Patents

Literature

84results about How to "Change particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

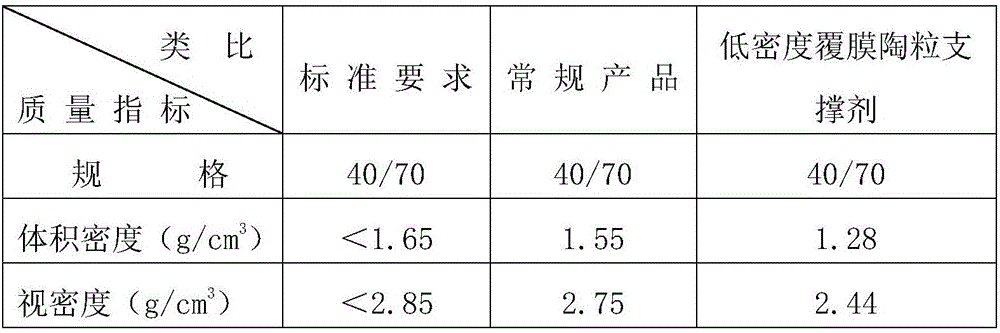

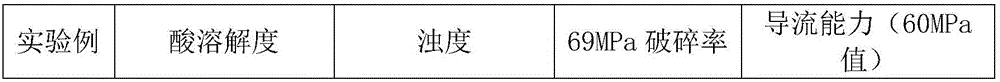

Low-density coated ceramsite proppant and preparation method thereof

ActiveCN106281299AImprove the finishImproves breakage resistanceDrilling compositionPetroleumMaterials science

The invention relates to a low-density coated ceramsite proppant and a preparation method thereof, and belongs to the field of petroleum proppants. A ceramsite base material and mixed resin coating the surface of the ceramsite base material are adopted, so that compared with the traditional proppant, the breaking-resistant capacity is greatly improved, the breaking rate is much lower under the condition of the same consumption of resin, and the low-density coated ceramsite proppant can be suitable for deeper well fracturing. Compared with the traditional proppant, the production cost is lower, the chemical inertness is better, the fracturing effective period can be prolonged, and the low-density coated ceramsite proppant is suitable for the fracturing construction under various complicated stratum environment conditions and is higher in flow conductivity.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Preparation method of silica gel carrier

The preparation method for silicagel carrier for polyolefin catalyst comprises: preparing silicate solution A with surfactant and dilute inorgaci acid solution B; adding solution A and B into reaction kettle, adjusting B solution for constant-temperature ageing; cooling, adding ammonium salt into the solution; after separating solid, filtering ,clearing, drying, grinding, and baking to obtain the objective product. This invention uses co-current flow method to form a great deal of crystal hucleus, decreases particle agglomeration and forms pore by space buffer action of surfactant, and can change the specific surface area and size and pore distribution of silicagel.

Owner:XIAMEN UNIV

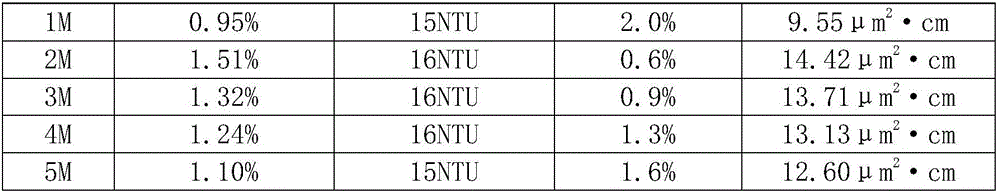

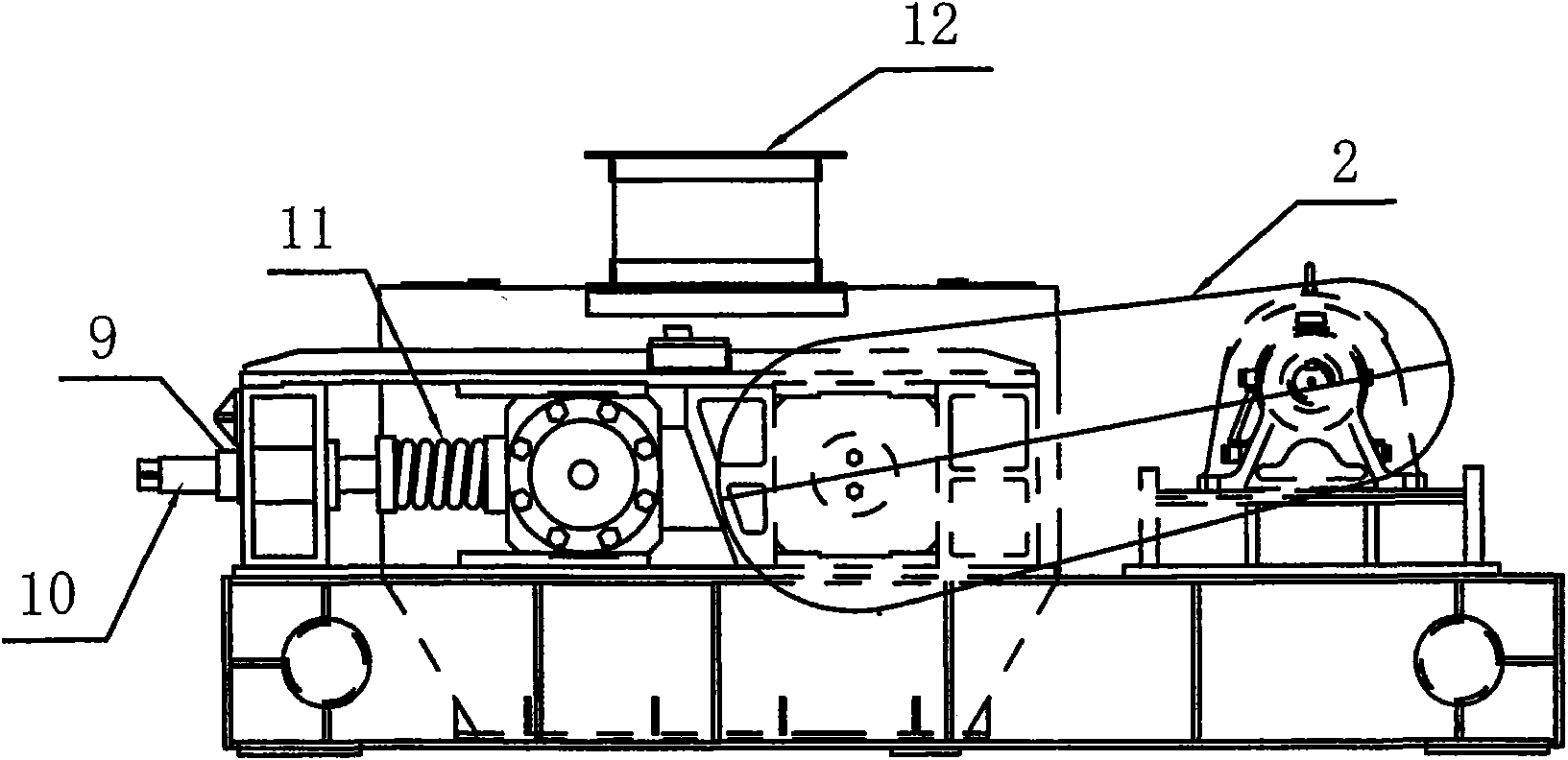

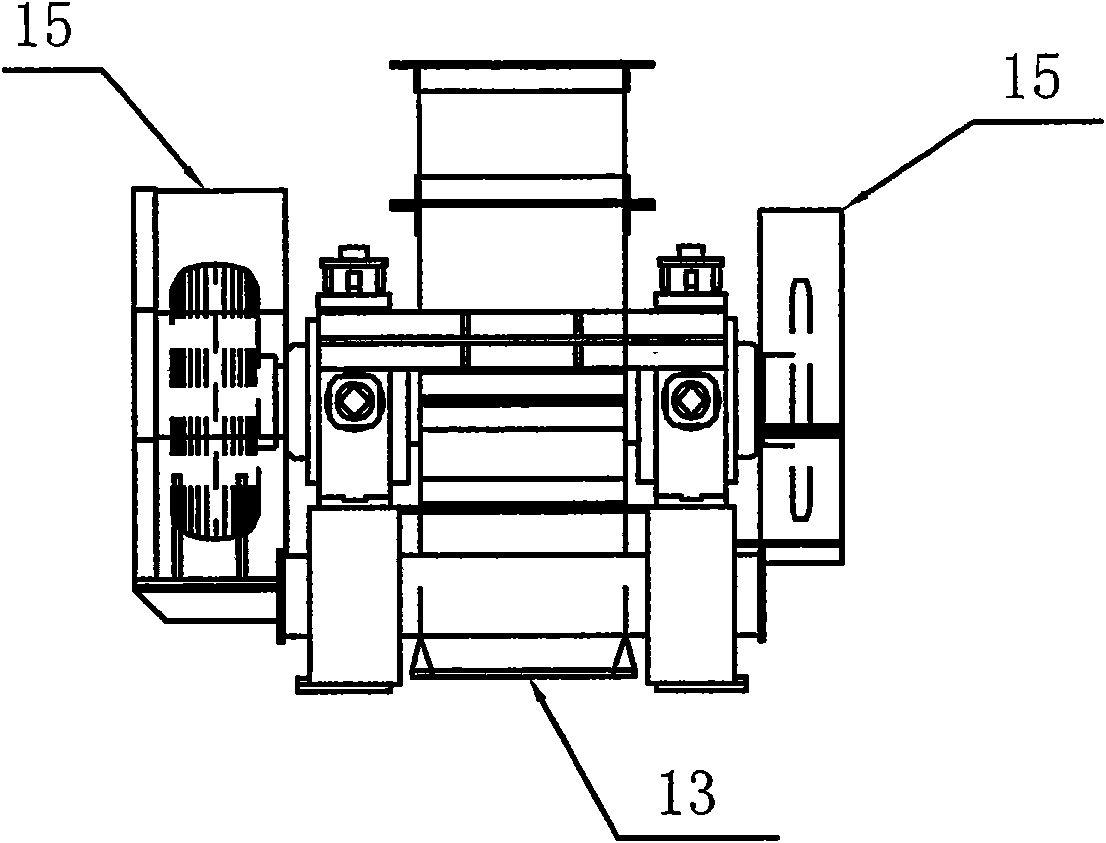

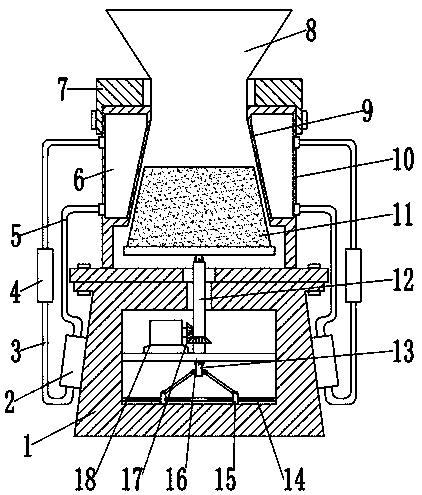

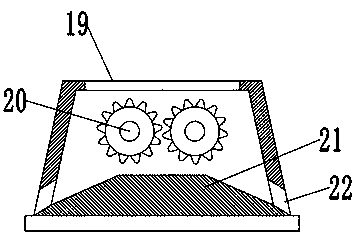

Double roller crusher

InactiveCN101992138AReduce vibration and shockIncrease driving force and crushing forcePreparing sample for investigationGrain treatmentsCrusherLow noise

The invention relates to a crusher which comprises a drive device, a driving shaft, a driven shaft, a transmission mechanism, rollers, a feed inlet, a feed outlet and a bracket, wherein the transmission mechanism comprises a driving tire and a driven tire; one end of the driving shaft is connected with the drive device, and the other end of the driving shaft is connected with the driving tire; the driven shaft is connected with the driven tire; the driving tire and the driven tire are mutually matched tightly; the rollers are respectively sleeved on the driving shaft and the driven shaft tightly; and straight teeth are fixed on the rollers. When the two rollers move relative to each other, materials entering the crusher are extruded, so that material particles are smaller, and the material particles smoothly enter an equipment body. The crusher has the advantages of large and adjustable transmission force, little damage to the equipment, smooth and safe operation, low noise, easy cleaning and no material residues.

Owner:霍春生

Nano composite material for intrauterine birth control device

The nano composite material for intrauterine birth control device consists of nano metal particle in the content of 0.5-50 wt% and biocompatible polymer. The said nano metal particle is nano copper particle, nano copper particle, nano zinc particle and / or nano silver particle. The nano composite material of the present invention features that the controllable release of the metal ions in some regulation can avoid violent release; and that raising the content in the solution can raise the birth control effect.

Owner:HUAZHONG UNIV OF SCI & TECH

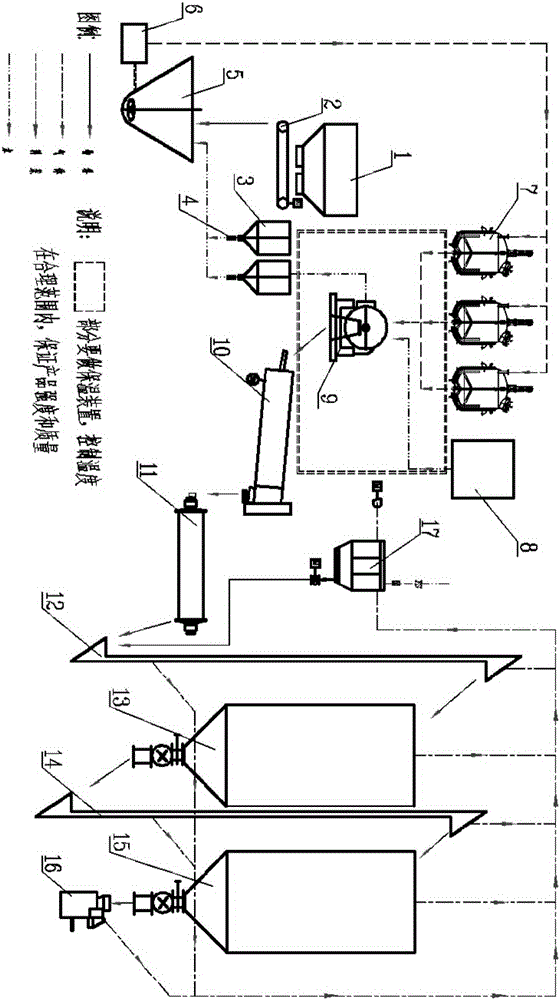

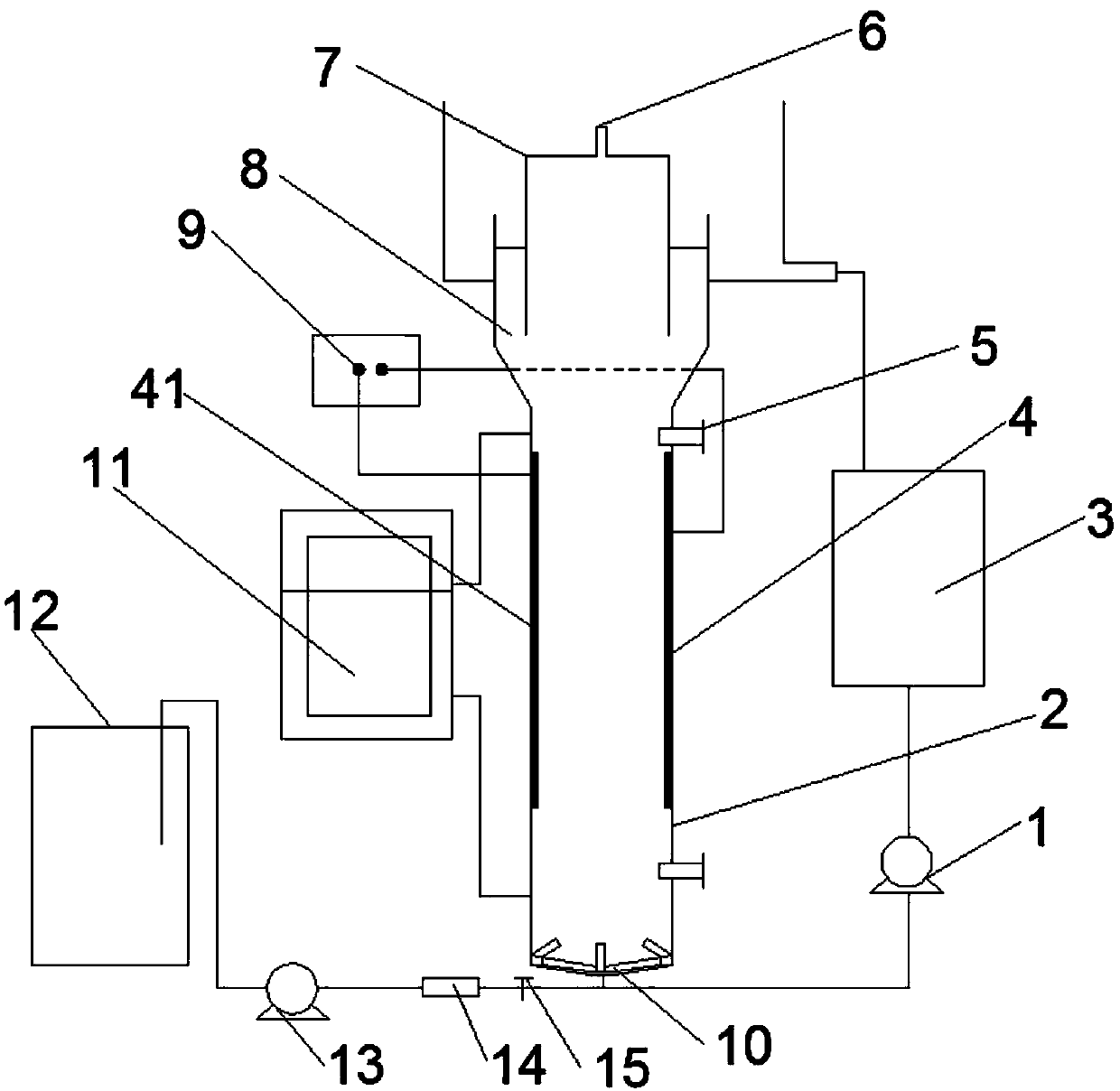

Alpha-high strength gypsum production system and application thereof

The invention discloses an alpha-high strength gypsum production system and an application thereof. The alpha-high strength gypsum production system mainly consists of a pulping tank, a reaction kettle, a centrifuge, a drying machine, a ball mill, an aging warehouse, a finished product warehouse and a packaging machine.

