Gradient porous Ti-6Al-4V block material concurrently having high strength and high absorption energy, and preparation method thereof

A technology of ti-6al-4v and block materials, applied in the field of porous materials, can solve the problems of high strength and high absorption energy, and achieve high strength, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

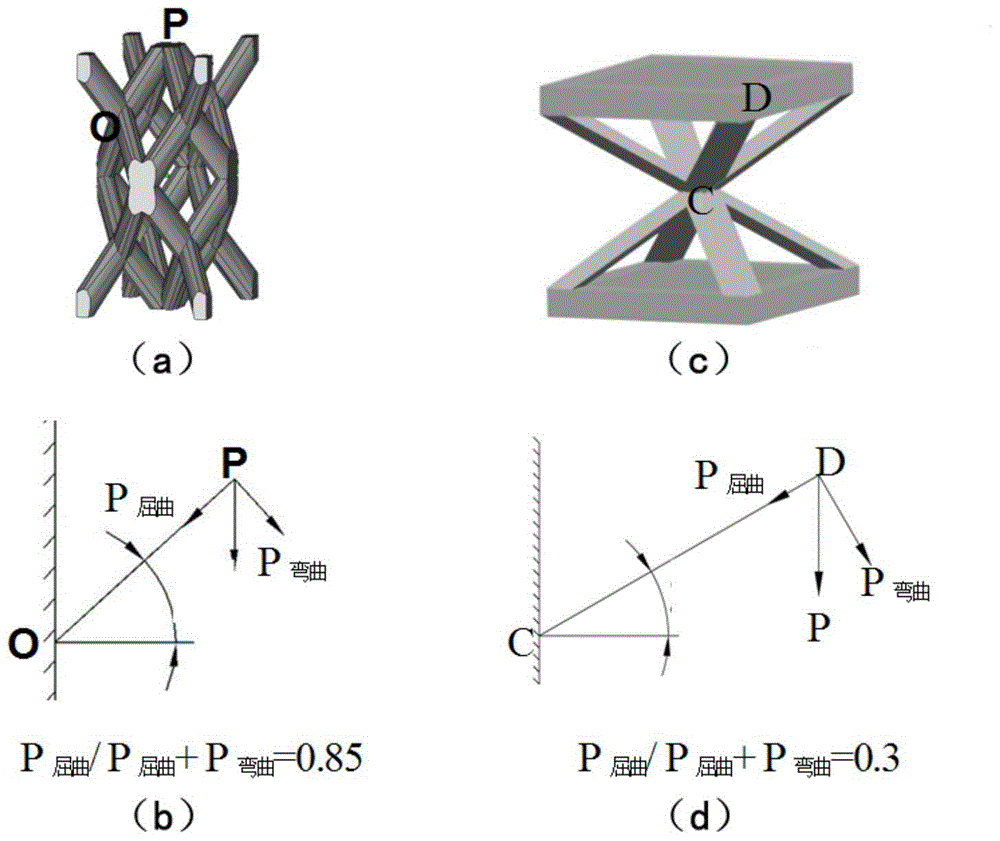

[0035] The gradient Ti-6Al-4V mesh designed by CAD software is shown in Figure 1-2 . The gradient porous material consists of two layers (outer layer and inner layer), the porosity of each layer is respectively: the outer layer is 68%, the inner layer is 76%, and the volume ratio of the outer layer to the inner layer is 1:1.5. The force analysis is carried out on the hole wall of the regular grid unit in each layer. By adjusting the force direction of the force acting on the hole wall, the buckling and bending components acting on the hole wall are adjusted so that the proportion of the buckling component is 85% ( Inner layer) and 30% (outer layer), to obtain such as figure 1 The grid units shown in (a)-(c) (the inner layer is a rhombic dodecahedral grid, and the outer layer is a G7 grid), the thickness of the hole wall is 0.5mm. Using Ti-6Al-4V alloy powder as raw material, the gradient porous Ti-6Al-4V bulk material was prepared by Arcam A1 electron beam melting equipment...

Embodiment 2

[0038] The gradient Ti-6Al-4V mesh designed by CAD software is shown in Figure 5-6 . The gradient porous material consists of two layers (outer layer and inner layer), the porosity of each layer is respectively: the outer layer 58%, the inner layer 70%, the volume ratio of the outer layer to the inner layer is 1:1. By adjusting the force direction of the force acting on the hole wall, the buckling and bending components acting on the hole wall are adjusted so that the proportions of the buckling components are 100% (inner layer) and 30% respectively. % (outer layer), obtained as Figure 5 The grid units shown in (a)-(c) (the inner layer is a cubic grid, the outer layer is a G7 grid), and the thickness of the hole wall is 0.5 mm. Using Ti-6Al-4V alloy powder as raw material, the gradient porous Ti-6Al-4V bulk material was prepared by Arcam A1 electron beam melting equipment. The electron beam scanning speed was 100mm / s and the electron beam current was 1.2mA. The prepared g...

Embodiment 3

[0041] The gradient Ti-6Al-4V mesh designed by CAD software is shown in Figure 9-10 . The gradient porous material has 3 layers of upper, middle and lower layers, and the porosity of each layer is 81% (upper layer), 85% (middle layer), and 88% (lower layer), and the volume ratio of the upper, middle and lower layers is 1:1. : 1, carry out the force analysis on the hole wall of the regular grid unit in each layer, adjust the buckling and bending components acting on the hole wall by adjusting the force direction of the force acting on the hole wall, so that the proportions of the buckling components are respectively 65% (upper layer), 51% (middle layer) and 35% (lower layer), obtained as Figure 9 The grid units shown in a, b, and c (the upper, middle, and lower grids are all rhombic dodecahedral grids), the thickness of the hole wall is 0.5mm. Using Ti-6Al-4V alloy powder as raw material, the gradient porous Ti-6Al-4V bulk material was prepared by Arcam A1 electron beam mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com