A preparation device for folding honeycomb precursor and its use method

A precursor and honeycomb technology, applied in the field of composite material manufacturing, can solve problems such as inability to produce, limited mechanical strength, etc., and achieve the effects of improving production efficiency, reducing production costs, and high-efficiency and low-cost production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

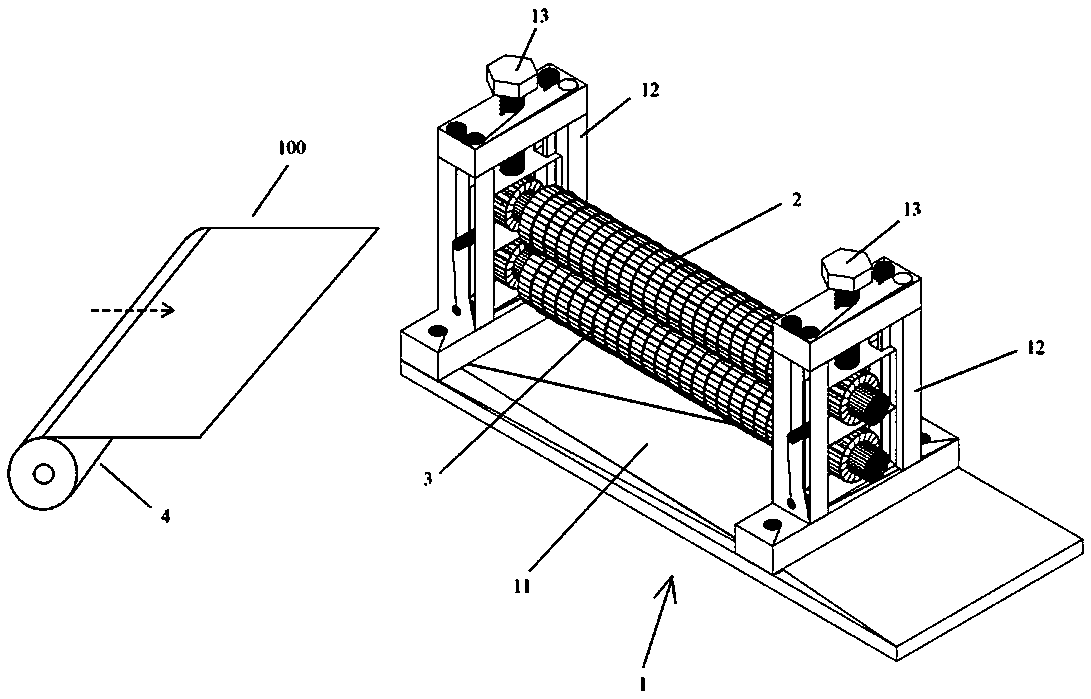

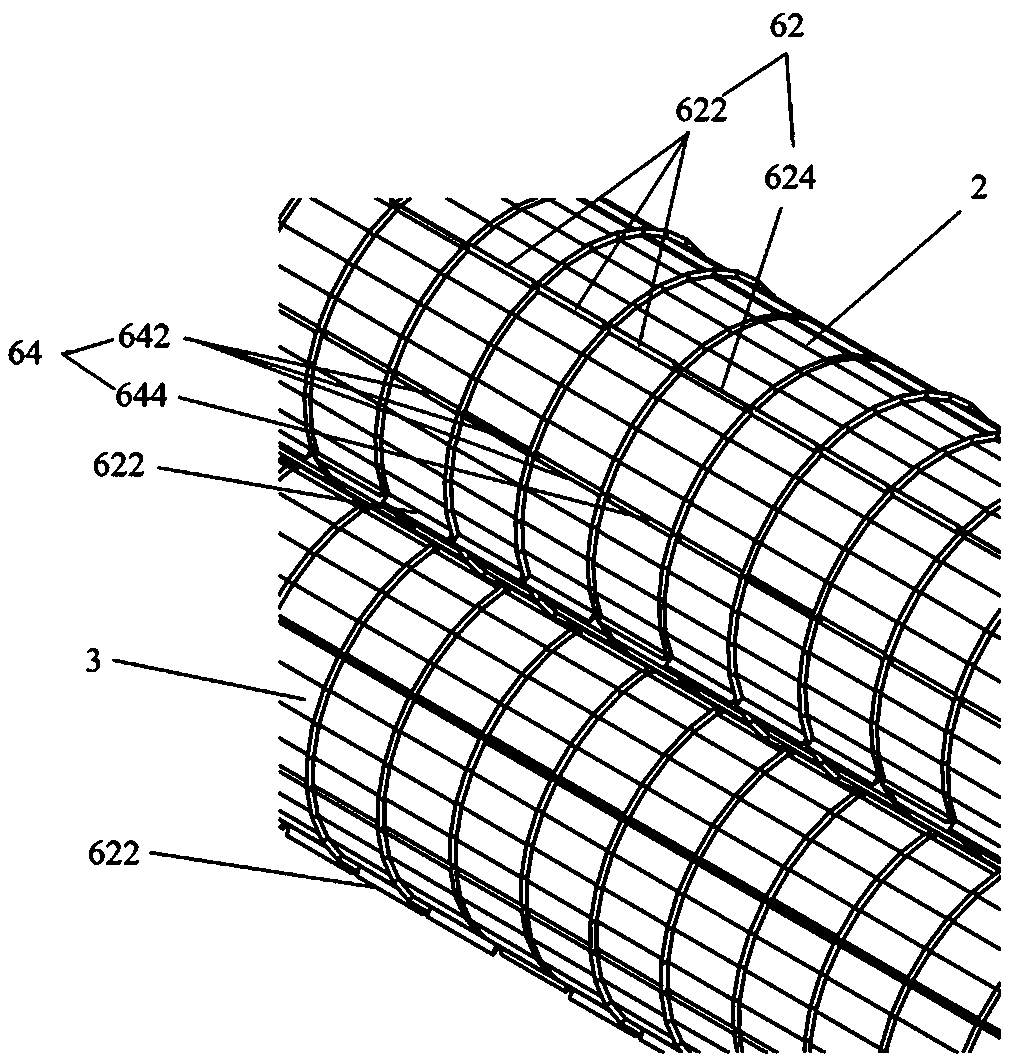

[0028] The invention provides a manufacturing device for folded honeycomb precursors, which is used to manufacture such as Image 6 The folded honeycomb precursor shown, the folded honeycomb precursor can be folded and pasted to obtain a fiber-reinforced polypropylene honeycomb core material.