Owner:赵云龙 +1

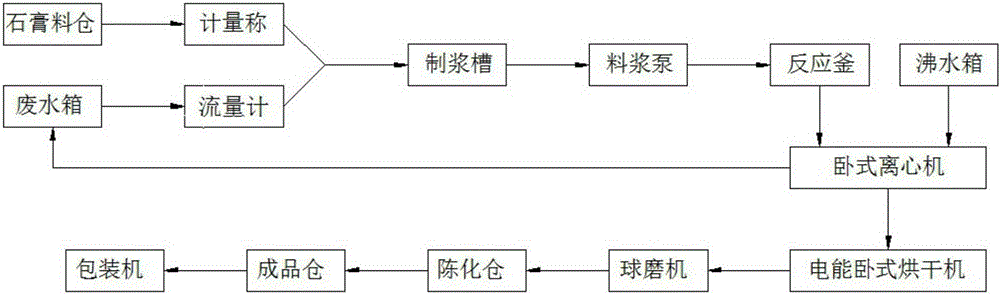

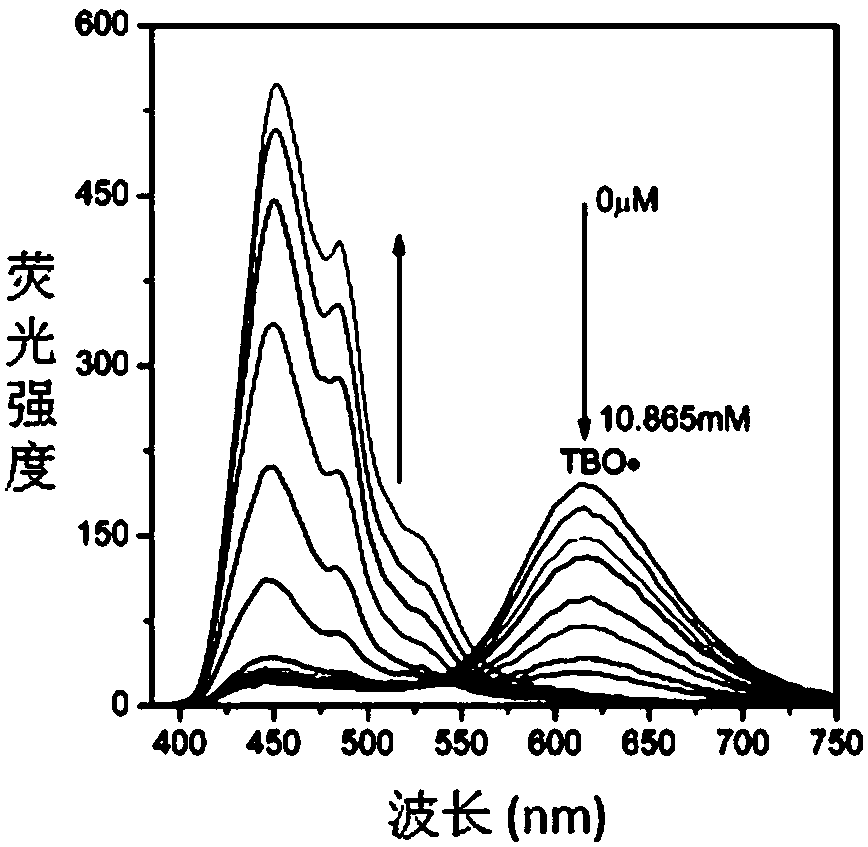

Method for preparing fluorescent adjustable p-phenylenediamine carbon dots

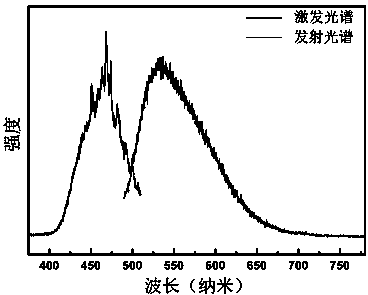

InactiveCN108641716AEasy to operateGood stabilityNanoopticsLuminescent compositionsChemistryP-Phenylenediamine

The invention discloses a method for preparing fluorescent adjustable p-phenylenediamine carbon dots, wherein the method comprises the following steps: 1) preparation of p-phenylenediamine carbon dots: dissolving p-phenylenediamine powder in ethanol, then sintering, separating and eluting; and 2) preparation of the fluorescent adjustable p-phenylenediamine carbon dots: adding tert-butyl peroxide radicals into an aqueous solution of the p-phenylenediamine carbon dots obtained in the step 1), and incubating, to obtain the carbon dots with emission sites at 450 nm, 490 nm and 530 nm. The invention provides the method for adding high-concentration tert-butyl peroxide radicals to change the particle size of the p-phenylenediamine carbon dots and thus obtaining the carbon dots at different fluorescence emission sites for the first time. By changing the precursor materials prepared by the carbon dots, the carbon dots with different fluorescence emission wavelengths are obtained. The operationis simple and the cost is saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

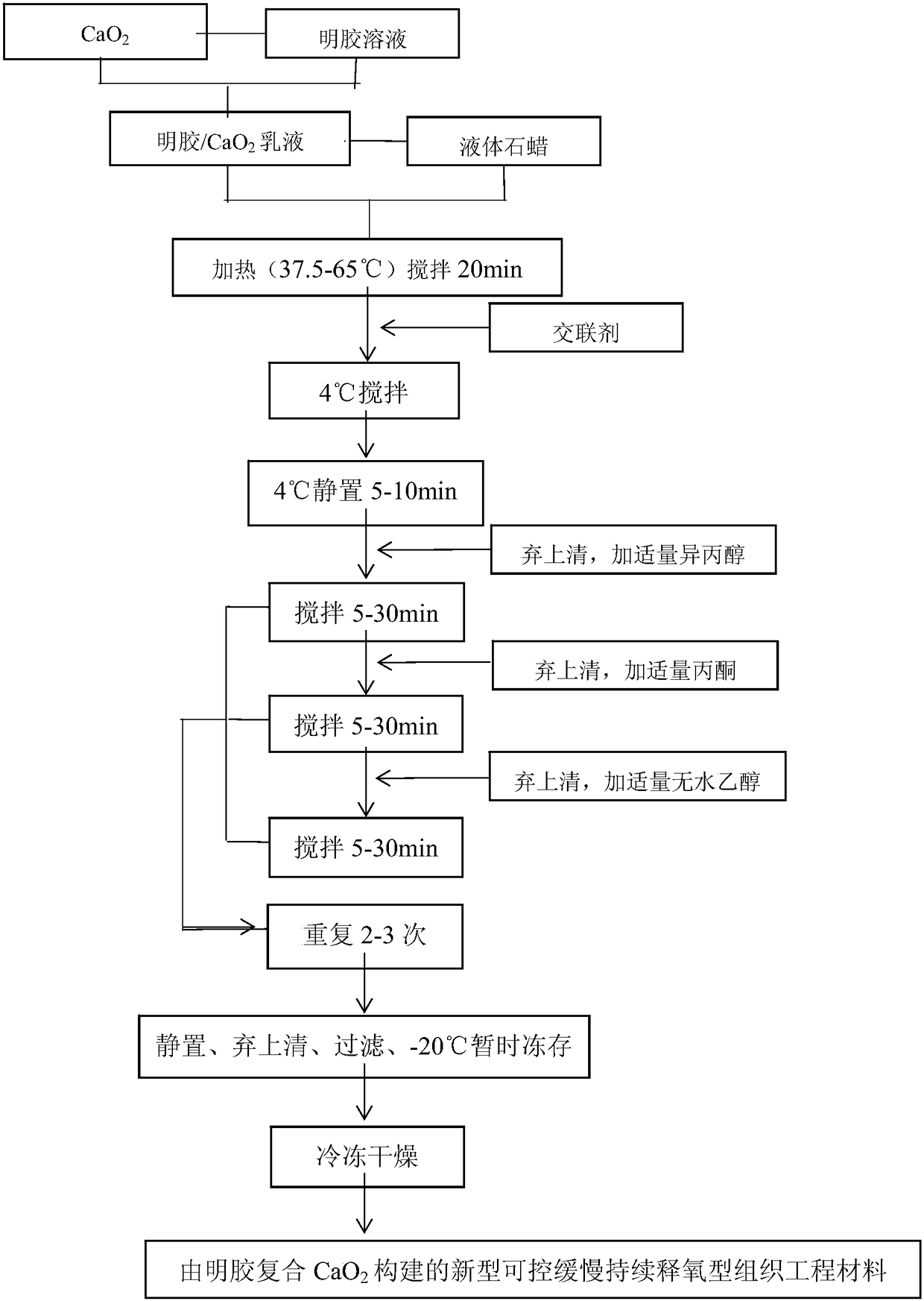

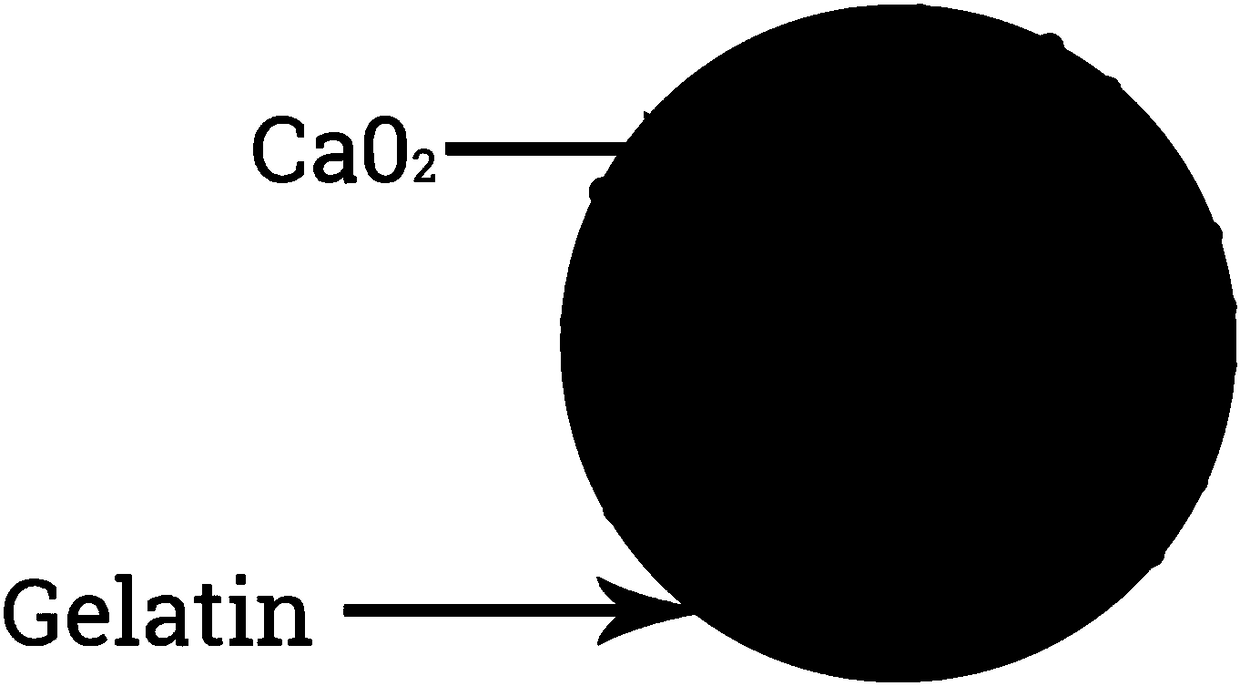

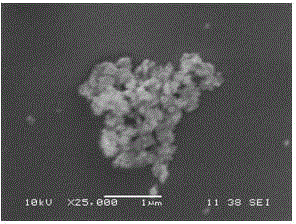

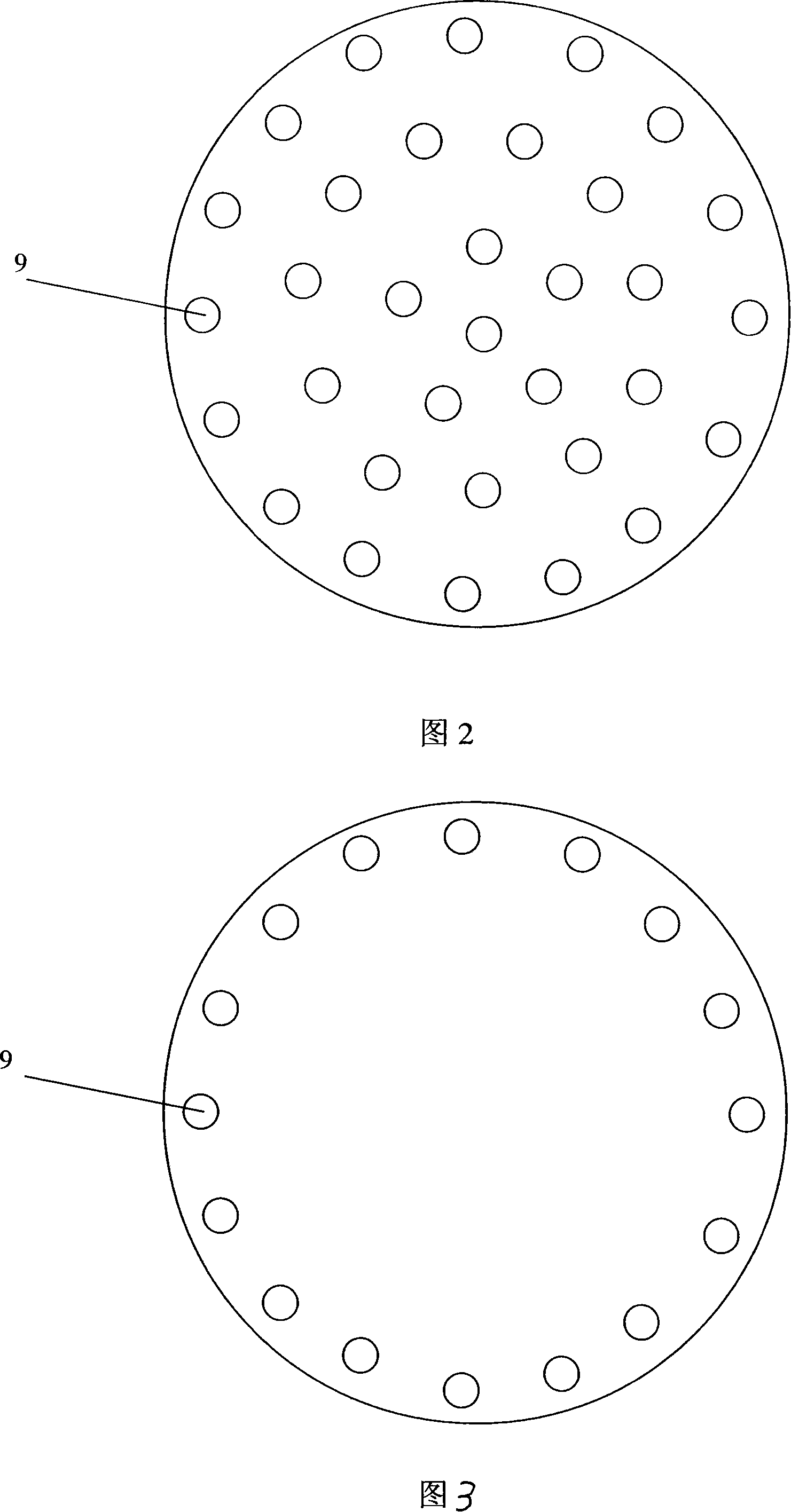

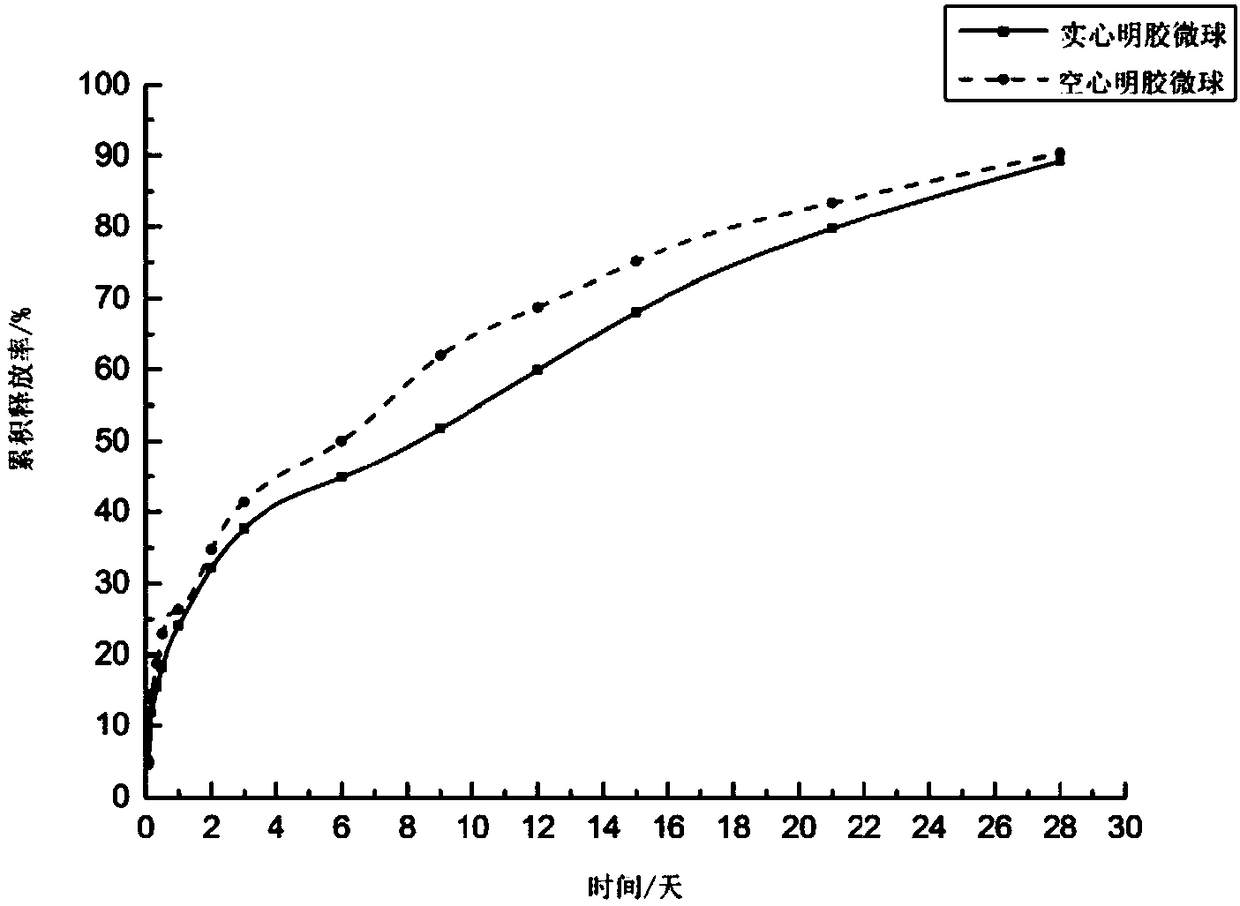

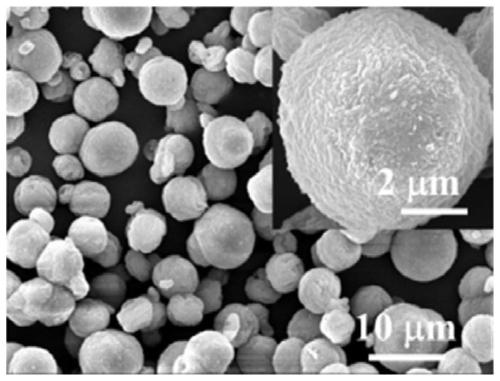

Sustained-release oxygen microsphere as well as preparation method and application thereof

ActiveCN108310470AControllable sizeExtended oxygen release timeTissue regenerationMicrocapsulesChemistryLarge applications

The invention discloses a sustained-release oxygen microsphere as well as a preparation method and application thereof. The sustained-release oxygen microsphere is a microsphere using gelatin as a matrix; the interior of the microsphere contains peroxidated inorganic particles, and preferably, the peroxidated inorganic particles are selected from one or multiple of CaO2 (calcium peroxide), MgO2 (magnesium peroxide), NaCO3 (sodium carbonate), SrO2 (strontium peroxide), BaO2 (barium peroxide), K2O2 (potassium peroxide), and Na2O2 (sodium peroxide). The sustained-release oxygen microsphere has the advantages that the size is controllable, the oxygen release time is long and controllable, the sudden release rate is low, the cell toxicity is low, the immunogenicity is low, the preparation process is relatively simple, the industrialized production is easily realized, and the like; the larger application prospect is realized in clinical application of bone defect repair.

