A sponge sofa structure

A sofa and sponge technology, which is applied to sofas, couchs, mattresses, etc., can solve the problems of difficulty in guaranteeing product shape uniformity, product shape changes, and low production efficiency, and achieves reduction of material costs, low production costs, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

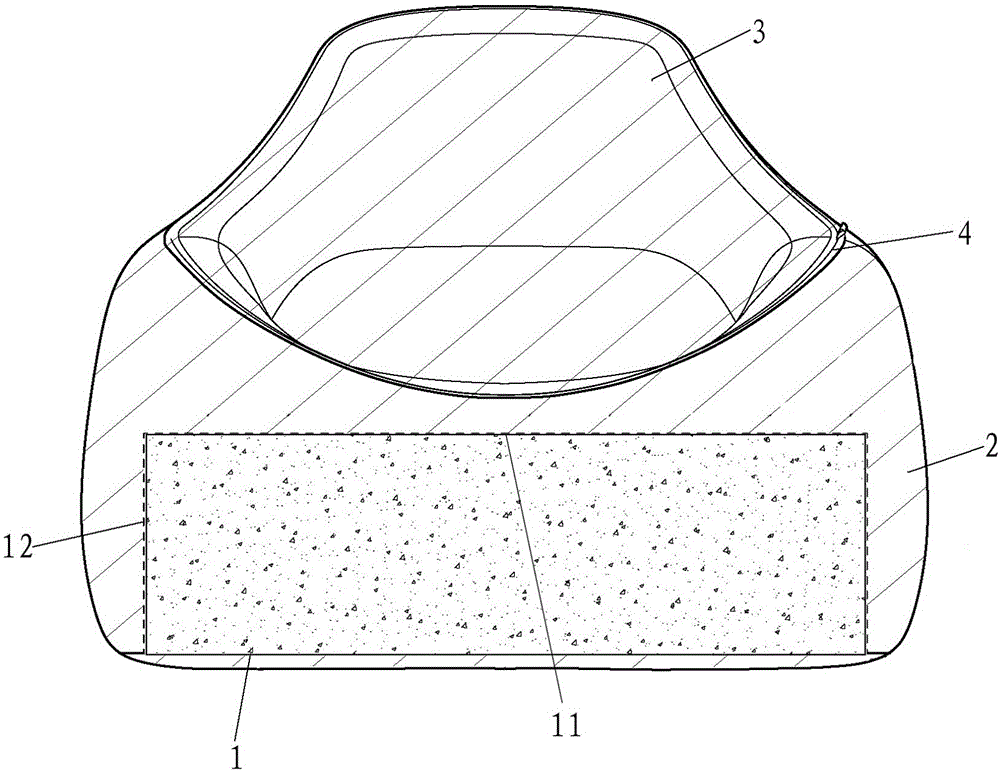

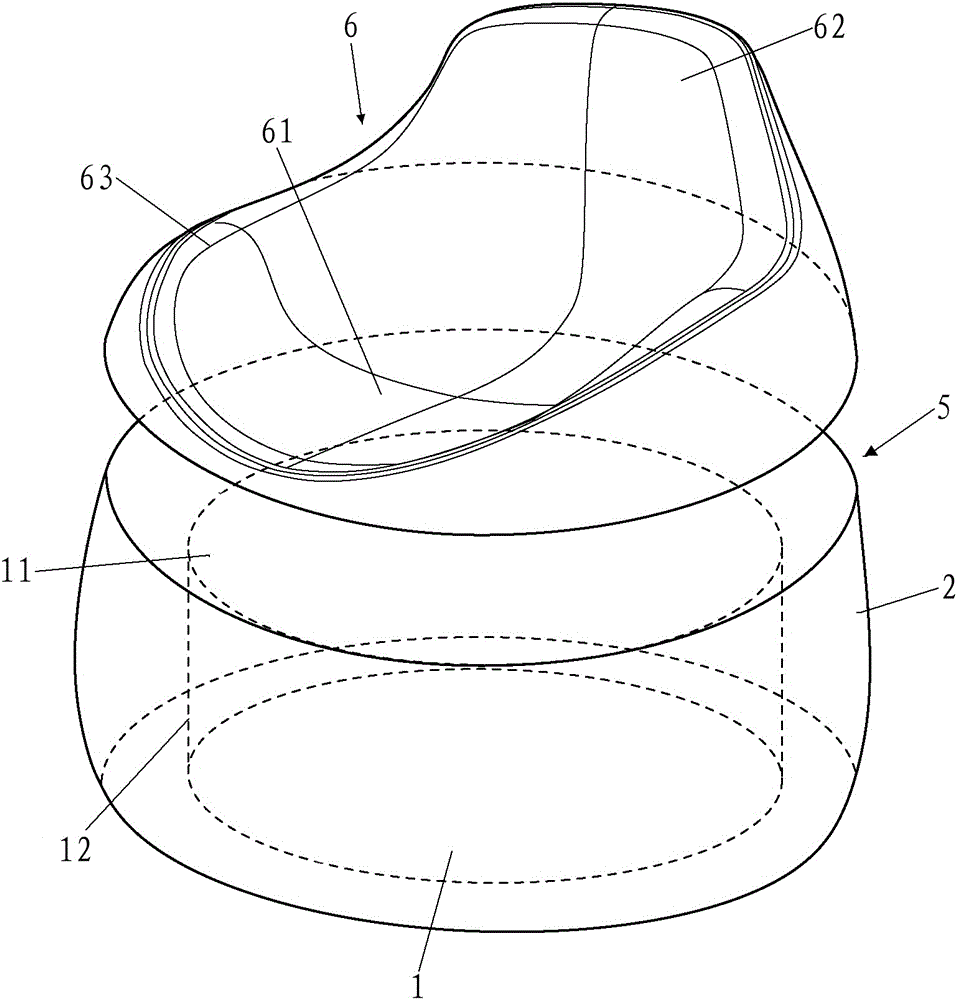

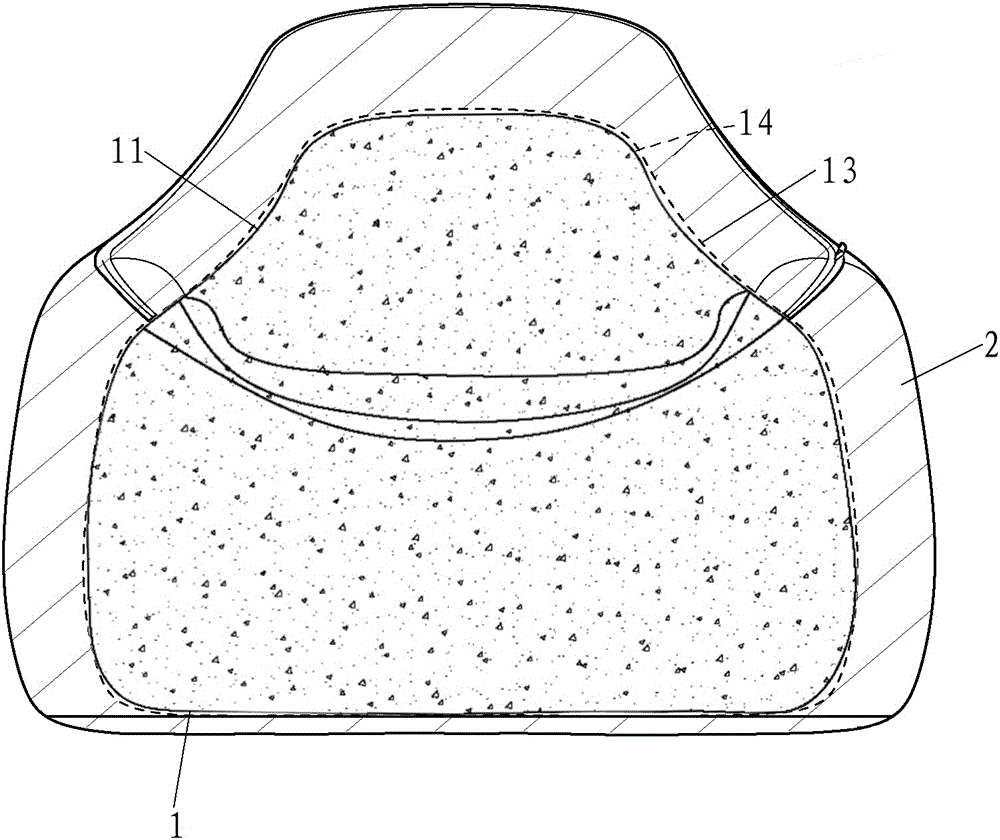

[0028] Such as Figure 1 to Figure 10 As shown, the present invention discloses a sponge sofa structure, which includes a Styrofoam foamed Styrofoam sofa base 1, and the outer surface of the Styrofoam sofa base 1 is integrally formed. Soak with sponge (PolyurethaneFoam) layer 2. The thickness of the sponge layer 2 is greater than or equal to 1cm.

[0029] Such as figure 1 As shown, the styrofoam sofa base 1 includes a seating surface 11 and a surrounding surface 12 supporting the seating surface 11, and the sponge layer 2 is directly integrally foamed on the outer surface of the seating surface 11 and the surrounding surface 12, while sitting On the surface 11, sofa backrest 3 and sofa armrest 4 are directly foamed. The sponge can be made of hard foam to ensure the support strength of the sofa backrest 3 and the sofa armrest 4. Of course, the support strength of the sofa backrest 3 and the sofa armrest 4 can be bound by leather or cloth outsourced to the sofa.

[0030] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com