Method for fast preparing hollow porous silicon dioxide/silver nanoparticle composite and product

A technology of porous silica and composite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Cumbersome and other problems, to achieve the effect of obvious antibacterial ability, clear and concise reaction principle, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

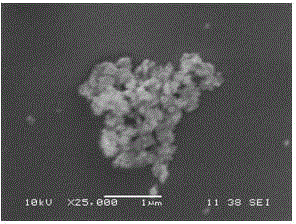

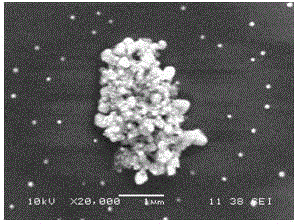

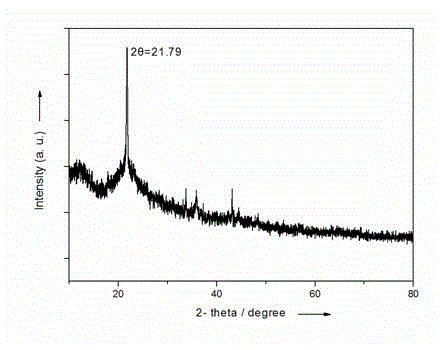

[0029] Dissolve 1.7100 g of glucose in 100 mL of distilled water, add 0.4 mL of sodium silicate solution with a silicon dioxide concentration of 20%, and place it in a high-pressure hydrothermal kettle for 24 h at 180 °C after mixing thoroughly. The resulting solution was washed with distilled water several times, centrifuged at 6000 r for 10 min and filtered. After multiple washes, dry overnight at 80°C under vacuum. The obtained product was heated at 4°C min -1 Calcination at 600 °C for 6 h at a heating rate of 6 h to remove carbon nuclei to generate hollow porous nano-silica particles. Disperse it well to 200 mL 4.0×10 -4 g·mL -1 Add 2.5 mL of 0.1 M hydrazine hydrate to the cetyltrimethylammonium bromide aqueous solution, mix well, and add 5 mL of 0.05 M dilute silver nitrate solution dropwise under the condition of magnetic stirring at a speed of 300 r, and continue the reaction for 5 min . The obtained product was washed, centrifuged at 2000 r for 5 min and filtered...

Embodiment 2

[0031] Dissolve 1.7100 g of glucose in 100 mL of distilled water, add 0.4 mL of sodium silicate solution with a silicon dioxide concentration of 20%, and place it in a high-pressure hydrothermal kettle for 24 h at 180 °C after mixing thoroughly. The resulting solution was washed with distilled water, centrifuged at 6000 r for 10 min and filtered. After multiple washes, dry overnight at 80°C under vacuum. The obtained product was heated at 4°C min -1 Calcination at 500 °C for 4 h at a heating rate of 500 °C to remove carbon nuclei to generate hollow porous nano-silica particles. The resulting product was fully dispersed to 200 mL 3.5×10 -4 g·mL -1 Add 3.0 mL of 0.1 M hydrazine hydrate to the cetyltrimethylammonium bromide aqueous solution, mix well, and add 5 mL of 0.05 M dilute silver nitrate solution dropwise under the condition of magnetic stirring at a speed of 300 r, and continue the reaction for 10 min . The obtained product was washed, centrifuged at 2000 r for 5 m...

Embodiment 3

[0033] Dissolve 1.3680 g of glucose in 100 mL of distilled water, add 0.4 mL of sodium silicate solution with a silicon dioxide concentration of 20%, mix well, place in a high-pressure hydrothermal kettle and continue heating at 180 °C for 24 h. The resulting solution was washed with distilled water several times, centrifuged at 6000 r for 10 min and filtered. After multiple washes, dry overnight at 80°C under vacuum. The obtained product was heated at 4°C min -1 Calcined at 550 °C for 4 h at a heating rate of 550 °C to remove carbon nuclei to generate hollow porous nano-silica particles. The resulting product was fully dispersed to 200 mL 4.0×10 -4 g·mL -1 Add 2.5 mL of 0.1 M hydrazine hydrate to the cetyltrimethylammonium bromide aqueous solution, mix well, and add 5 mL of 0.05 M dilute silver nitrate solution drop by drop under the condition of rotating speed of 300 r, and continue the reaction for 15 min . The obtained product was washed, centrifuged at 2000 r for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com