Owner:SOUTHERN MEDICAL UNIVERSITY

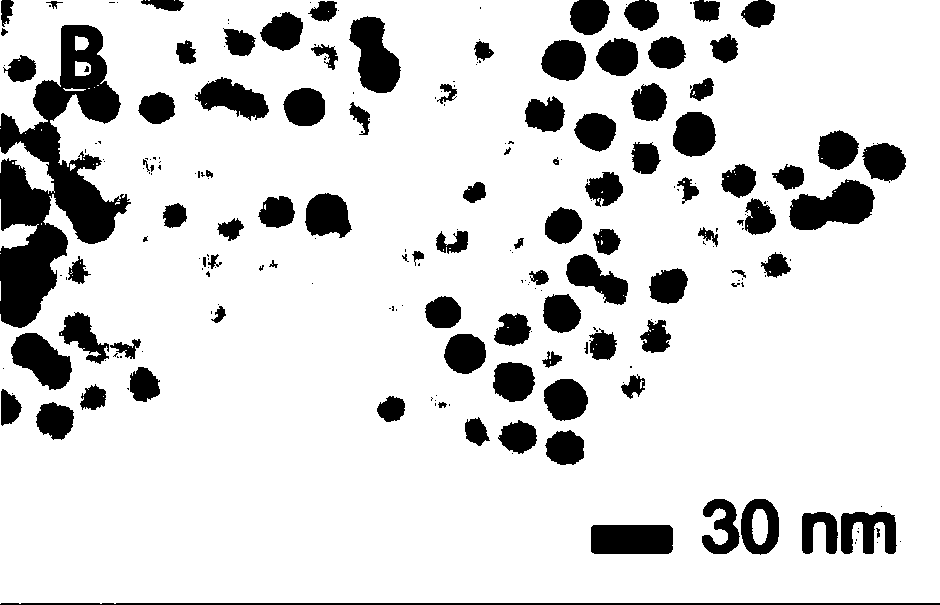

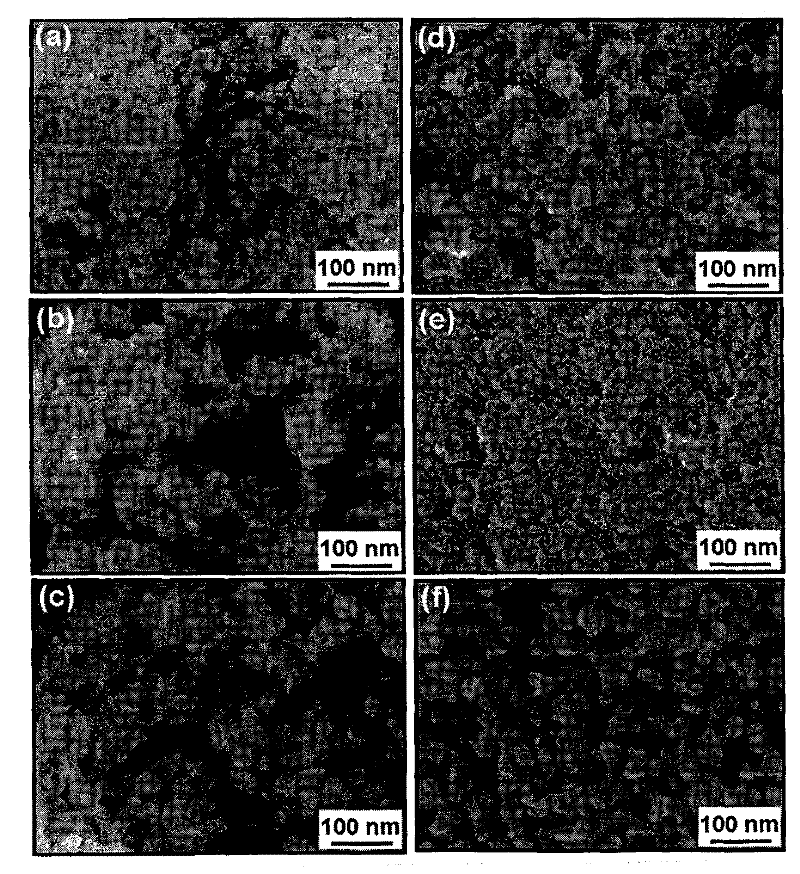

Method for fast preparing hollow porous silicon dioxide/silver nanoparticle composite and product

InactiveCN104439276AChange particle sizeRealize controllableMaterial nanotechnologyPorous siliconMixed solution

The invention relates to a method for fast preparing a hollow porous silicon dioxide / silver nanoparticle composite. The method includes the steps that a glucose water solution and a sodium silicate solution are mixed and then placed in a high-pressure hydrothermal kettle for a sustained reaction to obtain a carbonaceous ball silicon dioxide shell composite reactant, the reactant is centrifugally dried and then calcined in air for 3-8 h, and carbon nuclei are removed to obtain hollow porous silicon dioxide nanoparticles; the obtained silicon dioxide particles are fully dispersed in a mixed solution of a cetyl trimethyl ammonium bromide (CTAB) water solution and hydrazine hydrate, a dilute silver nitrate solution is added drop by drop, the mixture is stirred magnetically for a sustained reaction, and the obtained product is centrifugally separated to obtain the hollow porous silicon dioxide / silver nanoparticle material. The simple two-step method including a one-step hydrothermal method and a one-step reduction method is used for preparing hollow porous silicon dioxide / silver nanoparticles, and the hollow porous silicon dioxide nanoparticles are prepared through the one-step hydrothermal method, and the particle size of the hollow porous silicon dioxide nanoparticles can be adjusted conveniently; silver is reduced through the one-step reduction method, the preparation technology is simple, the reaction is fast, and large-scale industrial production can be achieved.

Owner:HUNAN UNIV OF SCI & TECH

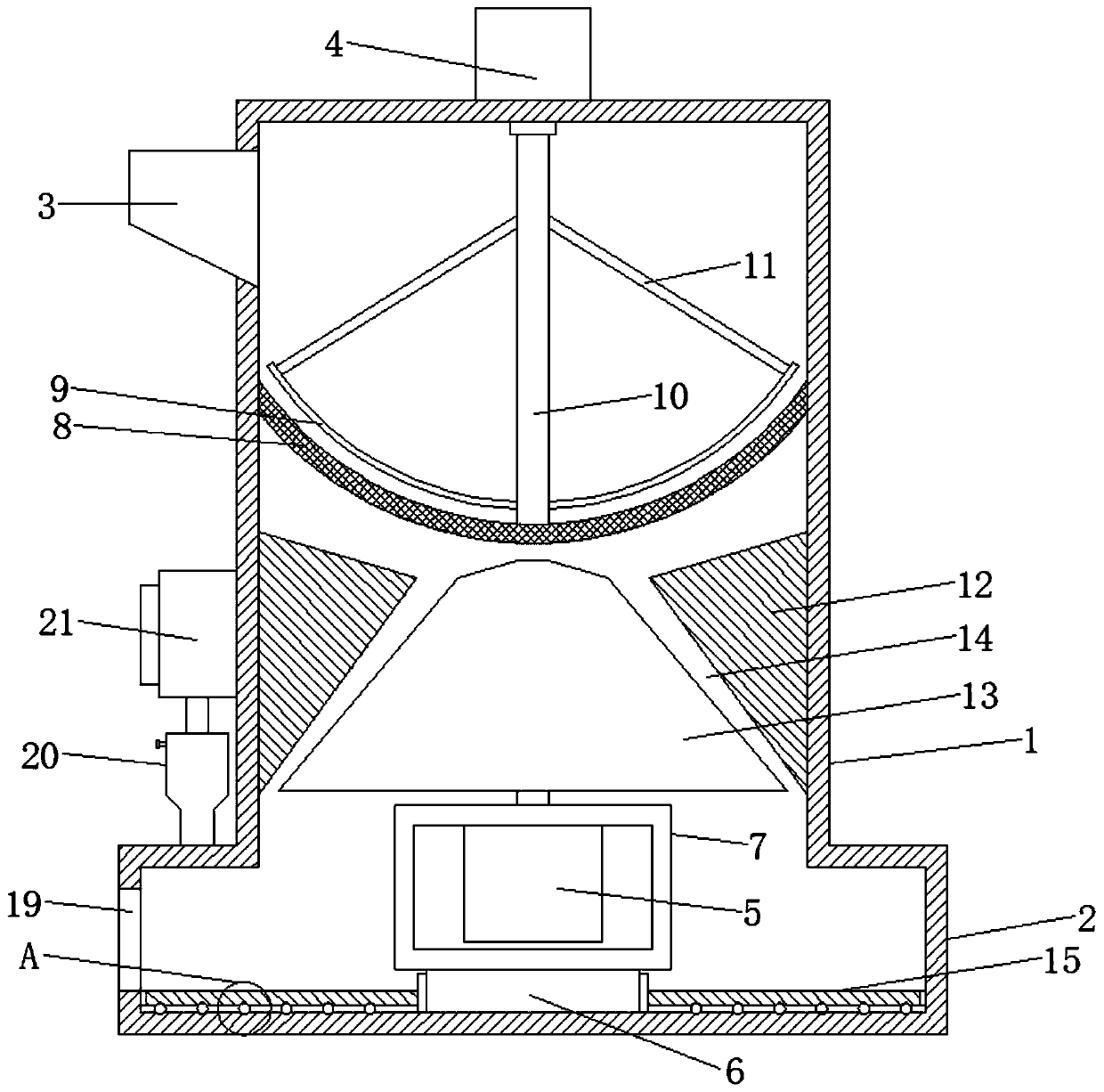

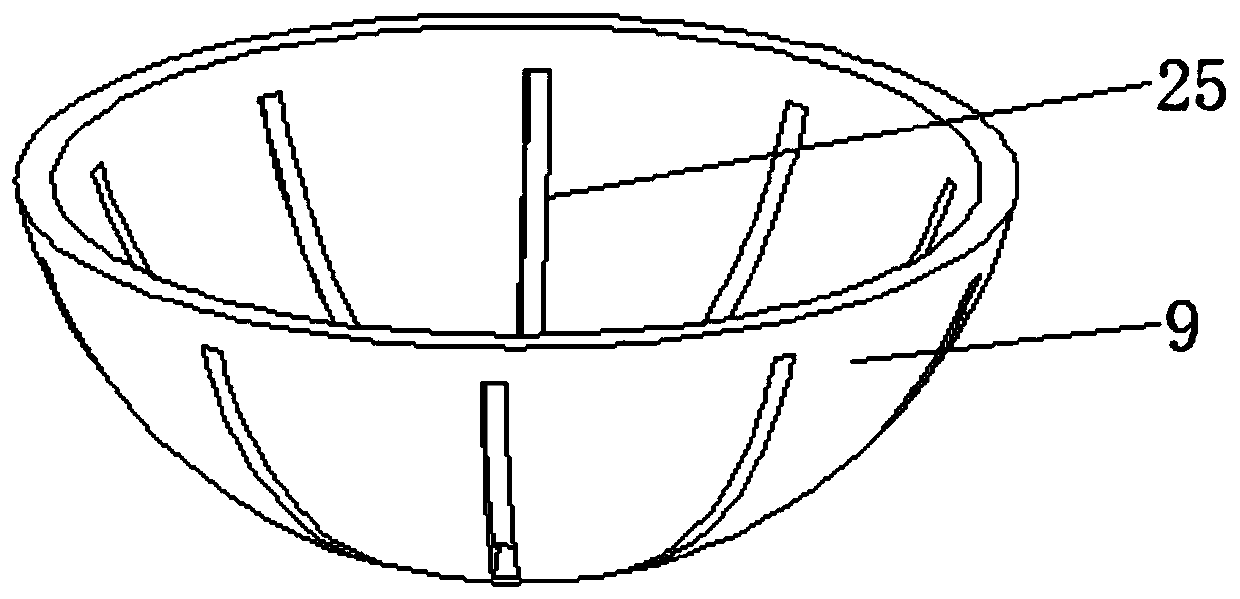

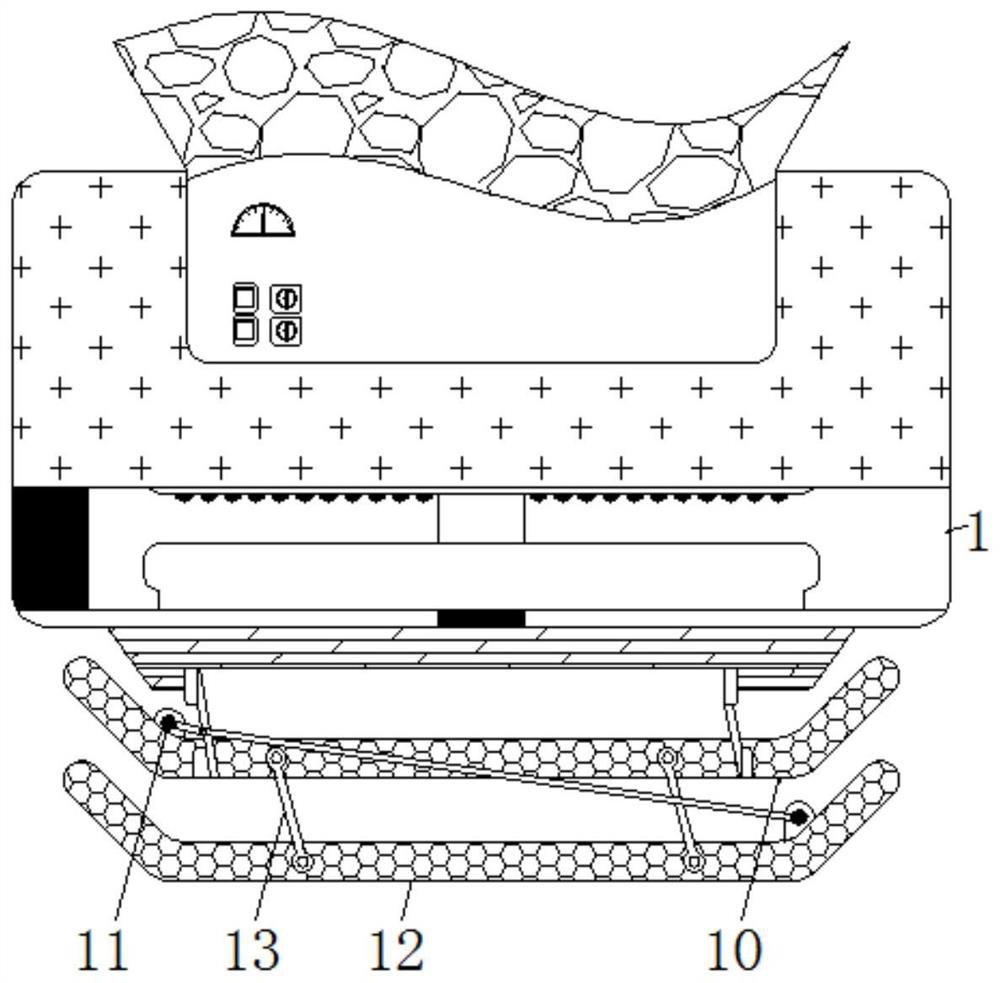

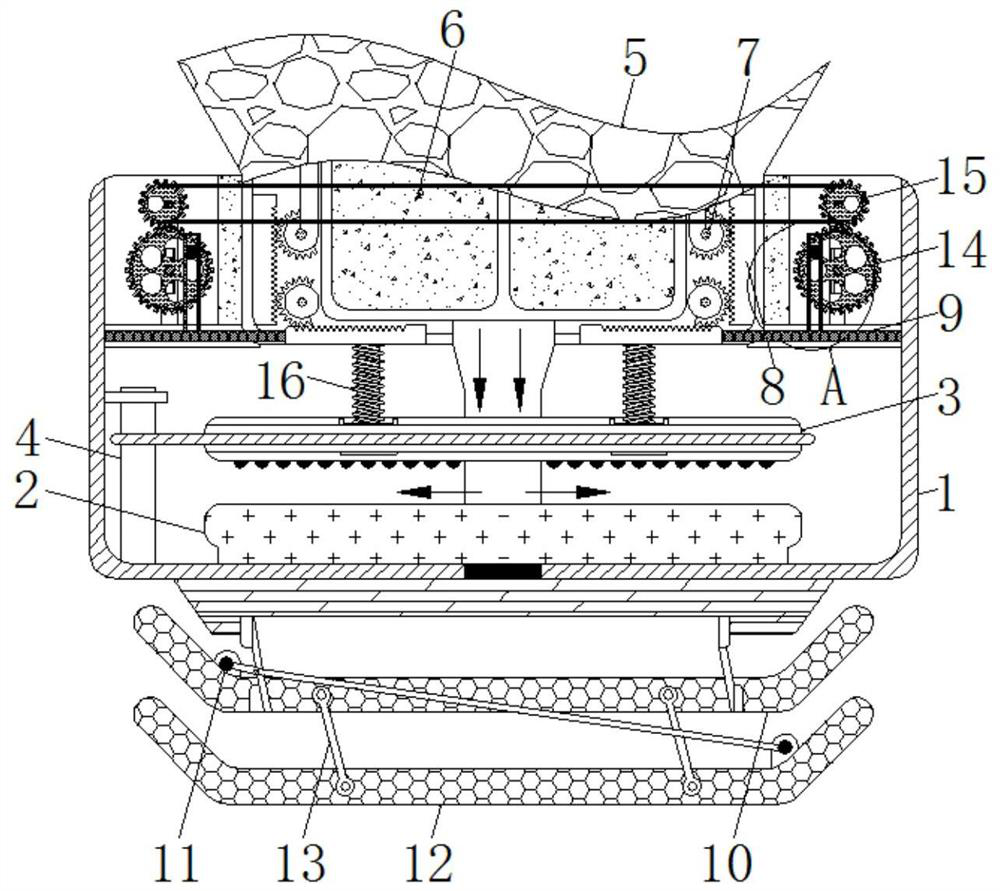

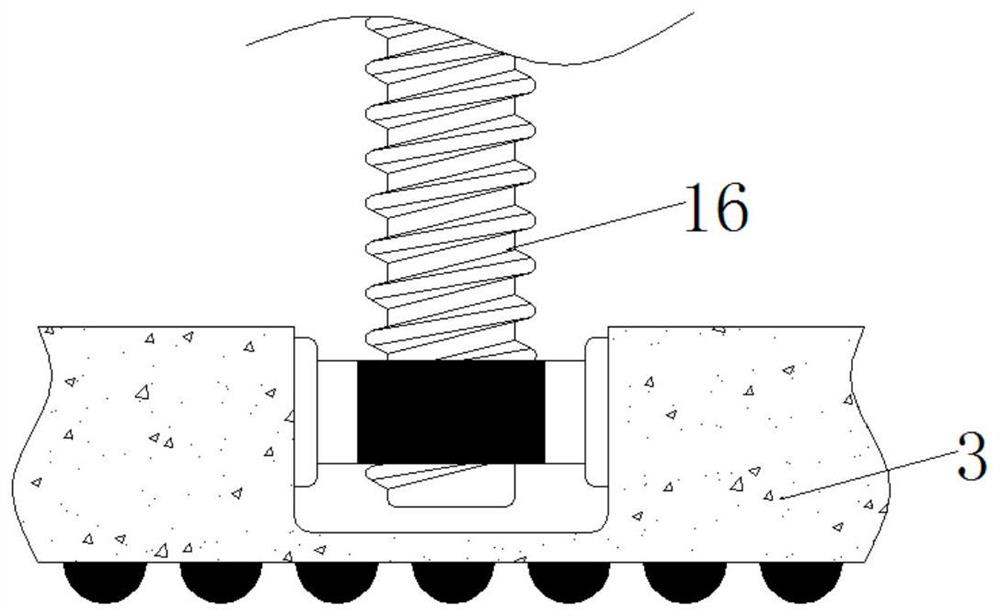

Sand and stone crushing equipment for building engineering

InactiveCN111054479AEasy to adjustWide range of applicationsCocoaGrain treatmentsElectric machineryArchitectural engineering

The invention relates to the field of building construction, and particularly discloses sand and stone crushing equipment for building engineering. The equipment comprises a crushing shell, a collection box, a feed hopper, a first motor and a second motor. A primary crushing net of a spherical structure is fixed on the middle part in the crushing shell; a primary grinding disc matched with the primary crushing net in parallel is fixed at the lower end of a rotating shaft, and the primary grinding disc is also of a spherical structure; the center of a grinding fixed seat is provided with a grinding cavity of a circular truncated cone structure, and a grinding roller of a circular truncated cone structure is coaxially arranged in the grinding fixed seat; and the bottom of the grinding rolleris fixedly connected to an output shaft of the second motor, the second motor is fixedly installed on a motor bracket, and a lifting mechanism is fixedly installed on the lower side of the motor bracket. The height of the grinding roller is changed through the arranged lifting mechanism, so that the distance between the grinding roller and the grinding cavity is adjusted, the particle size of crushed sand and stone is changed, adjustment is convenient and rapid, and the application range is wide.

