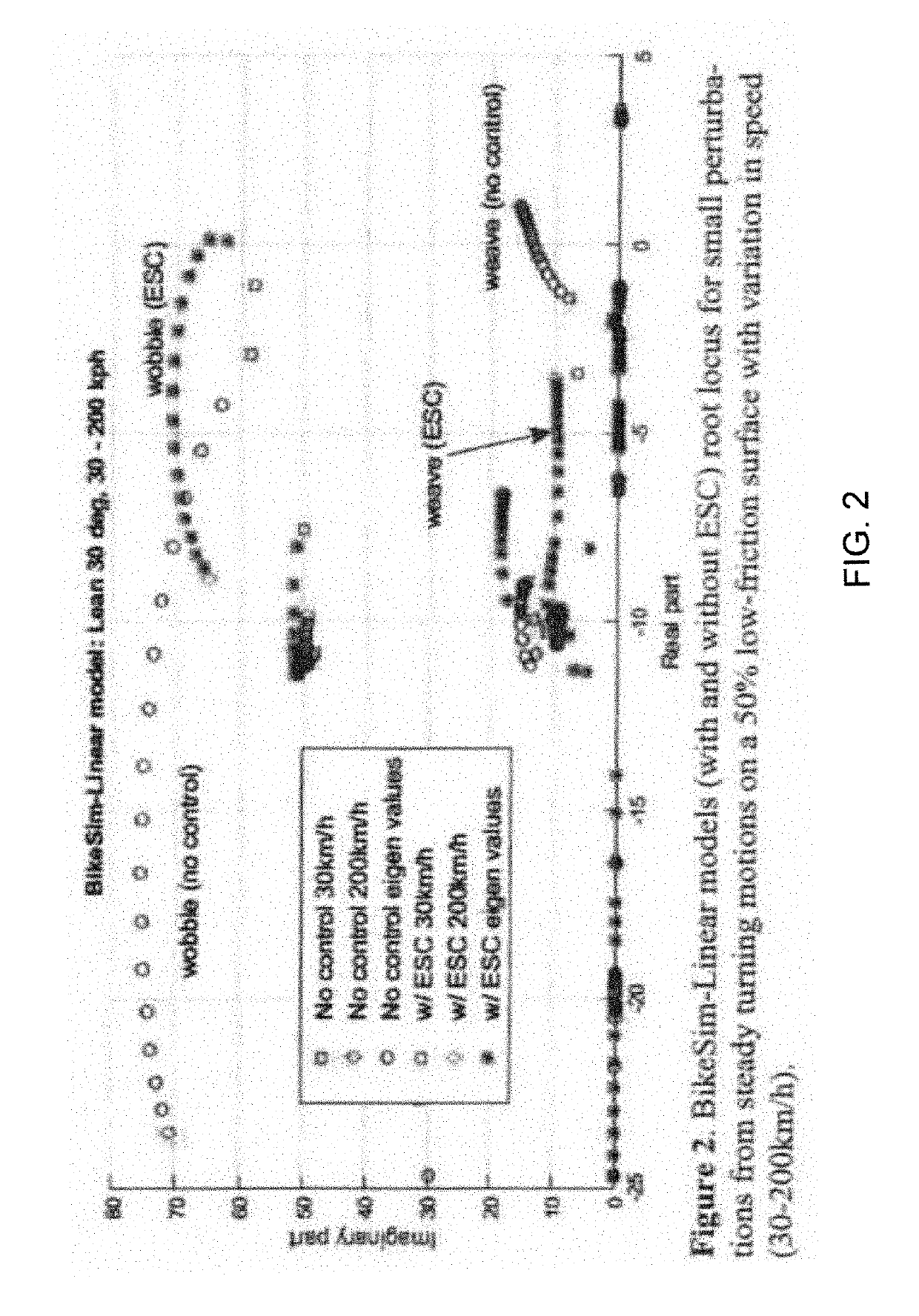

System and method to stabilize motorcycles

ActiveUS10435016B2Avoid lostLoss of stabilityBrake system interactionsCycle safety equipmentsSteering angleOn board

Owner:MECHANICAL SIMULATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com