Preparation method for size-controllable amorphous carbon array

An amorphous carbon and array technology, applied in nanocarbon, nanotechnology and other directions, can solve problems such as being unsuitable for industrial applications, complex methods, and no nanoscale templates have been found, and achieve easy control of appearance, simple equipment, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

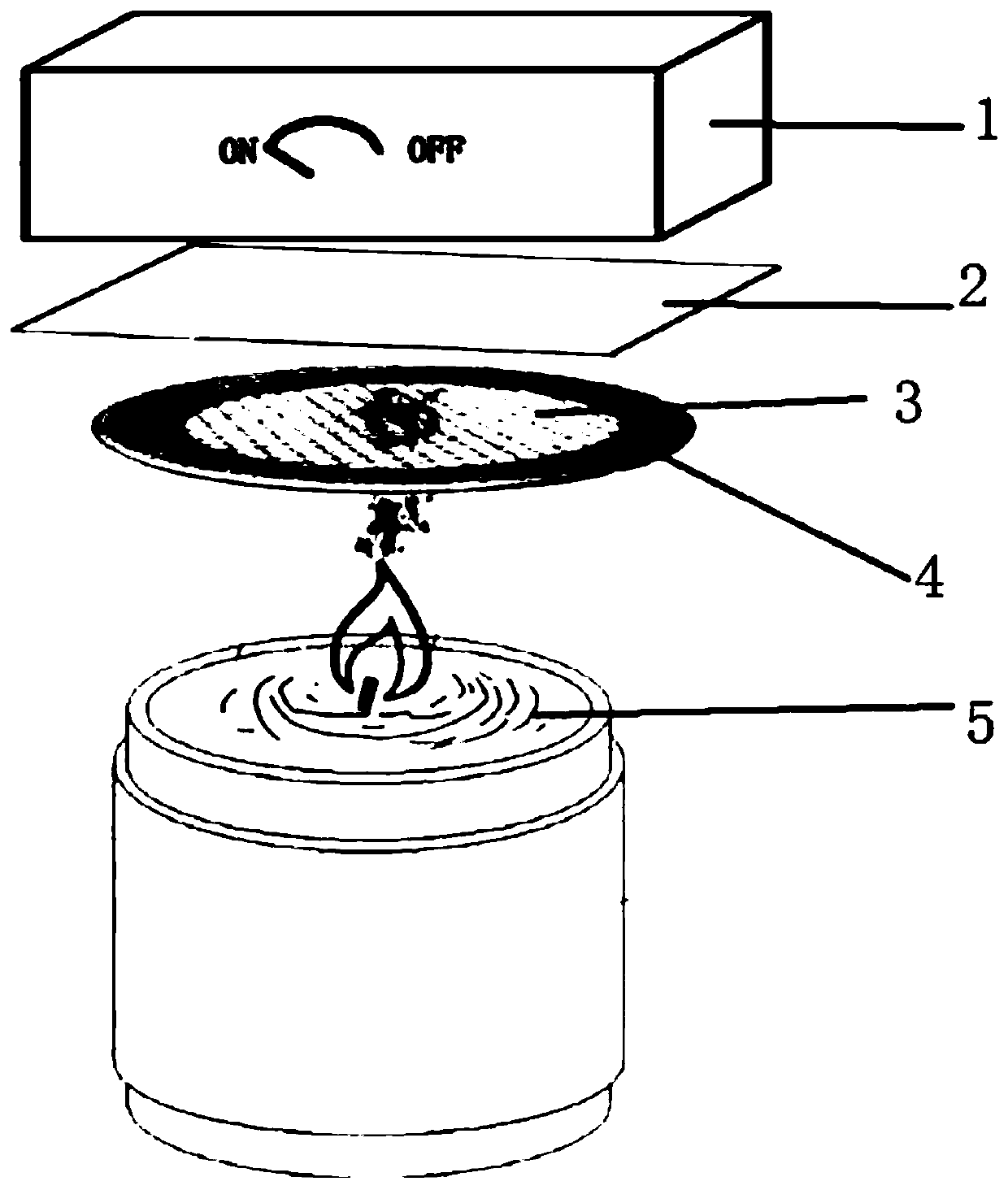

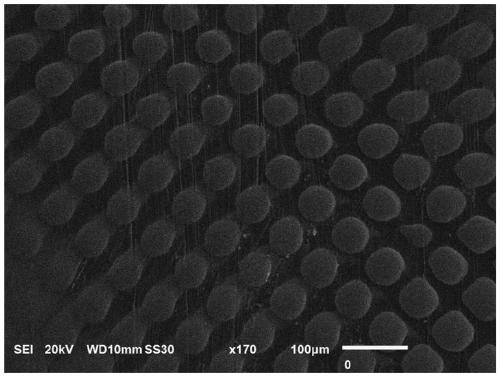

[0026] Weigh 50g of stearic acid in a beaker, heat it in an oven at 80°C to melt, transfer it to a 15mL round crucible, make a candle wick with cotton thread and insert it; the iron washer, take a size of 1×1cm 2 Soak the titanium sheet (base material) and the surface of the controllable magnet with ethanol for 10 minutes, wash away the impurities, and then rinse with deionized water; the titanium sheet is firmly adhered to the controllable magnet with double-sided adhesive, and the template material copper mesh is placed on the On the titanium sheet, put the iron gasket on the copper net, turn the magnet to "ON", turn the whole device over, and place it on the stand; light the candle, adjust the iron stand so that the middle of the candle flame is on the titanium sheet plane, and keep it for 20 seconds. The plane is covered with carbon black, remove the upper half of the device; move the magnet switch to "OFF", the iron washer and the copper mesh fall off, and an array with th...

Embodiment 2

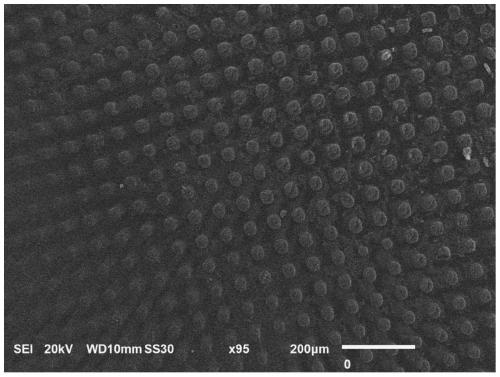