Owner:时守贺

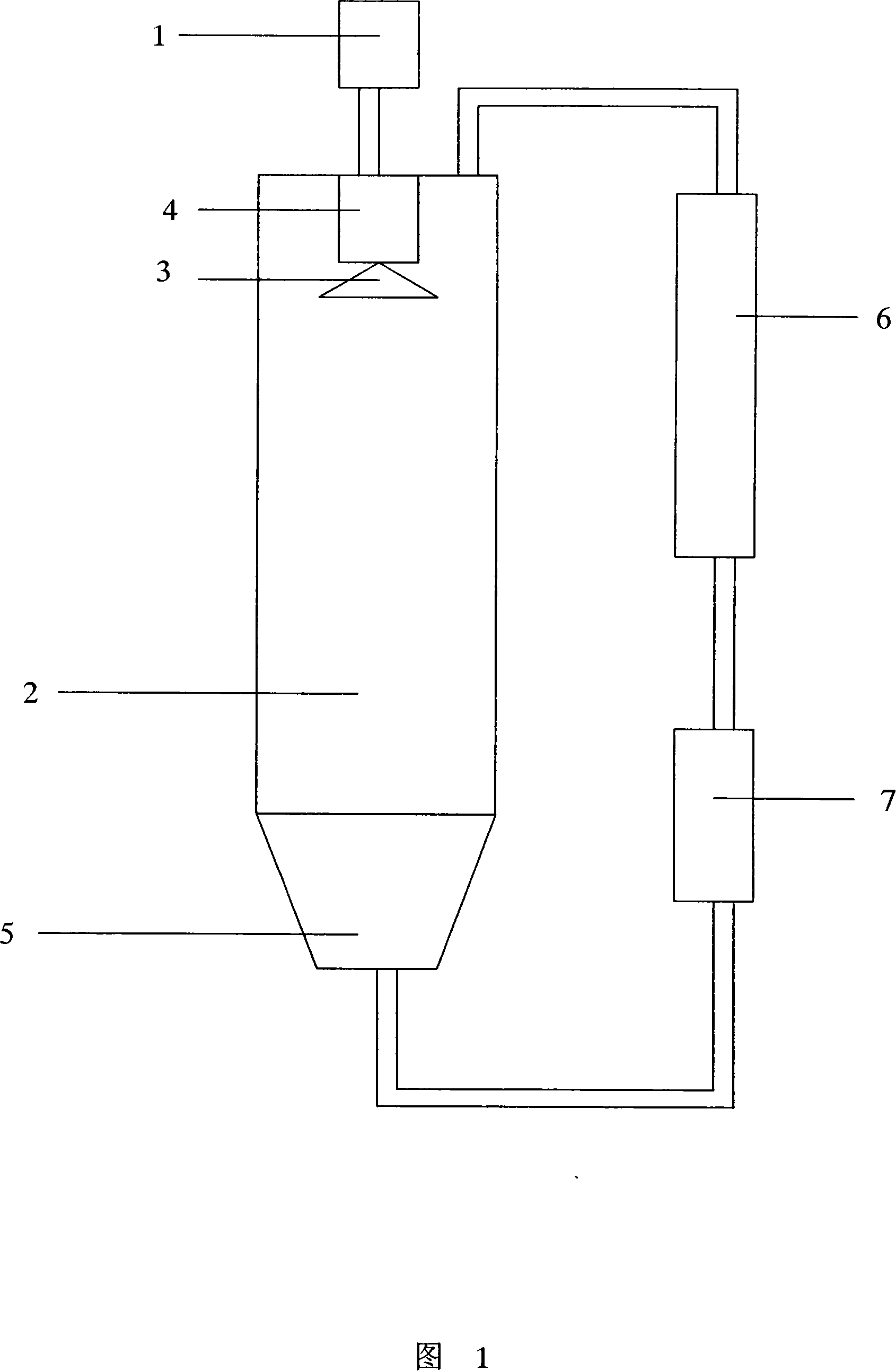

Petroleum resin ball granule and its production equipment and manufacturing method

The present invention relates to one kind of spherical petroleum resin particle and its production apparatus and process. The spherical petroleum resin particle in average size of 0.2-3 mm is produced in apparatus comprising a stock bin, a pelletizing tower connected through one pipeline to the stock bin, a nozzle in the top inside the pelletizing tower, a nozzle driving unit connected to the nozzle, one fluidizing cooler in the bottom of the pelletizing tower, a waste gas absorbing tower connected through one pipeline to the pelletizing tower, and a inert gas bin connected through one pipeline to the pelletizing tower. The spherical petroleum resin particle product has excellent flowability and high strength. The production apparatus has simple structure, and the production process is completely closed and environment friendly.

Owner:TIANJIN KAIER TECH DEV

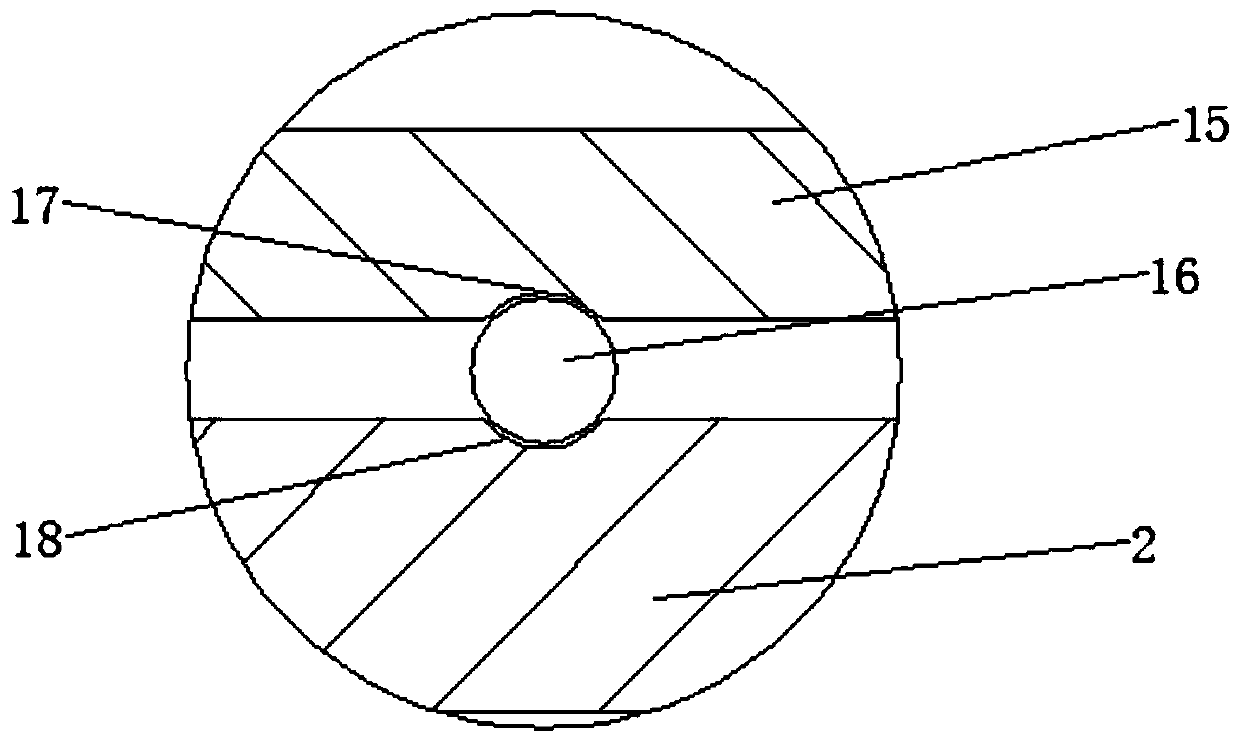

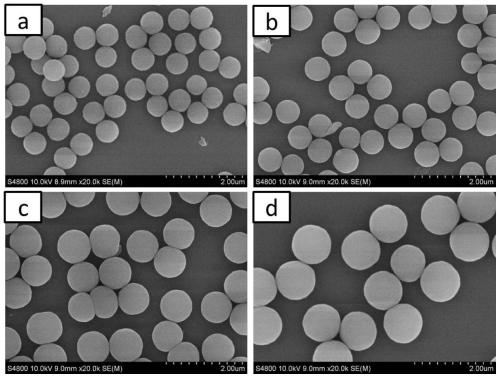

Hollow slow-release microsphere used for loading medicine and preparation method thereof

ActiveCN108451925AGood biocompatibility and degradabilityLow pricePeptide/protein ingredientsMacromolecular non-active ingredientsDrugPolystyrene microsphere

The invention discloses a hollow slow-release microsphere used for loading medicine and a preparation method thereof, and belongs to the technical field of medical slow-release microspheres. The method comprises the steps that an emulsification-crosslinking method is adopted to coat a shell-layer polymer material on the surface of a polystyrene microsphere to obtain the core-shell structure microsphere with the polystyrene microsphere as the core and with gelatin, sodium alginate tech grade, chitosan and polylactic acid as the shell, then the core polystyrene microsphere is immersed, dissolvedand removed through tetrahydrofuran, crosslinking and solidification are carried out on the microsphere to obtain the hollow slow-release microsphere, then the medicine is loaded on the hollow-structure microsphere, and the drug loading capacity of the medicine is greatly increased.

Owner:CENT SOUTH UNIV

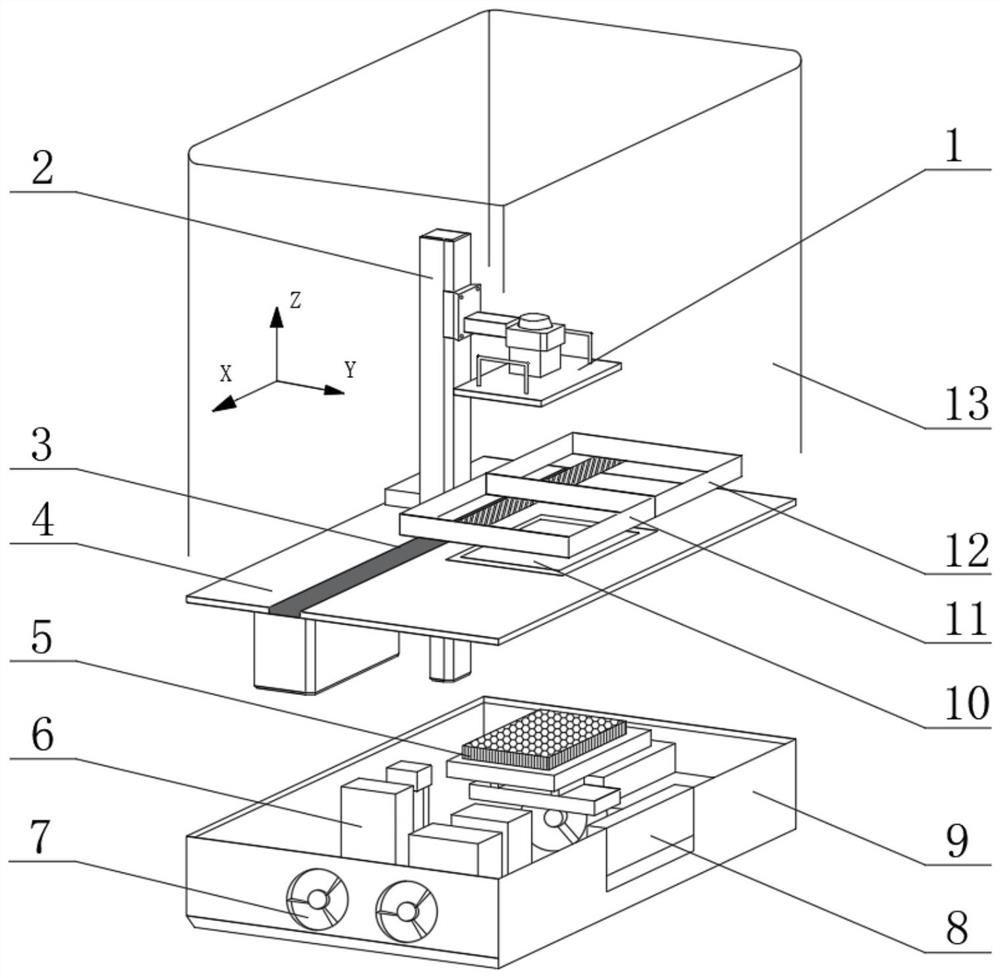

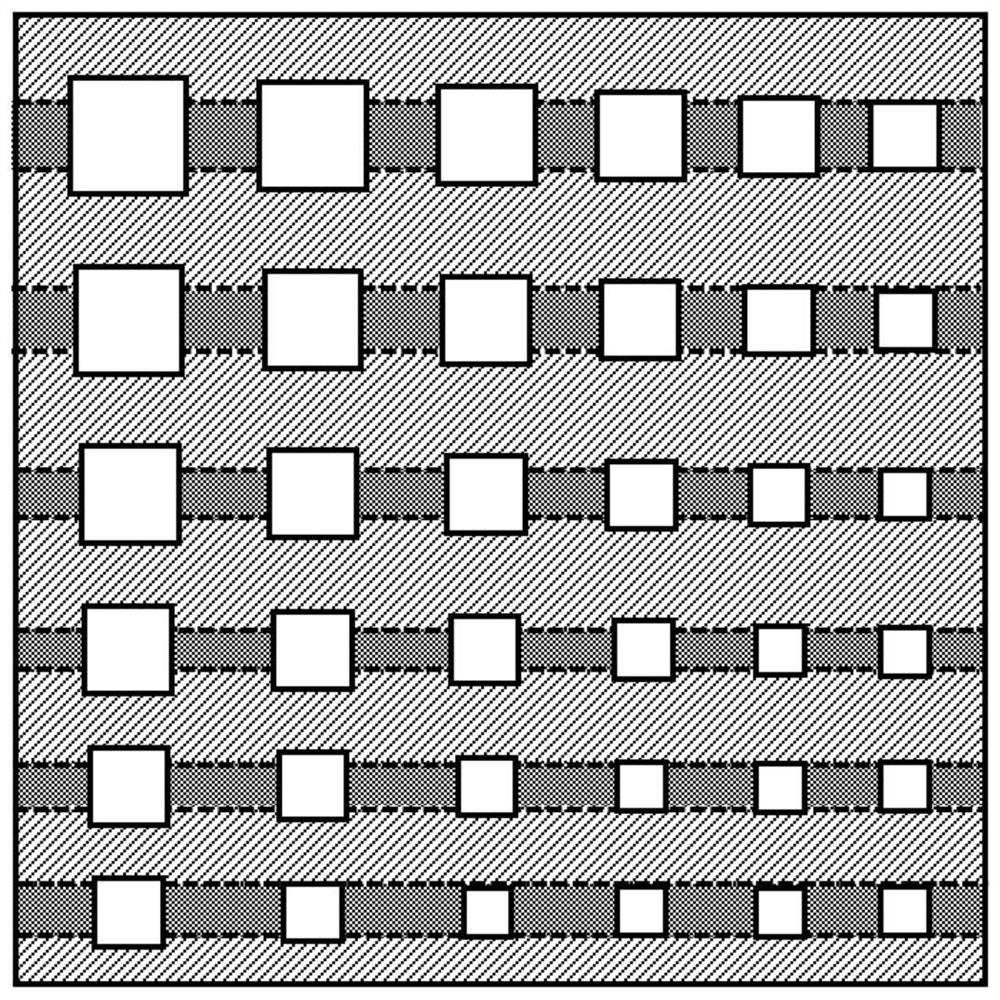

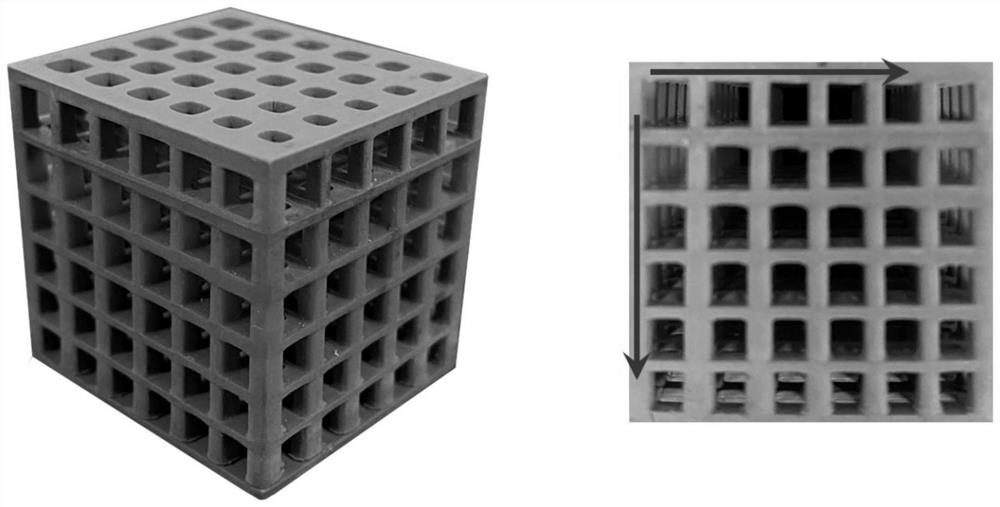

3D printing preparation method and device for heterogeneous bidirectional gradient aperture porous ceramic

ActiveCN114276145ARapid designFast preparationAdditive manufacturing apparatusCeramic shaping apparatusThermal dilatationManufacturing technology

The invention discloses a 3D printing preparation method and device for heterogeneous bidirectional gradient aperture porous ceramics, and belongs to the technical field of 3D printing of functional materials, gradient aperture functional materials are combined with an additive manufacturing technology, and alternate change of all layers of materials is achieved by controlling photocuring slurry, so that the 3D printing preparation method is suitable for 3D printing of the functional materials. Wherein the amorphous silicon powder content of the first precursor ceramic slurry is smaller than that of the second precursor ceramic slurry, so that the thermal expansion coefficient of the first precursor ceramic slurry is slightly higher than that of the second precursor ceramic slurry, pressure stress can be generated between pore layers after sintering, and the strength of the gradient aperture porous ceramic can be improved. In addition, the silicon powder can react with carbon residues generated by the photosensitive resin to be sintered, so that the green body is densified, and local microcracks between pore layers are effectively eliminated. In addition, the particle size of the silicon powder is changed, the macropores are controllable, meanwhile, the micropores are variable, and the functionality of the gradient aperture porous ceramic is further improved.

