Seabed natural gas hydrate collecting device

A collection device and natural gas technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., to achieve the effects of reliable connection, ensuring production safety, and convenient, fast and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

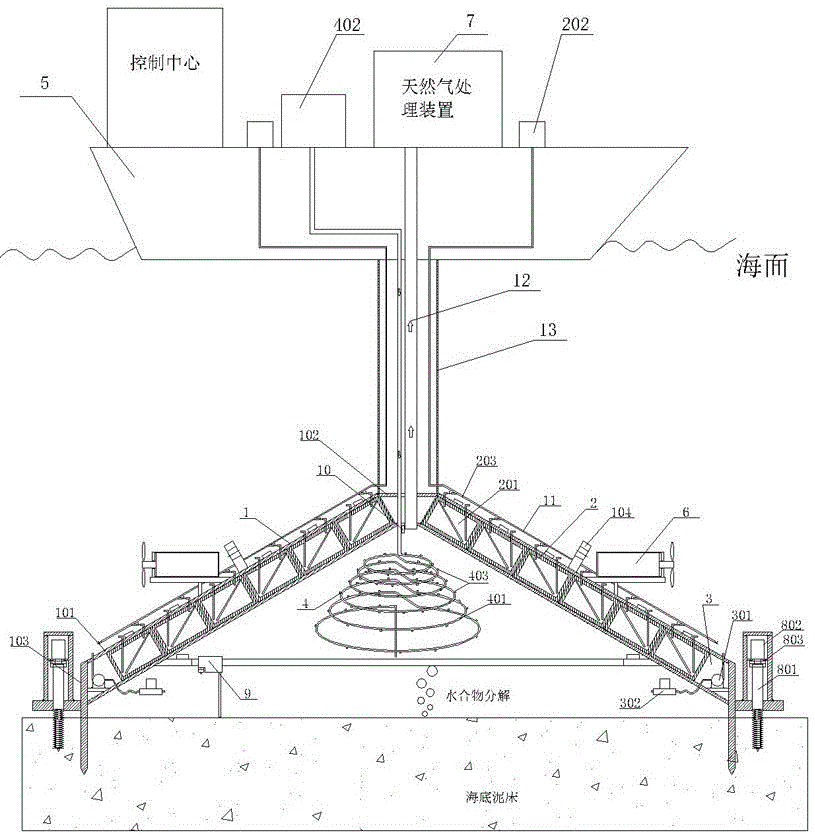

Embodiment 1

[0062] Such as figure 1 and Figure 13 As shown, the seabed natural gas hydrate collection device of the present invention includes a mother ship 5 and an empty natural gas collection cover 1. The mother ship 5 is provided with a natural gas collection and storage device 7 and a pressure supply module 202. The natural gas storage and storage device 7 The top of the natural gas collection cover 1 is connected to the top of the natural gas collection cover 1 through the gas production pipeline 12, and the natural gas collection cover 1 is connected to the bottom of the mother ship 5 through the riser 13, and the gas production pipeline 12 is arranged in the water riser 13; the bottom of the natural gas collection cover 1 is arranged around There is an anchoring system 8, a pressure regulation system 3 is provided at the bottom of the natural gas collection cover 1, a temperature regulation system 4 and an agitation system 9 are provided inside the natural gas collection cover 1...