[0028] Weigh 50g of stearic acid in a beaker, heat it in an oven at 80°C to melt, transfer it to a 15mL round crucible, make a candle wick with cotton thread and insert it; the iron washer, take a size of 1×1cm 2 The conductive glass (base material) and the surface of the controllable magnet are soaked in ethanol ultrasonically for 10 minutes to wash away impurities, and then rinse with deionized water; On the conductive glass, put the iron gasket on the copper grid, turn the magnet to "ON", turn the whole device upside down, and put it on the stand; light the candle, adjust the iron stand so that the middle of the candle flame is on the conductive glass plane, and keep it for 20 seconds , the plane is covered with carbon black, remove the upper half of the device; move the magnet switch to "OFF", the iron washer and the copper mesh fall off, and an array with the copper mesh as the template is obtained. (copper mesh, conductive glass)

Embodiment 3

[0030] Weigh 50g of stearic acid in a beaker, heat it in an oven at 80°C to melt, transfer it to a 15mL round crucible, make a candle wick with cotton thread and insert it into it; iron gasket, take a copper sheet (base material) with a size of 1×1cm2, The surface of the controllable magnet is ultrasonically soaked in ethanol for 10 minutes to remove impurities, and then rinsed with deionized water; the copper sheet is firmly glued to the controllable magnet with double-sided adhesive, the template material copper mesh is placed on the copper sheet, and the iron gasket is placed on the On the copper net, turn the magnet to "ON", turn the whole device upside down, and place it on the stand; light the candle, adjust the iron stand so that the middle of the candle flame is on the plane of the copper sheet, keep it for 20 seconds, and the plane is covered by carbon black, put it on Take off half of the device; move the magnet switch to "OFF", the iron washer and the copper mesh fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com