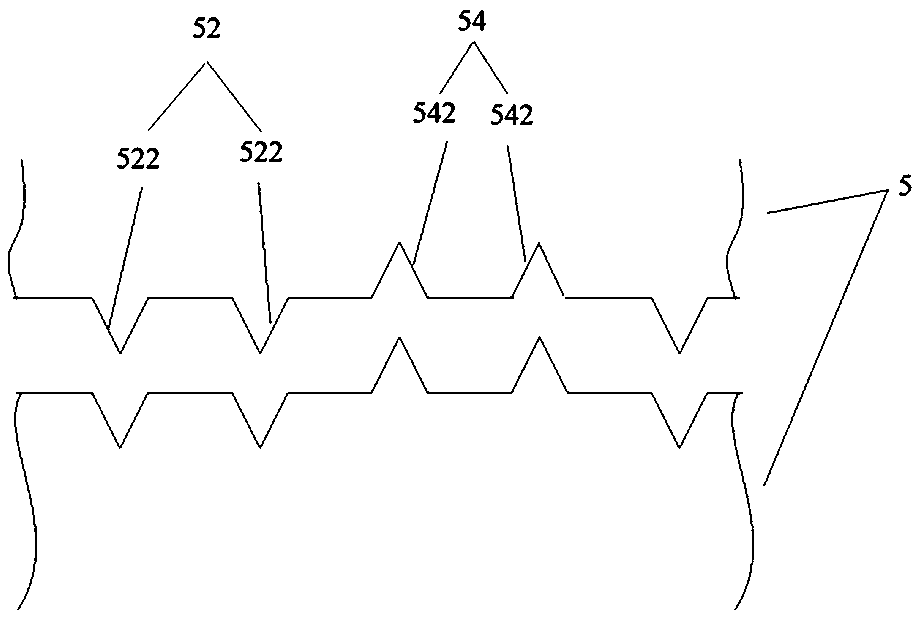

[0029] see Figure 1 to Figure 5 , the manufacturing device includes: a frame 1, an upper roller press wheel 2 and a lower roller press wheel 3 fixed on the frame 1, a feeding mechanism 4 and a control mechanism arranged on one side of the frame 1 (not shown in the figure), the upper roller press wheel 2 is set opposite to the lower roller press wheel 3, and the feeding mechanism 4 is used to feed the plastic sheet 100 into the upper roller press wheel 2 and the lower roller press wheel 3, the upper rolling knife wheel 2 and the lower rolling knife wheel 3 are provided with an annular knife structure 5 along its circumferential direction, and the upper rolling knife wheel 2 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com