Massage bathtub pump

A bathtub and pump cover technology, which is applied to pumps, pump devices, pump components, etc., can solve the problems of jacuzzi pumps, such as high vibration and noise, poor sealing effect, and fast wear, to achieve extended working life, convenient operation, and reduced noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

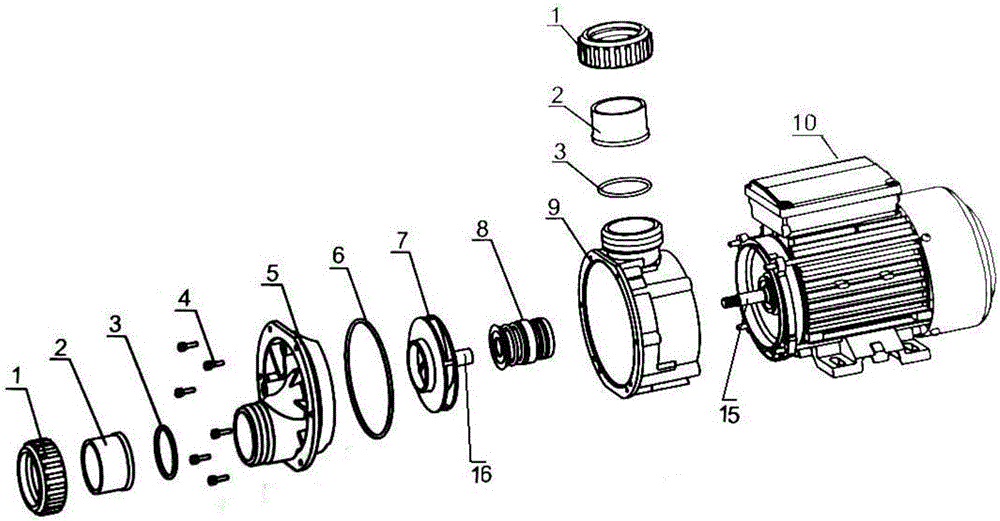

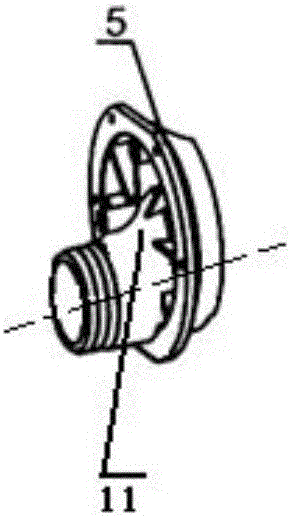

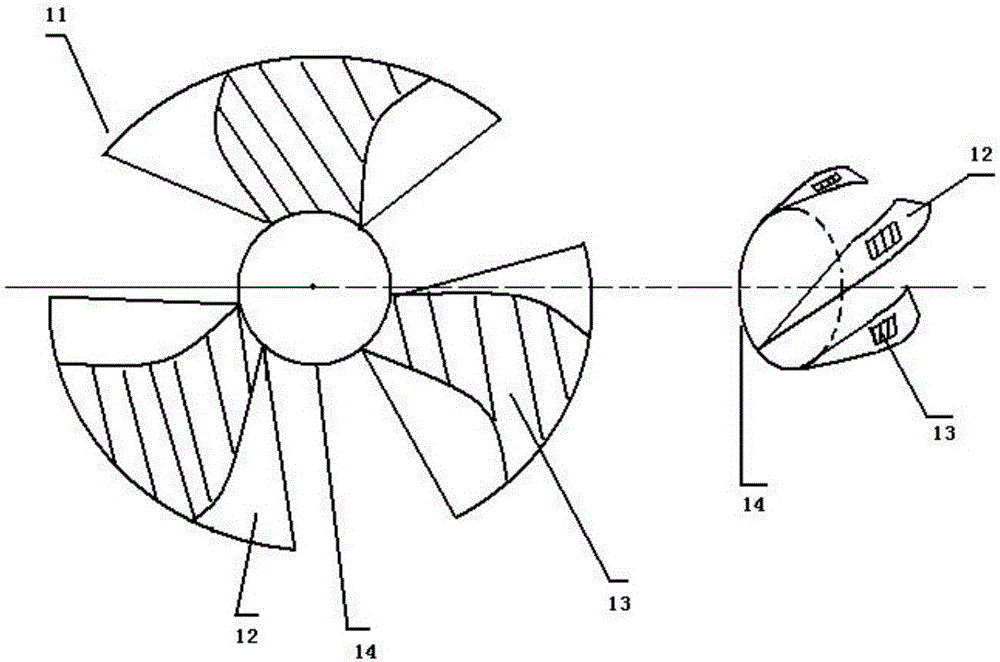

[0022] A massage bathtub pump, comprising a pump casing assembly 9, an impeller 7, a bearing 15, a pump cover assembly 5 and a motor 10, the impeller 7 is sleeved on the bearing 15 through a shaft sleeve 16, and one side of the impeller 7 passes through The large O-ring 6 is in sealing connection with the pump cover assembly 5, and the other side is connected with the pump casing assembly 9 through a mechanical seal 8, and the shaft sleeve 16 passes through the mechanical seal 8 and is socketed with the bearing 15, and the pump cover The assembly 5 is composed of a suction section, a cover shell and an introduction part 11. The introduction part 11 is composed of three guide vanes 12 connected by a circular collar 14 and bent in a certain direction. The three guide vanes 12 are uniform Distributed around the circle of the circular collar 14, the guide vanes 12 are fan-shaped, and the three guide vanes 12 are covered on the diverging suction pipe of the suction section. Protrud...

Embodiment 2

[0024] A massage bathtub pump, comprising a pump casing assembly 9, an impeller 7, a bearing 15, a pump cover assembly 5 and a motor 10, the impeller 7 is sleeved on the bearing 15 through a shaft sleeve 16, and one side of the impeller 7 passes through The large O-ring 6 is in sealing connection with the pump cover assembly 5, and the other side is connected with the pump casing assembly 9 through a mechanical seal 8, and the shaft sleeve 16 passes through the mechanical seal 8 and is socketed with the bearing 15, and the pump cover The assembly 5 is composed of a suction section, a cover shell and an introduction part 11. The introduction part 11 is composed of three guide vanes 12 connected by a circular collar 14 and bent in a certain direction. The three guide vanes 12 are uniform Distributed around the circle of the circular collar 14, the guide vanes 12 are fan-shaped, and the three guide vanes 12 are covered on the diverging suction pipe of the suction section. Protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com