Owner:JILIN UNIV

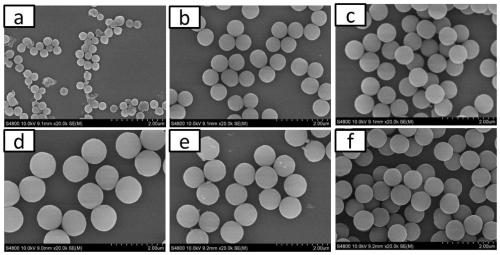

Large-scale prepared particle size-controllable nitrogen and oxygen doped carbon microsphere and preparation method and application thereof

ActiveCN109786118AGood electrochemical performanceIncrease mesopore volumeMaterial nanotechnologyHybrid capacitor electrodesSolventChemistry

The invention discloses a method for large-scale preparation of nitrogen and oxygen doped carbon microspheres. The method comprises the following steps of: stirring 2-8 parts of diallyl phthalate, 5-10 parts of acrylonitrile, 5-30 parts of a polymerizable monomer, 70-80 parts of a solvent and 0.2-1 part of azodiisobutyronitrile by weight under 70-80 DEG C for 3-5 hours, and carrying out centrifugal separation to obtain a solid powder product; heating the solid powder obtained in the step A to 800-900 DEG C at a certain speed under the protection of inert gas so as to obtain constant-temperature carbonization, and washing and drying the obtained black solid powder to obtain the nitrogen and oxygen doped carbon microspheres. The carbon microspheres are high in mesoporous content, high in specific area and favorable in capacitive performance, and can be used as a supercapacitor electrode material.

Owner:ZIBO VOCATIONAL INST

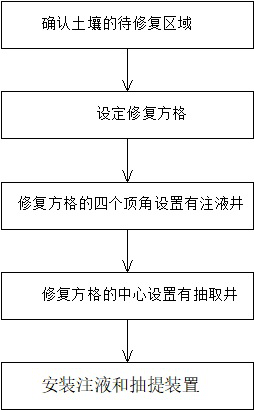

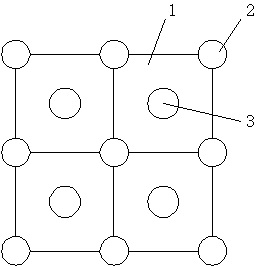

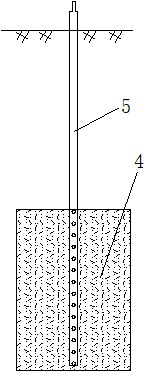

High-pressure splitting extrusion powder-mixing permeation-assisting in-situ remediation method for low-permeability polluted soil

PendingCN113020243AImprove permeabilityExpand the scope of repairContaminated soil reclamationSoil scienceIn situ remediation

The invention relates to a high-pressure splitting extrusion powder-mixing permeation-assisting in-situ remediation method for low-permeability polluted soil. The remediation method comprises the following steps: confirming a to-be-remedied area of soil; setting one or more remediation grids according to the size of the to-be-remedied area of the soil; arranging liquid injection wells at the four top corners of the repairing square grids; arranging an extraction well in the center of the repair grid; and mounting aliquid injection device at the liquid injection well, and mounting a negative pressure extraction device at the extraction well for liquid injection and extraction. Water and gas are injected into the polluted soil body through high-pressure jet grouting under high pressure, the original structure of the polluted soil body is destroyed, and a mud cake-shaped structure is formed, so that plant ash and sand are injected to be evenly mixed into the polluted soil body, the grain composition of the soil body is changed, and the permeability coefficient of the soil body is increased; and the chemical agent permeation rate is increased, the reaction rate and the permeation range are increased, the remediation range is increased, the remediation period is greatly shortened, the chemical agent dosage, the permeation path and the permeation range can be controlled, and secondary pollution is avoided.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

Polyethylene glycol-polyethyleneimine modified ferric oxide nanoparticle preparation method

ActiveCN108314091AUniform particle size distributionParticle size distribution can be controlledMaterial nanotechnologyInorganic non-active ingredientsSolubilityPolyethylene glycol

The invention discloses a polyethylene glycol-polyethyleneimine modified ferric oxide nanoparticle preparation method which comprises the following steps: 1) dissolving polyethylene glycol into dichloromethane, adding maleic anhydride, adding triethylamine and 4-dimethylamino pyridine at the same time, reacting for 48h to 72h under the room temperature condition and adding ice diethyl ether precipitate to obtain a product carboxylated polyethylene glycol; 2) dissolving the product into tetrahydrofuran, adding polyethyleneimine, adding dicyclohexyl carbodiimide and 4-dimehtylamino pyridine, reacting for 72h to 120h under room temperature and performing rotary evaporation to remove a solvent to obtain polyethylene glycol-polyethyleneimine copolymer; 3) obtaining polyethylene glycol-polyethyleneimine modified ferric oxide nanoparticles through a ligand exchange method. The ferric oxide nanoparticles prepared by the preparation method disclosed by the invention has the advantages of even particle size distribution and good water solubility and cytocompatibility.

Owner:XINYANG NORMAL UNIVERSITY

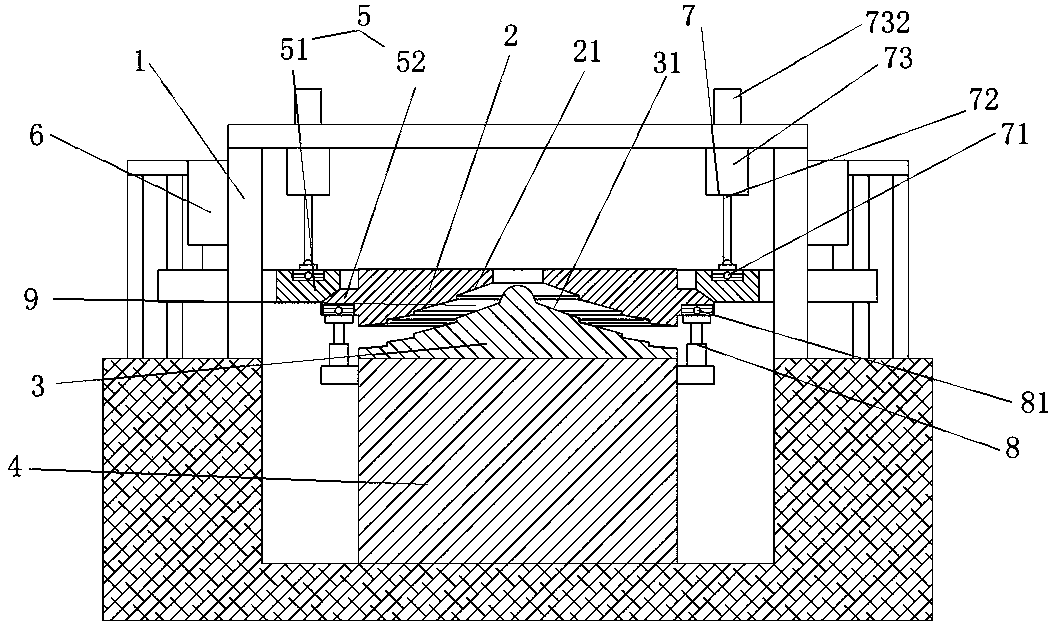

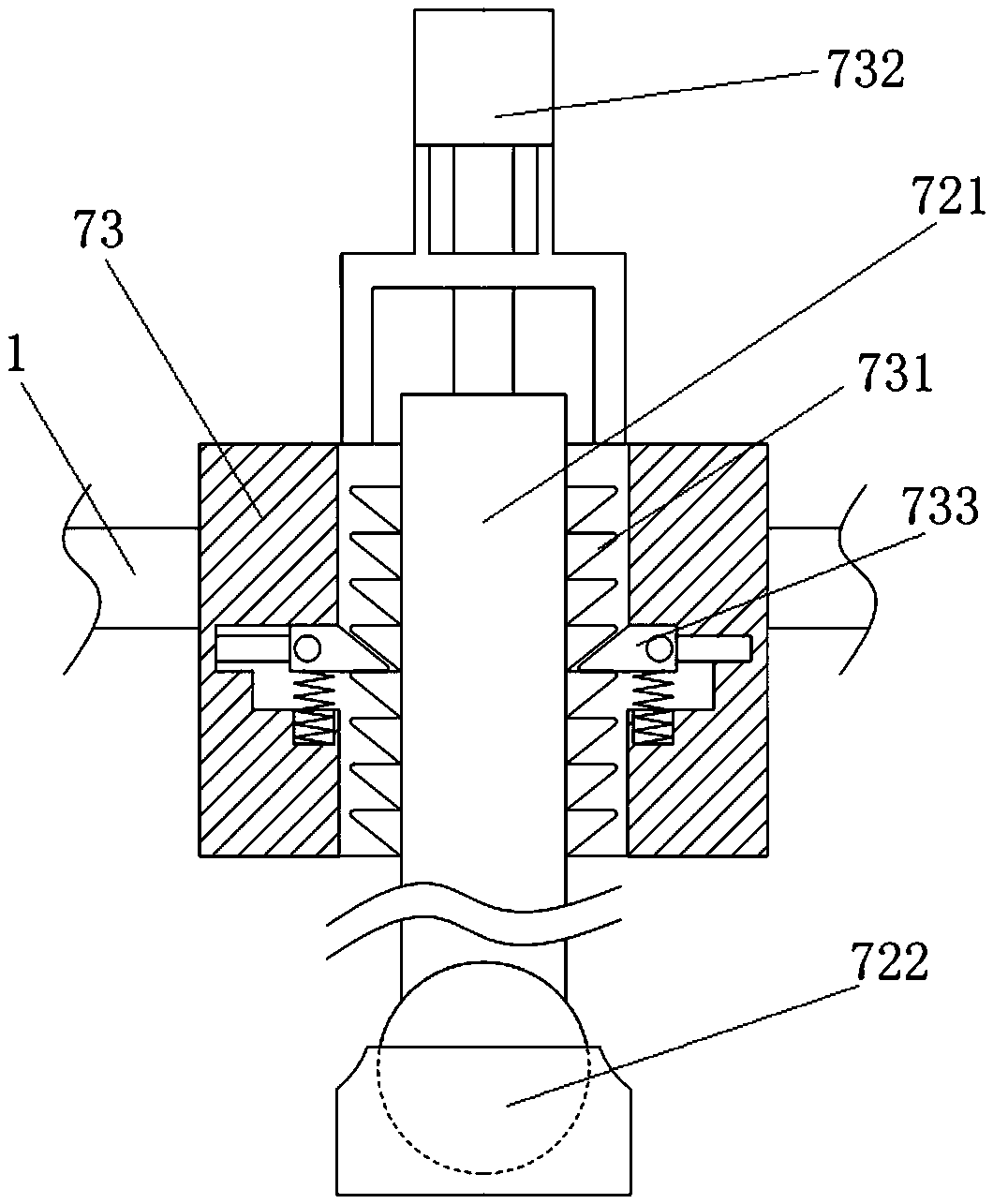

Cement component powder grinding equipment

ActiveCN110605163AGuaranteed grinding effectHeight adjustableCocoaGrain treatmentsEngineeringMechanical engineering

The invention aims to provide cement component powder grinding equipment, and aims to solve the problems existing in the prior art. The equipment comprises a rolling disc, a weight bearing disc, a weight bearing foundation and a rotary driver, wherein the rolling disc, the weight bearing disc, the weight bearing foundation and the rotary driver are sequentially arranged in a supporting frame in adownward stacked mode, and the rotary driver is connected with a gear pair and used for driving the grinding disc; the gear pair comprises a first gear ring and a second gear ring, wherein the first gear ring and the second gear ring mesh with each other in an oblique-teeth mode, the upper side of the first gear ring is connected with an adjusting device, and the lower side of the second gear ringis connected with a supporting device; and the lower surface of the grinding disc is provided with a rolling surface which is outwards stepped down in the radial direction, the upper surface of the weight bearing disc is provided with a weight bearing surface which is outwards stepped down in the radial direction, the rolling surface and the weight bearing surface are combined to form a powder grinding cavity, and the vertical height of the powder grinding cavity is gradually reduced from the center to the outside. According to the cement component powder grinding equipment, cement componentscan be fully ground in single equipment until the final required particle size is directly output, and meanwhile the particle size of produced objects is conveniently adjusted according to productionrequirements so that the equipment cost can be reduced, and economic benefits can be improved.

