Method for preparing ultrahigh-strength titanium alloy porous material based on additive manufacturing technology

A porous material and ultra-high-strength technology, which is applied in the field of preparing ultra-high-strength titanium alloy porous materials based on additive manufacturing technology, can solve the problems of porous titanium and titanium alloys with low density and ultra-high strength, and achieve low cost and wide application Foreground, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

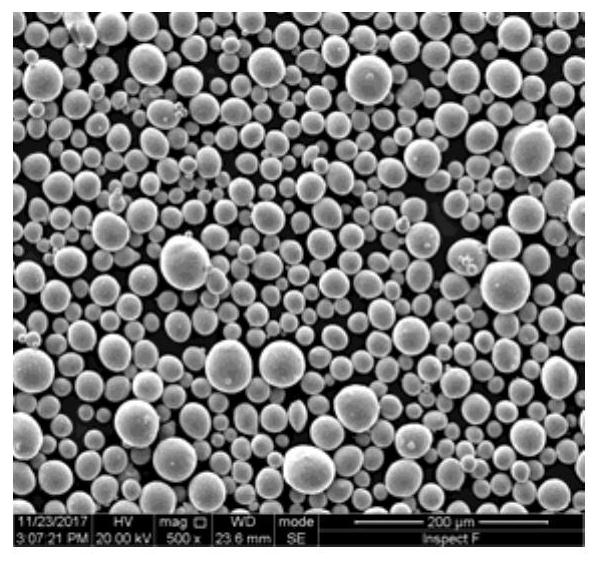

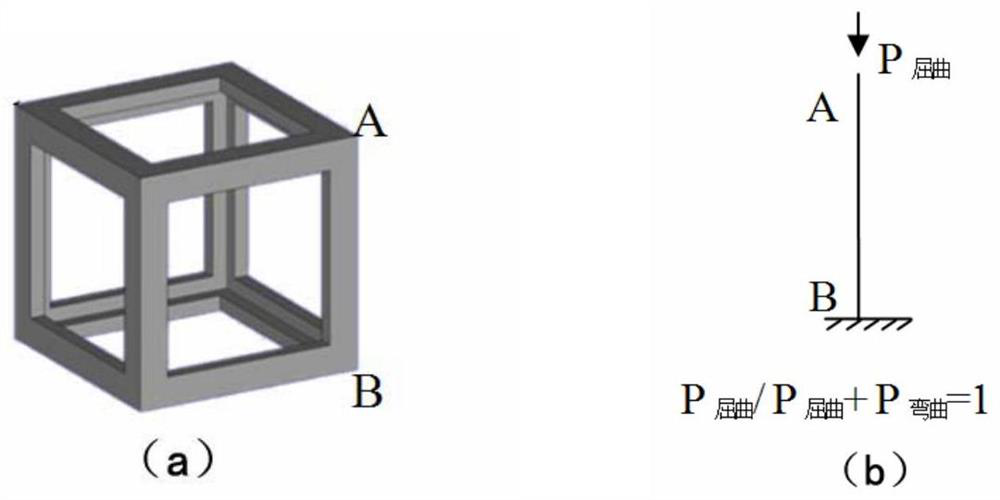

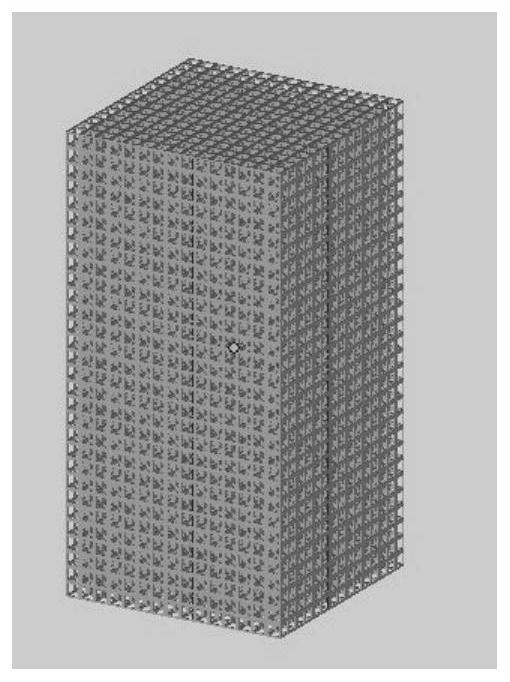

[0044] With Ti-5.25Al-5.1Mo-5.3V-2.5Cr-1Fe alloy powder ( figure 1 , the powder diameter is 15 μm-53 μm) as the raw material, and the total amount of impurity content O+N+H is adjusted to be 0.3-0.45wt%. The porous mesh unit designed by CAD software is shown in figure 2 . Adjust the tensile, compressive or bending components acting on the hole wall when the force is applied, so that the proportions of the buckling components are 100%, and the following is obtained: figure 2 For the grid cells shown, the pore wall thickness is 500 μm. The porous titanium alloy bulk material was prepared by Realizer SLM100 selective laser melting equipment, the laser source power was 200W, the scanning distance was 200μm, the layer thickness was 50μm, and the scanning rate was 1200mm / s. Such as image 3 As shown, the porosity of the prepared titanium alloy porous material is 78%, the average pore diameter is 800 μm, the pore wall thickness is 0.5mm, and the density is 1.43g / cm 3 . The eq...

Embodiment 2

[0047] For the Ti-5.1Al-5.5Mo-4.9V-3.5Cr-0.95Fe alloy, the total amount of impurity content O+N+H is adjusted to be 0.4-0.5 wt%. The porous mesh unit designed by CAD software is shown in Figure 5 . Adjust the tensile, compressive or bending components acting on the hole wall when the force is applied, so that the proportions of the buckling components are 85% respectively, and the following is obtained: Figure 5 For the grid cells shown, the hole wall thickness is 0.6mm. The porous titanium alloy bulk material was prepared by Realizer SLM100 selective laser melting equipment, the laser source power was 200W, the scanning distance was 200μm, the layer thickness was 50μm, and the scanning rate was 1200mm / s. Such as Image 6 As shown, the porosity of the prepared titanium alloy porous material is 68%, the average pore diameter is 500 μm, the pore wall thickness is 0.5mm, and the density is 1.63g / cm 3 . The equipment used for the two-step heat treatment is a vacuum heat tre...

Embodiment 3

[0050] For the Ti-24Nb-1Fe-6Sn-3Zr alloy, the total amount of impurity content O+N+H is adjusted to 0.35-0.50wt%. The porous mesh unit designed by CAD software is shown in Figure 8 . Adjust the tensile, compressive or bending components of the force acting on the hole wall so that the proportions of the buckling components are 75%, and the following is obtained: Figure 8 For the grid cells shown, the hole wall thickness is 0.6 mm. The porous titanium alloy bulk material was prepared by Realizer SLM100 selective laser melting equipment, the laser source power was 200W, the scanning distance was 200μm, the layer thickness was 50μm, and the scanning rate was 1200mm / s. Such as Figure 9 As shown, the porosity of the prepared titanium alloy porous material is 72%, the average pore diameter is 600 μm, the pore wall thickness is 0.5mm, and the density is 1.58g / cm 3 . The equipment used for the two-step heat treatment is a vacuum heat treatment furnace. Insulate at 760-780°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com