Method for preparing ultra-high-strength titanium alloy porous material based on additive manufacturing technology

A porous material and ultra-high-strength technology, which is applied in the field of preparing ultra-high-strength titanium alloy porous materials based on additive manufacturing technology, can solve the problems of low density and ultra-high strength of porous titanium and titanium alloys, and achieves low cost and preparation technology. Simple, broad-spectrum effects

Active Publication Date: 2022-05-31

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to provide a method for preparing ultra-high-strength titanium alloy porous materials based on additive manufacturing technology, so as to solve the problem that porous titanium and titanium alloys in the prior art cannot have both low density and ultra-high strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0050] For the Ti-24Nb-1Fe-6Sn-3Zr alloy, adjust the total amount of impurities O+N+H to be 0.35-0.50wt%. profit

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

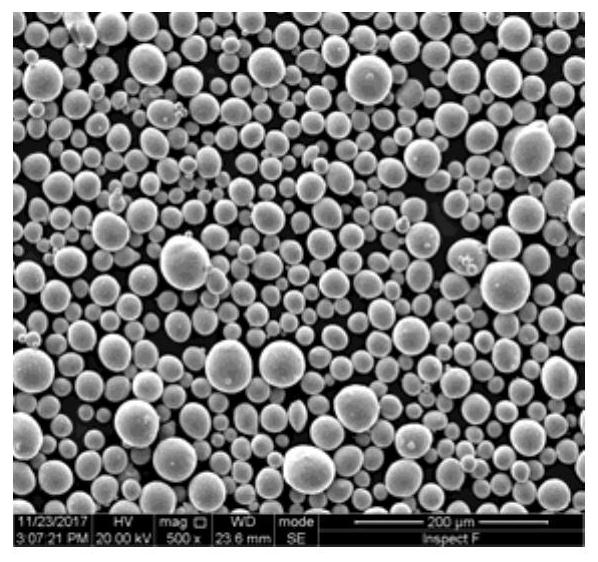

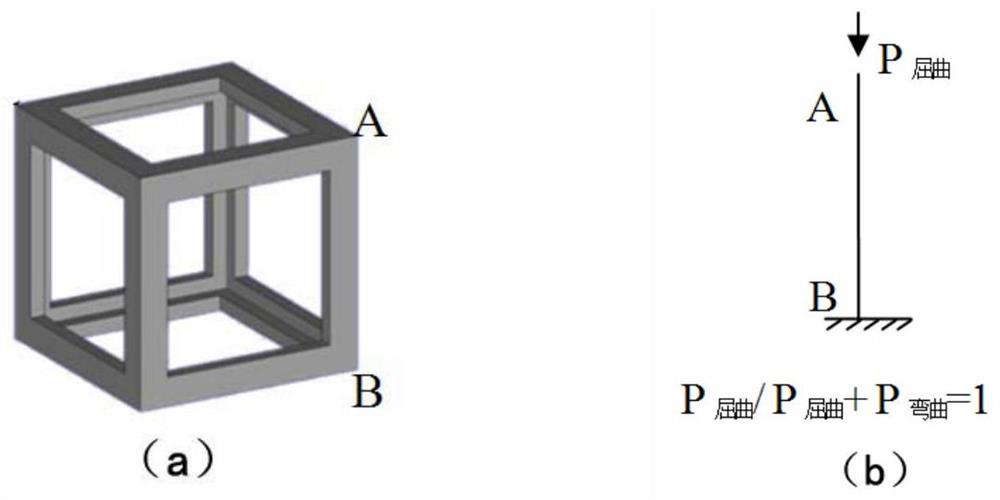

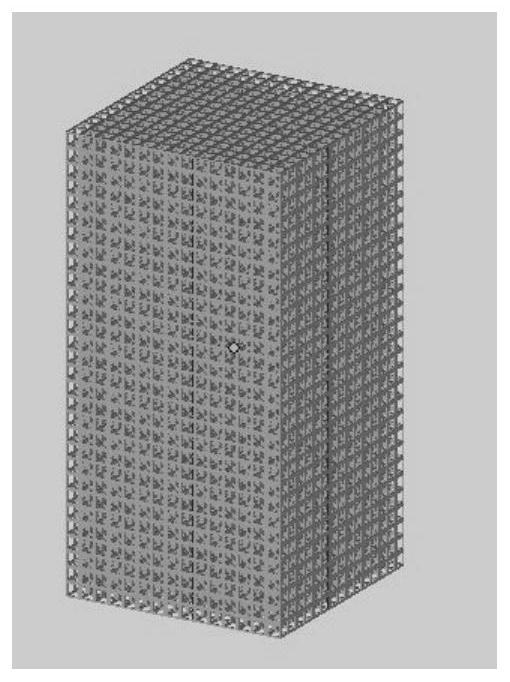

The invention relates to the field of porous material preparation, in particular to a method for preparing ultra-high-strength titanium alloy porous material based on additive manufacturing technology. This method prepares a uniform porous titanium alloy material with adjustable unit cell size and pore shape through "selective laser melting forming technology". By optimizing the process parameters of additive manufacturing and selecting appropriate heat treatment, it can be obtained: the effective density is 0.5-2.0g / cm 3 , the strength can reach 600MPa, and the absorption energy can reach 90MJ / m 3 , A uniform porous titanium alloy bulk material with an elastic modulus of 0.1-20GPa. The method of the invention has simple preparation process and low cost, is suitable for industrialized production, and has good application prospects in the fields of aerospace lightweight design, medical treatment, energy absorption and shock absorption, filtration and the like.

Description

Method for preparing ultra-high strength titanium alloy porous material based on additive manufacturing technology Technical field: The present invention relates to the field of porous material preparation, in particular to the preparation of ultra-high-strength titanium composites based on additive manufacturing technology. Methods for gold porous materials. Background technique: Porous material is a dual-property engineering material with both structure and function, and also has Many excellent properties, especially high specific strength, light weight, good energy absorption, large specific surface area, sound absorption and permeability, etc. Widely used in aerospace lightweight design, medical, energy absorption and shock absorption and filtration fields. In the medical field, porous titanium has a lower elastic modulus than its dense bulk material, which can reach the The degree of matching the modulus can effectively avoid the "stress shielding" effect; the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C14/00C22C1/08B22F3/105B22F10/28B33Y70/00B33Y40/00

CPCC22C14/00C22C1/08B33Y70/00B33Y40/00B22F3/105B22F10/28A61L27/32A61L27/06C25D5/18Y02P10/25

Inventor 李述军任德春刘玉敬侯文韬马英杰郝玉琳杨锐

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com