Owner:福建福清万年青水泥有限公司

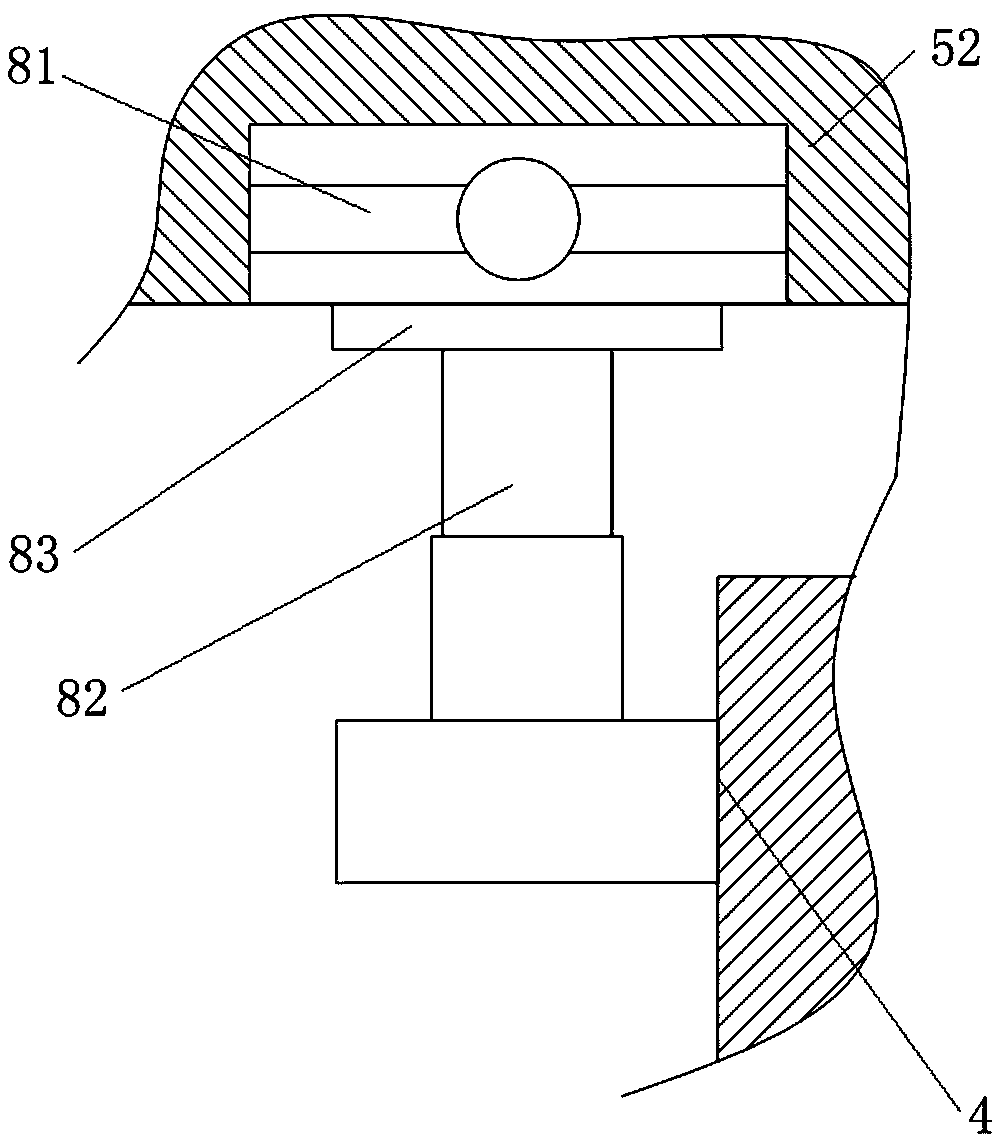

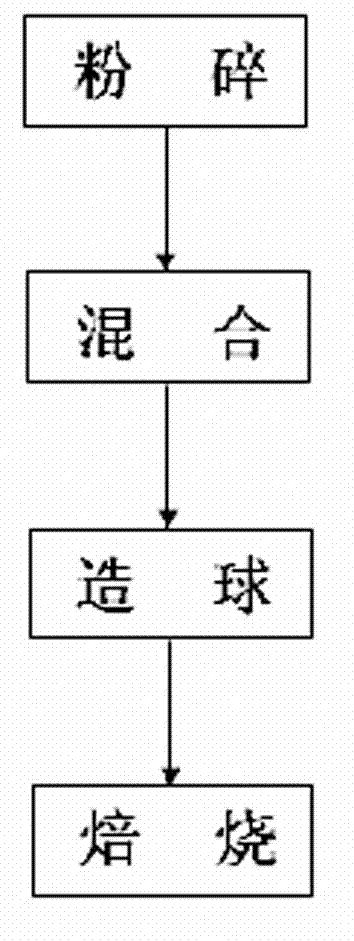

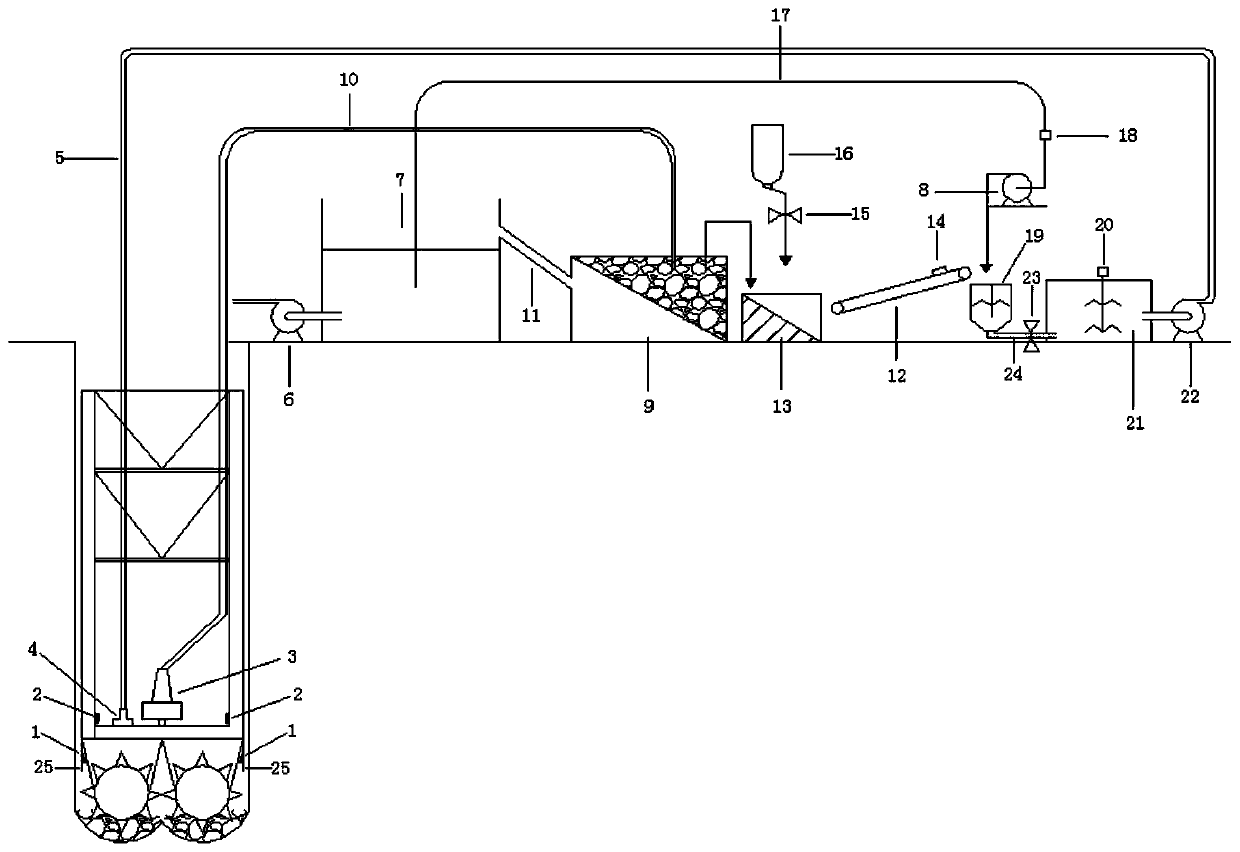

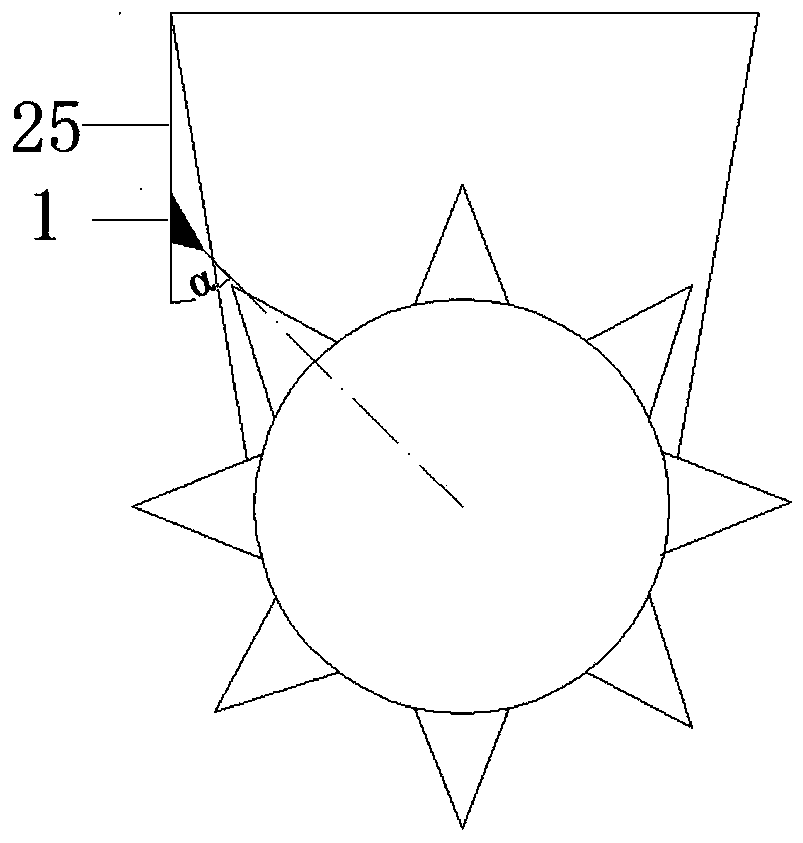

Pellet ore with good metallurgical property and proper alkalinity, and preparation method thereof

The invention discloses pellet ore with good metallurgical property and proper alkalinity and a preparation method thereof, and belongs to the technical field of modification of metallurgical materials. The reduction degree of the pellet ore is 64.00 to 67.00 percent. The pellet ore is prepared by adding limestone powder or dolomite powder with the granularity being less than or equal to 0.074 mm into powdered iron according to the using amount of 2.8 to 5.3 percent. The preparation method comprises the processes of crushing, mixing, pelletizing and roasting, and particularly comprises the following steps: crushing the limestone or the dolomite into powder with the granularity being 10 to 15 mm and then crushing into powder with the granularity being less than or equal to 0.074 mm; adding the limestone powder or the dolomite powder into the powdered iron according to the using amount of 2.8 to 5.3 percent, and mixing uniformly; adjusting the water content of the mixed ore material to be 8 to 9 percent and pelletizing in a disc pelletizing machine; and drying and preheating green balls at the temperature of 200 to 960 DEG C for 12 to 17 minutes, roasting at the temperature of 1,250 to 1,280 DEG C for 25 to 30 minutes, and cooling to room temperature to obtain the finished product pellet ore. The pellet ore prepared by the method has proper alkalinity and metallurgical property, is favorable for optimizing the burden structure of a blast furnace, reducing the coke ratio of the blast furnace and increasing the yield of the blast furnace, and has a good popularization and application value.

Owner:WUKUN STEEL

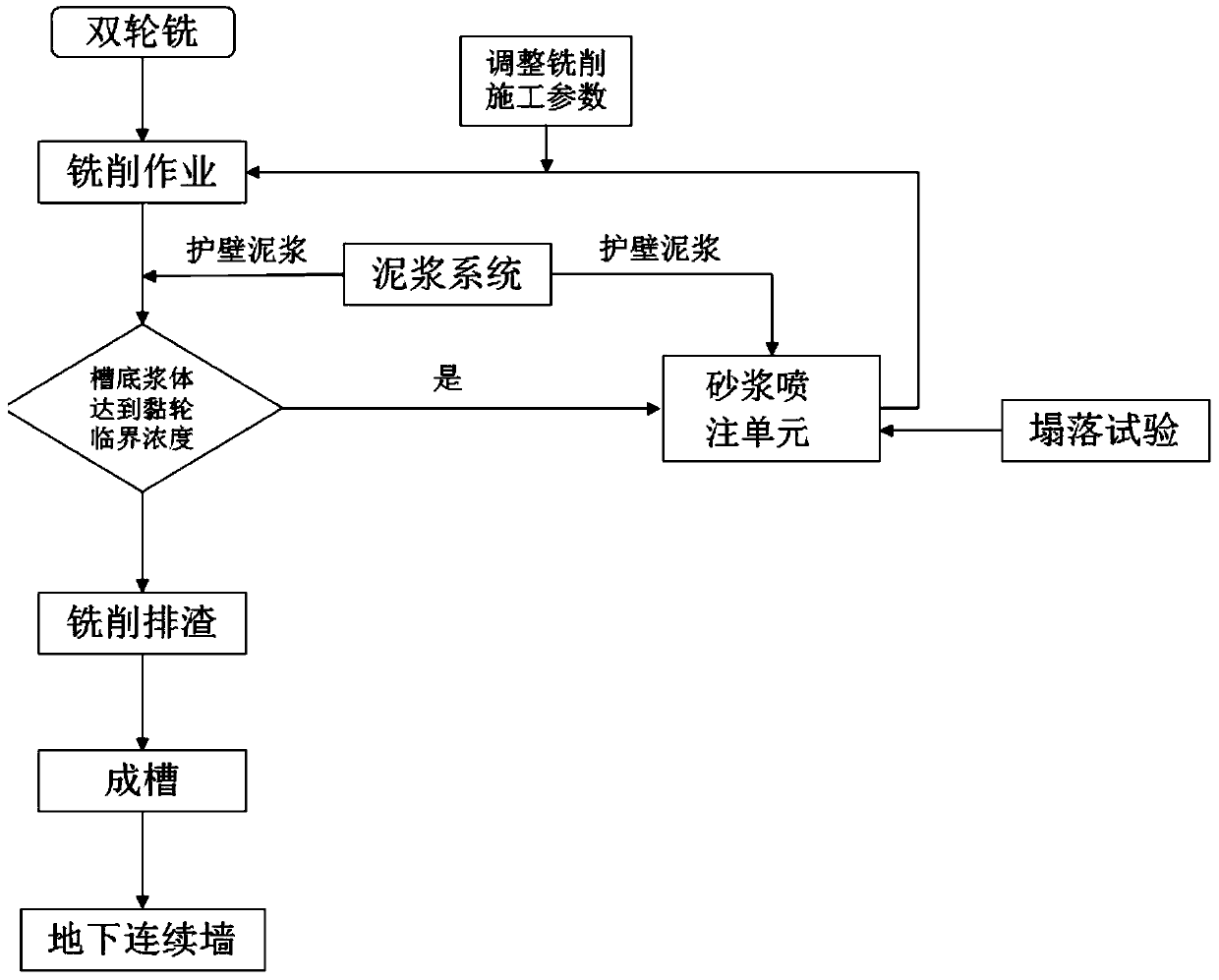

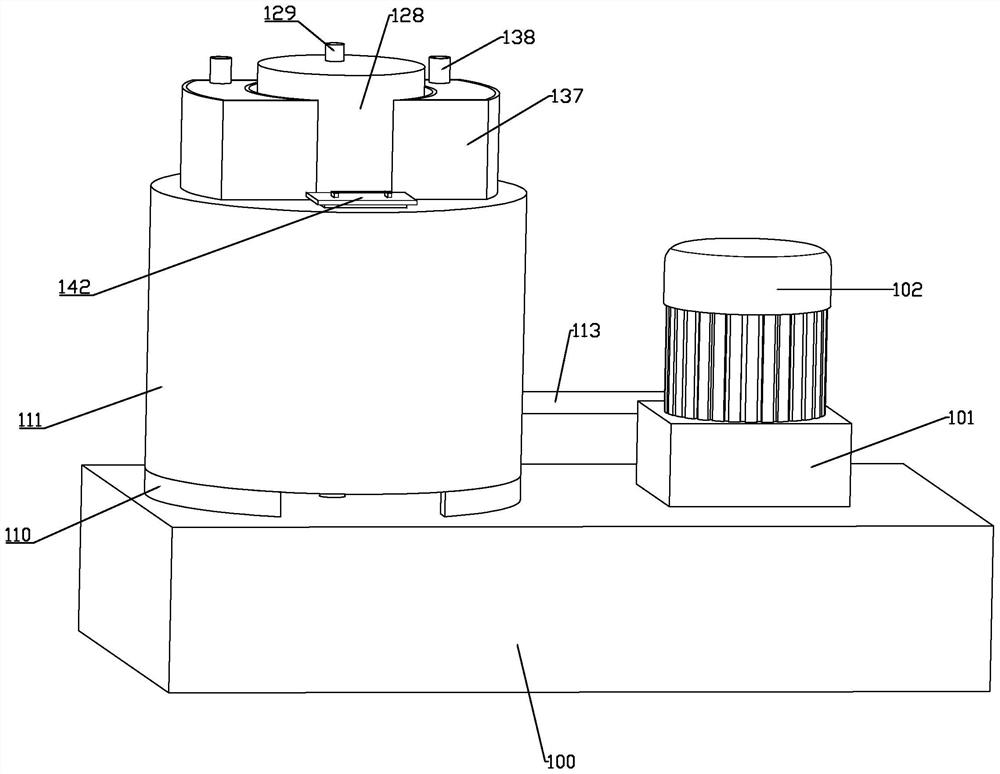

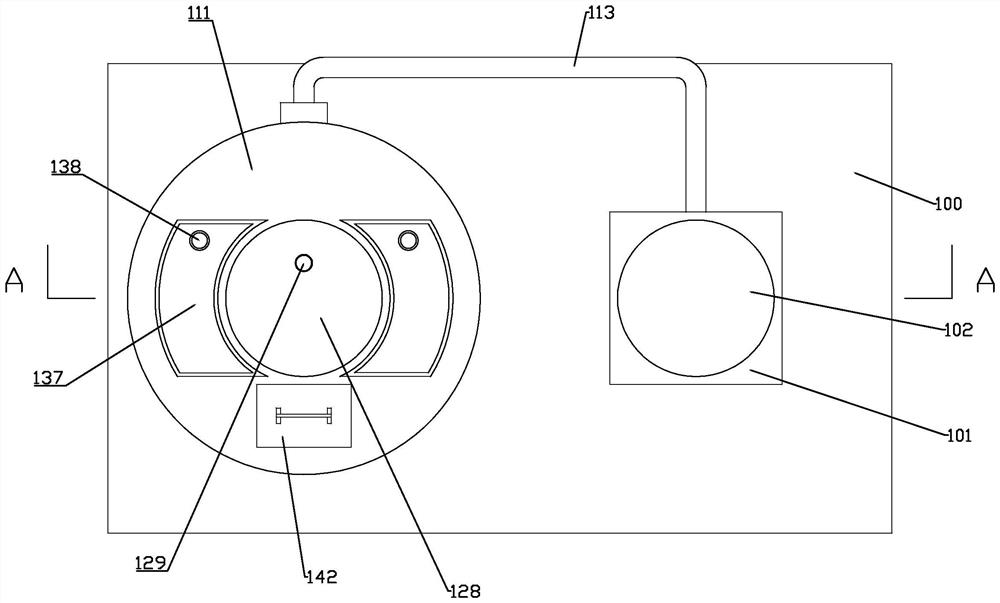

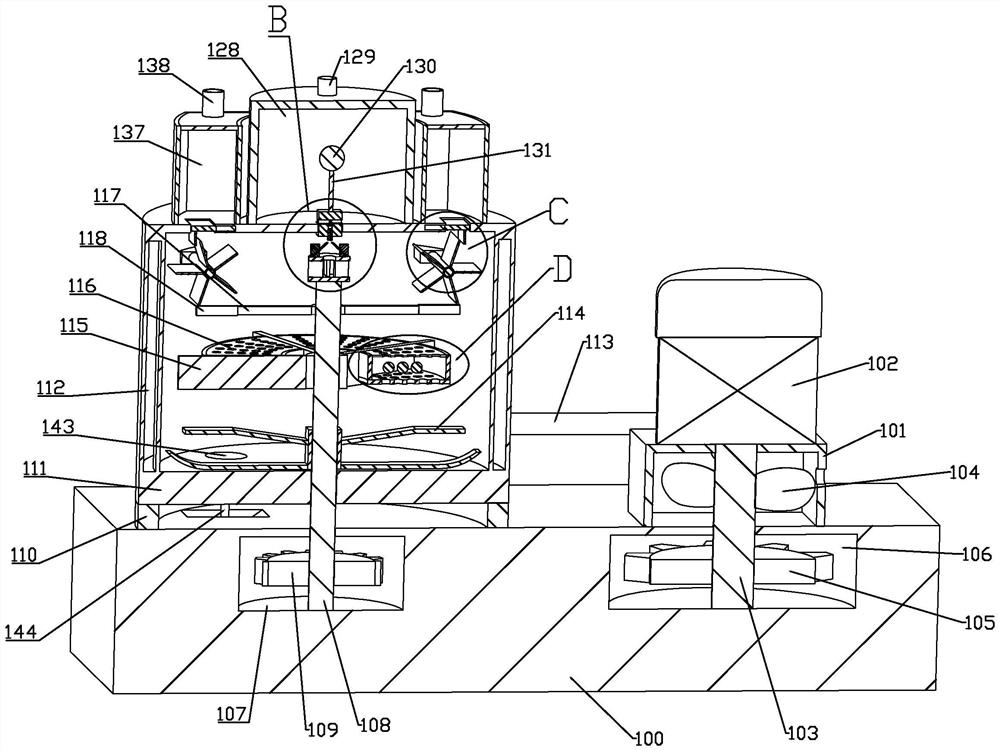

Wheel-sticking prevention mortar injecting system and method

ActiveCN110593340AReduce concentrationImprove liquiditySolid waste managementSoil-shifting machines/dredgersSlagSlurry

The invention discloses a wheel-sticking prevention mortar injecting system and method. The wheel-sticking prevention mortar injecting system comprises a concentration sensor and a mortar injection unit; when the concentration sensor detects that the concentration of slurry in a working area is greater than a set threshold value, the mortar injection unit is stared, mortar is injected into the working area by the mortar injection unit, the proportion of non-sticky particles is increased, and the concentration of the slurry in the working area is decreased. Through the construction method for injecting the mortar into the slurry in the working area (such as the groove bottom), the proportion of the non-sticky particles in the slurry at the groove bottom is increased, the concentration of the slurry at the groove bottom is decreased, the inherent characteristics of slurry in a deep sticky formation are changed, it is ensured that the slurry at the groove bottom has the good flowing characteristic, and the efficiency of sucking and discharging of the slurry at the groove bottom by a slag suction opening is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

High-speed kneading machine for soft PVC material production

The invention provides a high-speed kneading machine for soft PVC material production, and belongs to the technical field of PVC manufacturing. The high-speed kneading machine solves the problems that when an existing high-speed mixer runs, various raw material components cannot be effectively contacted and mixed and the working efficiency is reduced due to a manner of externally adding raw materials on a large scale at one time, and the quality of a formed product is reduced due to the fact that the viscosity of formed slurry is not well monitored in the mixing process. The high-speed kneading machine for soft PVC material production comprises a base, wherein a first placement cavity is defined in the base and located on the left side of the center line of the base, a second placement cavity is defined in the base and located on the right side of the center line of the base, and a supporting block is arranged at the upper end of the base and located on the left side of the center line of the base. When the high-speed kneading machine for producing the soft PVC material is used, raw materials are better mixed, and the viscosity of a finished product is more stable.

