Preparation method of polyurethane-polyisocyanurate thin-film graded material

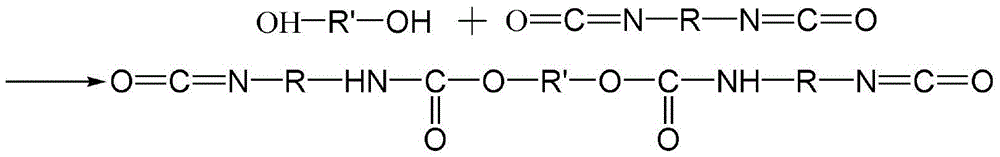

A technology of polyisocyanurate and gradient materials, which is applied in the field of preparing polyurethane-polyisocyanurate film gradient materials, can solve problems such as the inability to eliminate the viscoelasticity of the rubber-plastic transition area and the inability to change the elastic modulus, and achieve Good thermal stability and dielectric properties, the effect of extending the performance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

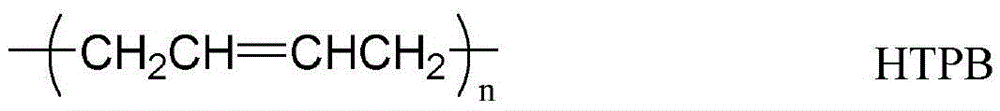

Method used

Image

Examples

Embodiment 1

[0033]Add 85.00g (0.05mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-necked flask, stir and raise the temperature to 105°C, dehydrate in vacuum at -0.1MPa for 2h, wait until the temperature drops to At about 60°C, add 17.40g (0.1mol) of 2,4-toluene diisocyanate (2,4-TDI) into the three-necked flask, after natural reaction for 40min, slowly raise the temperature to 80°C to continue the reaction for 1h, add 0.05g (0.05wt% of tetrahydrofuran-propylene oxide copolyether glycol quality) dibutyltin dilaurate catalyst continued to react for 1.5 hours, and then obtained 102.4g terminal NCO-based polyurethane prepolymers to above-mentioned mixed system vacuum defoaming;

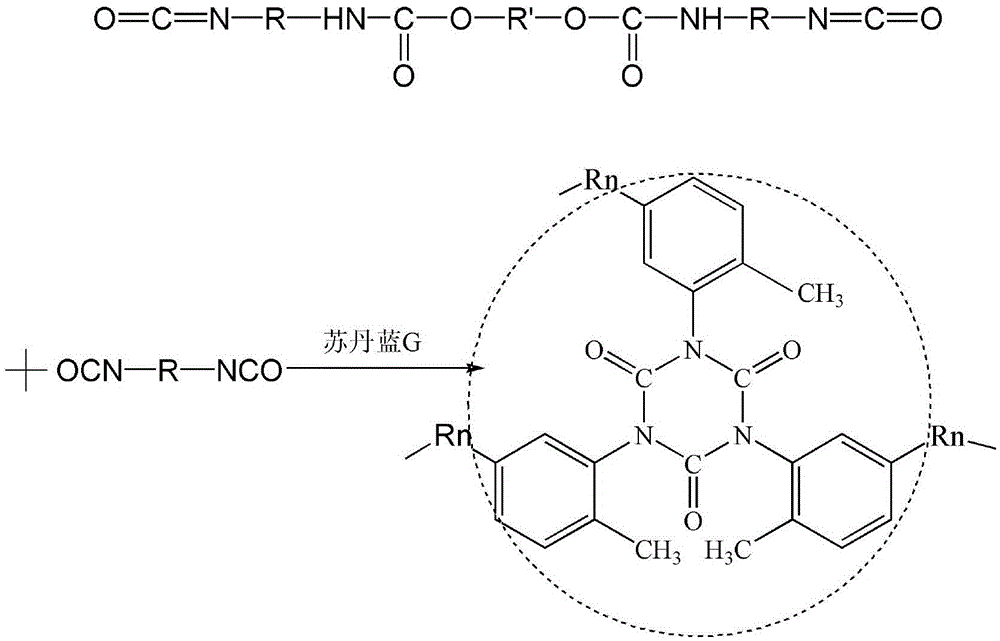

[0034] Add the anhydrous acetone of 81.92g (80wt%) in the above-mentioned prepolymer and fully stir to reduce the viscosity of the system, then add 1.54g (1.5%) of the Sudan Blue G catalyst in the presence of cyclotrimerization, and this process time is 2 hours , so that a p...

Embodiment 2

[0038] Add 85.00g (0.05mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-necked flask, stir and heat up to 100°C, vacuum dehydrate at -0.3MPa for 2h, wait until the temperature drops to At about 50°C, add 17.40g (0.1mol) of 2,4-toluene diisocyanate (2,4-TDI) into the three-necked flask, after natural reaction for 40min, slowly raise the temperature to 85°C to continue the reaction for 1h, add 0.05g (0.05wt%) dibutyltin dilaurate catalyst continued to react for 1.5 hours, and then the above-mentioned mixed system was vacuumed and defoamed to obtain the NCO-terminated polyurethane prepolymer.

[0039] Add 81.92g (80wt%) of anhydrous acetone in the above-mentioned prepolymer and fully stir to reduce the viscosity of the system, then add 5.12g (5wt% of the prepolymer quality) 2,4-TDI, add 1.62g ( The Sudan Blue G of 1.5%), cyclotrimerization reaction takes place in the presence of catalyst, and this process time is 2 hours, pours again on a...

Embodiment 3

[0043] Add 85.00g (0.05mol) of tetrahydrofuran-propylene oxide copolyether diol (PF-OP-151700) into a 500ml three-necked flask, stir and raise the temperature to 105°C, dehydrate in vacuum at -0.1MPa for 2h, wait until the temperature drops to At about 55°C, add 17.40g (0.1mol) of 2,4-toluene diisocyanate (2,4-TDI) into the three-necked flask, after natural reaction for 40min, slowly raise the temperature to 80°C to continue the reaction for 1h, add 0.1g (0.1wt%) dibutyltin dilaurate catalyst continued to react for 2 hours, and then vacuumize and defoam the above mixed system to obtain NCO-terminated polyurethane prepolymer.

[0044] Add 61.44g (60wt%) of anhydrous acetone in the above-mentioned prepolymer and fully stir to reduce the viscosity of the system, then add 10.24g (10wt% of the prepolymer quality) 2,4-TDI, add 1.72g ( 1.5%) of Sudan Blue G, the system undergoes a cyclotrimerization reaction in the presence of a catalyst. This process takes 1 hour, and then cast on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com