Frequency conversion high-speed wet type submersible pump

A submersible pump and wet-type technology, which is applied in the field of variable-frequency high-speed wet submersible pumps, can solve the problems of narrow performance range, heavy weight, and low head, and achieve the effect of wide performance range, light weight, and high head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

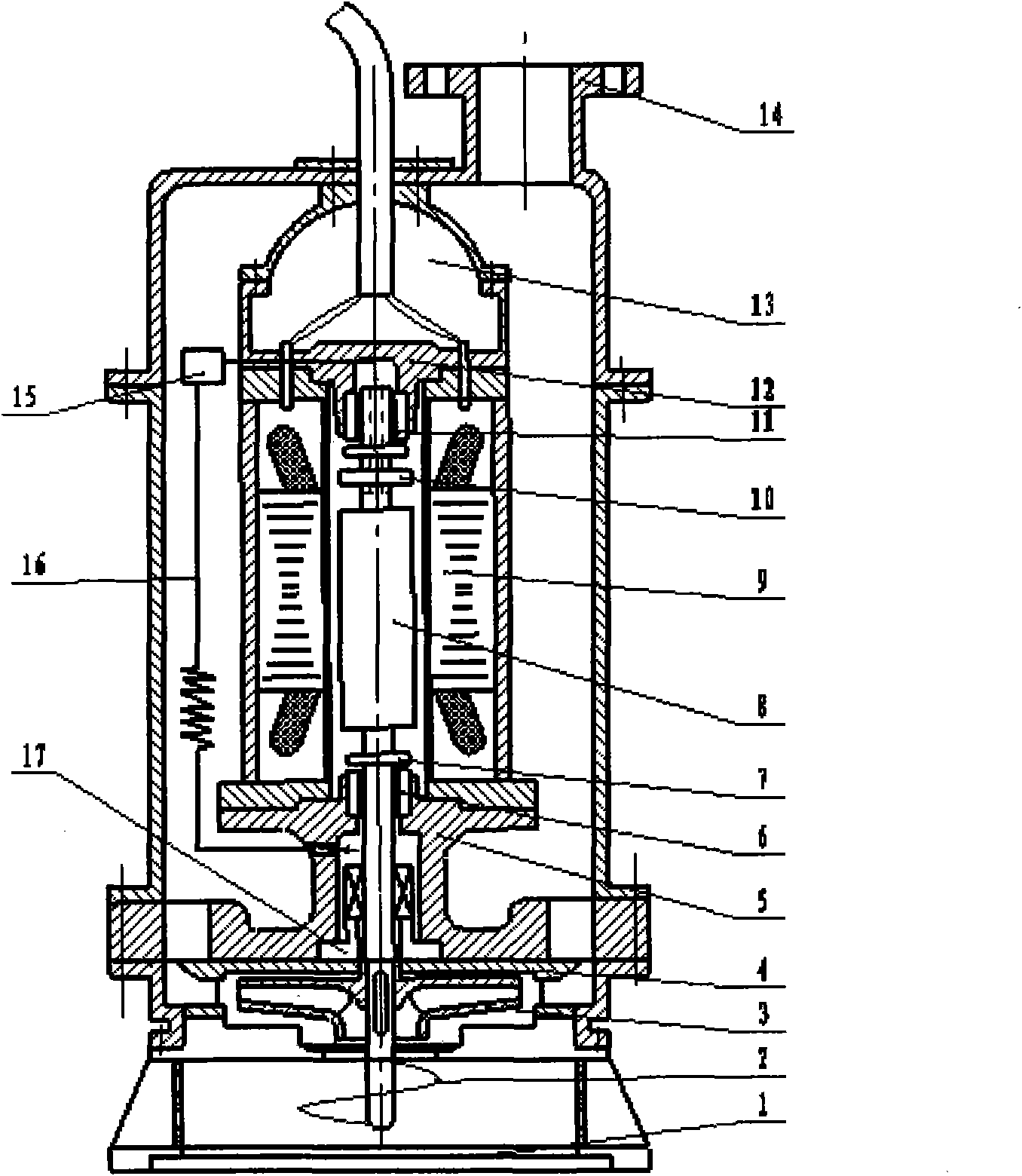

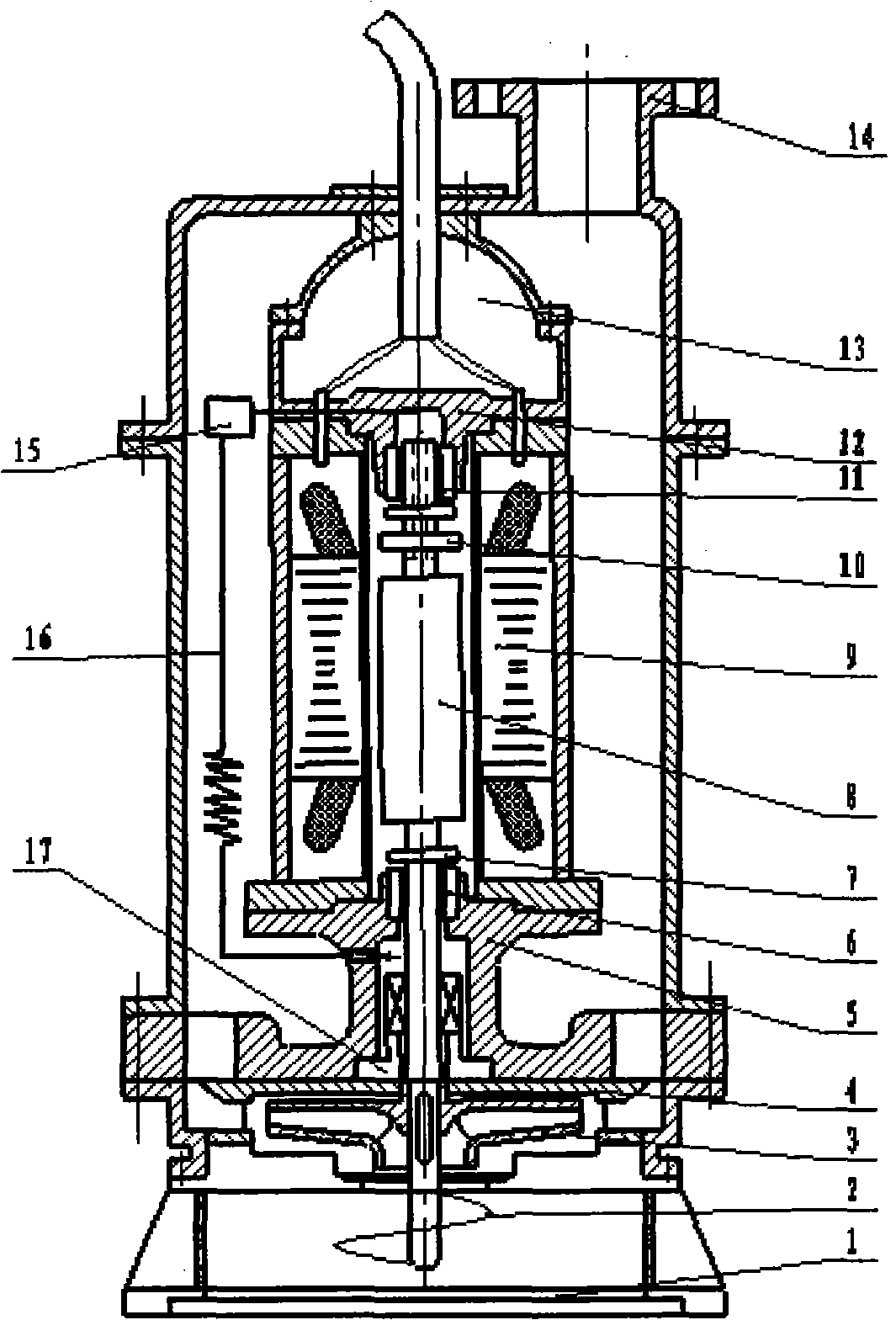

[0009] In conjunction with the accompanying drawings, the present invention will be further described below.

[0010] The invention includes base (1), impeller (3), guide vane (4), rear pump cover (5), leading bearing (6), thrust plate (7), motor, rear guiding bearing (11), rear end Cover (12), outlet flange (14), the impeller (3) of the pump is connected to the motor shaft, the type of impeller (3) is a partial flow or centrifugal structure, and a variable pitch inducer (2 ), the outlet of the impeller (3) is provided with a guide vane (4).

[0011] The conveying medium enters the unit from the base (1) at the lower end of the unit, enters the impeller (3) through the variable pitch inducer (2), and after being discharged from the impeller (3), enters the flow channel formed by the outer wall of the stator and the casing through the guide vane (4) , discharged through the outlet flange (14).

[0012] The motor adopts a variable frequency motor with a frequency of 50Hz-400Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com