Owner:广东冠星新型材料有限公司

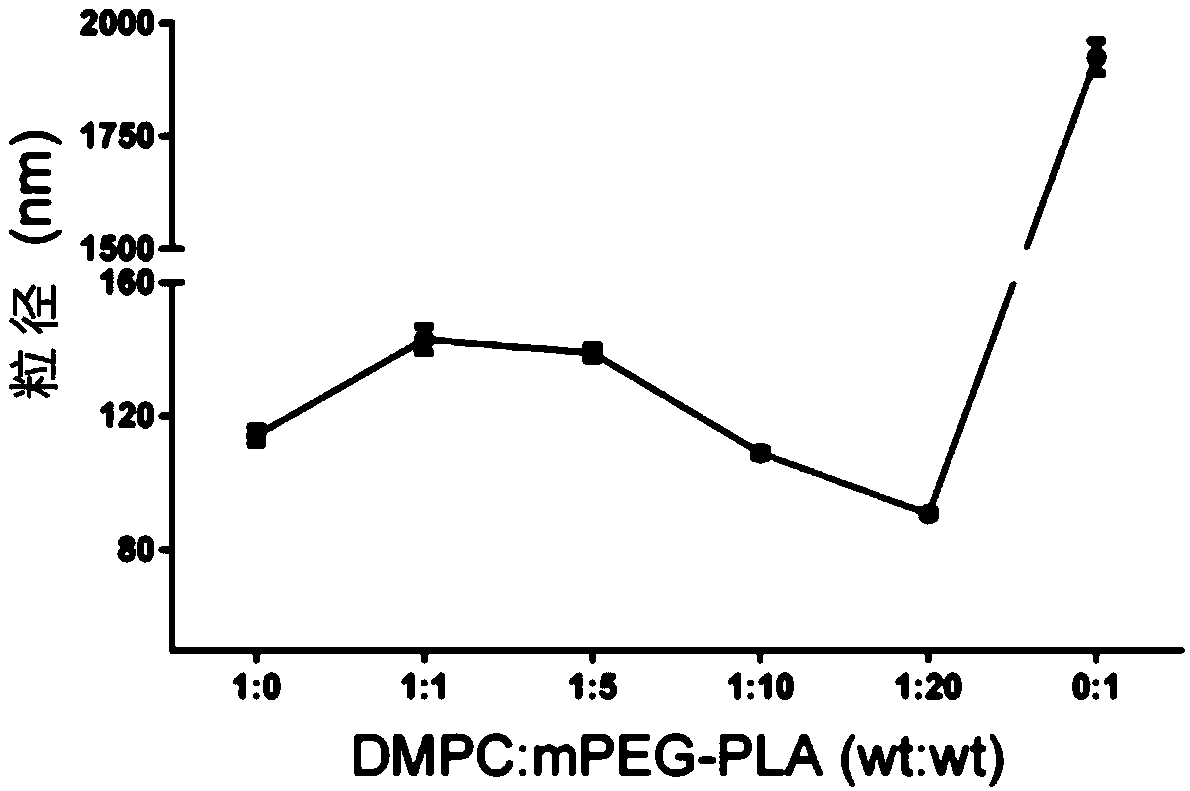

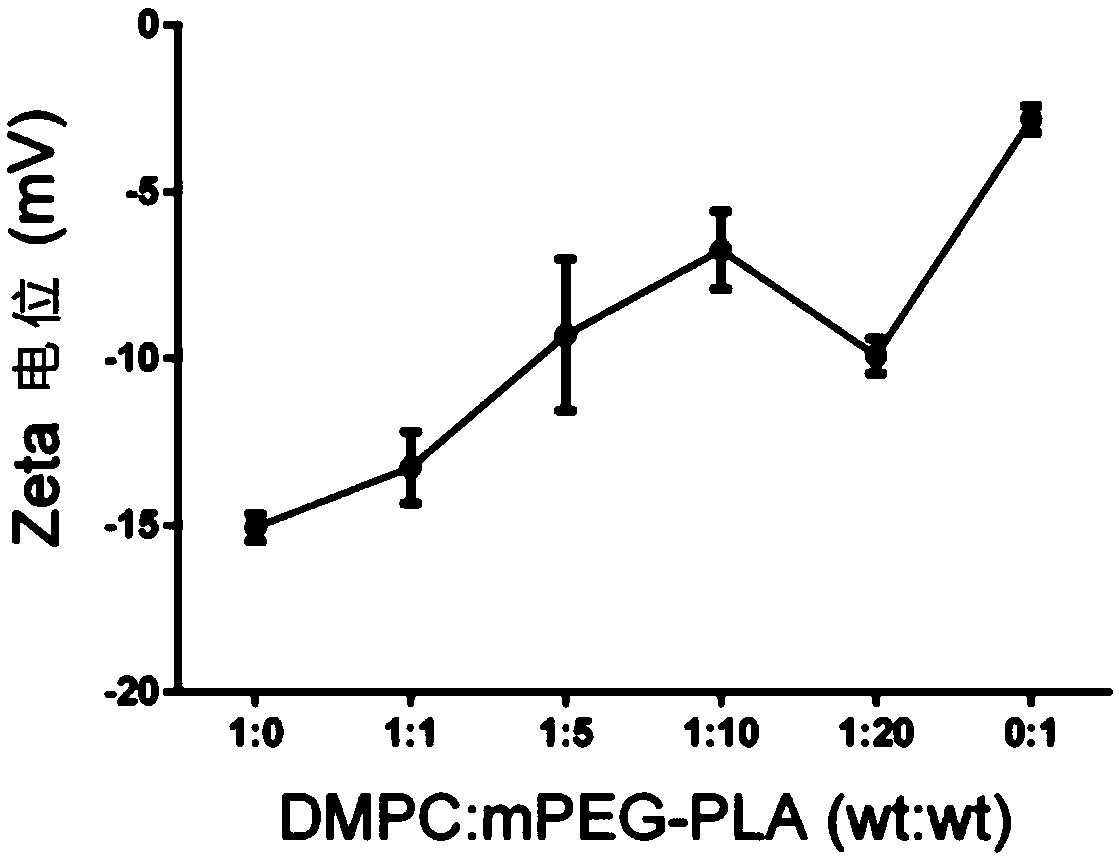

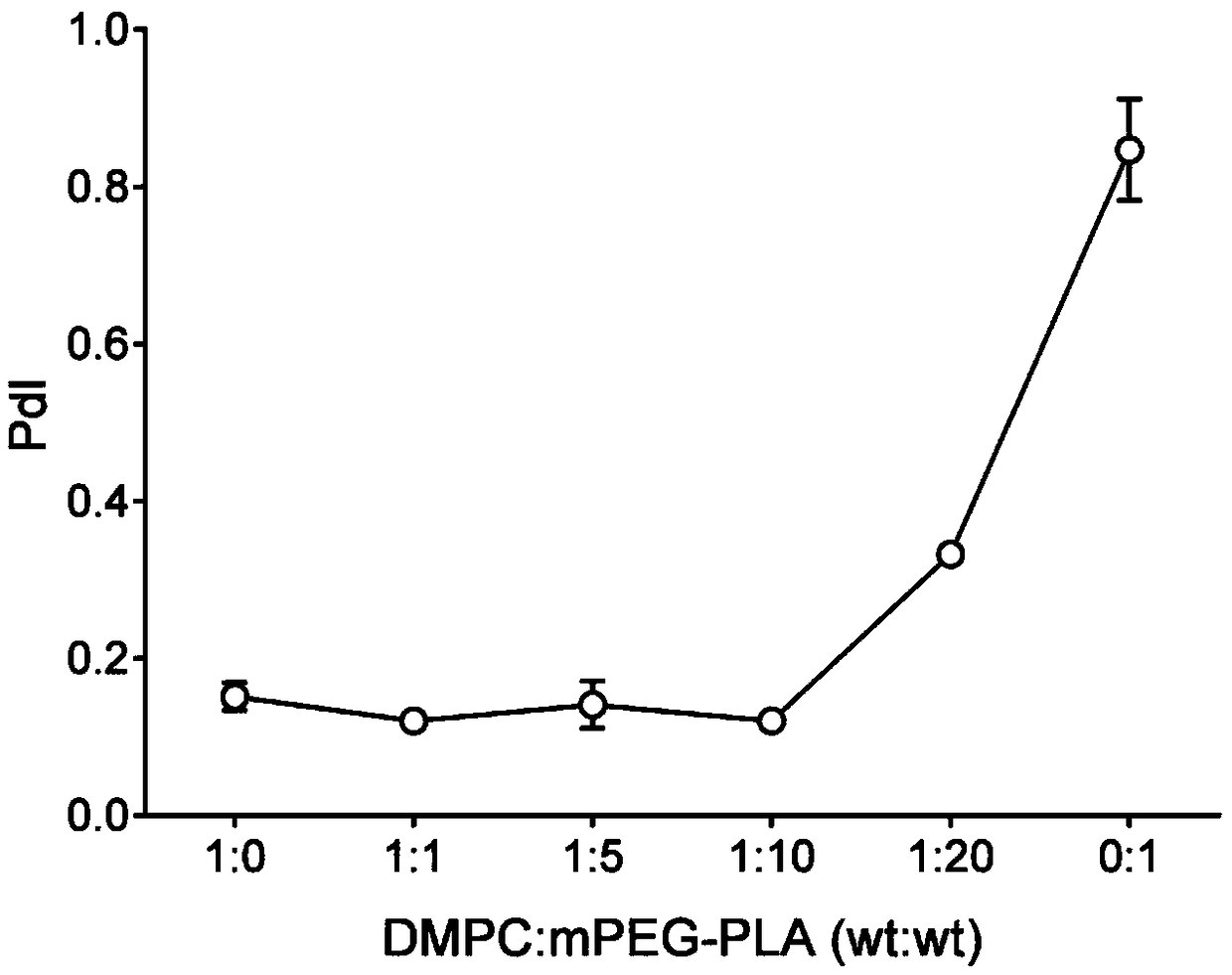

AST (astaxanthin)-supported phospholipid nanoparticles as well as preparation method and application thereof

ActiveCN109381447AChange propertiesChange particle sizeOrganic active ingredientsSenses disorderPoly-L-lactideMonomethoxypolyethylene glycol

The invention discloses AST (astaxanthin)-supported phospholipid nanoparticles and a preparation method thereof. The phospholipid nanoparticles are obtained by mixing an organic phase in which a highmolecular polymer and astaxanthin are dissolved and a water phase in which phospholipid are dissolved by emulsion solvent volatilization, wherein the high molecular polymer is single MPEG-PLA (methoxypoly(ethylene glycol)-poly(lactide) copolymer), and phospholipid is DMPC (1,2-dimyristoyl-sn-glycero-3-phosphocholine). Astaxanthin is subjected to entrapment modification of the phospholipid nanoparticles, the dissolution characteristic and size of astaxanthin are changed, and water solubility of lipid-soluble drug astaxanthin is greatly improved; meanwhile, astaxanthin is endowed with slow release characteristic by the phospholipid nanoparticles, that is, the drug is continuously and slowly released after entering cells of pathological changes, so that the administration frequency can be reduced, and the treatment effect can be enhanced.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

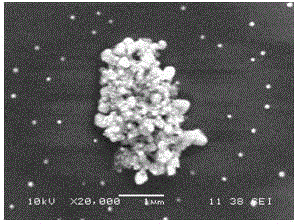

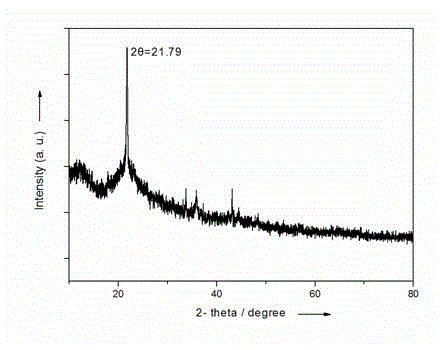

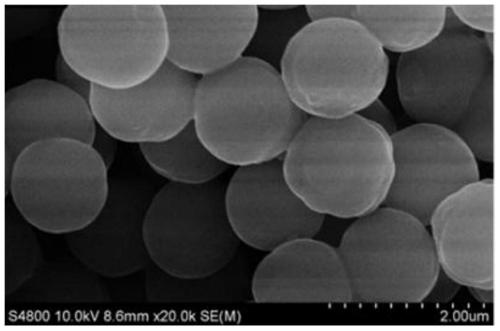

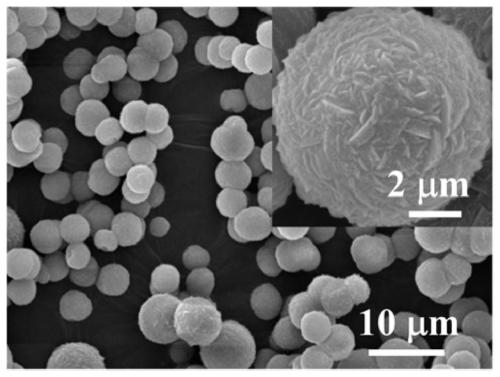

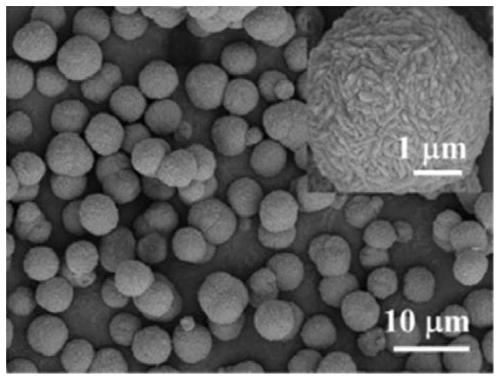

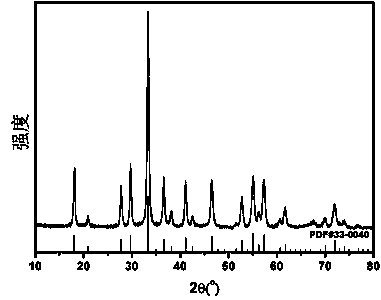

Eta-Al2O3 microsphere and preparation method and application thereof

ActiveCN110065959AImprove catalytic performanceGood for shape controlCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMicrosphereSodium aluminate

The invention discloses an eta-Al2O3 microsphere and a preparation method and application thereof. The preparation method comprises the following steps of: dissolving sodium aluminate in water to prepare a sodium aluminate solution, adding a certain amount of amide into the sodium aluminate solution, uniformly stirring to form clear liquid, and sealing and standing for a certain time for double hydrolysis to generate white precipitate; filtering to obtain the precipitate, washing, drying, and roasting to obtain the final product, namely the eta-Al2O3 microsphere. The results of a small experiment show that the eta-Al2O3 is a microsphere with an average particle diameter of 2.45-5.80 micro meters assembled by nano sheets, the specific surface area is 281.4-331.4cm <2> / g, the pore volume is0.24-0.28cm <3> / g, the average pore diameter is 3.4-4.2nm, and the surface of the microsphere is smoother along with the increase of the amide concentration; the appearance and texture properties of the eta-Al2O3 microsphere are similar to those of the microsphere of the small experiment, and the selectivity of the catalysts of all the examples is 80.5-83.9%, with no significant difference.

Owner:GUANGZHOU UNIVERSITY

YAG fluorescent powder used in semiconductor illumination and preparation method thereof

InactiveCN104046357AUniform size distributionImprove luminosityGas discharge lamp usageLuminescent compositionsInorganic saltsLuminescence

A YAG fluorescent powder used in semiconductor illumination disclosed by the invention is a powder formed by Y3Al5O12:Ce<3+> microspheres with diameter of 1-2 mum. The preparation method adopts inorganic salt as a precursor and a sol gel method to obtain theY3Al5O12:Ce<3+> fluorescent microspheres at lower heat treatment temperature. The invention has the advantages of simple preparation process, convenient operation, short preparation time and low heat treatment temperature, can greatly reduce energy consumption, and is suitable for industrial mass production. YAG fluorescent microspheres obtained by the invention have the characteristics of regular shape, uniformly distributed size and excellent luminescence properties and can be widely used for the production of white LED lighting device.

Owner:ZHEJIANG UNIV

Synthetic alkali, A-direction sapphire polishing solution and preparation method thereof

ActiveCN106700944ALower pHStable pHPolishing compositions with abrasivesInorganic saltsSURFACTANT BLEND

The invention provides synthetic alkali, an A-direction sapphire polishing solution and a preparation method thereof, relates to the technical field of gem and jade polishing, and discloses the synthetic alkali, the A-direction sapphire polishing solution consisting of the synthetic alkali, silica sol, a surfactant, strong alkali, an inorganic salt, deionized water and the like, and the preparation method of the synthetic alkali and the A-direction sapphire polishing solution. By adopting the A-direction sapphire polishing solution, the problems that in the prior art the pH value of the polishing solution in the polishing process of A-direction sapphire is not stable, the pH value of the polishing solution is gradually reduced along with polishing, the polishing velocity is reduced, the TTV value of an overall wafer is too large can be solved, and the technical effects that hydroxyl can be relatively continuously released in the polishing process of the polishing solution, the pH value of the polishing solution can be stable and the polishing velocity and the stability of a polished surface can be finally ensured can be achieved.

Owner:BEIJING GRISH HITECH

Flame-retardant polyurethane foaming thermal insulation material for thermal insulation sandwich panel and preparation method thereof

The invention discloses a flame-retardant polyurethane foaming thermal insulation material for a thermal insulation sandwich panel. The flame-retardant polyurethane foaming thermal insulation material is prepared from the following raw materials in parts by weight: 20 to 30 parts of polyol, 35 to 45 parts of isocyanate, 15 to 20 parts of a flame retardant, 2 to 3 parts of silicone oil, 1 to 2 parts of a nano additive, 1.5 to 2.5 parts of cyclopentane, 1 to 2 parts of a catalyst, 0.5 to 1 part of a cross-linking agent and 0.2 to 0.3 part of water, wherein the nano additive is prepared from quaternary ammonium salt intercalated bentonite and carboxylated nano cellulose. The invention further discloses a preparation method of the flame-retardant polyurethane foaming thermal insulation material for the thermal insulation laminboard. The flame-retardant polyurethane foaming thermal insulation material for the thermal insulation laminboard has excellent strength, thermal insulation performance and flame retardance and is good in use performance.

Owner:ANHUI EMINENT BUILDING MATERIALS TECH

Colloid mill for food processing

The invention relates to the technical field of food processing, in particular to a colloid mill for food processing, which comprises a base and a body fixedly installed on the base, wherein the bodyis provided with a cover plate; the interior of the body is provided with a processing cavity for processing and grinding materials, the interior of the processing cavity is rotatably provided with agrinding body, the upper part of the body is further provided with a feeding hopper, and the feeding hopper is communicated with the interior of the processing cavity; the interior of the base is provided with a mounting cavity, a partition plate is fixedly mounted in the interior of the mounting cavity, a rotating shaft is rotatably mounted on the partition plate, the rotating shaft is of a hollow structure, a lifting rod is slidably mounted in the rotating shaft, the upper end of the lifting rod is fixedly connected with the grinding body, and the lower end of the lifting rod extends downwards into the mounting cavity. The lifting rod moves up and down along the rotating shaft to drive the grinding body to ascend and descend, so that the distance between the grinding body and the inner wall of the body is changed, so that the particle size of the food during grinding is changed, and the processing effect of the food is improved.

Owner:JILIN AGRI SCI & TECH COLLEGE

Preparation method of slow-release-type metal antirust paper

InactiveCN108468249AImprove moisture absorption capacityImprove moisture absorption rateNon-fibrous pulp additionFlexible coversType metalChemistry

The invention discloses a preparation method of slow-release-type metal antirust paper, and belongs to the field of papermaking. The preparation method comprises the steps that attapulgite, a calciumchloride solution and macroporous silica gel are mixed uniformly, sintered and cooled to the room temperature to obtain a cooled product; the cooled product and deionized water are mixed and beaten, asupernatant and cetyl trimethyl ammonium bromide are taken, mixed, stirred and subjected to extraction filtration to obtain a filter cake, and the filter cake is washed with deionized water, dried and ground into powder to obtain an abrasive; the abrasive and morpholine are mixed, formaldehyde and cyclohexylamine carbonate are added after the temperature is increased, standing is conducted, a dinitrobenzoic acid aqueous solution is added after layering, standing and extraction filtration are conducted to obtain filter residues, and the filter residues are dried to obtain a dried product; thedried product, extracts, Arabic gum and a chitosan solution are mixed and stirred, the pH is adjusted, a curing agent is added for curing to obtain a cured product, a cationic starch gelatinization solution is added to the cured product, and stirring is conducted uniformly to obtain a stirred product; one surface of antirust base paper is uniformly coated with the stirred product and dried, and the other surface of the dried paper is compounded with a reinforcing material to obtain the metal antirust paper.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

Medical grinding device capable of solving problem that quantitative feeding cannot be achieved and particle size cannot be changed

The invention relates to the technical field of medical equipment, and discloses a medical grinding device capable of solving the problem that quantitative feeding cannot be achieved and the particle size cannot be changed. The medical grinding device comprises a shell. The whole device is supported through the shell, and a base is fixedly connected to the interior of the shell. Through the cooperative use of an upper sieve plate, a rotating rod, a lower sieve plate and a connecting rod, screening can be automatically conducted when herbal medicine is ground, the situation that a traditional grinding device does not have the grinding function is changed, and therefore the size of ground particles is more uniform; through cooperative use of a threaded rod and a grinding disc, the position of the grinding disc can be changed when the threaded rod is rotated, and therefore the distance between the grinding disc and the base is changed, the aim of changing the grinding particle size is achieved, intelligence is higher; and through cooperative use of a storage box, a baffle and a first gear, automatic quantitative feeding is achieved during grinding, on one hand, manual regular feeding is not needed, and on the other hand, blockage caused by the too large feeding amount is avoided.