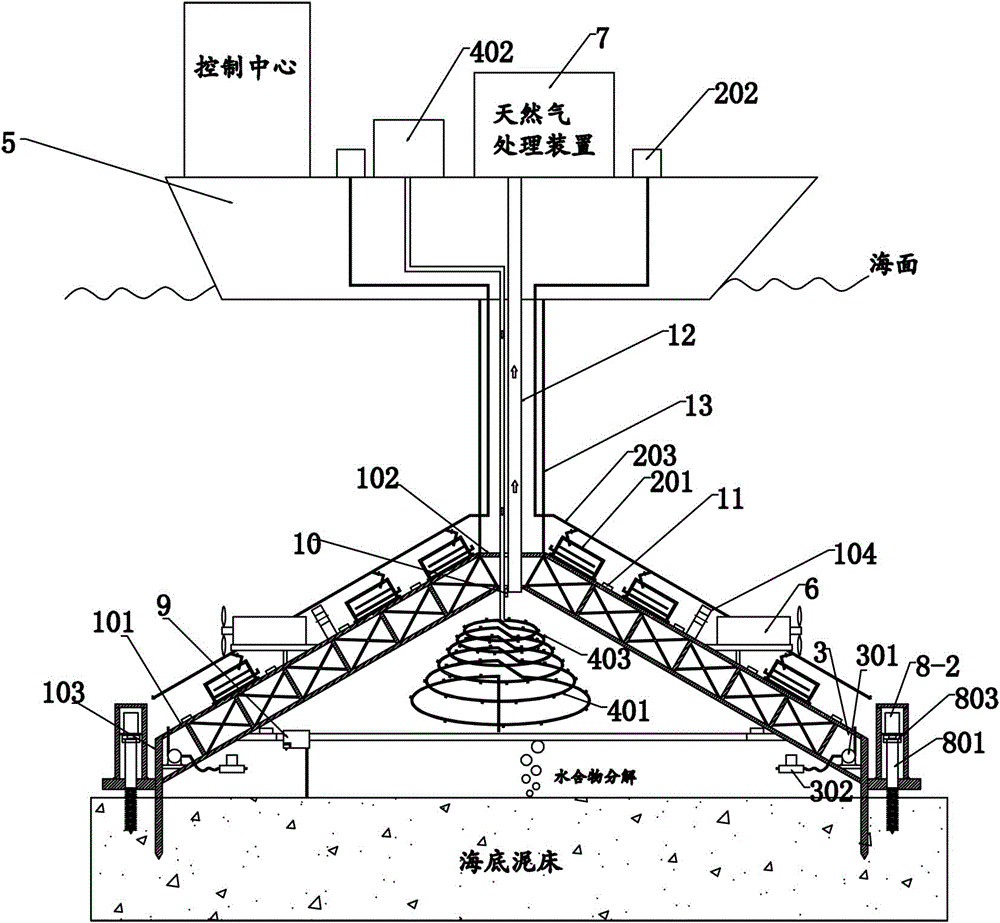

Embodiment 2

[0071] Such as figure 2 and Figure 14 As shown, this embodiment is similar to Embodiment 1, the difference is that: the outer wall of the natural gas collection cover 1 is provided with a density adjustment system 2, and the density adjustment system 2 includes a buoyancy module 201, a pressure supply module 202 and Pneumatic pipeline 203; wherein several buoyancy modules 201 are arranged on the outer wall of the housing 101, the buoyancy modules 201 include a sealed inner hollow box, an electronic liquid level gauge 207 is arranged in the box, and an electronic liquid level gauge 207 is arranged on the box There are drainage pipes 206 and air intake pipes 205 that communicate with the inside and outside, and the air intake pipes 205 of all buoyancy modules 201 are connected in parallel to the air pressure pipeline 203 , and the air pressure pipeline 203 is fixed on the outer wall of the shell 101 and passes through the riser 13 Connect to the pressure supply module 202.

...

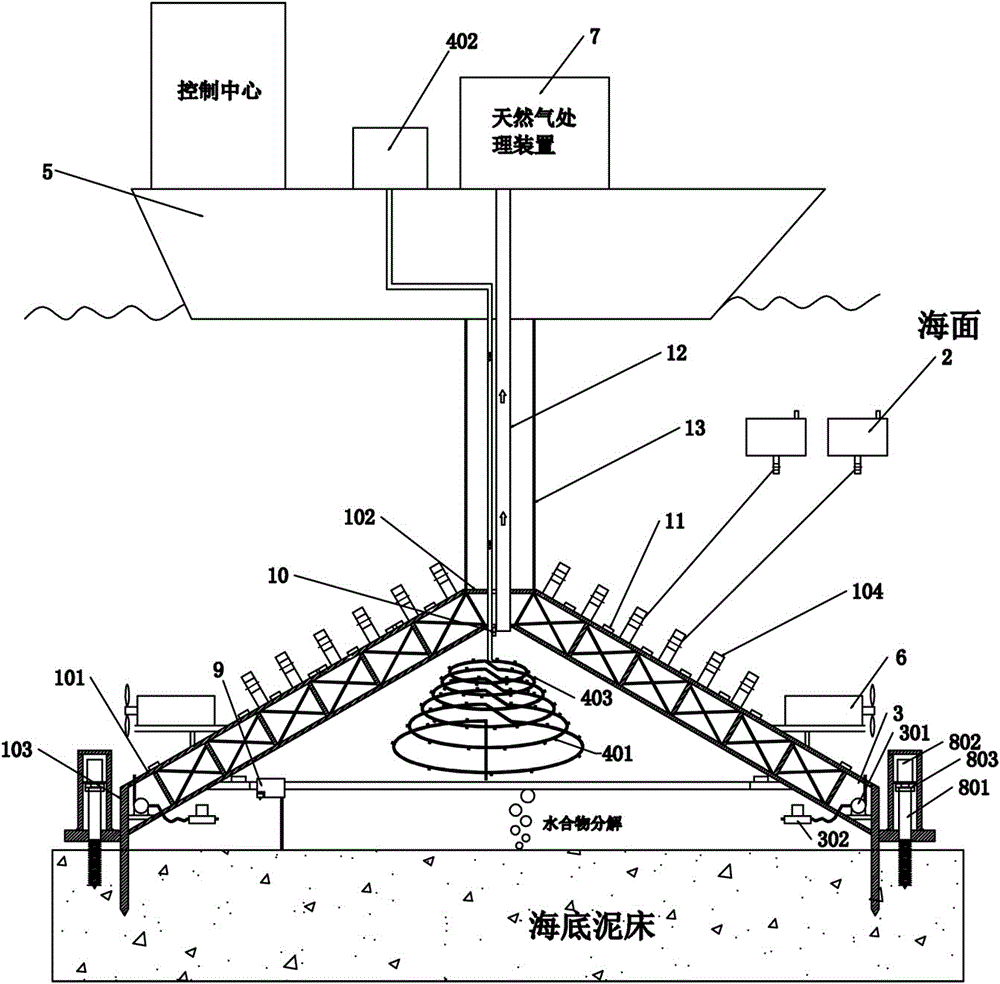

Embodiment 3

[0075] Such as image 3 and Figure 15 As shown, this embodiment is similar to Embodiment 1, and the difference is that a number of suspension rings 104 are arranged outside the natural gas collection cover 1, and a density adjustment system 2 is connected to the suspension rings 104 through cables. The system 2 includes several buoyancy modules 201 located outside the natural gas collection cover 1, the buoyancy modules 201 are sealed inner hollow boxes, the bottom of the buoyancy modules 201 is provided with a hanging ring, and the hanging ring and the hanging ring 104 pass through Cable connection, the top of the buoyancy module 201 is provided with a drainage pipe 204 connecting the inside and outside of the buoyancy module 201, the inside of the buoyancy module 201 is provided with an airbag 203, and the airbag 203 is connected to the air compressor 202 which can be controlled remotely and wirelessly.

[0076] Wherein the temperature regulation system 4 includes an oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com