Owner:安徽省成顺同生物科技有限公司

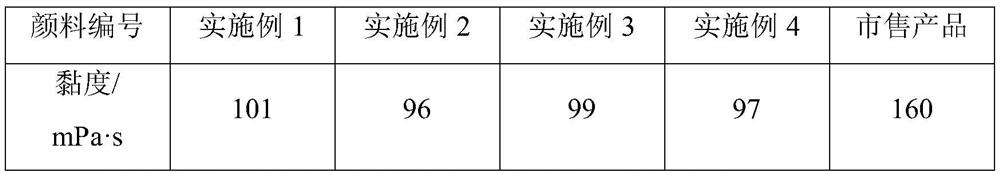

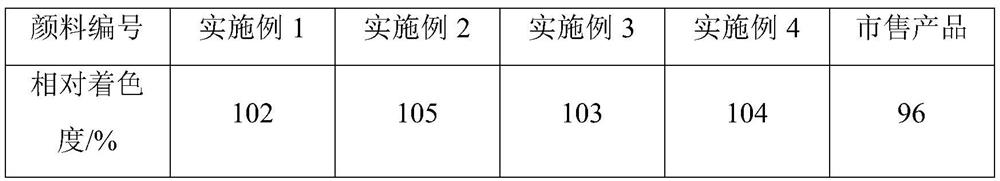

Preparation method of pigment red 57: 1

Provided is a process for preparing pigment red 57: 1. Through process improvement and adding of 2-aminophenol-4-sulfonic acid, 1-amino-2-naphthol-4-sulfonic acid or 3-amino-4-methoxybenzenesulfonic acid as a second coupling component, inter-particle force is attenuated, and particle size and color light are changed. Meanwhile, triethanolamine dodecylbenzene sulfonate, 4-hydroxybutyrate hydrazineand 4-hydroxybutyl acrylate are selected as a modifying substance and a dispersing agent to enhance the coloring power, effectively control the pigment crystal growth and improve the flowability. Microwave drying is adopted to improve the drying efficiency and avoid crystal form dehydration conversion. Airflow mill drying is adopted to reduce the average particle size of the pigment and increase the coloring strength. The pigment prepared by the technology effectively solves the problems of poor flowability, low coloring strength and the like of the traditional pigment.

Owner:PENGLAI XINGUANG PIGMENT CHEM

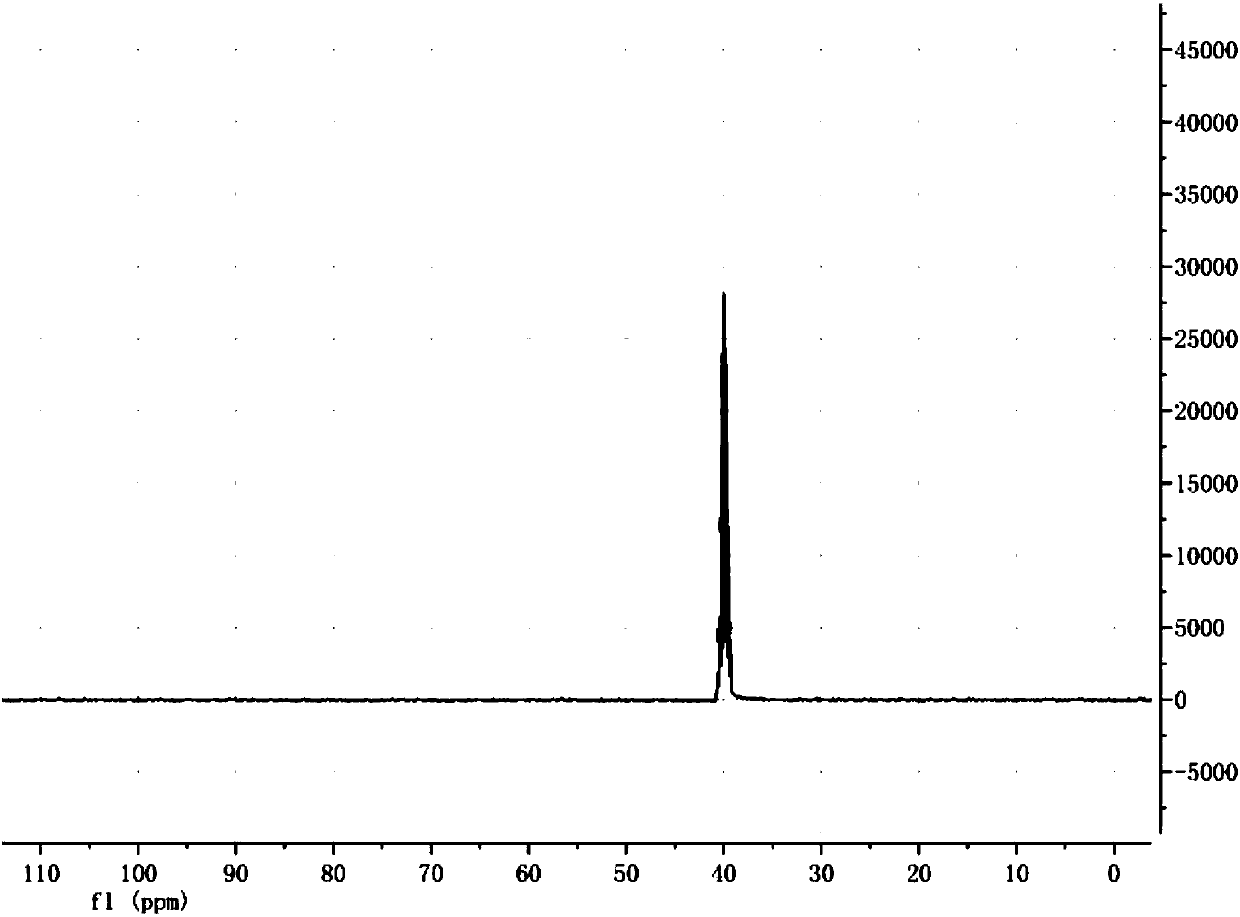

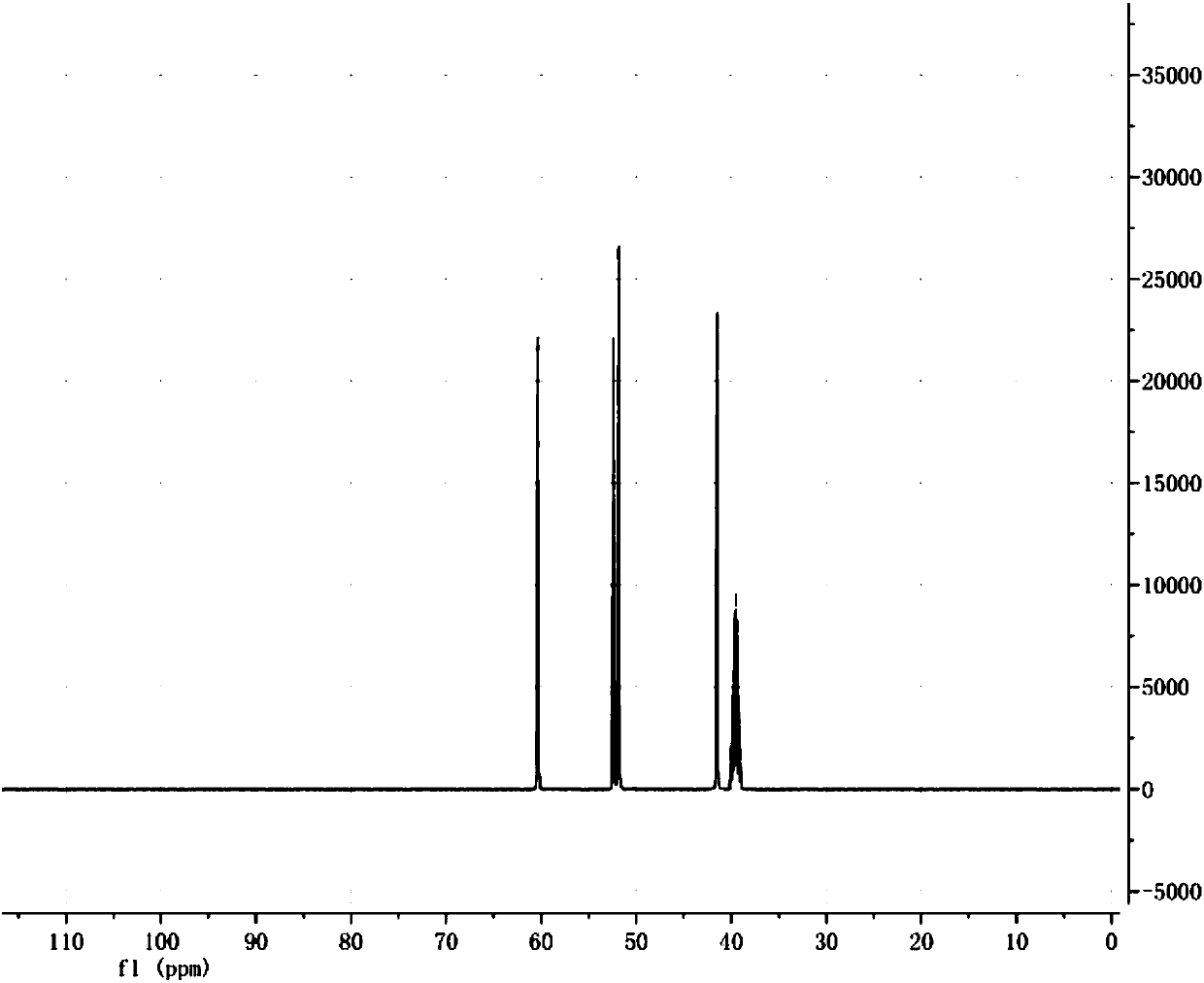

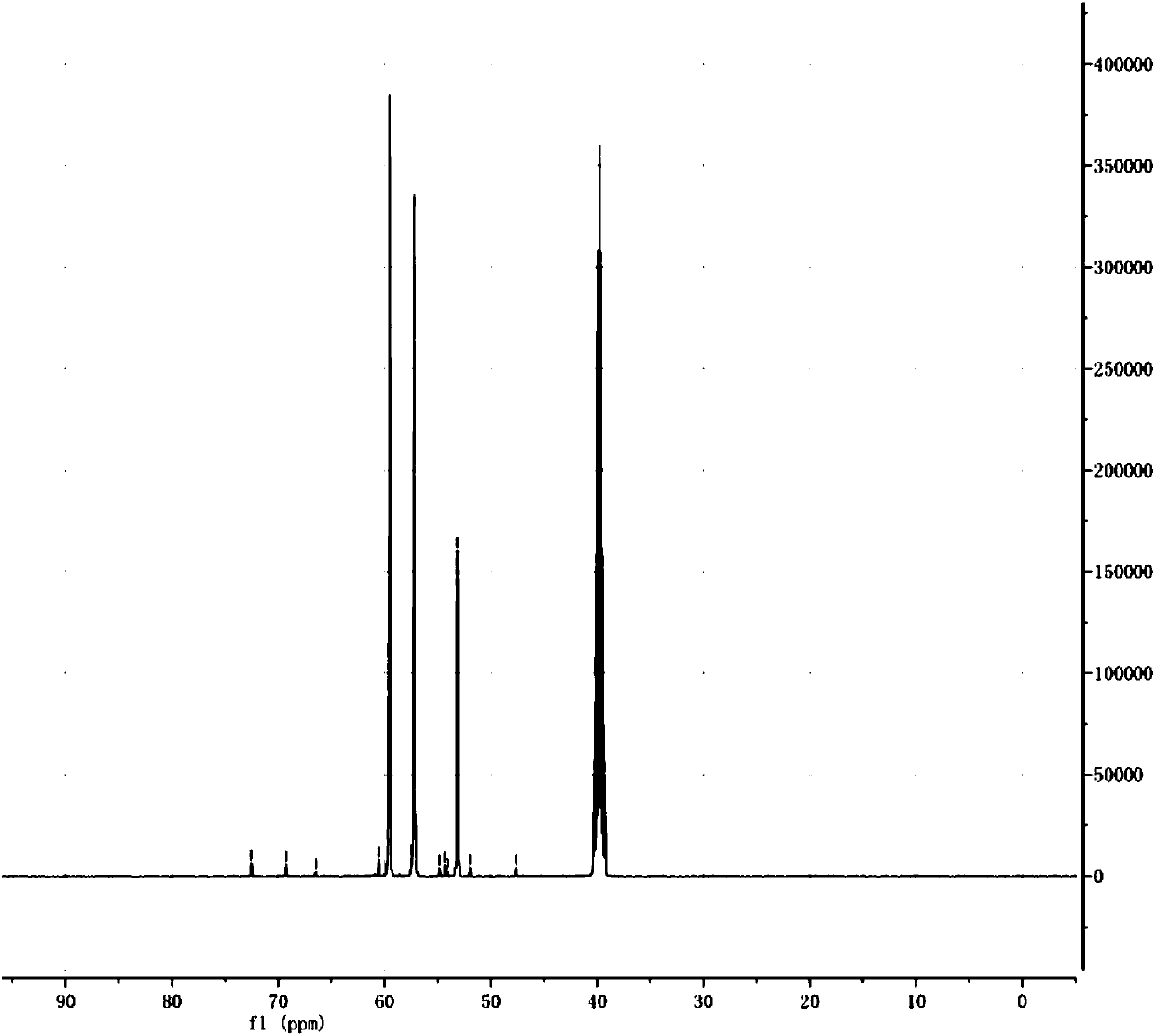

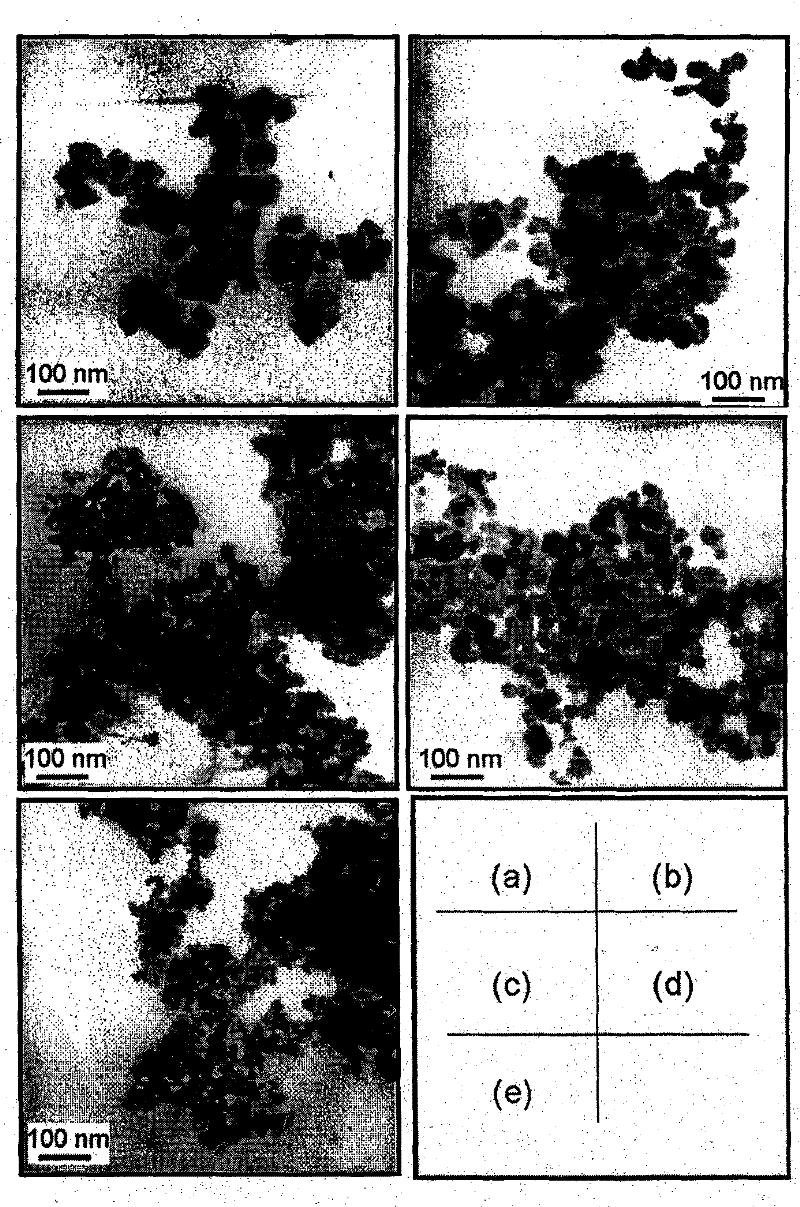

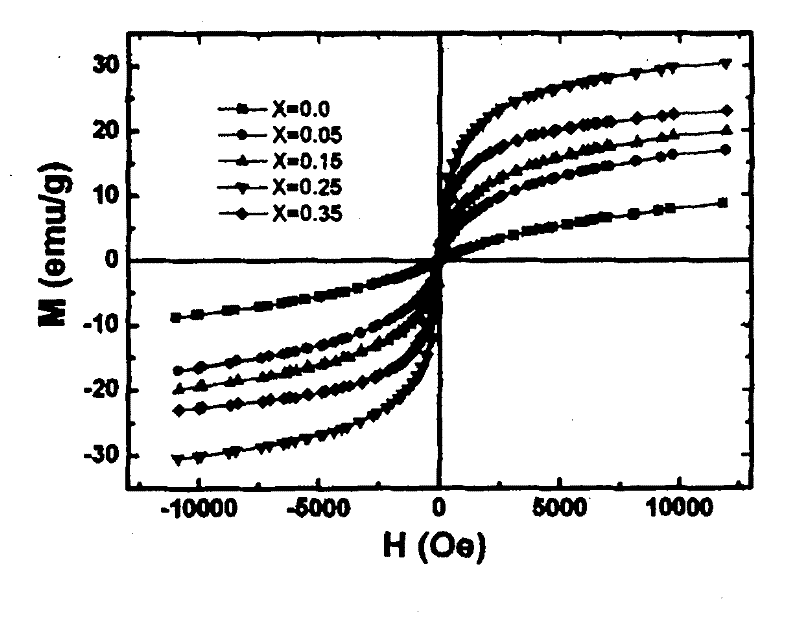

Preparation method of Mn-Zn ferrite cobalt-doped nano material

InactiveCN101723655BChange particle sizeWide range of particle size controllableInorganic material magnetismN-Butyl AlcoholMaterials science

Owner:LANZHOU UNIVERSITY

Anaerobic ammonium oxidation granular sludge cultivation method and cultivation device

PendingCN107555592AImprove settlement performanceImprove impact performanceTreatment with anaerobic digestion processesActivated sludgeProliferation rate

The invention relates to the technical field of biotreatment of wastewater, in particular to an anaerobic ammonium oxidation granular sludge cultivation method and a cultivation device. The method andthe device have the beneficial effects that (1) granular sludge formed by the method is high in sedimentation performance, water impact resisting capability and stability and low in disintegration rate, the formed particle sizes are larger, meanwhile, the phenomenon of sludge loss is obviously reduced, the concentration of the sludge in a reactor is increased, and the denitrification performanceis enhanced; (2) a negative graphite plate and a positive graphite plate are energized to form an electric field, and under the condition that an internal electric field exists, the characters of charging characteristic, granule diameter and the like of the activated sludge are changed, the proliferation rate is increased, the treatment efficiency is improved, the shortcomings of long generation time, slow domestication and breeding, high loss rate of microorganisms and the like of anaerobic ammonium oxidation bacteria are overcome, and the treatment efficiency is improved; (3) the device is simple in structure, relatively high in volumetric efficiency, convenient to operate and control and low in construction cost, the cultivation method is simple and easy, and an obvious effect is achieved.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com